Hotbed flatness, voodoo or scientific method?

Posted by lunarkingdom

|

Re: Hotbed flatness, voodoo or scientific method? June 22, 2015 11:15PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Hotbed flatness, voodoo or scientific method? June 22, 2015 11:21PM |

Registered: 11 years ago Posts: 1,277 |

That is the nickname they gave to the original Prusa I3 Y frame (looks like a frog or more like Frogger).

That is the plate the bearings, HPB, etc... goes on.

Edited 2 time(s). Last edit at 06/22/2015 11:24PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

That is the plate the bearings, HPB, etc... goes on.

Edited 2 time(s). Last edit at 06/22/2015 11:24PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? June 22, 2015 11:55PM |

Registered: 11 years ago Posts: 5,780 |

Oh. The undercarriage.

It looks like it was designed to bend and flex. How thick is this plate? The two bearings that share an axis should be spread all the way to the edges of the plate (I made this same mistake with my first design) as should the belt attachment points, the arms that support the levelers should be wider so they're less likely to bend/flex (I'm guessing one of those bent for you), and there should be three bed plate supports instead of four, with two adjustable for leveling.

It looks like it was designed to bend and flex. How thick is this plate? The two bearings that share an axis should be spread all the way to the edges of the plate (I made this same mistake with my first design) as should the belt attachment points, the arms that support the levelers should be wider so they're less likely to bend/flex (I'm guessing one of those bent for you), and there should be three bed plate supports instead of four, with two adjustable for leveling.

|

Re: Hotbed flatness, voodoo or scientific method? June 23, 2015 03:51AM |

Registered: 11 years ago Posts: 1,277 |

The plate is 6mm per design and in America 6.35mm (the one I have). Yes, it sucks as it wobbles if I press on it because the bearings are not far enough apart.

In the photo that bottom right leg is the hole that finally gave up and the threads are gone now. You are correct Prusa did a job in the design of Y and the original I3 didn't even have a tensioner on Y.

Where does this new plate go since the HPB needs to go below it so I am not sure where it goes.

edit: After have a rest I remember now why Prusa designed that frog with extended legs, and closer together Linear Bearing slots, because you don't need as long of 10mm alltreaded rods nor GT2 belt since it extends past them for a greater printing surface ability without requiring as much table space to hold it up. Do remember Josef Prusa said on his old blog that the i3 was designed to be aesthetically pleasing not designed to be functional. Know why I keep repeating that? I will tell because it sticks in my craw that he did that knowing what he did but only after thousands and thousands were made did he mention it. Had he been forthright from the get go I would have chosen my other printer I was going to make and that was the MM1.5 at the time. I bet if I had went with the MM I would not have had nearly this much trouble with very few hours of printing. I3 is not a bad printer, don't get me wrong, it just has issues and takes a lot of mods to make it work exceptionally well.

I will say Prusa taught me what not to do in a printer that is for sure. I still prefer Cartesian based printers but not ones with moveable beds. Oh, one other thing is that the i3 rework has even more issues than the orginal i3 yet it is a varient that was supposed to fix the issues. *shrug*

So, back to that plate as I need to know before I purchase it.

Thank you for all of your help.

Edited 1 time(s). Last edit at 06/23/2015 12:46PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

In the photo that bottom right leg is the hole that finally gave up and the threads are gone now. You are correct Prusa did a job in the design of Y and the original I3 didn't even have a tensioner on Y.

Where does this new plate go since the HPB needs to go below it so I am not sure where it goes.

edit: After have a rest I remember now why Prusa designed that frog with extended legs, and closer together Linear Bearing slots, because you don't need as long of 10mm alltreaded rods nor GT2 belt since it extends past them for a greater printing surface ability without requiring as much table space to hold it up. Do remember Josef Prusa said on his old blog that the i3 was designed to be aesthetically pleasing not designed to be functional. Know why I keep repeating that? I will tell because it sticks in my craw that he did that knowing what he did but only after thousands and thousands were made did he mention it. Had he been forthright from the get go I would have chosen my other printer I was going to make and that was the MM1.5 at the time. I bet if I had went with the MM I would not have had nearly this much trouble with very few hours of printing. I3 is not a bad printer, don't get me wrong, it just has issues and takes a lot of mods to make it work exceptionally well.

I will say Prusa taught me what not to do in a printer that is for sure. I still prefer Cartesian based printers but not ones with moveable beds. Oh, one other thing is that the i3 rework has even more issues than the orginal i3 yet it is a varient that was supposed to fix the issues. *shrug*

So, back to that plate as I need to know before I purchase it.

Thank you for all of your help.

Edited 1 time(s). Last edit at 06/23/2015 12:46PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? June 24, 2015 12:34AM |

Registered: 11 years ago Posts: 1,277 |

|

Re: Hotbed flatness, voodoo or scientific method? June 24, 2015 07:14AM |

Registered: 9 years ago Posts: 1,873 |

You still need to be able to level your bed, so it's going to go on top of your heater. You can use the heater pcb as a template for where to make the holes. You might need longer bed screws to cope with the extra thickness. That means you're still using your original Y carriage, so you need to do something about that stripped thread. Or replace the carriage.

Edited 1 time(s). Last edit at 06/24/2015 07:14AM by JamesK.

Edited 1 time(s). Last edit at 06/24/2015 07:14AM by JamesK.

|

Re: Hotbed flatness, voodoo or scientific method? June 24, 2015 09:10AM |

Registered: 11 years ago Posts: 5,780 |

The bottom right and left side holes align with the Y axis. Only one of those needs to be made adjustable to level the bed if you're going to use a 3 point leveling system. Use the stripped hole for the "reference" bed support by adding a nuts to both the top and underside of the plate. You'll have a spring on the top side of the "frog" plate that pushes the bed plate up against the reference screw head. You won't be making any bed leveling or zeroing adjustments at the reference screw. Don't put a fixed spacer between the "frog" plate and the bed plate at the reference screw. You need the spring- the bed has to be able to tilt at that screw or you'll create problems. The lower left side hole can be used for the Y axis pitch level adjuster. Drill a hole for a leveler above the bearing in the top of your photo (and a corresponding hole in the bed plate). That will be the Y-axis roll adjustment.

See SoM step #7 to see how I did the 3 point leveling in my machine. Be sure and read the notes in the photos and CAD drawings for an explanation of how the things work.

The three screws for the leveling mechanism have to be rigidly coupled to the "frog" plate. I did that in my printer by screwing them into heat resistant teflon blocks that are screwed to the undercarriage. When you push on the leveling screws from the side, they should not move- remember, the bed is going to move back and forth along the Y axis. Each time the bed reverses direction, accelerates, or decelerates there will be lateral force on the leveling screws because of the momentum of the bed. The screws have to be rigid or the bed will flop around whenever it moves and it will affect print quality. I drilled slightly undersized holes in the teflon blocks and let the screws cut their own threads into the teflon.

The bed plate "floats" on three compressed springs. The springs push the bed plate up from the undercarriage plate until it can't go up any more because the leveling screw heads stop it. The bed is prevented from moving laterally by countersinking the holes in the bed plate. The screw heads and countersunk holes are conical and will prevent lateral motion- if the bed plate tries to move laterally, the springs will have to compress. If you use strong springs and compress them with the leveling screws, the lateral motion of the bed will be almost zero, yet the bed will be able to tilt freely when you make leveling adjustments.

Leveling and zeroing:

1) heat both the bed and the extruder to print temperatures.

2) adjust Y axis pitch first: move the bed/extruder nozzle so the nozzle is very near the reference screw (screwed to the lower right in your photo). Move the Z axis setting to grab paper or whatever you normally do, then move the bed only to a point where the nozzle is near the Y-axis pitch adjustment screw (lower left in your photo). Adjust the pitch screw to grab the paper or whatever you normally do. You can verify that the pitch is set correctly by moving the bed back and forth- the nozzle should grab the paper evenly, everywhere along the length of the Y-axis movement. Don't be alarmed if it only grabs the paper near the the two screws.

3) adjust Y-axis roll: move the nozzle and bed plate so the nozzle is near the Y-axis roll adjustment screw (the one you added near the top bearing in your photo). Adjust the roll until the nozzle grabs the paper (or whatever you use). Now the bed should be as level (which means aligned with the true XY plane) as it can possibly be in your machine. Note that adjusting the roll does not affect the pitch, but will affect the Z=0 point.

4) set z=0: move the nozzle and bed to position the nozzle over the center of the bed. Adjust the Z axis position until the nozzle grabs the paper (or whatever you use) and set the Z=0 point. The reason for setting z=0 at the center of the bed is that the X and Y axis guide rails will flex and the bed and extruder won't actually be moving in linear paths- they'll be moving in curved paths (thanks to gravity) that both hit bottom when the nozzle is at the center of the bed (assuming the rails are close to parallel which may not be a good assumption depending on how the mounts are made and how well aligned they are). Since you will normally be printing at the center of the bed because that's where the temperature is likely to be most even and because slicer software usually puts the object at the center of the bed, that is where you're going to set the z=0 point.

If your machine uses flexy, end supported guide rails that are not aligned parallel to each other, and/or the frame flexes a lot, you may not be able to print edge to edge on the bed plate. You will probably have to relevel and zero the bed frequently. It won't be the bed plate's fault. If you use fully supported guide rails or linear guides and they are accurately aligned, and the printer's frame is stiff, you'll be able to print edge to edge because the bed and extruder nozzle will move in a path that is very nearly planar. You probably won't have to relevel or zero the bed for a long time. I haven't had to touch either adjustment in my printer for two months in spite of daily use and a few trips back and forth between home and the makerspace, and no, I don't use autotramming.

Anyone who has run Windows on their computer knows the frustration of the machine misbehaving and requiring a reboot to get it working again (for a while). Autotramming is to 3D printing what rebooting is to Windows. It is a stupid way of dealing with poor design and shabby construction.

If you decide all this is too much trouble, you can just go back to the original design and fix the stripped hole in the "frog" plate by any of many different ways:

1) enlarge the hole and tap it for a bigger screw- you may also have to enlarge the hole in your bed plate to accommodate the larger screw.

2) enlarge the hole and install a threaded insert of the original size

3) enlarge the hole and epoxy a nut of the original size to the top or bottom of the "frog" plate.

Edited 1 time(s). Last edit at 06/24/2015 10:09AM by the_digital_dentist.

See SoM step #7 to see how I did the 3 point leveling in my machine. Be sure and read the notes in the photos and CAD drawings for an explanation of how the things work.

The three screws for the leveling mechanism have to be rigidly coupled to the "frog" plate. I did that in my printer by screwing them into heat resistant teflon blocks that are screwed to the undercarriage. When you push on the leveling screws from the side, they should not move- remember, the bed is going to move back and forth along the Y axis. Each time the bed reverses direction, accelerates, or decelerates there will be lateral force on the leveling screws because of the momentum of the bed. The screws have to be rigid or the bed will flop around whenever it moves and it will affect print quality. I drilled slightly undersized holes in the teflon blocks and let the screws cut their own threads into the teflon.

The bed plate "floats" on three compressed springs. The springs push the bed plate up from the undercarriage plate until it can't go up any more because the leveling screw heads stop it. The bed is prevented from moving laterally by countersinking the holes in the bed plate. The screw heads and countersunk holes are conical and will prevent lateral motion- if the bed plate tries to move laterally, the springs will have to compress. If you use strong springs and compress them with the leveling screws, the lateral motion of the bed will be almost zero, yet the bed will be able to tilt freely when you make leveling adjustments.

Leveling and zeroing:

1) heat both the bed and the extruder to print temperatures.

2) adjust Y axis pitch first: move the bed/extruder nozzle so the nozzle is very near the reference screw (screwed to the lower right in your photo). Move the Z axis setting to grab paper or whatever you normally do, then move the bed only to a point where the nozzle is near the Y-axis pitch adjustment screw (lower left in your photo). Adjust the pitch screw to grab the paper or whatever you normally do. You can verify that the pitch is set correctly by moving the bed back and forth- the nozzle should grab the paper evenly, everywhere along the length of the Y-axis movement. Don't be alarmed if it only grabs the paper near the the two screws.

3) adjust Y-axis roll: move the nozzle and bed plate so the nozzle is near the Y-axis roll adjustment screw (the one you added near the top bearing in your photo). Adjust the roll until the nozzle grabs the paper (or whatever you use). Now the bed should be as level (which means aligned with the true XY plane) as it can possibly be in your machine. Note that adjusting the roll does not affect the pitch, but will affect the Z=0 point.

4) set z=0: move the nozzle and bed to position the nozzle over the center of the bed. Adjust the Z axis position until the nozzle grabs the paper (or whatever you use) and set the Z=0 point. The reason for setting z=0 at the center of the bed is that the X and Y axis guide rails will flex and the bed and extruder won't actually be moving in linear paths- they'll be moving in curved paths (thanks to gravity) that both hit bottom when the nozzle is at the center of the bed (assuming the rails are close to parallel which may not be a good assumption depending on how the mounts are made and how well aligned they are). Since you will normally be printing at the center of the bed because that's where the temperature is likely to be most even and because slicer software usually puts the object at the center of the bed, that is where you're going to set the z=0 point.

If your machine uses flexy, end supported guide rails that are not aligned parallel to each other, and/or the frame flexes a lot, you may not be able to print edge to edge on the bed plate. You will probably have to relevel and zero the bed frequently. It won't be the bed plate's fault. If you use fully supported guide rails or linear guides and they are accurately aligned, and the printer's frame is stiff, you'll be able to print edge to edge because the bed and extruder nozzle will move in a path that is very nearly planar. You probably won't have to relevel or zero the bed for a long time. I haven't had to touch either adjustment in my printer for two months in spite of daily use and a few trips back and forth between home and the makerspace, and no, I don't use autotramming.

Anyone who has run Windows on their computer knows the frustration of the machine misbehaving and requiring a reboot to get it working again (for a while). Autotramming is to 3D printing what rebooting is to Windows. It is a stupid way of dealing with poor design and shabby construction.

If you decide all this is too much trouble, you can just go back to the original design and fix the stripped hole in the "frog" plate by any of many different ways:

1) enlarge the hole and tap it for a bigger screw- you may also have to enlarge the hole in your bed plate to accommodate the larger screw.

2) enlarge the hole and install a threaded insert of the original size

3) enlarge the hole and epoxy a nut of the original size to the top or bottom of the "frog" plate.

Edited 1 time(s). Last edit at 06/24/2015 10:09AM by the_digital_dentist.

|

Re: Hotbed flatness, voodoo or scientific method? June 24, 2015 11:33AM |

Registered: 11 years ago Posts: 1,277 |

I made the frog plate three point by using a 1/8" strip across the back. The two front screws (the left side screw towards me is stripped) is one of the two screws and the far back side is the lone screw in the middle of the board.

Now, here is a new problem...weight. 6.35mm frog plate and this new 6.35mm above it with one additional issue and that is the middle of the back has to be cut away (I think this is where some of my 3 point leveling issues are) because that is where the MK2B's electrical connections are. MK2B is bowled (as most are to some degree) so the metal plate is only connected via the two front screws. Has to look like the picture shown which makes only the MK2B being able to use the third screw (as it currently is).

Edited 2 time(s). Last edit at 06/24/2015 12:07PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

Now, here is a new problem...weight. 6.35mm frog plate and this new 6.35mm above it with one additional issue and that is the middle of the back has to be cut away (I think this is where some of my 3 point leveling issues are) because that is where the MK2B's electrical connections are. MK2B is bowled (as most are to some degree) so the metal plate is only connected via the two front screws. Has to look like the picture shown which makes only the MK2B being able to use the third screw (as it currently is).

Oops, this is not how I did it as the wires going in from the back side (for 3 point) was so much easier. My frog plate's now stripped hole (in your scheme) would have my strip so would be locked down with the middle hole facing to the left side. I really think having this MK2 is hindering me in many many ways. Trinity Labs used to carry a self sticking flexible Kapton like heater with everything all ready to go.[edit: in your Instructables post I was reading it just now and spotted the Kapton heater I was talking about which makes all of this so much easier.] I don't care much for those silicone heaters as they are reported to have their own set of issues. Phenoelic board based heaters have warp, flex, and those mounting points on one side that will dead short on you with anything metal (like a heat spreader or this dead flat aluminum plate) laying across it.Quote

the_digital_dentist

The bottom right and left side holes align with the Y axis

Edited 2 time(s). Last edit at 06/24/2015 12:07PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? June 24, 2015 05:46PM |

Registered: 11 years ago Posts: 1,277 |

By the way I just tried to level my bed (that stripped hole is not stripped for a black oxide m3 I have but the SS it is) rearranging it as you said and everything cold I can get it level to within .01mm on a feeler gauge but heat the nozzle and bed up and that center pops right up while the farther away I get from the center (where the thermistor is) the more level it becomes. This tells me that MK2B has to go it is a POS but I have not found one I can attach to the dead flat metal yet. 24v 160-200watt and not in PCB form but something that will easily stick to the underside of the plate. This way I can get rid of three problems. #1 Warp in the middle. #2 Having it be the only item that the third screw attaches to and #3 Wobble. #3 is directly caused by #2 because with four screws into just the PCB it wobbles a little but with four screws attached to my heat spreader it is rock solid.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? June 24, 2015 10:15PM |

Registered: 9 years ago Posts: 483 |

You can use an inexpensive laser pointer to test flatness. Here's one site with an explanation: [www.cnccookbook.com]

|

Re: Hotbed flatness, voodoo or scientific method? June 24, 2015 10:28PM |

Registered: 11 years ago Posts: 1,277 |

Damn, my laser level is only a dot. :/ Digital Level with a laser inside and it is a dot.Quote

etfrench

You can use an inexpensive laser pointer to test flatness. Here's one site with an explanation: [www.cnccookbook.com]

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? June 25, 2015 01:14AM |

Registered: 11 years ago Posts: 1,277 |

So, I am looking for a Kapton heater to stick onto the flat plate and went to AliExpress since eBay was doa.

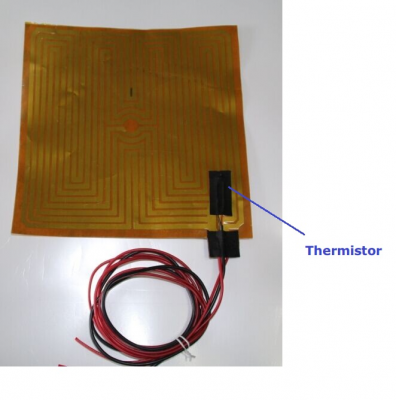

Here is a picture of the one being sold:

I asked the seller "You supply a thermistor for this but where does it go? Seems you forgot to make a hole in the middle of the heater for it." and I get a response that this is what they are selling and the picture used in the listing is for reference only.

Still, that thermistor is in the wrong spot but why would you use the first picture as your listing picture when the second one is accurate and just looks more professional AND doesn't even remotely look like the listing picture? edit: Am I not wrong but when you enlarge the second picture right in the middle is a spot for a thermistor? Sure looks like it to me so why of to the side like that?

What I am looking for is 200mm square 24v @200 watts that will stick to the bottom so I can use the metal flat plate's third hole I will drill and not the MK2B's and have to cut away the metal around the power connectors.

Edited 1 time(s). Last edit at 06/25/2015 01:16AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

Here is a picture of the one being sold:

I asked the seller "You supply a thermistor for this but where does it go? Seems you forgot to make a hole in the middle of the heater for it." and I get a response that this is what they are selling and the picture used in the listing is for reference only.

Still, that thermistor is in the wrong spot but why would you use the first picture as your listing picture when the second one is accurate and just looks more professional AND doesn't even remotely look like the listing picture? edit: Am I not wrong but when you enlarge the second picture right in the middle is a spot for a thermistor? Sure looks like it to me so why of to the side like that?

What I am looking for is 200mm square 24v @200 watts that will stick to the bottom so I can use the metal flat plate's third hole I will drill and not the MK2B's and have to cut away the metal around the power connectors.

Edited 1 time(s). Last edit at 06/25/2015 01:16AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? June 25, 2015 10:07AM |

Registered: 11 years ago Posts: 335 |

I'm using one of these for a build I'm working on:

[www.ebay.com]

I was intrigued because they let you completely customize the heater. You can choose the voltage, power, size, shape, thermistor and have some neat options like an insulating layer on the back. Their webpage has some more information on the options available.

I contacted them with what I wanted (6"x6", 200W, 24V, adhesive backed, 5mm insulation, ntc100) and they put up the listing for me.

It still hasn't arrived so I don't know what the quality is like.

[www.ebay.com]

I was intrigued because they let you completely customize the heater. You can choose the voltage, power, size, shape, thermistor and have some neat options like an insulating layer on the back. Their webpage has some more information on the options available.

I contacted them with what I wanted (6"x6", 200W, 24V, adhesive backed, 5mm insulation, ntc100) and they put up the listing for me.

It still hasn't arrived so I don't know what the quality is like.

|

Re: Hotbed flatness, voodoo or scientific method? June 25, 2015 11:15AM |

Registered: 11 years ago Posts: 1,277 |

I have heard some bad things about silicone heaters. First of all they break down, or so it is said, and secondly the thermistor temps are really off by a lot. Probably due to being in the wrong position on not really touching the surface that is being heated up. Kapton heaters don't suffer from that if the thermistor is put in the middle and touches the surface being heated.Quote

691175002

I'm using one of these for a build I'm working on:

[www.ebay.com]

I was intrigued because they let you completely customize the heater. You can choose the voltage, power, size, shape, thermistor and have some neat options like an insulating layer on the back. Their webpage has some more information on the options available.

I contacted them with what I wanted (6"x6", 200W, 24V, adhesive backed, 5mm insulation, ntc100) and they put up the listing for me.

It still hasn't arrived so I don't know what the quality is like.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? June 25, 2015 12:42PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Dark Alchemist

I have heard some bad things about silicone heaters. First of all they break down, or so it is said, and secondly the thermistor temps are really off by a lot. Probably due to being in the wrong position on not really touching the surface that is being heated up. Kapton heaters don't suffer from that if the thermistor is put in the middle and touches the surface being heated.

My 230V 350W silicone heater has worked fine so far, The thermistor reading is a long way off on the high side, probably because the thermistor is embedded in the silicone instead of in contact with the aluminium bed plate. I was thinking of adding my own thermistor in contact with the bed plate, however it really isn't a problem, now that I know I have to set it to 70C indicated to print PLA direct on the glass bed, and 140C to print ABS.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hotbed flatness, voodoo or scientific method? June 25, 2015 01:33PM |

Registered: 11 years ago Posts: 1,277 |

The thermistor being off isn't bad if you have a thermo coupler (which I do not) to measure the true temp at the center then just change as needed. The Kapton heaters do not add weight to the bed either but it seems they are hard to come by though when you find one they are cheaper. They seem to be very abundant for Delta printer (round ones).

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? June 30, 2015 05:25AM |

Registered: 11 years ago Posts: 1,277 |

You know I almost purchased this then realized they did the 3 point holes wrong.

[www.amazon.com]

The 3 point holes (reason I did it their way when I posted "oops" above) are supposed to run parallel to Y not perpendicular to it. I can't find any Y plate to take the place of the frog that does 3 point leveling correctly I also found a suspicious post on Amazon in praise of it then 2.5 months later the exact same post on a blog from the same dude. Word for word and space for space so I don't think that is a very good plate in reality especially when they told me they have never done 3 point so don't know if it works with the plate (but they sure advertise 3 point).

edit: Yep, he had to be a shill as every blog posted across the net on that plate he replied exactly the same as he did on Amazon reviews. God, I hate shills.

Edited 2 time(s). Last edit at 06/30/2015 05:32AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

[www.amazon.com]

The 3 point holes (reason I did it their way when I posted "oops" above) are supposed to run parallel to Y not perpendicular to it. I can't find any Y plate to take the place of the frog that does 3 point leveling correctly I also found a suspicious post on Amazon in praise of it then 2.5 months later the exact same post on a blog from the same dude. Word for word and space for space so I don't think that is a very good plate in reality especially when they told me they have never done 3 point so don't know if it works with the plate (but they sure advertise 3 point).

edit: Yep, he had to be a shill as every blog posted across the net on that plate he replied exactly the same as he did on Amazon reviews. God, I hate shills.

Edited 2 time(s). Last edit at 06/30/2015 05:32AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? June 30, 2015 06:31AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Hotbed flatness, voodoo or scientific method? June 30, 2015 06:44AM |

Registered: 11 years ago Posts: 1,277 |

If I do buy it I will put the new hole inbetween the two SC8UUs as there is room there and the other side with the one SC8UU doesn't have much meat there for a M3 tapped hole.Quote

the_digital_dentist

That plate looks a lot better than the one you started with. Just drill a third hole next to the single bearing.

If you're looking for something premade that is exactly what you need to fit your machine I think you'll be looking for a looooong time, and maybe never finding.

Yep, to your second assertion since Prusa flubbed up the design so much.

Now this will take care of any nonsense on the Y as I will ditch the printed LM8UU holders that are always getting lose and no zip ties that has so much play in them I can barely touch the frog plate and it moves up, or down, on me. What I really wish is I could have those two farther apart as that has been a gripe of mine from day one before I even had the other pieces of my machine. Farther apart, if even by 5mm, would make it so much more steady without really sacrificing any Y coverage.

I noticed that the holes are all through hole so not tapped. Hmmmm, that would be odd for adding my Mic6 on top and trying to level it without those being tapped.

Edited 2 time(s). Last edit at 06/30/2015 07:09AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? June 30, 2015 10:24AM |

Registered: 11 years ago Posts: 5,780 |

Even if those holes were tapped, it would not be sufficient for leveling screws. Grab any screw/nut and try wiggling the nut on the screw. It moves a lot. Now imagine standing your bed plate on 3 of those. What will happen to the plate when the Y axis reverses direction? In my printer I drove the leveling screws into teflon blocks with undersized holes so the screws would form their own threads in the teflon and the teflon would grip the screws tightly. The screws don't/can't wiggle in the teflon blocks. The holes in the undercarriage plate are for mounting the teflon blocks, not the leveling screws.

|

Re: Hotbed flatness, voodoo or scientific method? June 30, 2015 10:30AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Hotbed flatness, voodoo or scientific method? June 30, 2015 10:35AM |

Registered: 11 years ago Posts: 5,780 |

If the two run along the X axis and the third adjusts the roll around the X axis, the roll screw will be at the front edge of the bed and the pitch adjust screw at the back edge which might make it hard to reach.

If the two are aligned with the Y axis, the reference screw is at the back, the pitch screw at the front edge and the roll screw at the mid point of either the left or right side of the bed.

Aligning along the Y axis makes screw access easier, but it may depend on how your machine is built. Performance wise they are the same.

If the two are aligned with the Y axis, the reference screw is at the back, the pitch screw at the front edge and the roll screw at the mid point of either the left or right side of the bed.

Aligning along the Y axis makes screw access easier, but it may depend on how your machine is built. Performance wise they are the same.

|

Re: Hotbed flatness, voodoo or scientific method? June 30, 2015 10:37AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Hotbed flatness, voodoo or scientific method? June 30, 2015 10:46AM |

Registered: 11 years ago Posts: 5,780 |

When you mount the levelers, you want them to be next to the bearings. If you put them on opposite sides- two levelers on the edge of the plate with one bearing, The undercarriage plate will be able to flex. Putting the bed levelers next to the bearings -one leveler next to the side with the single bearing and two on the other edge- they'll have much more solid support. There won't be anything flexing except the guide rails.

|

Re: Hotbed flatness, voodoo or scientific method? June 30, 2015 03:57PM |

Registered: 11 years ago Posts: 1,277 |

I saw how you mounted the teflon but no way in hades can I do that on this printer then I went to prices some chunks of Teflon and said I will just have to go really slow. First things first is to fix this flatness, when heated, issue so I can print again.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 01, 2015 05:16PM |

Registered: 8 years ago Posts: 396 |

Quote

Dark Alchemist

So, I am looking for a Kapton heater to stick onto the flat plate and went to AliExpress since eBay was doa.

Here is a picture of the one being sold:

I asked the seller "You supply a thermistor for this but where does it go? Seems you forgot to make a hole in the middle of the heater for it." and I get a response that this is what they are selling and the picture used in the listing is for reference only.

Still, that thermistor is in the wrong spot but why would you use the first picture as your listing picture when the second one is accurate and just looks more professional AND doesn't even remotely look like the listing picture? edit: Am I not wrong but when you enlarge the second picture right in the middle is a spot for a thermistor? Sure looks like it to me so why of to the side like that?

What I am looking for is 200mm square 24v @200 watts that will stick to the bottom so I can use the metal flat plate's third hole I will drill and not the MK2B's and have to cut away the metal around the power connectors.

The aluminum plate I bought had a carved groove and spot for thermistor. I put my pcb heater under it, then a thick piece of carboard to force the PCB into contact with the aluminum plate. it also acts as insulator. then the "frog plate" which in my case is not frogged. it is same shape as my top plate.

so its a sammich

build plate

thermistor+kapton tape

pcb heater

carboard

bottom plate

[www.ebay.com]

[www.ebay.com]

And when i set all four corners to the same levelness using a z probe, i can measure anywhere on the bed and it is the same value +/i .01mm.. Also, I do my levelling with the bed warm.

Edited 2 time(s). Last edit at 07/01/2015 05:17PM by thetazzbot.

|

Re: Hotbed flatness, voodoo or scientific method? July 01, 2015 07:30PM |

Registered: 11 years ago Posts: 1,277 |

tazz, I did the same and forget it.

This brings something up I do not understand so I need some insight.

MK2B and that heat spreader. Now I am using 3 point leveling and when everything is just about the same feel (I can't use my DTI as I can't print the holder for it for my machine or I would) the home position is drooping down bad. The thing is that is where one screw is missing (1 in the middle in the back and 2 in the front facing me on each corner) but when I take the plate off there is no droop against a flat surface. I don't get it since the i3, and variants, only care about one section of the smooth rods and the nozzle goes left to right and back. If Y had anything to do with this then the nozzle would see a droop all across that edge but it doesn't. How?

Edited 1 time(s). Last edit at 07/01/2015 07:32PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

This brings something up I do not understand so I need some insight.

MK2B and that heat spreader. Now I am using 3 point leveling and when everything is just about the same feel (I can't use my DTI as I can't print the holder for it for my machine or I would) the home position is drooping down bad. The thing is that is where one screw is missing (1 in the middle in the back and 2 in the front facing me on each corner) but when I take the plate off there is no droop against a flat surface. I don't get it since the i3, and variants, only care about one section of the smooth rods and the nozzle goes left to right and back. If Y had anything to do with this then the nozzle would see a droop all across that edge but it doesn't. How?

Edited 1 time(s). Last edit at 07/01/2015 07:32PM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 01, 2015 08:50PM |

Registered: 8 years ago Posts: 396 |

Quote

tazz, I did the same and forget it.

i don't know what that means...

i feel like the corners without attachments will move or sag one way or the other. it's just a gut feeling. if the spring between the two plates is at all week, somethings going to wiggle where it shouldnt. i'm not an expert.. but i know that if i have one screw in the middle, i can press down on a corner and it will move, and that bugs me.

so what i have is one static screw with a spacer in one corner, and three adjusters in the remaining corners.

|

Re: Hotbed flatness, voodoo or scientific method? July 01, 2015 10:41PM |

Registered: 11 years ago Posts: 1,277 |

Well, three screws are better at this than four and I can attest to that for me. They say three points define a plane but what they forget to tell you is that the three points must be non-collinear to define a plane. Well, if you look at our 3 points on our beds I think they fail that criteria but I am not 100% sure since one of the points is not collinear with the other two.Quote

thetazzbot

Quote

tazz, I did the same and forget it.

i don't know what that means...

i feel like the corners without attachments will move or sag one way or the other. it's just a gut feeling. if the spring between the two plates is at all week, somethings going to wiggle where it shouldnt. i'm not an expert.. but i know that if i have one screw in the middle, i can press down on a corner and it will move, and that bugs me.

so what i have is one static screw with a spacer in one corner, and three adjusters in the remaining corners.

These are brand new springs and are stiff as hell springs but not overly so. They are the Ultimaker springs with a designation of D1450/D2150 and Material: Stainless Steel Diameter of String: 1.2 mm Outside Diameter: 7.5 mm Inner Diameter: 5 mm Height: 20 mm Circles: 9.

As far as not understanding what I said above I meant I used that exact same setup with those exact same parts to no avail. Matter of fact I am still using them for this and before anyone says anything this plate is NOT bent or droops until it is on the bed. 3, 4, 6 , 26, 32 screws it doesn't matter (lol) that corner droops.

edit: So, I do not understand why that corner has always drooped and with four spring it is even worse as the droop pulls on the opposite corner.

edit: I changed the phrasing about the three points.

Edited 5 time(s). Last edit at 07/02/2015 02:21AM by Dark Alchemist.

_______

I await Skynet and my last vision will be of a RepRap self replicating the robots that is destroying the human race.

|

Re: Hotbed flatness, voodoo or scientific method? July 02, 2015 01:25AM |

Registered: 11 years ago Posts: 5,780 |

Sorry, only registered users may post in this forum.