Theorethical (math) questions about spur gears

Posted by khiraly

|

Theorethical (math) questions about spur gears July 12, 2010 03:41PM |

Registered: 16 years ago Posts: 204 |

Hi,

Im studying spur gears since two days already. I have some math questions about gears.

Im seeing many spur gears with 67, 127 teeths, and Im unable to generate it.

There are basically two standard for gears: metric and US. The metric is basically

defined with module [m], number of teeth [N] and pressure angle [PA].

The US version is defined using diametral pitch[P] instead of module.

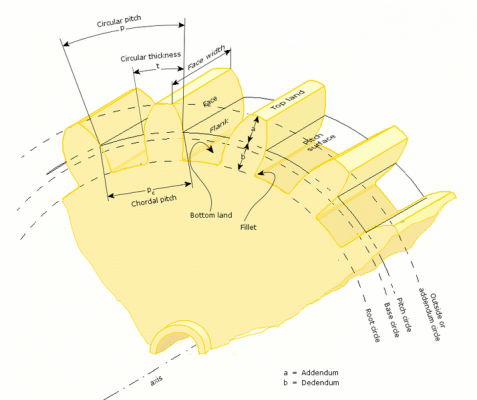

For nomenclature here is a nice wikipedia picture:

There are some important circles (diameters) along the gear.

These are:

Root diameter [DR] = P*cos(PA)

Base diameter [DB] = P-2*b

Pitch diameter [P] = N*m

Outside diameter [DO] = P+2*a

addendum [a] = m

dedendum [d] = 1.25*m (it varies between standards, and module(m) sizes)

Lets take the following example:

N: 42 m: 2.0 a: 2.0 b: 2.5 PA: 20.00 deg

DR: 79.0 DB: 78.934180146 D: 84.0 DO: 88.0

In that case base diameter [DB] is smaller then root diameter [DR] !

So it cant be generated.

So I have no idea how am I supposed to generate a gear with high enough teeths.

It would be really awesome to find a dxf drawing of a metric gear with 127 teeth!

It exists, many catalogue does list them.

Here are some pictures to show the problem.

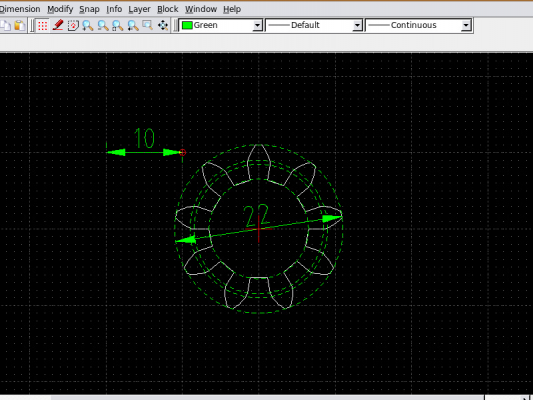

Gear with 9 teeth (works):

N: 9 m: 2.0 a: 2.0 b: 2.5 PA: 20.00 deg

DR: 13.0 DB: 16.9144671741 D: 18.0 DO: 22.0

Gear with 17 teeth (works):

N: 17 m: 2.0 a: 2.0 b: 2.5 PA: 20.00 deg

DR: 29.0 DB: 31.9495491067 D: 34.0 DO: 38.0

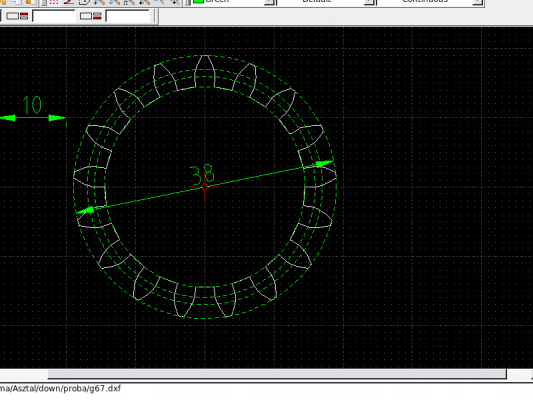

Gear with 41 teeth (works, but barely):

N: 41 m: 2.0 a: 2.0 b: 2.5 PA: 20.00 deg

DR: 77.0 DB: 77.0547949044 D: 82.0 DO: 86.0

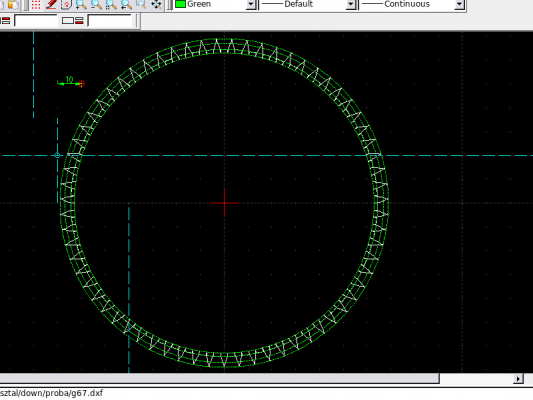

Gear with 67 teeth (does not work. from 42 teeth, it does not work):

N: 67 m: 2.0 a: 2.0 b: 2.5 PA: 20.00 deg

DR: 129.0 DB: 125.918811185 D: 134.0 DO: 138.0

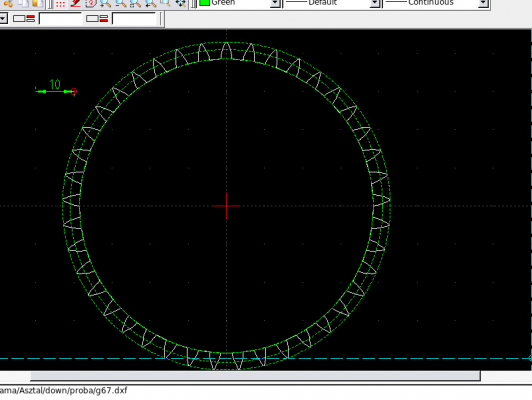

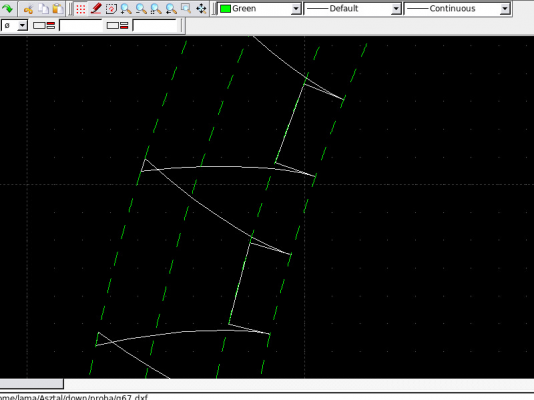

G67 closeup, to better see the problem:

I basically followed this site:

[www.cartertools.com]

And cross-checked with this: [www.roymech.co.uk]

For math please look at this site:

[mathworld.wolfram.com]

List of definitions, and formulas:

[www.gizmology.net]

Here is a gear generator flash site: [woodgears.ca]

gears related standards: [www.gearandracks.com]

Maybe someone is more deeply digged than I, and can shed some light, what is the correct

math to generate high number teeths (67, 127, 200 teeths).

Forrest, if you are reading this, maybe you figured it out already, because you are working

other type of gears too (herringbone gears).

Any idea, links, etc are welcome!

Best regards,

Laszlo

[blog.arcol.hu]

Edited 2 time(s). Last edit at 07/12/2010 03:43PM by khiraly.

Im studying spur gears since two days already. I have some math questions about gears.

Im seeing many spur gears with 67, 127 teeths, and Im unable to generate it.

There are basically two standard for gears: metric and US. The metric is basically

defined with module [m], number of teeth [N] and pressure angle [PA].

The US version is defined using diametral pitch[P] instead of module.

For nomenclature here is a nice wikipedia picture:

There are some important circles (diameters) along the gear.

These are:

Root diameter [DR] = P*cos(PA)

Base diameter [DB] = P-2*b

Pitch diameter [P] = N*m

Outside diameter [DO] = P+2*a

addendum [a] = m

dedendum [d] = 1.25*m (it varies between standards, and module(m) sizes)

Lets take the following example:

N: 42 m: 2.0 a: 2.0 b: 2.5 PA: 20.00 deg

DR: 79.0 DB: 78.934180146 D: 84.0 DO: 88.0

In that case base diameter [DB] is smaller then root diameter [DR] !

So it cant be generated.

So I have no idea how am I supposed to generate a gear with high enough teeths.

It would be really awesome to find a dxf drawing of a metric gear with 127 teeth!

It exists, many catalogue does list them.

Here are some pictures to show the problem.

Gear with 9 teeth (works):

N: 9 m: 2.0 a: 2.0 b: 2.5 PA: 20.00 deg

DR: 13.0 DB: 16.9144671741 D: 18.0 DO: 22.0

Gear with 17 teeth (works):

N: 17 m: 2.0 a: 2.0 b: 2.5 PA: 20.00 deg

DR: 29.0 DB: 31.9495491067 D: 34.0 DO: 38.0

Gear with 41 teeth (works, but barely):

N: 41 m: 2.0 a: 2.0 b: 2.5 PA: 20.00 deg

DR: 77.0 DB: 77.0547949044 D: 82.0 DO: 86.0

Gear with 67 teeth (does not work. from 42 teeth, it does not work):

N: 67 m: 2.0 a: 2.0 b: 2.5 PA: 20.00 deg

DR: 129.0 DB: 125.918811185 D: 134.0 DO: 138.0

G67 closeup, to better see the problem:

I basically followed this site:

[www.cartertools.com]

And cross-checked with this: [www.roymech.co.uk]

For math please look at this site:

[mathworld.wolfram.com]

List of definitions, and formulas:

[www.gizmology.net]

Here is a gear generator flash site: [woodgears.ca]

gears related standards: [www.gearandracks.com]

Maybe someone is more deeply digged than I, and can shed some light, what is the correct

math to generate high number teeths (67, 127, 200 teeths).

Forrest, if you are reading this, maybe you figured it out already, because you are working

other type of gears too (herringbone gears).

Any idea, links, etc are welcome!

Best regards,

Laszlo

[blog.arcol.hu]

Edited 2 time(s). Last edit at 07/12/2010 03:43PM by khiraly.

|

Re: Theorethical (math) questions about spur gears July 12, 2010 06:05PM |

Registered: 13 years ago Posts: 7,616 |

You want tooth thickness and tooth gap to be the same at the pitch circle, not at the base circle.

Module = circular pitch / pi --> choose one of these two to be constant on all participating gears

Pitch circle diameter = number of teeth * module / pi

Base circle diameter = number of teeth * module * cos(20deg)

Axes distance = 0.5 * module * ( teeth number wheel one +- teeth number wheel two ) // plus/minus for outside/inside gears

When constructing gears, outside diameter and root diameter are secondary citizens. Get the other two right, first. Then draw the convolutions. Chopping teeth at the top and at the bottom is the last step.

Construction gear teeth is a pretty complicated matter, the above doesn't mention e.g. special cases for low tooth number wheels or leveled material stress.

Module = circular pitch / pi --> choose one of these two to be constant on all participating gears

Pitch circle diameter = number of teeth * module / pi

Base circle diameter = number of teeth * module * cos(20deg)

Axes distance = 0.5 * module * ( teeth number wheel one +- teeth number wheel two ) // plus/minus for outside/inside gears

When constructing gears, outside diameter and root diameter are secondary citizens. Get the other two right, first. Then draw the convolutions. Chopping teeth at the top and at the bottom is the last step.

Construction gear teeth is a pretty complicated matter, the above doesn't mention e.g. special cases for low tooth number wheels or leveled material stress.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Theorethical (math) questions about spur gears July 12, 2010 06:53PM |

Registered: 16 years ago Posts: 204 |

> You want tooth thickness and tooth gap to be the same at the pitch circle, not at the base circle.

Correct, you are right. My mistake.

> Pitch circle diameter = number of teeth * module / pi

It is wrong. If you look at the 9 teeth gear, the outside diameter is 22mm, the root diameter is 13mm.

If we solve your equaton: P = 9*2/pi = 18/3.14 = 5.7 mm

The pitch diameter cant be smaller then the root diameter!

> Base circle diameter = number of teeth * module * cos(20deg)

This is not correct either. It is the root circle diameter. The base circle diameter is P-2*b

Which is bigger then the root circle diameter. (until I dont play with the teeth numbers).

Anyway, thank you catching the tooth-gap distance issue!

I will look into it, and correct the math in my program.

Best regards,

Laszlo

Correct, you are right. My mistake.

> Pitch circle diameter = number of teeth * module / pi

It is wrong. If you look at the 9 teeth gear, the outside diameter is 22mm, the root diameter is 13mm.

If we solve your equaton: P = 9*2/pi = 18/3.14 = 5.7 mm

The pitch diameter cant be smaller then the root diameter!

> Base circle diameter = number of teeth * module * cos(20deg)

This is not correct either. It is the root circle diameter. The base circle diameter is P-2*b

Which is bigger then the root circle diameter. (until I dont play with the teeth numbers).

Anyway, thank you catching the tooth-gap distance issue!

I will look into it, and correct the math in my program.

Best regards,

Laszlo

|

Re: Theorethical (math) questions about spur gears July 13, 2010 02:14AM |

Registered: 16 years ago Posts: 204 |

Also seems like the formulas Im using matches with this example:

[www.sdp-si.com]

python arcolgears.py -n 24 -m 3.0

N: 24 m: 3.0 a: 3.0 b: 3.75 PA: 20.00 deg

DR: 64.5 DB: 67.6578686966 D: 72.0 DO: 78.0

Or this pdf:

[mdmetric.com]

Or this:

[www.qtcgears.com]

Where even explain the pitch diameter and circular pitch:

pitch diameter = N * m

circular pitch = m * pi

The problem is, there are number of teeths, where these formulas are simply does not work.

It will always happen (above a teeth number) that the

base diameter (pitch diameter * cos pressure angle) will be smaller then the root diameter (pitch diameter - 2*dedendum).

Im a bit lost, because Im followed metric calculations, while every book seems to be

US based.

Edited 2 time(s). Last edit at 07/13/2010 02:28AM by khiraly.

[www.sdp-si.com]

python arcolgears.py -n 24 -m 3.0

N: 24 m: 3.0 a: 3.0 b: 3.75 PA: 20.00 deg

DR: 64.5 DB: 67.6578686966 D: 72.0 DO: 78.0

Or this pdf:

[mdmetric.com]

Or this:

[www.qtcgears.com]

Where even explain the pitch diameter and circular pitch:

pitch diameter = N * m

circular pitch = m * pi

The problem is, there are number of teeths, where these formulas are simply does not work.

It will always happen (above a teeth number) that the

base diameter (pitch diameter * cos pressure angle) will be smaller then the root diameter (pitch diameter - 2*dedendum).

Im a bit lost, because Im followed metric calculations, while every book seems to be

US based.

Edited 2 time(s). Last edit at 07/13/2010 02:28AM by khiraly.

|

Re: Theorethical (math) questions about spur gears July 13, 2010 02:55AM |

Registered: 13 years ago Posts: 7,616 |

Quote

Pitch circle diameter = number of teeth * module / pi

Pitch circle diameter = number of teeth * module

Sorry for confusing circular pitch and module myself.

Quote

> Base circle diameter = number of teeth * module * cos(20deg)

This is not correct either. It is the root circle diameter.

Base circle is the circle your convolution is perpendicular on, right? No mistake on this one on my side.

Quote

original posting

In that case base diameter [DB] is smaller then root diameter [DR] !

It's quite possible for the base diameter being smaller than the root diameter.

There's also a minimum number of teeth for workable wheel combinations constructed from convolutions alone, which is 14 - 17 teeth on the smaller wheel. To get a lower tooth number you need extra considerations, for example a contact diameter differing from the pitch diameter, a smaller tooth height (standardized at a = module, b = 1.2 * module) or a different contact angle (standardized at alpha = 20deg). Neither of these are mentioned in the initial set of formulas.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Theorethical (math) questions about spur gears July 13, 2010 04:02AM |

Registered: 16 years ago Posts: 204 |

Traumflug Wrote:

-------------------------------------------------------

>> > Base circle diameter = number of teeth * module

>> * cos(20deg)

>>

>> This is not correct either. It is the root circle

>> diameter.

>

> Base circle is the circle your convolution is

> perpendicular on, right? No mistake on this one on

> my side.

Yepp, you are right. From the base circle starts the involute line.

This was my mistake.

> It's quite possible for the base diameter being smaller than the root diameter.

This is the key factor of my troubles.

So if I understand right, the goal is to have the height of a teeth: 2b+2a

The outside diameter is fix (pitch diameter+2a)

The bottom of the teeth is always the root circle, even if it is bigger then the

base circle.

Thank you. I'll fix my script later today and examine it further. The issue.

Also I found this online gear generator:

[woodgears.ca]

Where the tooth spacing(mm) is equal to module * pi.

If I write for example m=2, N=14 (tooth spacing is 6.14)

Then I get almost exactly the same result then my drawing (I can check it

there is a shaft hole diam(mm) input field), the pitch diameter matches, the

base diameter matches. Only the outside and root diameter does not match,

because he uses different relations between module and addendum.

(I use a=m, while he is using somewhat smaller).

So finally everything clears up.

Best regards,

Laszlo

[blog.arcol.hu]

-------------------------------------------------------

>> > Base circle diameter = number of teeth * module

>> * cos(20deg)

>>

>> This is not correct either. It is the root circle

>> diameter.

>

> Base circle is the circle your convolution is

> perpendicular on, right? No mistake on this one on

> my side.

Yepp, you are right. From the base circle starts the involute line.

This was my mistake.

> It's quite possible for the base diameter being smaller than the root diameter.

This is the key factor of my troubles.

So if I understand right, the goal is to have the height of a teeth: 2b+2a

The outside diameter is fix (pitch diameter+2a)

The bottom of the teeth is always the root circle, even if it is bigger then the

base circle.

Thank you. I'll fix my script later today and examine it further. The issue.

Also I found this online gear generator:

[woodgears.ca]

Where the tooth spacing(mm) is equal to module * pi.

If I write for example m=2, N=14 (tooth spacing is 6.14)

Then I get almost exactly the same result then my drawing (I can check it

there is a shaft hole diam(mm) input field), the pitch diameter matches, the

base diameter matches. Only the outside and root diameter does not match,

because he uses different relations between module and addendum.

(I use a=m, while he is using somewhat smaller).

So finally everything clears up.

Best regards,

Laszlo

[blog.arcol.hu]

|

Re: Theorethical (math) questions about spur gears July 13, 2010 06:33AM |

Registered: 16 years ago Posts: 204 |

I semi-fixed the tooth issue. Now the tooth and gap has the same width at the pitch diameter.

Also when the Root diameter is bigger then the base diameter, I made the two diameter equal.

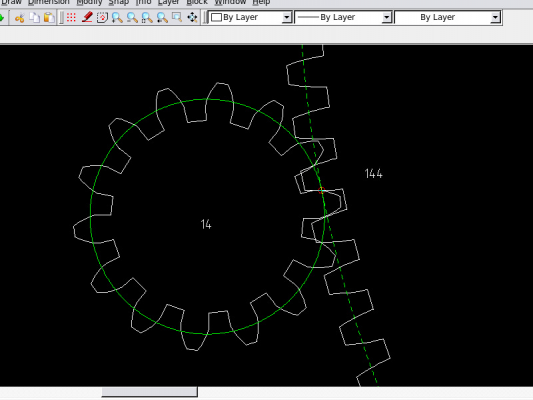

Is is almost good. Here is a screenshot:

However the bigger gear is 144 teeth version, and the involute profile seems a bit too straight to me.

Laszlo

[blog.arcol.hu]

Also when the Root diameter is bigger then the base diameter, I made the two diameter equal.

Is is almost good. Here is a screenshot:

However the bigger gear is 144 teeth version, and the involute profile seems a bit too straight to me.

Laszlo

[blog.arcol.hu]

|

Re: Theorethical (math) questions about spur gears July 13, 2010 06:43AM |

Registered: 13 years ago Posts: 7,616 |

Quote

(I use a=m, while he is using somewhat smaller).

He's right, but doesn't use the most standardized design. You need some clearance between your root circle and the tooth top of the opposite wheel, so always a < b. Standards recommend a = m and b = 1.2 * m.

BTW., this online gear generator uses a contact diameter different from the pitch diameter (check the boxes to the right of the input field). This is possible and allows lower teeth numbers, but isn't the most simple design.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Theorethical (math) questions about spur gears July 13, 2010 06:46AM |

Registered: 16 years ago Posts: 204 |

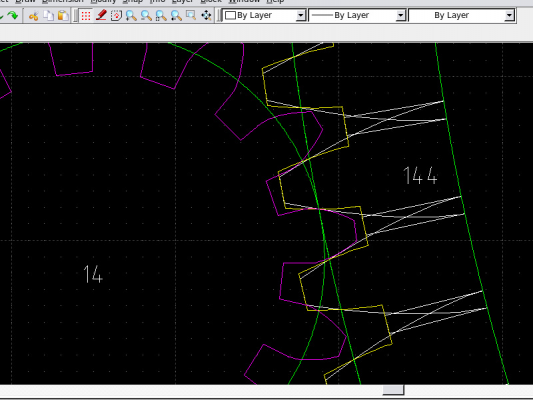

Looks like it is not the right solution. Here is a screenshot demonstrating it:

magenta: 14 teeth gear (m=2)

white: 144 teeth gear without DB=DR modification (m=2)

yellow: 144 teeth gear with DB=DR modification (m=2)

So it is clear, that the correct method would be finding the intersection

mathematically, and trim each involute profile curve by DR.

I gave up here. I think i just wait a couple of week to give an another shoot

to this problem. Until then I use gears with small number of teeths (the program

warns when the DR>DB ). With m=2 I can get 41 teeth, so it should be enough.

DR: Root diameter (the bottom of the tooth)

DB: base diameter (starts the involute profile from here)

Best regards,

Laszlo

[blog.arcol.hu]

Edited 2 time(s). Last edit at 07/13/2010 06:50AM by khiraly.

magenta: 14 teeth gear (m=2)

white: 144 teeth gear without DB=DR modification (m=2)

yellow: 144 teeth gear with DB=DR modification (m=2)

So it is clear, that the correct method would be finding the intersection

mathematically, and trim each involute profile curve by DR.

I gave up here. I think i just wait a couple of week to give an another shoot

to this problem. Until then I use gears with small number of teeths (the program

warns when the DR>DB ). With m=2 I can get 41 teeth, so it should be enough.

DR: Root diameter (the bottom of the tooth)

DB: base diameter (starts the involute profile from here)

Best regards,

Laszlo

[blog.arcol.hu]

Edited 2 time(s). Last edit at 07/13/2010 06:50AM by khiraly.

|

Re: Theorethical (math) questions about spur gears July 13, 2010 06:49AM |

Registered: 13 years ago Posts: 7,616 |

Quote

Also when the Root diameter is bigger then the base diameter, I made the two diameter equal.

Why? The only measure for the root diameter is to make room for the opposite's wheel teeth. Everything smaller stresses the material unneccessarily.

You 14/144 pair nicely shows where an undercut would be necessary. That's yet another story ;-)

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Theorethical (math) questions about spur gears July 13, 2010 06:52AM |

Registered: 16 years ago Posts: 204 |

|

Re: Theorethical (math) questions about spur gears July 14, 2010 10:18AM |

Registered: 14 years ago Posts: 92 |

Depending on the ratios, which affects how many teeth are being expected to contact at once, you can separate the pitch circles and adjust the addendum and dedendum (flank profile outside and inside of the pitch circle) to strengthen the teeth, turn down the outer diameter to produce stub teeth, or both.

Edited 1 time(s). Last edit at 07/14/2010 10:22AM by murrayd.

Edited 1 time(s). Last edit at 07/14/2010 10:22AM by murrayd.

|

Re: Theorethical (math) questions about spur gears July 18, 2010 02:49PM |

Admin Registered: 13 years ago Posts: 730 |

I posted some MATLAB scripts for drawing gears that might be useful here [www.reprap.org]

The involute drawing function is pretty clunky and basic, but it might be something you could modify to suit your needs.

-Matt

The involute drawing function is pretty clunky and basic, but it might be something you could modify to suit your needs.

-Matt

|

Re: Theorethical (math) questions about spur gears July 18, 2010 07:18PM |

Registered: 15 years ago Posts: 59 |

|

Re: Theorethical (math) questions about spur gears July 20, 2010 12:11AM |

Admin Registered: 13 years ago Posts: 730 |

|

Re: Theorethical (math) questions about spur gears July 20, 2010 07:41AM |

Registered: 13 years ago Posts: 486 |

You may also want to look at my openscad script: [www.thingiverse.com]

|

Re: Theorethical (math) questions about spur gears August 19, 2010 01:59PM |

|

Re: Theorethical (math) questions about spur gears August 19, 2010 05:41PM |

Registered: 13 years ago Posts: 7,616 |

The minimum number of teeth is independent from the module. It's 14 to 17 for gears with contact diameter = pitch diameter .

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

questions about gear wheel November 20, 2011 06:36AM |

I would like to write a function with Matlab. The function must draw me a gearwheel of 50 teeth . But I would like to use the instruction " Plot polar" . I have already written the code but he doesn't draw ho i want. Here is also my code. Perhaps find someone what is my mistake.

greetings

code:

-----------------------------------------------------

function[]=neu_rad()

Ri=49.92; %internal radius

Ra=52; % Expresses radius

for alfa=0:0.1:7.2 % draw one period

b=mod(alfa,7.2);

if (b<4.3)

X=Ri*sin(alfa);

Y=Ri*cos(alfa);

else if(b>=4.3 && b<=4.7)

z=0.48712*b+4.27; %straight equation positive upward gradient

X=Ri*sin(alfa)+z*sin(alfa);

Y=Ri*cos(alfa)+z*cos(alfa);

else if (b>4.7 && b<=7)

X=Ra;

Y=Ra;

else if (b>=7 && b<=7.2)

z=-0.48712*b+10.71; %straight equation negative upward gradient

X=Ri*sin(alfa)+z*sin(alfa);

Y=Ri*cos(alfa)+z*cos(alfa);

end

end

end

end

plot(X,Y,'b-')

axis equal

hold on

end

greetings

code:

-----------------------------------------------------

function[]=neu_rad()

Ri=49.92; %internal radius

Ra=52; % Expresses radius

for alfa=0:0.1:7.2 % draw one period

b=mod(alfa,7.2);

if (b<4.3)

X=Ri*sin(alfa);

Y=Ri*cos(alfa);

else if(b>=4.3 && b<=4.7)

z=0.48712*b+4.27; %straight equation positive upward gradient

X=Ri*sin(alfa)+z*sin(alfa);

Y=Ri*cos(alfa)+z*cos(alfa);

else if (b>4.7 && b<=7)

X=Ra;

Y=Ra;

else if (b>=7 && b<=7.2)

z=-0.48712*b+10.71; %straight equation negative upward gradient

X=Ri*sin(alfa)+z*sin(alfa);

Y=Ri*cos(alfa)+z*cos(alfa);

end

end

end

end

plot(X,Y,'b-')

axis equal

hold on

end

|

Re: Theorethical (math) questions about spur gears November 20, 2011 06:52AM |

Registered: 13 years ago Posts: 1,352 |

Sorry, only registered users may post in this forum.