Looking at building a Large FDM

Posted by SpannerHands

|

Looking at building a Large FDM May 15, 2015 10:11AM |

Registered: 8 years ago Posts: 18 |

Hi All

I am new here, been a long time reader of your wonderful forum and love the idea of the RepRap community...

I am the director of a toy manufacturing business specialising in large ride-on battery operated toys in Wales (UK) and responsible for product design (just the ideas man & a big kid really) sadly we don't manufacture in the UK as I am sure you all know, its all done out of china these days, but hoping to change that in the future... or maybe people will print their own toys in the future so its all exciting...

I have been using desktop 3D printers for a few years, and have also enjoyed printing orders at home for 3D hubs which has been fun... Currently I have a Printrbot Simple metal (really like it) , Da Vinci 1.0A (its ok) and had an Ultimaker 2 (which I just sold)...

I have fallen in love with 3D printing, and slowly my home as been filling up with many 3D printed parts, its so nice to design something and have such instant satisfaction seeing the completed item in just a few minutes or hours later : -)

In the last few years I have used 3D printing companies out in China to make prototypes of new large designs to show our customers, but have found this is very expensive and lead times have been unreasonable for us (because wanting it fast costs a small fortune), so now I am inching to build something myself I have been thinking of a few ideas but was hoping that you might be able to steer me in a good direction...

So how large a printer I am looking for, well as big as can be achieved so have been looking at designs that can be scaled easily but ideally looking at 1000 x 1000 x 1000 mm as would love to print some supper large objects...

Question is

1. What are the major pitfalls of making a large printer

2. Is there any current RepRap's that large I missed, or something best to base a design of?

3. What would be better corexy , cartesian or some sort of Printerbot simple metal design on steroids?

4. If I do end up designing and building my own printer how best to show the progress on here?

5. If I build a printer I would love to make it open source but it it considered unreasonable if I offer it for sale as a kit afterwards?

Thanks for reading my long post...

I am new here, been a long time reader of your wonderful forum and love the idea of the RepRap community...

I am the director of a toy manufacturing business specialising in large ride-on battery operated toys in Wales (UK) and responsible for product design (just the ideas man & a big kid really) sadly we don't manufacture in the UK as I am sure you all know, its all done out of china these days, but hoping to change that in the future... or maybe people will print their own toys in the future so its all exciting...

I have been using desktop 3D printers for a few years, and have also enjoyed printing orders at home for 3D hubs which has been fun... Currently I have a Printrbot Simple metal (really like it) , Da Vinci 1.0A (its ok) and had an Ultimaker 2 (which I just sold)...

I have fallen in love with 3D printing, and slowly my home as been filling up with many 3D printed parts, its so nice to design something and have such instant satisfaction seeing the completed item in just a few minutes or hours later : -)

In the last few years I have used 3D printing companies out in China to make prototypes of new large designs to show our customers, but have found this is very expensive and lead times have been unreasonable for us (because wanting it fast costs a small fortune), so now I am inching to build something myself I have been thinking of a few ideas but was hoping that you might be able to steer me in a good direction...

So how large a printer I am looking for, well as big as can be achieved so have been looking at designs that can be scaled easily but ideally looking at 1000 x 1000 x 1000 mm as would love to print some supper large objects...

Question is

1. What are the major pitfalls of making a large printer

2. Is there any current RepRap's that large I missed, or something best to base a design of?

3. What would be better corexy , cartesian or some sort of Printerbot simple metal design on steroids?

4. If I do end up designing and building my own printer how best to show the progress on here?

5. If I build a printer I would love to make it open source but it it considered unreasonable if I offer it for sale as a kit afterwards?

Thanks for reading my long post...

|

Re: Looking at building a Large FDM May 15, 2015 10:50AM |

Registered: 10 years ago Posts: 14,672 |

First, I suggest you calculate what your print times will be, because you will probably not want to wait days for a print to finish. If you are prepared to sacrifice print resolution, you can get a large nozzle, e.g. the E3D Volcano, which is available in sizes up to 1.2mm. That will help with the print time.

If you do go ahead, then I suggest you avoid Cartesian, because accelerating a 1m square bed fast enough to get a decent print speed (all the while keeping it level) will be difficult - and of course you would need a 2m x 1m machine footprint. So I suggest either CoreXY or Delta. With CoreXY, you still have the problem of moving a large heavy bed in the Z direction, while keeping it flat. Other people may be able to advise you how to do that.

Delta has the advantage of a fixed bed and a very regular construction. However, the height of a delta is approximately the 1.2 times the printable bed radius. plus the build height, plus another 200mm or so (better allow a bit more for your larger build). So even if 1m diameter printable area is enough for you instead of 1m square, you would still need about 2.45m available height for a 1m printable height. If you will be using it in a factory, you may have that much headroom. I think a delta of this size could even use standard Nema 17 stepper motors and off-the-shelf electronics.

As for the pitfalls, I think the main ones are likely to be getting a flat enough bed that size, ensuring sufficient rigidity and accuracy in the frame, and avoiding things vibrating in sympathy with the stepper motors. If you intend to print ABS, then consider an filtered enclosure mandatory, both to avoid warping and to filter out fumes and particulates (or expect H&S to be after you).

There is nothing unreasonable about making a design open source and then offering a kit for it, and there are already other people doing that.

HTH!

Edited 4 time(s). Last edit at 05/15/2015 10:55AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If you do go ahead, then I suggest you avoid Cartesian, because accelerating a 1m square bed fast enough to get a decent print speed (all the while keeping it level) will be difficult - and of course you would need a 2m x 1m machine footprint. So I suggest either CoreXY or Delta. With CoreXY, you still have the problem of moving a large heavy bed in the Z direction, while keeping it flat. Other people may be able to advise you how to do that.

Delta has the advantage of a fixed bed and a very regular construction. However, the height of a delta is approximately the 1.2 times the printable bed radius. plus the build height, plus another 200mm or so (better allow a bit more for your larger build). So even if 1m diameter printable area is enough for you instead of 1m square, you would still need about 2.45m available height for a 1m printable height. If you will be using it in a factory, you may have that much headroom. I think a delta of this size could even use standard Nema 17 stepper motors and off-the-shelf electronics.

As for the pitfalls, I think the main ones are likely to be getting a flat enough bed that size, ensuring sufficient rigidity and accuracy in the frame, and avoiding things vibrating in sympathy with the stepper motors. If you intend to print ABS, then consider an filtered enclosure mandatory, both to avoid warping and to filter out fumes and particulates (or expect H&S to be after you).

There is nothing unreasonable about making a design open source and then offering a kit for it, and there are already other people doing that.

HTH!

Edited 4 time(s). Last edit at 05/15/2015 10:55AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Looking at building a Large FDM May 15, 2015 11:11AM |

Registered: 10 years ago Posts: 869 |

Quote

SpannerHands

1. What are the major pitfalls of making a large printer

Large amount of power if you have a heated bed. Need of heated build chamber. Print time unless layer height and extruded width are large, then loss of quality. Need to use larger structural components due to spans involved. Increased diameter linear rods/rails/etc due to unacceptable amounts of sag with smaller diameters over longer spans. Stability. Possibly larger motors, drive mechanisms, etc due to additional weight of moving parts.

Quote

2. Is there any current RepRap's that large I missed, or something best to base a design of?

I don't know of any that specifically were that large but that doesn't mean there isn't any. There have been a variety of people that have asked about large formats but I don't think any have really documented it and made it an actual model.

Quote

3. What would be better corexy , cartesian or some sort of Printer bot simple metal design on steroids?

CoreXY is a subset of Cartesian, you still have distinct movement in 2 directions. The main competing alternative is delta which may not be practical at that size. It is funny that you mentioned a Printrbot design on steroids...

At the size you're looking at, you're probably looking at either a fixed bed with gantry that moves in 3 dimensions, or still a gantry of some sorts for X-Y movement with the build plate moving up to the nozzle and lowering as it prints. You won't want rapid movements of the build surface at that size.

Quote

4. If I do end up designing and building my own printer how best to show the progress on here?

Always. It's a requirement.

In all seriousness though, you're welcome and encouraged to do so, but you don't have to.

In all seriousness though, you're welcome and encouraged to do so, but you don't have to.Quote

5. If I build a printer I would love to make it open source but it it considered unreasonable if I offer it for sale as a kit afterwards?

Nope. Not at all. It's not great form to pimp your product in it's own posts that are blatantly self serving (especially if you don't disclose your financial interest), but having a "Hey, I built a new type of printer" thread to show it off and describe features, how it's better, etc that has a small section where you offer to sell assembled printers is usually ok. We also do have a for sale forum as well as you can put a simple link in your signature.

|

Re: Looking at building a Large FDM May 15, 2015 11:48AM |

Registered: 8 years ago Posts: 18 |

Thanks for your reply: -)

I understand, don't really want to have a print take a week...

Will probably design & build own hot ends and nozzles, so I can quickly switch nozzles dependant on size of object, might even consider water cooling so enclosed build chamber will not be an issue, but if that fails then E3D volcano is the next best thing...

Was thinking that maybe for massive objects use upto 2mm nozzles, but part of the design might even have the option of stacking mutable extrudes for mass production of mutable large objects...

I was thinking of the design like an Ultimaker or core XY but having the bed fixed in place and rising the whole printer in the Z or maybe a combination of core XY and the Maximus 3D Z arrangement...

but I do have an out the box idea that I will try first to see if its possible as out of the box is always my favourite path... and will post if it works...

Delta printers look fun, but as you said the hight required becomes an issue...

The flat bed is not such and issue, glass is very stable at that size with some support, and as I intend the bed to be to be fixed, Worst case I could always just get an aluminium bed that size ground flat...

Quote

dc42

First, I suggest you calculate what your print times will be, because you will probably not want to wait days for a print to finish. If you are prepared to sacrifice print resolution, you can get a large nozzle, e.g. the E3D Volcano, which is available in sizes up to 1.2mm. That will help with the print time.

HTH!

I understand, don't really want to have a print take a week...

Will probably design & build own hot ends and nozzles, so I can quickly switch nozzles dependant on size of object, might even consider water cooling so enclosed build chamber will not be an issue, but if that fails then E3D volcano is the next best thing...

Was thinking that maybe for massive objects use upto 2mm nozzles, but part of the design might even have the option of stacking mutable extrudes for mass production of mutable large objects...

Quote

dc42

If you do go ahead, then I suggest you avoid Cartesian, because accelerating a 1m square bed fast enough to get a decent print speed (all the while keeping it level) will be difficult - and of course you would need a 2m x 1m machine footprint. So I suggest either CoreXY or Delta. With CoreXY, you still have the problem of moving a large heavy bed in the Z direction, while keeping it flat. Other people may be able to advise you how to do that.

HTH!

I was thinking of the design like an Ultimaker or core XY but having the bed fixed in place and rising the whole printer in the Z or maybe a combination of core XY and the Maximus 3D Z arrangement...

but I do have an out the box idea that I will try first to see if its possible as out of the box is always my favourite path... and will post if it works...

Quote

dc42

Delta has the advantage of a fixed bed and a very regular construction. However, the height of a delta is approximately the 1.2 times the printable bed radius. plus the build height, plus another 200mm or so (better allow a bit more for your larger build). So even if 1m diameter printable area is enough for you instead of 1m square, you would still need about 2.45m available height for a 1m printable height. If you will be using it in a factory, you may have that much headroom. I think a delta of this size could even use standard Nema 17 stepper motors and off-the-shelf electronics.

HTH!

Delta printers look fun, but as you said the hight required becomes an issue...

Quote

dc42

As for the pitfalls, I think the main ones are likely to be getting a flat enough bed that size, ensuring sufficient rigidity and accuracy in the frame, and avoiding things vibrating in sympathy with the stepper motors. If you intend to print ABS, then consider an filtered enclosure mandatory, both to avoid warping and to filter out fumes and particulates (or expect H&S to be after you).

HTH!

The flat bed is not such and issue, glass is very stable at that size with some support, and as I intend the bed to be to be fixed, Worst case I could always just get an aluminium bed that size ground flat...

|

Re: Looking at building a Large FDM May 15, 2015 12:06PM |

Registered: 8 years ago Posts: 18 |

Quote

cdru

Large amount of power if you have a heated bed. Need of heated build chamber. Print time unless layer height and extruded width are large, then loss of quality. Need to use larger structural components due to spans involved. Increased diameter linear rods/rails/etc due to unacceptable amounts of sag with smaller diameters over longer spans. Stability. Possibly larger motors, drive mechanisms, etc due to additional weight of moving parts.

I don't know of any that specifically were that large but that doesn't mean there isn't any. There have been a variety of people that have asked about large formats but I don't think any have really documented it and made it an actual model.

CoreXY is a subset of Cartesian, you still have distinct movement in 2 directions. The main competing alternative is delta which may not be practical at that size. It is funny that you mentioned a Printrbot design on steroids...

At the size you're looking at, you're probably looking at either a fixed bed with gantry that moves in 3 dimensions, or still a gantry of some sorts for X-Y movement with the build plate moving up to the nozzle and lowering as it prints. You won't want rapid movements of the build surface at that size.

Always. It's a requirement.In all seriousness though, you're welcome and encouraged to do so, but you don't have to.

Nope. Not at all. It's not great form to pimp your product in it's own posts that are blatantly self serving (especially if you don't disclose your financial interest), but having a "Hey, I built a new type of printer" thread to show it off and describe features, how it's better, etc that has a small section where you offer to sell assembled printers is usually ok. We also do have a for sale forum as well as you can put a simple link in your signature.

Thanks for your reply : -)

Heated bed was looking at 240V and have already found a supplier on that front...

Your right a heated build chamber or at least enclosed will have to be a must for stability...

With regards to rods and rails I was thinning along the line of Linear guide blocks/carriages using rails mounted to Aluminium Profile should give me good stability...

I have a "printerbot on steroids design" idea where unlike the printerbot the X movement instead will move along the bed rather than the bed moving itself if that makes sense,... ( will be mocking the elements of this up over the next month to see if its possible will post some pics)

I think that its more beneficial to share designs with the community as I would love to have peoples inputs & contributions or ideas so regardless of a kit being available for others to give it a bash if they want to build one, at least in the end I want everyone too come along for the ride even if I fail...

|

Re: Looking at building a Large FDM May 15, 2015 12:07PM |

Registered: 10 years ago Posts: 1,401 |

Since we are talking about big printers, I want to ask one question to the more knowledgeable people here:

On big scale printers will hydraulic systems be suitable?

See I have work with hydraulic equipment for a long long time, they can be quite precise and simple to implement and operate, one source of power "the pump" and multiple actuators will move the axis (don't fix your mind in one type of printer). Flow meters and regulators can be used to secure correct distance travel and lasers can measure it to count for any error. Liquids can't be compressed so starts and stops can be quite fast, there is no reverberation (with proper valve implementation) and to my knowledge there is no backlash issues. Cylinders can be designed as part of the frame and used for railing too.

I don't want to hijack this post, but rather show other alternatives of operation rather than standard nemas, belts and leadscrews.

Edited 2 time(s). Last edit at 05/15/2015 12:16PM by ggherbaz.

On big scale printers will hydraulic systems be suitable?

See I have work with hydraulic equipment for a long long time, they can be quite precise and simple to implement and operate, one source of power "the pump" and multiple actuators will move the axis (don't fix your mind in one type of printer). Flow meters and regulators can be used to secure correct distance travel and lasers can measure it to count for any error. Liquids can't be compressed so starts and stops can be quite fast, there is no reverberation (with proper valve implementation) and to my knowledge there is no backlash issues. Cylinders can be designed as part of the frame and used for railing too.

I don't want to hijack this post, but rather show other alternatives of operation rather than standard nemas, belts and leadscrews.

Edited 2 time(s). Last edit at 05/15/2015 12:16PM by ggherbaz.

|

Re: Looking at building a Large FDM May 15, 2015 12:10PM |

Registered: 11 years ago Posts: 5,780 |

You could eliminate the need for absolute bed flatness and a heater by printing on a sacrificial layer of plastic foam, the way some older StrataSys industrial machines did (still do?). You have to bury the extruder nozzle into the foam for the first layer, so I'm not sure it would be good for a delta- many use magnets to suspend the extruder on the effectors- the extruder might move or the effectors may flex when the extruder nozzle bangs into and drags through the first mm of foam for the first layer of the print. If you print using a raft, that sort stuff may not matter.

PIR foam is fire retardant and does not break down chemically at extruder nozzle temperatures. I have used it successfully on my cartesian machine in the past and it has been used in one of the StrataSys machines at the Milwaukee Makerspace a few times. On the foam you get best results when you print on a raft. You can just cut the cheap ($0.50/ sqft in the US) foam away from the print if it doesn't want to let go. On the topic of cost- a 4' x 8' x 1" thick sheet costs about $15 at Home Depot and similar stores. Don't worry about the size- the foam cuts cleanly with a razor knife so you can cut the sheet up at the store and take it home in your Ferrari. Each piece of foam can be reused multiple times, so one 4' x 8' sheet should last most people through a couple years' prints.

This foam is also good for making thermal enclosures because it is fire retardant (unlike the pink and blue polystyrene foams), easy to cut with a razor knife, and a great insulator. You prep it for printing by peeling the foil/paper backing off one or both sides. If you build a thermal enclosure for your printer you can use a left over piece as a printing test piece. Just move the Z axis up about 24mm in your slicing software, tape the foam to your unheated print bed, and print.

I'm thinking about redesigning the undercarriage in my printer to accommodate quick, easy, print bed change-outs If I get around to it, I'll try to design it so the beds can be swapped without releveling them or rezeroing the Z axis. I want to be able to switch between a heated flat plate when I need the super flat bottom surface on the print, and a lower mass and maybe faster printing foam bed for when the speed is more important that the bottom surface finish. Sometimes it is very difficult to get large prints off my kapton-taped, aluminum tooling plate bed- the foam could just be cut away from parts that don't want to let go.

PIR foam is fire retardant and does not break down chemically at extruder nozzle temperatures. I have used it successfully on my cartesian machine in the past and it has been used in one of the StrataSys machines at the Milwaukee Makerspace a few times. On the foam you get best results when you print on a raft. You can just cut the cheap ($0.50/ sqft in the US) foam away from the print if it doesn't want to let go. On the topic of cost- a 4' x 8' x 1" thick sheet costs about $15 at Home Depot and similar stores. Don't worry about the size- the foam cuts cleanly with a razor knife so you can cut the sheet up at the store and take it home in your Ferrari. Each piece of foam can be reused multiple times, so one 4' x 8' sheet should last most people through a couple years' prints.

This foam is also good for making thermal enclosures because it is fire retardant (unlike the pink and blue polystyrene foams), easy to cut with a razor knife, and a great insulator. You prep it for printing by peeling the foil/paper backing off one or both sides. If you build a thermal enclosure for your printer you can use a left over piece as a printing test piece. Just move the Z axis up about 24mm in your slicing software, tape the foam to your unheated print bed, and print.

I'm thinking about redesigning the undercarriage in my printer to accommodate quick, easy, print bed change-outs If I get around to it, I'll try to design it so the beds can be swapped without releveling them or rezeroing the Z axis. I want to be able to switch between a heated flat plate when I need the super flat bottom surface on the print, and a lower mass and maybe faster printing foam bed for when the speed is more important that the bottom surface finish. Sometimes it is very difficult to get large prints off my kapton-taped, aluminum tooling plate bed- the foam could just be cut away from parts that don't want to let go.

|

Re: Looking at building a Large FDM May 15, 2015 03:24PM |

Registered: 11 years ago Posts: 335 |

I never understood the ubiquity of CoreXY designs among hobbyists. It is an inferior derivative of the H-bot belt path. No commercial systems use CoreXY. H-bot is the standard for high speed cartesian positioning. Stratasys uses an H-bot belt path in the majority of their printers. Many laser cutters use an H-bot belt path.

CoreXY is a hack to compensate for poor frame rigidity by twisting and crossing the timing belt. I guess it is fine if you are trying to make something as cheaply as possible, but for a large printer you are going to need decent linear motion regardless.

CoreXY is a hack to compensate for poor frame rigidity by twisting and crossing the timing belt. I guess it is fine if you are trying to make something as cheaply as possible, but for a large printer you are going to need decent linear motion regardless.

|

Re: Looking at building a Large FDM May 15, 2015 06:05PM |

Registered: 8 years ago Posts: 18 |

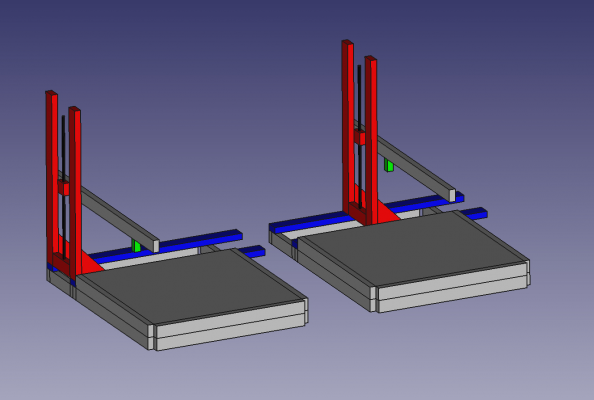

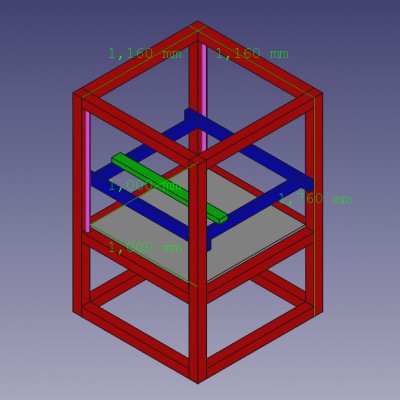

Well this is my basic brain dump of what I have in mind for a printerbot style design on steroids...

Build area 1000 x 1000 x 1000 mm

Constructed from 40 x 80 mm aluminium profile

Z axix is in RED using a single ball and screw, this carriage moves along a linear rail in blue making up the X axis movement.

The Y axis is fixed to the Z and the extruder(s) move along that making the Y axis movement in green.

All movement will be made using precision hardened linear rails bolted to the aluminium profile

Ideas for driving the X axis? maybe a double precision belt design for extra torque driven off a double shaft stepper with two belt systems?

Please feel free to shoot me down if this idea is hopeless...

Does anyone have any good links for cheaper/ better linear rail or other suggestions, was looking at this http://www.gsf-promounts.com/precision-hardened-linear-rail/

Build area 1000 x 1000 x 1000 mm

Constructed from 40 x 80 mm aluminium profile

Z axix is in RED using a single ball and screw, this carriage moves along a linear rail in blue making up the X axis movement.

The Y axis is fixed to the Z and the extruder(s) move along that making the Y axis movement in green.

All movement will be made using precision hardened linear rails bolted to the aluminium profile

Ideas for driving the X axis? maybe a double precision belt design for extra torque driven off a double shaft stepper with two belt systems?

Please feel free to shoot me down if this idea is hopeless...

Does anyone have any good links for cheaper/ better linear rail or other suggestions, was looking at this http://www.gsf-promounts.com/precision-hardened-linear-rail/

|

Re: Looking at building a Large FDM May 15, 2015 09:06PM |

Registered: 9 years ago Posts: 1,873 |

Looks interesting. I'm sure you could make it work with enough $$$, but I'm not sure how fast it would go. My biggest concern would be the amount of moving mass on your x-axis, and the twisting moments applied when the head is at the top front position. I keep finding myself drawn towards core-xy with a Z-bed. The forces all look much more manageable in that layout (but I'm just a clueless beginner, so don't mind me).

Whatever you do, I'm sure it's going to be a fascinating build - can't wait to see how it goes!

Whatever you do, I'm sure it's going to be a fascinating build - can't wait to see how it goes!

|

Re: Looking at building a Large FDM May 16, 2015 01:52AM |

Registered: 8 years ago Posts: 5,232 |

I think, the delta design needs a second chance here. If you have a small room with headroom of 2.5meters, you can actually use the "problem" of the tall delta design to your advantage.

Just build the top of the delta right under your ceiling. That would give your design extra stablility.

-Olaf

Just build the top of the delta right under your ceiling. That would give your design extra stablility.

-Olaf

|

Re: Looking at building a Large FDM May 16, 2015 03:51AM |

Registered: 9 years ago Posts: 978 |

I think that the biggest issue is reliability.

I have a 100x100x100 printer, and at best, half the objects that size print OK first time. Printing a 200x200x200 object with the same reliability would be 1/8 (because it is cubed) of a 100x100x100 object, so only 1 in 16 would print first time. Printing a 1000x1000x1000 would mean that 1 in 2000 things would print first time. Remember that all else being equal, each of those objects will take 1000 times as long to print and use 1000 times as much filament and 1000 times as much electricity.

Let's say you can increase speed by 1000 times so you can print an object as fast as me, but 10 times bigger in each dimension, Let's say it takes 1 day to produce some object. I'll get mine done today (50%) or tomorrow (25%) or the next day (12.5%)... 87.5% chance I'll have something in 3 days. You OTOH have 1/2000 + 1/(2000*1999) + 1/(2000*1998) = almost no chance of producing anything in 3 days... you'll have to do 1000 prints (i.e. 3 years) just to get a 50/50 probability of success.

NB: I'm not saying this isn't possible... there are plenty of people with 200x200x200 printers, and they seem quite happy, so I guess their reliability is probably better than mine. Just saying it needs to be thought about.

I have a 100x100x100 printer, and at best, half the objects that size print OK first time. Printing a 200x200x200 object with the same reliability would be 1/8 (because it is cubed) of a 100x100x100 object, so only 1 in 16 would print first time. Printing a 1000x1000x1000 would mean that 1 in 2000 things would print first time. Remember that all else being equal, each of those objects will take 1000 times as long to print and use 1000 times as much filament and 1000 times as much electricity.

Let's say you can increase speed by 1000 times so you can print an object as fast as me, but 10 times bigger in each dimension, Let's say it takes 1 day to produce some object. I'll get mine done today (50%) or tomorrow (25%) or the next day (12.5%)... 87.5% chance I'll have something in 3 days. You OTOH have 1/2000 + 1/(2000*1999) + 1/(2000*1998) = almost no chance of producing anything in 3 days... you'll have to do 1000 prints (i.e. 3 years) just to get a 50/50 probability of success.

NB: I'm not saying this isn't possible... there are plenty of people with 200x200x200 printers, and they seem quite happy, so I guess their reliability is probably better than mine. Just saying it needs to be thought about.

|

Re: Looking at building a Large FDM May 16, 2015 04:09AM |

Registered: 10 years ago Posts: 14,672 |

It would be a good idea to power at least the electronics and stepper motors via a UPS, to take care of power brownouts. Possibly the hot end too.

Delta printers have moving parts that are subjected to light loads, which helps reliability. My delta is very reliable now, I've done several 8 hour prints without any failures. The only reliability issue I ever had with it was the extruder losing its grip on the filament. I solved that by reducing the extruder stepper current to 400mA, so that if the filament can't be fed fast enough because the nozzle is obstructed, it skips steps instead of chewing through the filament.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Delta printers have moving parts that are subjected to light loads, which helps reliability. My delta is very reliable now, I've done several 8 hour prints without any failures. The only reliability issue I ever had with it was the extruder losing its grip on the filament. I solved that by reducing the extruder stepper current to 400mA, so that if the filament can't be fed fast enough because the nozzle is obstructed, it skips steps instead of chewing through the filament.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Looking at building a Large FDM May 16, 2015 04:44AM |

Registered: 8 years ago Posts: 18 |

Quote

JamesK

Looks interesting. I'm sure you could make it work with enough $$$, but I'm not sure how fast it would go. My biggest concern would be the amount of moving mass on your x-axis, and the twisting moments applied when the head is at the top front position. I keep finding myself drawn towards core-xy with a Z-bed. The forces all look much more manageable in that layout (but I'm just a clueless beginner, so don't mind me).

Whatever you do, I'm sure it's going to be a fascinating build - can't wait to see how it goes!

One sure thing it will be interesting... and thanks for your input, you made some good points...

The mass on the X will be quite high, but with good linear rails & double precision belt design I will be hoping it will help the stepper control its movement and maybe I can sort the rest out in the firmware, I am thinking you will be able to allow for slower acceleration, but as the objects will be large you pick up speed then decelerate rather than just run the hole thing slower...

The 40 x 80 mm aluminium profile is very ridged, from my beer mat maths you would only be looking at a 0.06 mm droop at the end point with a 1KG load... (warning beer mat maths was involved) but this will be the first thing I test before progressing with the build...

The fist issue I have hit with the core xy or even Hbot is the belt length is going to ridiculous over 8m and looking at belt specifications of 10mm GT2 I will be seeing mm's of stretch, not very good with knowledge how this will effect things or best practices to overcome that issue...

|

Re: Looking at building a Large FDM May 16, 2015 04:59AM |

Registered: 8 years ago Posts: 18 |

Quote

o_lampe

I think, the delta design needs a second chance here. If you have a small room with headroom of 2.5meters, you can actually use the "problem" of the tall delta design to your advantage.

Just build the top of the delta right under your ceiling. That would give your design extra stablility.

-Olaf

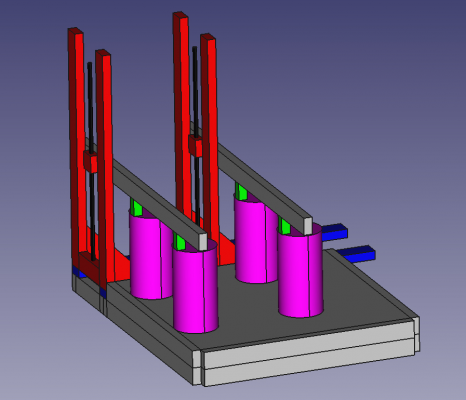

I have not ruled out doing a delta design, however the one thing you cant get with a delta that puts me off is duplication... for example if my design does work then this should be possible?...

|

Re: Looking at building a Large FDM May 16, 2015 05:27AM |

Registered: 10 years ago Posts: 14,672 |

For duplication to be possible with that design, you would need the bed to be so flat and the XY mechanism to be so accurate and rigid that you can print without using bed compensation. That may be very hard to achieve when doing large prints.

Personally, I would go for a delta design if you have sufficient headroom. The belts would be about 4.5m long.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Personally, I would go for a delta design if you have sufficient headroom. The belts would be about 4.5m long.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Looking at building a Large FDM May 16, 2015 05:29AM |

Registered: 8 years ago Posts: 18 |

Quote

frankvdh

I think that the biggest issue is reliability.

I have a 100x100x100 printer, and at best, half the objects that size print OK first time. Printing a 200x200x200 object with the same reliability would be 1/8 (because it is cubed) of a 100x100x100 object, so only 1 in 16 would print first time. Printing a 1000x1000x1000 would mean that 1 in 2000 things would print first time. Remember that all else being equal, each of those objects will take 1000 times as long to print and use 1000 times as much filament and 1000 times as much electricity.

Let's say you can increase speed by 1000 times so you can print an object as fast as me, but 10 times bigger in each dimension, Let's say it takes 1 day to produce some object. I'll get mine done today (50%) or tomorrow (25%) or the next day (12.5%)... 87.5% chance I'll have something in 3 days. You OTOH have 1/2000 + 1/(2000*1999) + 1/(2000*1998) = almost no chance of producing anything in 3 days... you'll have to do 1000 prints (i.e. 3 years) just to get a 50/50 probability of success.

NB: I'm not saying this isn't possible... there are plenty of people with 200x200x200 printers, and they seem quite happy, so I guess their reliability is probably better than mine. Just saying it needs to be thought about.

Thanks for that, understand what you are saying... Very much doubt the reliability is going to be one in 2000 chance, my printerbot for example is the only printer I own that's not failed randomly, recently I printed 100 vape stands for a shop and no joke 100% all the way through, over 200 hours of printing...

With regards to print time, its not a 1000 times more as will not be printing the whole thing @ 0.2mm layer hight with a 0.4mm nozzle...

I have run designs through simplify 3D as its printing time is more or less spot on in my experience... (please note same object but not exactly scaled so its not 100% correct, just an idea)

Approx 100 x 100 x 100 object 0.4 mm Nozzle 0.2 mm Layer Height

Build time: 3 hours 19 minutes

Filament length: 5306.0 mm

Plastic weight: 46.88 g (0.10 lb)

Material cost: 2.16

Approx 1000 x 1000 x 1000 object 2 mm Nozzle 1 mm Layer Height

Build time: 84 hours 40 minutes (3 1/2 days LOL)

Filament length: 4152431.2 mm

Plastic weight: 36689.76 g (80.89 lb)

Material cost: 1687.73

|

Re: Looking at building a Large FDM May 16, 2015 05:33AM |

Registered: 8 years ago Posts: 18 |

Quote

dc42

It would be a good idea to power at least the electronics and stepper motors via a UPS, to take care of power brownouts. Possibly the hot end too.

Delta printers have moving parts that are subjected to light loads, which helps reliability. My delta is very reliable now, I've done several 8 hour prints without any failures. The only reliability issue I ever had with it was the extruder losing its grip on the filament. I solved that by reducing the extruder stepper current to 400mA, so that if the filament can't be fed fast enough because the nozzle is obstructed, it skips steps instead of chewing through the filament.

Don't worry think a UPS will be a must, I even have some older UPS server ones I can use that are over 6000W each...

Delta is still on the cards, frantically looking at designs and information on them : - )

|

Re: Looking at building a Large FDM May 16, 2015 05:40AM |

Registered: 8 years ago Posts: 18 |

Quote

dc42

For duplication to be possible with that design, you would need the bed to be so flat and the XY mechanism to be so accurate and rigid that you can print without using bed compensation. That may be very hard to achieve when doing large prints.

Personally, I would go for a delta design if you have sufficient headroom. The belts would be about 4.5m long.

Seem to be getting a lot of build delta advice, I have space in one of my units for a printer to live so if I did go down that route its not imposable...

Will be having a look at your nice blog about your Delta, see you have been using the Duet electronics, are they working well for your delta?

|

Re: Looking at building a Large FDM May 16, 2015 06:03AM |

Registered: 9 years ago Posts: 978 |

Quote

SpannerHands

Approx 1000 x 1000 x 1000 object 2 mm Nozzle 1 mm Layer Height

Build time: 84 hours 40 minutes (3 1/2 days LOL)

Filament length: 4152431.2 mm

Plastic weight: 36689.76 g (80.89 lb)

Material cost: 1687.73

These figures are just boggling to me!

80lb = 36 spools of filament! One spool every 2 hours or so. Hope you got an automatic spool changer figured

And 49m/hr of filament. And hope you got a cheap source of bulk filament. Actually, you'll probably want quality filament rather than cheap to get the reliability.

And 49m/hr of filament. And hope you got a cheap source of bulk filament. Actually, you'll probably want quality filament rather than cheap to get the reliability.2mm nozzle

You could just lay down 1.75mm filament and glue it in place without melting it.

You could just lay down 1.75mm filament and glue it in place without melting it. And hope you took the 80lb into account when you looked at sizing the motors.

Good luck!

|

Re: Looking at building a Large FDM May 16, 2015 06:13AM |

Registered: 8 years ago Posts: 18 |

Quote

frankvdh

Quote

SpannerHands

Approx 1000 x 1000 x 1000 object 2 mm Nozzle 1 mm Layer Height

Build time: 84 hours 40 minutes (3 1/2 days LOL)

Filament length: 4152431.2 mm

Plastic weight: 36689.76 g (80.89 lb)

Material cost: 1687.73

These figures are just boggling to me!

80lb = 36 spools of filament! One spool every 2 hours or so. Hope you got an automatic spool changer figuredAnd 49m/hr of filament. And hope you got a cheap source of bulk filament. Actually, you'll probably want quality filament rather than cheap to get the reliability.

2mm nozzleYou could just lay down 1.75mm filament and glue it in place without melting it.

And hope you took the 80lb into account when you looked at sizing the motors.

Good luck!

Yea the figures look fun don't they, and will be needing some luck...

I have a meeting with a filament company next week at the London 3D print show to continue the discussion of filament spools on an industrial scale (i.e. very large spools) + the possibility of sending waste back for re-extruding into spools, as having a print fail 50 hours into a print could waste 1K of filament!

The weight itself is not an issue because the bed is stationary, hence why I want everything else to move around that...

Edited 1 time(s). Last edit at 05/16/2015 06:24AM by SpannerHands.

|

Re: Looking at building a Large FDM May 16, 2015 07:14AM |

Registered: 10 years ago Posts: 14,672 |

Quote

SpannerHands

Will be having a look at your nice blog about your Delta, see you have been using the Duet electronics, are they working well for your delta?

The Duet is working very nicely thank you - but I would say that, because I added the delta support to the firmware. Unlike other delta firmwares, it doesn't use segmentation to approximate delta motion, and it can auto calibrate with just one set of X probe readings.

Since I wrote those blog entries, I have rebuilt the machine with a 300mm diameter bed with a mains voltage heater. I am about to increase the build height to 400mm. When that is done, I will publish another blog entry about it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Looking at building a Large FDM May 16, 2015 08:20AM |

Registered: 9 years ago Posts: 1,873 |

I haven't built a coreXY (yet!), but it looks to me like 2 belts each of roughly 2*x+y - call it 3m+ for the target 1m^2 area. I suspect that's doable with fairly standard belts, especially as coreXY keeps the moving mass fairly low and we're not aiming for absolute highest speed. But definitely something to keep an eye on.

Those filament volume & weight estimates are awesome. Designing for mostly hollow structures might be necessary - monocoques all the way?

A big delta is really appealing too, just from an aesthetics point of view. They are so neat to watch.

I guess you've done a review of existing large format designs? There seems to be quite a lot already out there. 3dp have an interesting design that's right in the ballpark size wise: [3dpunlimited.com]

Edited 1 time(s). Last edit at 05/16/2015 08:21AM by JamesK.

Those filament volume & weight estimates are awesome. Designing for mostly hollow structures might be necessary - monocoques all the way?

A big delta is really appealing too, just from an aesthetics point of view. They are so neat to watch.

I guess you've done a review of existing large format designs? There seems to be quite a lot already out there. 3dp have an interesting design that's right in the ballpark size wise: [3dpunlimited.com]

Edited 1 time(s). Last edit at 05/16/2015 08:21AM by JamesK.

|

Re: Looking at building a Large FDM May 16, 2015 09:10AM |

Registered: 8 years ago Posts: 18 |

Quote

JamesK

Those filament volume & weight estimates are awesome. Designing for mostly hollow structures might be necessary - monocoques all the way?

Believe it or not that was an optimised model I tested it with and something I hope to be able to print...

If you printed a 1000x1000x1000 cube with 10% infill you get this...

Build time: 256 hours 12 minutes (10 days)

Filament length: 18249082.6 mm

Plastic weight: 161243.95 g (355.48 lb)

Material cost: 7417.22

Quote

JamesK

I guess you've done a review of existing large format designs? There seems to be quite a lot already out there. 3dp have an interesting design that's right in the ballpark size wise: [3dpunlimited.com]

Not being unfair there are indeed a few companies already making some large format printers and have spoken to two of them, but they have overheads etc.. and at the prices they are selling them for (cant blame them for it) I looked at the pie in the sky bomb costs of the 3DP for example, and TBH I could probably make 2 for the same price... The charge $1300 or £826 for a second Extruder head, which I though as a bit OTT... Considering the printer costs £12K in the first place...

|

Re: Looking at building a Large FDM May 16, 2015 11:19AM |

Registered: 8 years ago Posts: 5,232 |

After reading all those numbers, it would be clear to me to look for another ( but boring ) way.

Build a 5 axis CNC machine that fulfills your 1m³ requirement.

Use it to build positive models from cheap styrofoam and cover them with polyester/glassfibre & epoxy-resin to finally build the part, you´re looking after.

Still a challenge to build the machine yourself and much cheaper too

-Olaf

Build a 5 axis CNC machine that fulfills your 1m³ requirement.

Use it to build positive models from cheap styrofoam and cover them with polyester/glassfibre & epoxy-resin to finally build the part, you´re looking after.

Still a challenge to build the machine yourself and much cheaper too

-Olaf

|

Re: Looking at building a Large FDM May 16, 2015 01:16PM |

Registered: 8 years ago Posts: 18 |

Quote

o_lampe

After reading all those numbers, it would be clear to me to look for another ( but boring ) way.

Build a 5 axis CNC machine that fulfills your 1m³ requirement.

Use it to build positive models from cheap styrofoam and cover them with polyester/glassfibre & epoxy-resin to finally build the part, you´re looking after.

Still a challenge to build the machine yourself and much cheaper too

-Olaf

If I was only ever going to use this for static prototypes then your right, but I already have a router table for foam for that exact purpose, you just slice the product up into large layers route them out, join and finish...

But the hole point of a 3D printer is to have an option left open for building larger 3D printed items, maybe not all huge, but the ability to print 4 x 500 mm3 items simultaneously is what really fascinates me...

|

Re: Looking at building a Large FDM May 16, 2015 08:01PM |

Registered: 8 years ago Posts: 18 |

Well had an interesting afternoon, I had some Aluminium Profile laying around, so started to mock up the original Z axis design I had, complete failure its mental heavy so did not even bother continuing...

So it looks like the box design it is...

But what do you recommend COREXY or H-BOT?

The frame will be very rigged and carriage running on proper ball and rail, so I was thinking that the tongue you inherit in the X will not be an issue if I went with a H-BOT design?

So it looks like the box design it is...

But what do you recommend COREXY or H-BOT?

The frame will be very rigged and carriage running on proper ball and rail, so I was thinking that the tongue you inherit in the X will not be an issue if I went with a H-BOT design?

|

Re: Looking at building a Large FDM May 16, 2015 10:51PM |

Registered: 9 years ago Posts: 1,873 |

Shame - it would have been an impressive beast to see. I suspect any printer you make at this scale is going to come out pretty heavy though!

Core-xy vs H-bot is going to be an interesting conversation. I was interested to see 691175002's assertion that core-xy was inferior, previously I'd only seen favourable comments about core-xy. Your point about belt length seems valid, but a H-bot still needs 2x+2y in a single belt, [edit - actually, looking again, it looks more like 4y+2x!] so I'm not convinced that's less of a stretching problem. In principle core-xy would allow you to use lighter components for the same tolerances and so achieve higher motion speeds - whether that really amounts to much in practice is debatable. The couple of larger format printers that I quickly googled this morning, it looked like they were using straightforward independent axis motion systems. Stuff that's simple to think about and easy to engineer. Might be worth keeping that option open, especially if multiple heads/simultaneous printing is on the wish list.

Edited 2 time(s). Last edit at 05/16/2015 10:56PM by JamesK.

Core-xy vs H-bot is going to be an interesting conversation. I was interested to see 691175002's assertion that core-xy was inferior, previously I'd only seen favourable comments about core-xy. Your point about belt length seems valid, but a H-bot still needs 2x+2y in a single belt, [edit - actually, looking again, it looks more like 4y+2x!] so I'm not convinced that's less of a stretching problem. In principle core-xy would allow you to use lighter components for the same tolerances and so achieve higher motion speeds - whether that really amounts to much in practice is debatable. The couple of larger format printers that I quickly googled this morning, it looked like they were using straightforward independent axis motion systems. Stuff that's simple to think about and easy to engineer. Might be worth keeping that option open, especially if multiple heads/simultaneous printing is on the wish list.

Edited 2 time(s). Last edit at 05/16/2015 10:56PM by JamesK.

|

Re: Looking at building a Large FDM May 17, 2015 02:48AM |

Registered: 8 years ago Posts: 18 |

Yea, its is a shame, but after a nights sleep, I thought of solution to make the Z arm 50% lighter, so might not be completely dead yet...

And thanks James as you you have reminded me of something I always overlook, KISS Keep It Simple Stupid, so unless there is a major advantage with core-XY or H-BOT its going to be simple...

And thanks James as you you have reminded me of something I always overlook, KISS Keep It Simple Stupid, so unless there is a major advantage with core-XY or H-BOT its going to be simple...

|

Re: Looking at building a Large FDM May 17, 2015 02:40PM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.