1 Meter bot project

Posted by oak1477

|

1 Meter bot project June 11, 2015 12:46PM |

Registered: 9 years ago Posts: 24 |

Hello everyone

This summer I have been given the privilege of interning for the 3d printing company Re:3d the makers of the Gigabot, a printer with a 2 foot cubed build space. Their motto is think big, print huge, and following their motto they asked me to design and build a printer with a build space of a meter cubed. They also asked me to make a build log and share it with the community, so I will be periodically updating this thread during major steps of the build. Please feel free to post questions or comments I will be happy to answer questions you have

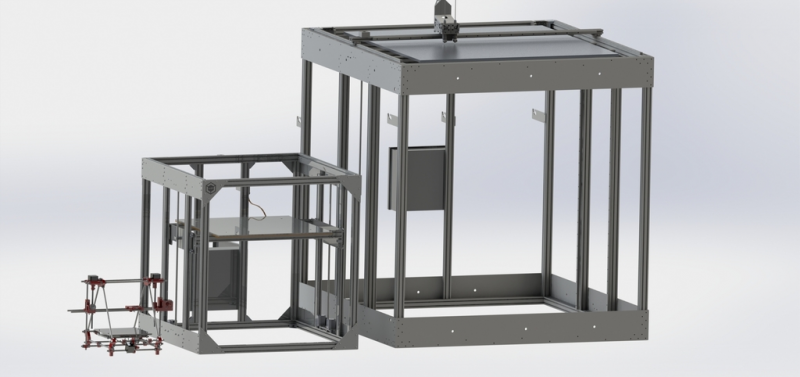

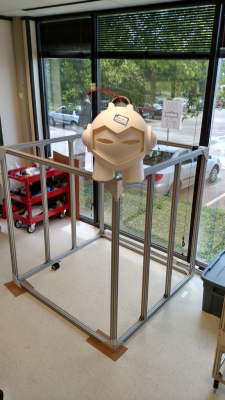

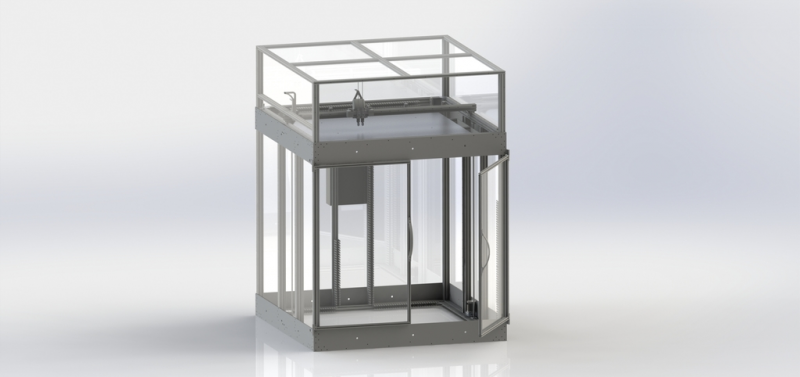

Here is a sneak peak of what is to come and a little size comparison for you:

Thanks expect an update soon and happy printing!

Edited 1 time(s). Last edit at 06/11/2015 01:00PM by oak1477.

This summer I have been given the privilege of interning for the 3d printing company Re:3d the makers of the Gigabot, a printer with a 2 foot cubed build space. Their motto is think big, print huge, and following their motto they asked me to design and build a printer with a build space of a meter cubed. They also asked me to make a build log and share it with the community, so I will be periodically updating this thread during major steps of the build. Please feel free to post questions or comments I will be happy to answer questions you have

Here is a sneak peak of what is to come and a little size comparison for you:

Thanks expect an update soon and happy printing!

Edited 1 time(s). Last edit at 06/11/2015 01:00PM by oak1477.

|

Re: 1 Meter bot project June 12, 2015 11:39AM |

Registered: 9 years ago Posts: 24 |

The frame of the bot is 40mm by 40mm aluminum extrusion the side plates are going to made of 3/16" thick aluminum and will go around the entire frame of the bot.

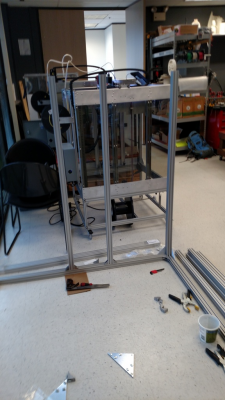

when we received the extrusion we made a test assembly

I am working on finalizing the panels and those will soon be sent off for machining.

when we received the extrusion we made a test assembly

I am working on finalizing the panels and those will soon be sent off for machining.

|

Re: 1 Meter bot project June 12, 2015 04:24PM |

Registered: 9 years ago Posts: 19 |

|

Re: 1 Meter bot project June 12, 2015 04:35PM |

Registered: 9 years ago Posts: 24 |

There will be a heated bed, which we have custom ordered for the bot. It is a silicon rubber heating pad. Yes it will require a lot of power (like 2500 watts)

it will be similar to this, this is one of the 2 foot beds

Edited 1 time(s). Last edit at 06/12/2015 04:36PM by oak1477.

it will be similar to this, this is one of the 2 foot beds

Edited 1 time(s). Last edit at 06/12/2015 04:36PM by oak1477.

|

Re: 1 Meter bot project June 12, 2015 05:33PM |

Registered: 9 years ago Posts: 19 |

Quote

oak1477

There will be a heated bed, which we have custom ordered for the bot. It is a silicon rubber heating pad. Yes it will require a lot of power (like 2500 watts)

it will be similar to this, this is one of the 2 foot beds

Awesome

|

Re: 1 Meter bot project June 12, 2015 10:10PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: 1 Meter bot project June 15, 2015 09:49AM |

Registered: 9 years ago Posts: 24 |

Just a small update this morning about the motors,

for the z and y motors we have decided that nema 17 motors were not going to cut it mostly due to weight issues (the aluminum plate for the bed is supposed to be about 43 pounds according to solidworks, In their place we have decided to use nema 23 motors

size comparison:

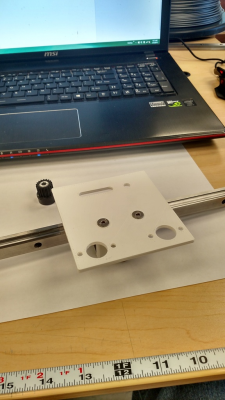

for the y mounts we are going to be mounting them to the 40mm x 40mm extrusion using mounting blocks which we are going to be manufacturing, we have 3d printed test of the part in both pla and taulman 910 and decided ultimately that actually manufacturing the parts would be a better plan.

for the z and y motors we have decided that nema 17 motors were not going to cut it mostly due to weight issues (the aluminum plate for the bed is supposed to be about 43 pounds according to solidworks, In their place we have decided to use nema 23 motors

size comparison:

for the y mounts we are going to be mounting them to the 40mm x 40mm extrusion using mounting blocks which we are going to be manufacturing, we have 3d printed test of the part in both pla and taulman 910 and decided ultimately that actually manufacturing the parts would be a better plan.

|

Re: 1 Meter bot project June 15, 2015 10:13AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: 1 Meter bot project June 15, 2015 10:20AM |

Registered: 9 years ago Posts: 24 |

|

Re: 1 Meter bot project June 16, 2015 10:53AM |

Registered: 9 years ago Posts: 24 |

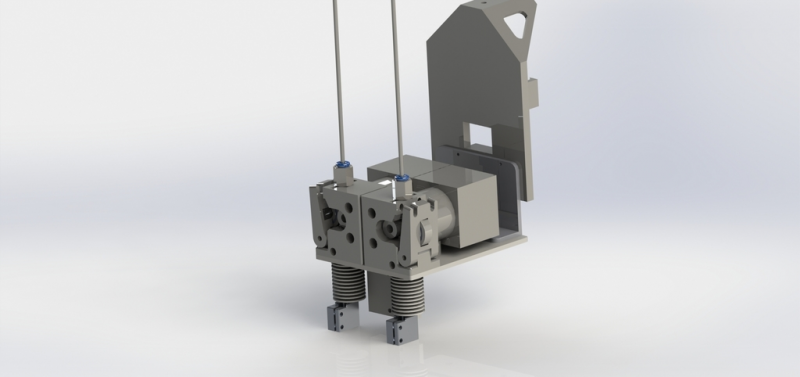

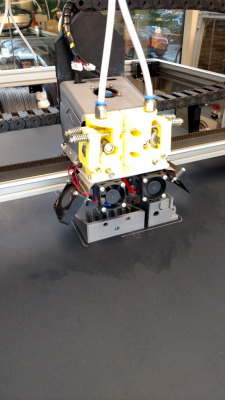

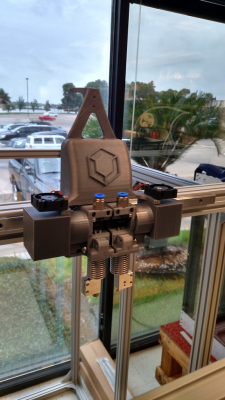

Another update for you guys. From day one we identified the x axis as the most problematic area of the build and we are now on revision 3 of the x axis platform. This printer will have dual extruders with the e3d volcano hot end. as for the motion we are going to be using linear rails with a belt pulling it.

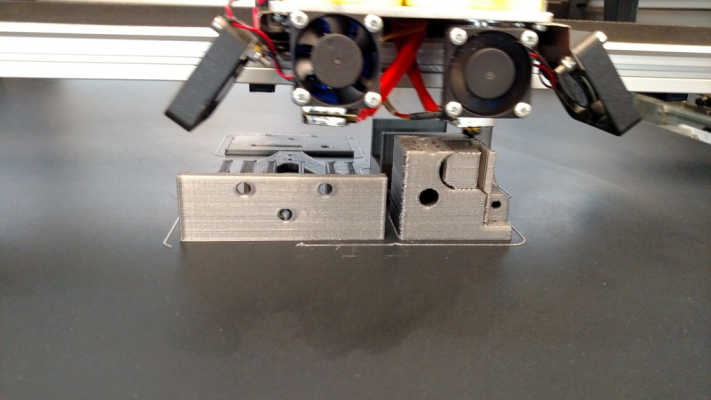

because of this area being such a complicated piece we have printed many prototypes for the mounting assembly before we send them off to be milled

here is what rev 2 two was going to be, we then realized that there would be a major issue with the height so it was abandoned and redesigned

rev 3 solves the height issue but there are still a few slight changes that need to be made to the design ton compact it a bit

and for those who were wondering where rev 1 went, it was so early in the design that it ended up being abandoned and helped solve a ton of problems for rev 2.

thanks expect another update, we will hopefully be getting more parts in soon. Thanks and happy printing

because of this area being such a complicated piece we have printed many prototypes for the mounting assembly before we send them off to be milled

here is what rev 2 two was going to be, we then realized that there would be a major issue with the height so it was abandoned and redesigned

rev 3 solves the height issue but there are still a few slight changes that need to be made to the design ton compact it a bit

and for those who were wondering where rev 1 went, it was so early in the design that it ended up being abandoned and helped solve a ton of problems for rev 2.

thanks expect another update, we will hopefully be getting more parts in soon. Thanks and happy printing

|

Re: 1 Meter bot project June 17, 2015 07:01PM |

Registered: 9 years ago Posts: 24 |

More parts have finally arrived. All of the linear rails we ordered came to the shop this afternoon and we immediately got to mounting the y axis rails to the frame.

The goodies

mounted to the frame

the carriage for the rail

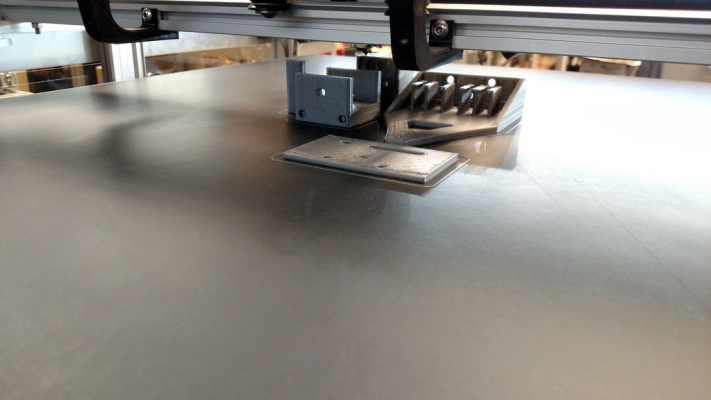

I have been printing some prototypes for random parts of the the x carriage

I have been also printing some test parts to hold the x axis to the y rails

And finally I wanted to show you how far the cad has progressed here is a render I did today of the full bot

Thanks guys, hope you enjoy and keep following if you have any questions I would love to answer them. Happy printing

The goodies

mounted to the frame

the carriage for the rail

I have been printing some prototypes for random parts of the the x carriage

I have been also printing some test parts to hold the x axis to the y rails

And finally I wanted to show you how far the cad has progressed here is a render I did today of the full bot

Thanks guys, hope you enjoy and keep following if you have any questions I would love to answer them. Happy printing

|

Re: 1 Meter bot project June 17, 2015 07:07PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: 1 Meter bot project June 17, 2015 07:41PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: 1 Meter bot project June 18, 2015 04:13AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: 1 Meter bot project June 18, 2015 10:01AM |

Registered: 9 years ago Posts: 24 |

Honestly we were worried about the rigidity as well on the but so far just with the build up not using the full 6 inch 3/16" plate that we are wrapping the entire thing with has been quite surprising. We have had to beef up the rail for the x axis but other than that it is pretty solid so far. We also decided that we should get some really heavy corner brackets for extra strength, but if it turns out that isn't enough that may happen.

|

Re: 1 Meter bot project June 18, 2015 07:22PM |

Registered: 9 years ago Posts: 24 |

Sorry just a small update today we had the bed come in. It is so big it came on a pallet and took at least two of use to comfortably carry it into the office.

|

Re: 1 Meter bot project June 18, 2015 07:26PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: 1 Meter bot project June 19, 2015 10:52AM |

Registered: 9 years ago Posts: 24 |

If our calculations are correct about seventy thousandths. We use a mounting system involving springs to allow the bed to have some flex

|

Re: 1 Meter bot project June 19, 2015 12:38PM |

Registered: 11 years ago Posts: 205 |

Quote

o_lampe

I´m wondering how such a huge frame is getting along without any diagonal struts? They would reduce the load on all the vertical struts alot...

-Olaf

It seems that no one teaches basis physics or mechanics anymore. The comment "seems very ridgid" is really reassuring. I'll bet they don't own a dial indicator or else don't know how to use it. Please mount a dial indicator on a tripod or ladder with the tip against the frame at variuos points. Then apply a force equal to your expected linear thrust and report the deflection you see. Then compare that to the positioning accuracy you claim for your design so it can be assesed whether that is a valid claim.

If you don't have a dial indicator please buy yourself one. It would be sad to know you spent over 100K for an education that didn't teach you much.

|

Re: 1 Meter bot project June 19, 2015 01:02PM |

Registered: 9 years ago Posts: 24 |

Thanks for the advice, the reason we have posted this was to get input from the community and stuff like that is exactly what we are looking for. We actually don't have the sheet metal that we are going to be mounting around the frame so we were going to be doing actual testing when we get the actual frame assembled, at the moment we are just test fitting parts. Also, just out of curiosity what would you consider a acceptable amount of deflection.

|

Re: 1 Meter bot project June 19, 2015 03:01PM |

Registered: 9 years ago Posts: 344 |

It all depends on layer height and width you use for printing. What nozzle diameter are you using? This roughly gives you the maximal total error you can tolerate on Z to at least have a hope to lay down the first layer. Deflection is just one of the (many) factors to consider. Depending on how heavy your carriage is, without diagonal supports you may have some problems of shear deformation at high enough printing speed. Well, you will have some shear anyway but if you print slowly it will not be noticeable in "artistic" prints.

Edited 1 time(s). Last edit at 06/19/2015 03:09PM by cristian.

Edited 1 time(s). Last edit at 06/19/2015 03:09PM by cristian.

|

Re: 1 Meter bot project June 19, 2015 03:41PM |

Registered: 11 years ago Posts: 335 |

Quote

oak1477

Also, just out of curiosity what would you consider a acceptable amount of deflection.

It varies. For precision applications I would normally say <0.05mm. I suspect most 3d printers are in the 0.5-0.1mm range. Subsequent layers generally have similar toolpaths so deflection will have the same effect on each layer (effectively making it invisible unless you are getting resonance/ringing).

I actually keep a couple spring scales in my toolbox for exactly this purpose. The dial indicator should be mounted to the table. Using a tripod or other fixed reference doesn't represent what the part will be seeing.

Another extremely important measurement is bidirectional repeatability. Zero a dial indicator on the carriage and perform a couple of random movements before returning to origin. This directly measures how well successive layers will line up which is a major contributor to print quality.

|

Re: 1 Meter bot project June 19, 2015 04:03PM |

Registered: 9 years ago Posts: 1,873 |

Quote

Subsequent layers generally have similar toolpaths so deflection will have the same effect on each layer (effectively making it invisible unless you are getting resonance/ringing).

That's exactly the question I was trying to thrash around in my head - thanks for expressing it better than I could. It's not clear that there's any fixed answer to what the accuracy should be as it's evidently going to heavily depend on the toolpath. There's a question in mind as to what the use cases for such a big printer are - does it make sense to take a 1m3 printer and print small objects with a 0.2mm nozzle and .1mm layers? Or to wait 4 days for a big object at those sizes? Perhaps a big printer is mostly going to be used with a 1mm nozzle and .8mm layers, in which case the accuracy requirements could presumably be relaxed somewhat.

|

Re: 1 Meter bot project June 19, 2015 05:20PM |

Registered: 9 years ago Posts: 24 |

thanks for all thoughts guys, it is awesome to get all this feedback from everybody. On the hot end, we realized the normal size nozzle was way too small, we found the volcano hot end has .6, .8, 1, and 1.2 mm so we are going with that hot end for the exact reason you stated. we don't want to wait a crazy amount of time for a print.

the nozzles

and we have also done some test fitting of the x axis we printed all of the parts (including the motors and gearboxes since we didn't have them on hand yet)

the nozzles

and we have also done some test fitting of the x axis we printed all of the parts (including the motors and gearboxes since we didn't have them on hand yet)

|

Re: 1 Meter bot project June 19, 2015 05:30PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: 1 Meter bot project June 19, 2015 05:33PM |

Registered: 9 years ago Posts: 24 |

|

Re: 1 Meter bot project June 20, 2015 03:05AM |

Registered: 8 years ago Posts: 5,232 |

Quote

JamesK

Perhaps a big printer is mostly going to be used with a 1mm nozzle and .8mm layers, in which case the accuracy requirements could presumably be relaxed somewhat.

As a customer I wouldn´t accept a big print where the errors are also" scaled up".

I´d expect the same sharp corners and flat surfaces as with a common 0.4mm nozzle.

-Olaf

|

Re: 1 Meter bot project June 20, 2015 03:32AM |

Registered: 9 years ago Posts: 344 |

Quote

o_lampe

As a customer I wouldn´t accept a big print where the errors are also" scaled up".

I´d expect the same sharp corners and flat surfaces as with a common 0.4mm nozzle.

-Olaf

It is impossible to obtain the same sharpness on Z with different nozzle diameters. A 1mm nozzle will always give you rounded corners with a radius of at least 0.5mm.

|

Re: 1 Meter bot project June 20, 2015 04:16AM |

Registered: 8 years ago Posts: 5,232 |

Quote

cristian

Quote

o_lampe

As a customer I wouldn´t accept a big print where the errors are also" scaled up".

I´d expect the same sharp corners and flat surfaces as with a common 0.4mm nozzle.

-Olaf

It is impossible to obtain the same sharpness on Z with different nozzle diameters. A 1mm nozzle will always give you rounded corners with a radius of at least 0.5mm.

Yes, I should´ve said it in other words..

If I print a part 10x bigger, the errors I get, should not be "scaled up "10x.

The difference between 0.4 and 1.2 nozzle is acceptable.

|

Re: 1 Meter bot project June 20, 2015 01:23PM |

Registered: 11 years ago Posts: 205 |

If you claim a positioning accuracy of 0.005" then the deflection had better be much less than that or combined with lots of other factors you can't possibly get that kind of accuracy. Note that deflection in the frame will produce a position error that will be huge for small parts and probably much less for very large parts.

Sorry, only registered users may post in this forum.