Y axis loosing position during print, again, during infill of small areas

Posted by lunarkingdom

|

Y axis loosing position during print, again, during infill of small areas May 17, 2015 01:39PM |

Registered: 9 years ago Posts: 182 |

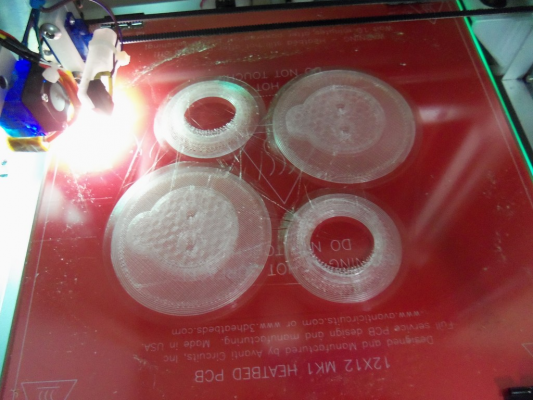

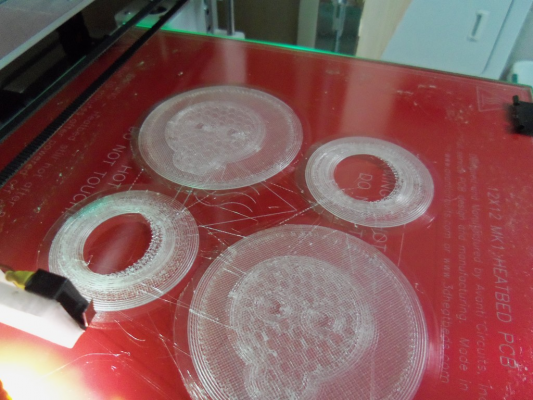

Hey, I was able to print at 100mm/sec with my current settings on another print but I made a new file with smaller wall thickness and what is basically happening is when trying to infill a very narrow gap it looses position while wiggling the Y axis so fast in such a small gap. I already lowered my jerk from 3000 to 2000 and my acceleration from 3000 to 2000 which worked really well on other prints with thicker walls. How do I slow down the tiny back and forth infill a bit? I ran the same print at 40mm/sec and it failed just like when it was going 100 mm/sec. I will post a pic of the result and post my config in a few minutes, I appreciate any help you can give.

Edited 1 time(s). Last edit at 05/17/2015 02:26PM by lunarkingdom.

Edited 1 time(s). Last edit at 05/17/2015 02:26PM by lunarkingdom.

|

Re: Y axis loosing position during print, again, during infill of small areas May 17, 2015 01:43PM |

Registered: 9 years ago Posts: 182 |

#define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,800,495} // default steps per unit for Ultimaker

#define DEFAULT_MAX_FEEDRATE {300, 300, 5, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {2000,2000,100,10000} // X was 3k, Y was 3k, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 2000 // X, Y, Z and E acceleration in mm/s^2 for printing moves was 3k

#define DEFAULT_RETRACT_ACCELERATION 3000 // E acceleration in mm/s^2 for retracts

#define DEFAULT_TRAVEL_ACCELERATION 2000 // X, Y, Z acceleration in mm/s^2 for travel (non printing) moves was 3k

// The speed change that does not require acceleration (i.e. the software might assume it can be done instantaneously)

#define DEFAULT_XYJERK 10.0 // (mm/sec) was 20

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec)

Edited 2 time(s). Last edit at 05/17/2015 01:45PM by lunarkingdom.

#define DEFAULT_MAX_FEEDRATE {300, 300, 5, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {2000,2000,100,10000} // X was 3k, Y was 3k, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 2000 // X, Y, Z and E acceleration in mm/s^2 for printing moves was 3k

#define DEFAULT_RETRACT_ACCELERATION 3000 // E acceleration in mm/s^2 for retracts

#define DEFAULT_TRAVEL_ACCELERATION 2000 // X, Y, Z acceleration in mm/s^2 for travel (non printing) moves was 3k

// The speed change that does not require acceleration (i.e. the software might assume it can be done instantaneously)

#define DEFAULT_XYJERK 10.0 // (mm/sec) was 20

#define DEFAULT_ZJERK 0.4 // (mm/sec)

#define DEFAULT_EJERK 5.0 // (mm/sec)

Edited 2 time(s). Last edit at 05/17/2015 01:45PM by lunarkingdom.

|

Re: Y axis loosing position during print, again, during infill of small areas May 17, 2015 01:49PM |

Registered: 9 years ago Posts: 182 |

|

Re: Y axis loosing position during print, again, during infill of small areas May 17, 2015 06:29PM |

Registered: 9 years ago Posts: 182 |

I am starting to think it is a current problem, well I would like to rule out if it is a current issue anyway, the info on my stepper motors:

Manufacturer Part Number 17HS19-1684S1

Step Angle 1.8°

Step Accuracy 5%

Holding Torque 45Ncm(64oz.in)

Rated Current/phase 1.68A

Phase Resistance 1.65ohms

Voltage 2.8V

Inductance 2.8mH±20%(1KHz)

Weight 400g

I am using an Ice-Blue Stepstick stepper driver, the only specs I have are from an email from the sellers:

We use a 0.05 ohm sense resistor, giving Vref = 0.4 x I, so for a maximum I = 2 amps, Vref = 0.8V. We run them on our Mendel90LCs at 0.4V for X, Y and E, and 0.5V for Z without heatsinks. Above 1.2 amps we recommend the use of heatsinks and above 1.6 amps, active fan cooling as well.

How do I tune the stepstick driver to the stepper motor specs? The only thing I can measure is the voltage using the pot as + and the input ground as -

Edited 1 time(s). Last edit at 05/17/2015 07:24PM by lunarkingdom.

Manufacturer Part Number 17HS19-1684S1

Step Angle 1.8°

Step Accuracy 5%

Holding Torque 45Ncm(64oz.in)

Rated Current/phase 1.68A

Phase Resistance 1.65ohms

Voltage 2.8V

Inductance 2.8mH±20%(1KHz)

Weight 400g

I am using an Ice-Blue Stepstick stepper driver, the only specs I have are from an email from the sellers:

We use a 0.05 ohm sense resistor, giving Vref = 0.4 x I, so for a maximum I = 2 amps, Vref = 0.8V. We run them on our Mendel90LCs at 0.4V for X, Y and E, and 0.5V for Z without heatsinks. Above 1.2 amps we recommend the use of heatsinks and above 1.6 amps, active fan cooling as well.

How do I tune the stepstick driver to the stepper motor specs? The only thing I can measure is the voltage using the pot as + and the input ground as -

Edited 1 time(s). Last edit at 05/17/2015 07:24PM by lunarkingdom.

|

Re: Y axis loosing position during print, again, during infill of small areas May 17, 2015 08:31PM |

Registered: 9 years ago Posts: 182 |

|

Re: Y axis loosing position during print, again, during infill of small areas May 17, 2015 09:32PM |

Registered: 9 years ago Posts: 182 |

Sorry, only registered users may post in this forum.