Reprapping Engines

Posted by Ian Woollard

|

Reprapping Engines September 20, 2007 07:45PM |

Ok, I was trying to work out whether it's theoretically possible to print out a mechanical engine.

The biggest problem would be making a piston, since that requires accurate machining, and while you could add some milling device to a reprap printer, but it seems relatively complex.

Another thought I just had, if instead of using a piston you print out a chamber from some kind of highish temperature flexible material, perhaps the chamber could generate mechanical power by changing shape (say with heating or with steam pressure), and thus driving a crank that way as it moves.

That way you could print it out with just one operation. It would probably greatly reduce efficiency, but nevertheless it could work.

Better ideas? Comments?

The biggest problem would be making a piston, since that requires accurate machining, and while you could add some milling device to a reprap printer, but it seems relatively complex.

Another thought I just had, if instead of using a piston you print out a chamber from some kind of highish temperature flexible material, perhaps the chamber could generate mechanical power by changing shape (say with heating or with steam pressure), and thus driving a crank that way as it moves.

That way you could print it out with just one operation. It would probably greatly reduce efficiency, but nevertheless it could work.

Better ideas? Comments?

|

Re: Reprapping Engines September 20, 2007 07:57PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Reprapping Engines September 20, 2007 10:00PM |

Registered: 16 years ago Posts: 25 |

|

Re: Reprapping Engines September 21, 2007 01:50AM |

Admin Registered: 16 years ago Posts: 13,884 |

... until yo have no tools for sintering high-temp or applying bulk metal or ceramics, i would try 'organic-style' devices with membranes and pistons.

Some folks in Bremen university designed and build micro-grippers with an included hydraulic/pneumatic membrane-actuator, which was driven by heating resistors ...

I used special ferrofluids as magnetically controlled actuators and used them too as stick'n-slip-free bearings or compressible isolation-structures - maybe this can help?

Some folks in Bremen university designed and build micro-grippers with an included hydraulic/pneumatic membrane-actuator, which was driven by heating resistors ...

I used special ferrofluids as magnetically controlled actuators and used them too as stick'n-slip-free bearings or compressible isolation-structures - maybe this can help?

|

Re: Reprapping Engines September 21, 2007 11:17AM |

Registered: 17 years ago Posts: 97 |

Sterlings require very tight fitting seals to be efficient. A fluidyne might be possible however, since that uses a fluid to generate a perfect seal.

But fluidynes dont generate much power, and one made out of plastic is going to be solar only as the heat source which further reduces max power output. A large enough one would certainly work but what would be involved I can only guess. A furfural ceramic fluidyne would allow for much higher heats but the pressures could potential be dangerous.

Mike

The view expressed in this post are my own and in no way reflect those of my employer. Attempts at implimenation are at your own risk.

But fluidynes dont generate much power, and one made out of plastic is going to be solar only as the heat source which further reduces max power output. A large enough one would certainly work but what would be involved I can only guess. A furfural ceramic fluidyne would allow for much higher heats but the pressures could potential be dangerous.

Mike

The view expressed in this post are my own and in no way reflect those of my employer. Attempts at implimenation are at your own risk.

|

Anonymous User

Re: Reprapping Engines September 21, 2007 04:24PM |

Even a ceramic engine is going to need to be machine-precise, which might not yet be within the tolerances of the first generation reprap.

Recently investment casting (lost wax) has come in to common use in the manufacture of gun parts (but probably not for barrels or chambers). Can a decent internal combustion engine be made completly from castings?

Recently investment casting (lost wax) has come in to common use in the manufacture of gun parts (but probably not for barrels or chambers). Can a decent internal combustion engine be made completly from castings?

|

Re: Reprapping Engines September 21, 2007 10:38PM |

Admin Registered: 17 years ago Posts: 1,915 |

drvanthorp Wrote:

-------------------------------------------------------

> Recently investment casting (lost wax) has come in

> to common use in the manufacture of gun parts (but

> probably not for barrels or chambers).

Hope they're not planning on putting those guns to hard use. The South Africans tried to use investment casting to do the frame for their home-grown Mamba service pistol. It was a disaster.

I guess it could have been the South Africans to use very hot loads for hardball rounds that ruined those frames, but I doubt it.

> Can a

> decent internal combustion engine be made

> completly from castings?

They used to make automobile engines that way. You cast them and then machine them to tolerance. The closer the casting to final product the less machine time required. For all I know they still make engines that way.

-------------------------------------------------------

> Recently investment casting (lost wax) has come in

> to common use in the manufacture of gun parts (but

> probably not for barrels or chambers).

Hope they're not planning on putting those guns to hard use. The South Africans tried to use investment casting to do the frame for their home-grown Mamba service pistol. It was a disaster.

I guess it could have been the South Africans to use very hot loads for hardball rounds that ruined those frames, but I doubt it.

> Can a

> decent internal combustion engine be made

> completly from castings?

They used to make automobile engines that way. You cast them and then machine them to tolerance. The closer the casting to final product the less machine time required. For all I know they still make engines that way.

|

Re: Reprapping Engines September 22, 2007 12:07AM |

Registered: 16 years ago Posts: 246 |

|

Re: Reprapping Engines September 22, 2007 12:48AM |

Registered: 16 years ago Posts: 113 |

|

Re: Reprapping Engines September 22, 2007 02:03PM |

Admin Registered: 16 years ago Posts: 13,884 |

... here i have a link (site in german) to a stirling-engine made of sheets of paper, aluminium and membranes: [www.science-shop.de]

... here the video of the paper-stirling on a hot coffee-pot: [www.science-shop.de]

(it runs on ice-blocks too)

... and here the manual and technical description in english: [www.science-shop.de]

So you can adapt and print the parts and assemble them to a running engine ...

Ciao, Viktor

... here the video of the paper-stirling on a hot coffee-pot: [www.science-shop.de]

(it runs on ice-blocks too)

... and here the manual and technical description in english: [www.science-shop.de]

So you can adapt and print the parts and assemble them to a running engine ...

Ciao, Viktor

|

Re: Reprapping Engines September 23, 2007 07:41PM |

Registered: 16 years ago Posts: 25 |

> here i have a link (site in german) to a stirling-engine made of sheets of

> paper, aluminium and membranes:

Thanks, Victor! That is exactly what I had in mind! As Mike said, an engine made without very close tolerances will not be very powerful, but for a first-generation RepRap, it is a cool way to start...

> paper, aluminium and membranes:

Thanks, Victor! That is exactly what I had in mind! As Mike said, an engine made without very close tolerances will not be very powerful, but for a first-generation RepRap, it is a cool way to start...

|

Re: Reprapping Engines September 24, 2007 01:31AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi rmadams,

i'm glad to help you

Why not playing around with plastic-made steam-engines?

There are people, which 'reinvented' micro-steam-motors for MEMS, and with the same approach - plastic-membranes, -pistons and with ferrofluidic isolation i can design resizing chambers and with heating resistors and aether or other lowtemp-boiling fluids i can build a room-temp-steam-motor from molded plastics ...

Ciao, Viktor

i'm glad to help you

Why not playing around with plastic-made steam-engines?

There are people, which 'reinvented' micro-steam-motors for MEMS, and with the same approach - plastic-membranes, -pistons and with ferrofluidic isolation i can design resizing chambers and with heating resistors and aether or other lowtemp-boiling fluids i can build a room-temp-steam-motor from molded plastics ...

Ciao, Viktor

|

Re: Reprapping Engines November 02, 2007 02:04PM |

While I'm sure that pistons give you much more power, and permit a more conventional engine because of the tolerances involved I was thinking more of a steam or compressed air driven bellows system- if you can print the bellows out of a flexible polymer you should be able to print the other components fairly easily; including the 'boiler' n.b. low pressure to avoid killing people please!

Another thing that could work great and would be even easier would be printing out an aeolipile.

Another thing that could work great and would be even easier would be printing out an aeolipile.

|

Re: Reprapping Engines November 02, 2007 05:53PM |

Admin Registered: 16 years ago Posts: 13,884 |

... i mustn't have heat or air-pressure to move pistons - as in the 'Artificial Muscles'-thread mentioned, i can build solid-state pumps and valves only from hoses and solenoids, if i have MRF or ferrofluid as active and transporting medium ...

With MRF i already designed peristaltic pumps, which move the fluid only through serial switching of solenoids, without any moving parts ...

With a different setup i can make an oszillating pump from two tubes, bellow-couplings and solenoids, where a moving and a static piece of tube acts as pair of corresponding pistons and/or valves in the same time, so i can transport the stiffened fluid with the moving tube or hold it in place with the static part, so the moving part can relax for the next run ...

For pumping air i build a kind of rotating helix, partially flled with ferrofluid, where i have moving cavities in the ferrofluid, which can transport air or a not ferrofluid-soluble fluid with a very high accuracy and high forces or pressures (dependant of the length of the tube)

The good thing is, that i can scale the tubes and hoses freely, the size will be defined by the solenoids, so a valve-micro-pump-combination is so big, as four solenoids in a bulk.

Or imagine a central oszillating pump and an array of twenty or more small solenoids, where every two control a different capillarie for my 'tentacles-hands' or another hydraulic structure ...

Viktor

With MRF i already designed peristaltic pumps, which move the fluid only through serial switching of solenoids, without any moving parts ...

With a different setup i can make an oszillating pump from two tubes, bellow-couplings and solenoids, where a moving and a static piece of tube acts as pair of corresponding pistons and/or valves in the same time, so i can transport the stiffened fluid with the moving tube or hold it in place with the static part, so the moving part can relax for the next run ...

For pumping air i build a kind of rotating helix, partially flled with ferrofluid, where i have moving cavities in the ferrofluid, which can transport air or a not ferrofluid-soluble fluid with a very high accuracy and high forces or pressures (dependant of the length of the tube)

The good thing is, that i can scale the tubes and hoses freely, the size will be defined by the solenoids, so a valve-micro-pump-combination is so big, as four solenoids in a bulk.

Or imagine a central oszillating pump and an array of twenty or more small solenoids, where every two control a different capillarie for my 'tentacles-hands' or another hydraulic structure ...

Viktor

|

Re: Reprapping Engines November 04, 2007 11:17AM |

Registered: 16 years ago Posts: 10 |

The thing is, what you are describing is not an engine Viktor, since it doesn't generate mechanical power, it *uses* mechanical power. However, similar techniques could work.

It would be interesting in theory if it would be possible to build a Reprap that is powered by steam for example.

It would be interesting in theory if it would be possible to build a Reprap that is powered by steam for example.

|

Re: Reprapping Engines November 04, 2007 12:28PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Ian,

... what i describe, is a hydraulic machine, powered by a moving magnetic 'virtual piston', which articulates varying pressure, that is phase-senitive switched to the appropriate hydraulic 'muscles', and then bend or move the corresponding mechanical structures ...

It's the same principle, as in an hydraulic motivated excavator, powered by a combustion-engine ...

Or better a bionic-sample: - imagine a octopus-like 'creature', which move its arms/tentacles through pressure-changing in capilaries all over the body - and the pressure/vacuum is activated through his 'heart-beat' and some electromagnetical or 'micro-steam-powerded muscles' ...

Viktor

... what i describe, is a hydraulic machine, powered by a moving magnetic 'virtual piston', which articulates varying pressure, that is phase-senitive switched to the appropriate hydraulic 'muscles', and then bend or move the corresponding mechanical structures ...

It's the same principle, as in an hydraulic motivated excavator, powered by a combustion-engine ...

Or better a bionic-sample: - imagine a octopus-like 'creature', which move its arms/tentacles through pressure-changing in capilaries all over the body - and the pressure/vacuum is activated through his 'heart-beat' and some electromagnetical or 'micro-steam-powerded muscles' ...

Viktor

|

Re: Reprapping Engines November 04, 2007 02:44PM |

Registered: 16 years ago Posts: 10 |

|

Re: Reprapping Engines November 04, 2007 03:47PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Ian,

... obviously right

I'm maybe half'n step ahead - when there's an reprapped 'engine', then there can be reprapped 'muscles' too ...

Back to reprapping 'hardcore engines'.

With MRF-hose-valves and reprapped bellows- or membrane-chambers i have all together, what makes a low-temp stirling-motor.

I need a low-temp boiling fluid in the chamber (maybe aether - but what's with dissolving the plastics?), a heating-resistor to expand the fluid, what expands the chamber and moves a piston or so ...

The magnetic valves should be another type, then in my 'pure-MRF'-system: here the MRF or ferrofluid stays in the valve (best with an atached permanent-magnet) and the solenoids morph the magnetic fluid, so it goes away and opens the valve or comes together and block the way, so the expanding steam could be directed in the right hoses.

When the moving forces of this motor are strong enough, to pump the MRF in the previously described hydraulic system, then i'm on the way

Viktor

... obviously right

I'm maybe half'n step ahead - when there's an reprapped 'engine', then there can be reprapped 'muscles' too ...

Back to reprapping 'hardcore engines'.

With MRF-hose-valves and reprapped bellows- or membrane-chambers i have all together, what makes a low-temp stirling-motor.

I need a low-temp boiling fluid in the chamber (maybe aether - but what's with dissolving the plastics?), a heating-resistor to expand the fluid, what expands the chamber and moves a piston or so ...

The magnetic valves should be another type, then in my 'pure-MRF'-system: here the MRF or ferrofluid stays in the valve (best with an atached permanent-magnet) and the solenoids morph the magnetic fluid, so it goes away and opens the valve or comes together and block the way, so the expanding steam could be directed in the right hoses.

When the moving forces of this motor are strong enough, to pump the MRF in the previously described hydraulic system, then i'm on the way

Viktor

|

Re: Reprapping Engines November 04, 2007 09:45PM |

Registered: 16 years ago Posts: 10 |

|

Re: Reprapping Engines November 05, 2007 05:00AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Ian,

... ok, boiling water can be used too

Another point - i can build a pure current/magnetic-driven MRF-engine without heating and steaming, when i dont need much displacement.

I described it already in another thread, but here is a short scetch:

When i surround a MRF-filled elastic silicone-hose with three or more solenoids and switch the solenoids in a sequence, then the MRF acts as block-valve in every activated solenoid-gap, but through the sequencing i have a traveling effect, which embed an unsymetric sucking-force in the surrounding fluid MRF, so with every sequence a small amount of MRF is moved through the setup.

With reverting the sequence i can revert the moving direction of the MRF too.

The amount of transported/pumped fluid isn't so big, but for expanding and releasing of small-sized capillaries and cavities in elastic tentacle-structures it should be enough ...

Viktor

... ok, boiling water can be used too

Another point - i can build a pure current/magnetic-driven MRF-engine without heating and steaming, when i dont need much displacement.

I described it already in another thread, but here is a short scetch:

When i surround a MRF-filled elastic silicone-hose with three or more solenoids and switch the solenoids in a sequence, then the MRF acts as block-valve in every activated solenoid-gap, but through the sequencing i have a traveling effect, which embed an unsymetric sucking-force in the surrounding fluid MRF, so with every sequence a small amount of MRF is moved through the setup.

With reverting the sequence i can revert the moving direction of the MRF too.

The amount of transported/pumped fluid isn't so big, but for expanding and releasing of small-sized capillaries and cavities in elastic tentacle-structures it should be enough ...

Viktor

|

Anonymous User

Re: Reprapping Engines November 05, 2007 11:29AM |

Forrest Higgs Wrote:

-------------------------------------------------------

> drvanthorp Wrote:

> --------------------------------------------------

> -----

> > Recently investment casting (lost wax) has come

> in

> > to common use in the manufacture of gun parts

> (but

> > probably not for barrels or chambers).

>

> Hope they're not planning on putting those guns to

> hard use. The South Africans tried to use

> investment casting to do the frame for their

> home-grown Mamba service pistol. It was a

> disaster.

It is the frames that they are making from castings. Also other mechanical parts that to not have to withstand high forces (no cast barrels or chambers).

-------------------------------------------------------

> drvanthorp Wrote:

> --------------------------------------------------

> -----

> > Recently investment casting (lost wax) has come

> in

> > to common use in the manufacture of gun parts

> (but

> > probably not for barrels or chambers).

>

> Hope they're not planning on putting those guns to

> hard use. The South Africans tried to use

> investment casting to do the frame for their

> home-grown Mamba service pistol. It was a

> disaster.

It is the frames that they are making from castings. Also other mechanical parts that to not have to withstand high forces (no cast barrels or chambers).

|

Re: Reprapping Engines November 05, 2007 07:13PM |

Registered: 16 years ago Posts: 246 |

Hmm. The triple point of water is about -1C and a partial vacuum. How about using an evacuated, rigid, and sealed region for a steam engine, and transferring the force to an unevacuated region for pumping, using a spinning magnet. You could also use the steam engines own force, or the force of a neighbor unit, to scavenge air out of the thing, to help preserve the vacuum.

|

Re: Reprapping Engines November 06, 2007 03:34AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Sean,

... there are many possibilities and methods, for working with potential-differences, when you can switch and direct forces to the right 'muscles' ...

My simplest approach is an oszillating piston, which changes the pressure in the main-tube periodically between max and min (~vacuum?).

Through phase-right switching valves i can selectively output pressure (valve open short before and after max) or vacuum (before and at min), so i can with a single pump and a valve-array control any count of cavities, capillaries, pistons or elastic 'muscles' with a microcontroller, which switches the solenoids to block or release the virtual valves ...

When i have to control micro-cavities so there aren't big volumes to move, the 'pure-MRF-sequential-valve-pump' would be the 'heartbeat' of the system, and some valves in an array define different pressure-areas - and without any other mechanics i can move, morph and work with my 'tentacles'

Viktor

... there are many possibilities and methods, for working with potential-differences, when you can switch and direct forces to the right 'muscles' ...

My simplest approach is an oszillating piston, which changes the pressure in the main-tube periodically between max and min (~vacuum?).

Through phase-right switching valves i can selectively output pressure (valve open short before and after max) or vacuum (before and at min), so i can with a single pump and a valve-array control any count of cavities, capillaries, pistons or elastic 'muscles' with a microcontroller, which switches the solenoids to block or release the virtual valves ...

When i have to control micro-cavities so there aren't big volumes to move, the 'pure-MRF-sequential-valve-pump' would be the 'heartbeat' of the system, and some valves in an array define different pressure-areas - and without any other mechanics i can move, morph and work with my 'tentacles'

Viktor

|

Re: Reprapping Engines November 06, 2007 01:02PM |

Registered: 16 years ago Posts: 10 |

|

Re: Reprapping Engines November 06, 2007 02:05PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Ian,

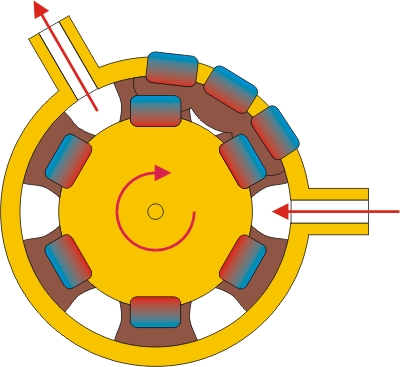

... i tested some MRF-pumping methods with moving and spinning magnets (see the image for two rotating setups), but for best pumping of MRF i had the sequencial switching solenoids - it seems, that the traveling effect in the elastic hose needs sharper activating and releasing edges, than the moving magnets can perform ...

The spinning magnets works good with ferrofluid - when you close the box and fill the inner room nearly 60% with ferrofluid, then you have ferrofluid on the magnets and cavities between, so you can transport air-bubbles in the cavities.

To pump/move air in the rotating direction you have to insert a magnetic-ferrofluid barrier and drill an inlet and outlet besides the barrier, so you can define the way of the air-bubbles ...

Viktor

Edited 1 time(s). Last edit at 11/06/2007 02:08PM by Viktor Dirks.

... i tested some MRF-pumping methods with moving and spinning magnets (see the image for two rotating setups), but for best pumping of MRF i had the sequencial switching solenoids - it seems, that the traveling effect in the elastic hose needs sharper activating and releasing edges, than the moving magnets can perform ...

The spinning magnets works good with ferrofluid - when you close the box and fill the inner room nearly 60% with ferrofluid, then you have ferrofluid on the magnets and cavities between, so you can transport air-bubbles in the cavities.

To pump/move air in the rotating direction you have to insert a magnetic-ferrofluid barrier and drill an inlet and outlet besides the barrier, so you can define the way of the air-bubbles ...

Viktor

Edited 1 time(s). Last edit at 11/06/2007 02:08PM by Viktor Dirks.

|

Re: Reprapping Engines November 06, 2007 02:53PM |

Admin Registered: 16 years ago Posts: 13,884 |

... here i have a sketch of a spinning magnet-ferrofluid air-pump ...

Viktor

Edited 2 time(s). Last edit at 11/06/2007 02:58PM by Viktor Dirks.

Viktor

Edited 2 time(s). Last edit at 11/06/2007 02:58PM by Viktor Dirks.

|

Re: Reprapping Engines November 06, 2007 02:58PM |

Registered: 16 years ago Posts: 10 |

|

Re: Reprapping Engines November 06, 2007 03:14PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Ian,

... the spinner is a pump, you need a motor to activate it ...

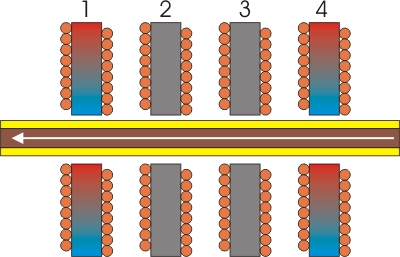

Here is a sketch of the previous mentioned MRF-Engine:

If you activate the solenoids in the sequence 1,2,3,4,1,2,3... then the MRF (brown) in the elastic hose (yellow) would travel slow from right to left ...

Viktor

Edited 1 time(s). Last edit at 11/06/2007 03:16PM by Viktor Dirks.

... the spinner is a pump, you need a motor to activate it ...

Here is a sketch of the previous mentioned MRF-Engine:

If you activate the solenoids in the sequence 1,2,3,4,1,2,3... then the MRF (brown) in the elastic hose (yellow) would travel slow from right to left ...

Viktor

Edited 1 time(s). Last edit at 11/06/2007 03:16PM by Viktor Dirks.

|

Re: Reprapping Engines November 07, 2007 05:30PM |

Registered: 16 years ago Posts: 10 |

|

Re: Reprapping Engines November 07, 2007 08:31PM |

Registered: 16 years ago Posts: 622 |

Sorry, only registered users may post in this forum.