1 Meter bot project

Posted by oak1477

|

Re: 1 Meter bot project June 20, 2015 01:48PM |

Registered: 11 years ago Posts: 5,780 |

Quote

garyhlucas

If you claim a positioning accuracy of 0.005" then the deflection had better be much less than that or combined with lots of other factors you can't possibly get that kind of accuracy. Note that deflection in the frame will produce a position error that will be huge for small parts and probably much less for very large parts.

Good point. The printer should be matched to the size of the parts it is going to print. Printing tiny parts with a huge printer is not only sort of silly, but likely to yield poorer results than printing the same part with a much smaller printer, all else being equal.

|

Re: 1 Meter bot project June 20, 2015 04:30PM |

Registered: 9 years ago Posts: 344 |

Quote

garyhlucas

Note that deflection in the frame will produce a position error that will be huge for small parts and probably much less for very large parts.

I would relate this argument more to layer height and width than to the global size of the part to be printed, in particular if it has sharp corners.

Of course layer height and width may in turn be considered proportional to the size of the printed part.

|

Re: 1 Meter bot project June 25, 2015 12:11PM |

Registered: 9 years ago Posts: 24 |

Hello everyone,

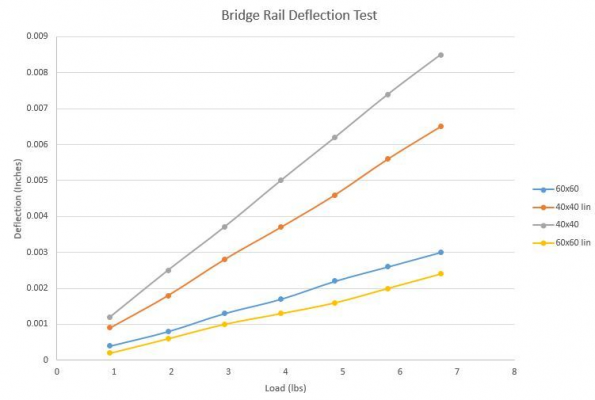

Sorry it has taken so long for another update it has gotten super busy for me recently. We ended up having to completely redo the assembly of the cad, and that took a few days. We also finally have received the new extrusions for the x axis and and were unsure if just the 40x40 extrusion would cut it so we decided to do some deflection test on it (we also saw how interested some people were in this).

here is the rig we set up for the deflection and a few pictures of the test in general.

so we tested a 60x40 and the 40x40 extrusion with and without linear rails here is the data we got, we have decided to move up to the 60x40 extrusion for our x axis

Sorry it has taken so long for another update it has gotten super busy for me recently. We ended up having to completely redo the assembly of the cad, and that took a few days. We also finally have received the new extrusions for the x axis and and were unsure if just the 40x40 extrusion would cut it so we decided to do some deflection test on it (we also saw how interested some people were in this).

here is the rig we set up for the deflection and a few pictures of the test in general.

so we tested a 60x40 and the 40x40 extrusion with and without linear rails here is the data we got, we have decided to move up to the 60x40 extrusion for our x axis

|

Re: 1 Meter bot project June 25, 2015 04:02PM |

Registered: 9 years ago Posts: 344 |

|

Re: 1 Meter bot project June 30, 2015 11:26AM |

Registered: 9 years ago Posts: 24 |

Hey guys sorry for the silence this weekend i was at a robotics competition. Do not worry more testing will be coming soon and we will be sharing all of our results with you. At the moment we are machining some parts so i wanted to update on that and later today I will be posting more photos.

Have a great day and keep printing.

Have a great day and keep printing.

|

Re: 1 Meter bot project June 30, 2015 06:19PM |

Registered: 9 years ago Posts: 24 |

Hey guys as promised another update today

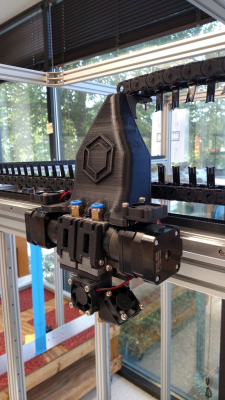

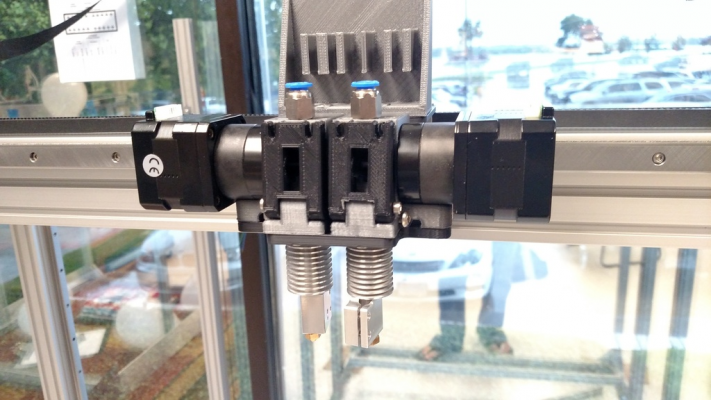

I got some more parts ready we have the actual motors mounted to the extruders

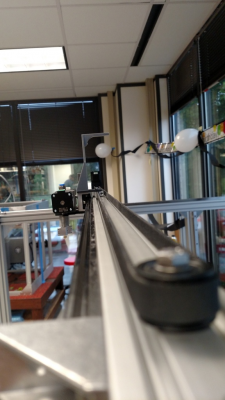

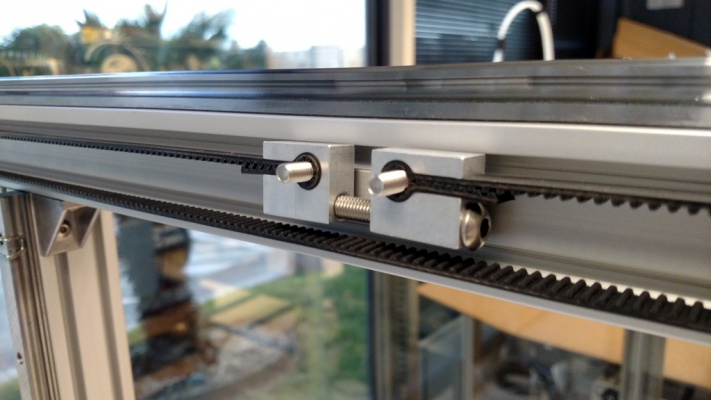

we also did your first fit of all of the major parts of the x axis including the belts

Have a great day and keep printing.

I got some more parts ready we have the actual motors mounted to the extruders

we also did your first fit of all of the major parts of the x axis including the belts

Have a great day and keep printing.

|

Re: 1 Meter bot project June 30, 2015 07:22PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: 1 Meter bot project July 01, 2015 03:59AM |

Registered: 8 years ago Posts: 5,232 |

Had a nice party?

First thing I recon´d were the white balloons

Seriously:

Aren´t you afraid the long belts eventually start to swing, when they are unsupported all the way back?

I thought of a different way to mount the extruder assembly, where both sides of the belt are fixed/guided.

-Olaf

First thing I recon´d were the white balloons

Seriously:

Aren´t you afraid the long belts eventually start to swing, when they are unsupported all the way back?

I thought of a different way to mount the extruder assembly, where both sides of the belt are fixed/guided.

-Olaf

|

Re: 1 Meter bot project July 01, 2015 10:14AM |

Registered: 9 years ago Posts: 24 |

Quote

o_lampe

Had a nice party?

First thing I recon´d were the white balloons

Seriously:

Aren´t you afraid the long belts eventually start to swing, when they are unsupported all the way back?

I thought of a different way to mount the extruder assembly, where both sides of the belt are fixed/guided.

-Olaf

We actually had a guy in the office with a birthday so we had set up some decorations and a cake for when he got in, and I would love to hear your idea further on the belts.

|

Re: 1 Meter bot project July 01, 2015 10:29AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: 1 Meter bot project July 01, 2015 02:32PM |

Registered: 10 years ago Posts: 770 |

Thats why a lot of larger machines have a rack and pinion setup...Quote

o_lampe

Aren´t you afraid the long belts eventually start to swing, when they are unsupported all the way back?

I thought of a different way to mount the extruder assembly, where both sides of the belt are fixed/guided.

-Olaf

|

Re: 1 Meter bot project July 02, 2015 06:41PM |

Registered: 9 years ago Posts: 24 |

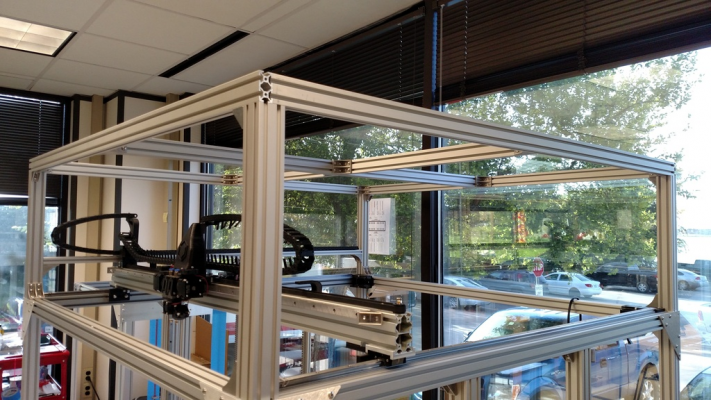

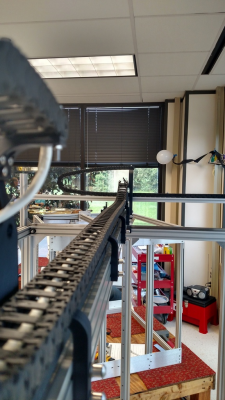

Hey guys update time. Been working hard all day and the cable trays are on the bot for the first time

thanks guys have a great 4th of July weekend and happy printing

thanks guys have a great 4th of July weekend and happy printing

|

Re: 1 Meter bot project July 06, 2015 07:22PM |

Registered: 9 years ago Posts: 24 |

Hey guys another update on the bot

I did some revisions on the design to how the y belts attach to the top bar. We were originally going to use some sheet metal flanges, but decided that was too complicated and time consuming. We settled on 3/8" angle iron as a possible solution that would be easier to work with. I designed a simple bracket and we printed it to test fit everything. Below are a few pictures of some of the y axis stuff

I did some revisions on the design to how the y belts attach to the top bar. We were originally going to use some sheet metal flanges, but decided that was too complicated and time consuming. We settled on 3/8" angle iron as a possible solution that would be easier to work with. I designed a simple bracket and we printed it to test fit everything. Below are a few pictures of some of the y axis stuff

|

Re: 1 Meter bot project July 08, 2015 06:17AM |

Registered: 9 years ago Posts: 25 |

|

Re: 1 Meter bot project July 08, 2015 06:57AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: 1 Meter bot project July 08, 2015 08:16AM |

Registered: 11 years ago Posts: 5,780 |

There's a 3D printable belt clamp that looks a lot like that tensioner here: [www.youmagine.com]

|

Re: 1 Meter bot project July 08, 2015 08:46AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: 1 Meter bot project July 08, 2015 06:43PM |

Registered: 10 years ago Posts: 553 |

Quote

JamesK

I like the design for the belt tensioner. I've been making all sorts of a mess around that. Yours is much simpler and tidier. Time to hit the mill again!

Same here. Great job on the design. Can't wait to see how everything turns out! This is one hell of an internship!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: 1 Meter bot project July 10, 2015 09:46AM |

Registered: 9 years ago Posts: 24 |

Hey guys update time, sorry these past few days have still been crazy here in Houston but i finally got some cool stuff to show you.

First off i know that this isn't the meter bot but a fellow intern just finished the frame of a bamboo and 3d printed bike so I had to share just a photo of that

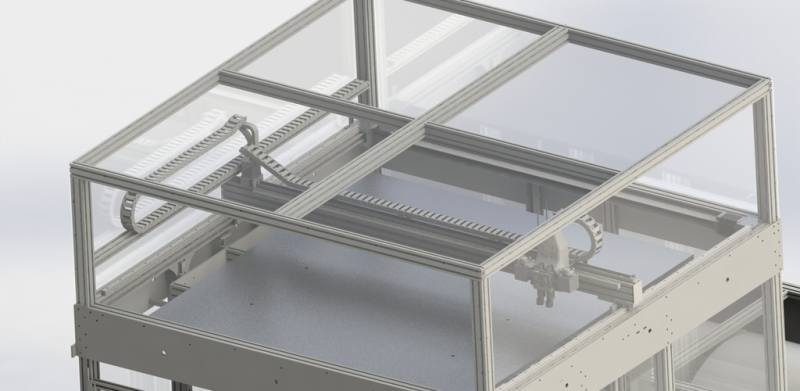

Now for the printer, I have been working pretty hard to get as much into the CAD as possible so earlier this week inserted all of the cable trays

Here is my favorite render of it:

I also made some changes to the cover for the hot end assembly. We ended up going with a larger cover to hide all of the wiring that was coming into the assembly. I am pretty happy with the finished look of the cover

and finally, we got the extrusion for the top cover so I assembled that and installed it. The printer is now officially taller than me

Thanks guys for everything. Have a great weekend and happy printing

First off i know that this isn't the meter bot but a fellow intern just finished the frame of a bamboo and 3d printed bike so I had to share just a photo of that

Now for the printer, I have been working pretty hard to get as much into the CAD as possible so earlier this week inserted all of the cable trays

Here is my favorite render of it:

I also made some changes to the cover for the hot end assembly. We ended up going with a larger cover to hide all of the wiring that was coming into the assembly. I am pretty happy with the finished look of the cover

and finally, we got the extrusion for the top cover so I assembled that and installed it. The printer is now officially taller than me

Thanks guys for everything. Have a great weekend and happy printing

|

Re: 1 Meter bot project July 13, 2015 05:12PM |

Registered: 9 years ago Posts: 24 |

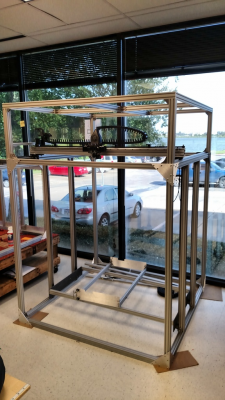

hey guys another update we just got the side panels in and test fitted on the bot. We are going to send them off to be finished and then we will begin final assembly.

|

Re: 1 Meter bot project July 13, 2015 08:05PM |

Registered: 11 years ago Posts: 205 |

|

Re: 1 Meter bot project July 13, 2015 08:26PM |

Registered: 9 years ago Posts: 24 |

Quote

garyhlucas

I'm only guessing, but it looks like you still don't understand the meaning of stiff.

We are still just test fitting parts, once everything is assembled we are going to be doing deflection testing on the frame. We have yet to fully assemble the frame so there has been no point in testing a frame that is just test fitted together. If our design is not stiff enough we will be changing it.

|

Re: 1 Meter bot project July 14, 2015 05:19AM |

Registered: 9 years ago Posts: 977 |

Hi,

I don't want to sound like a sourpuss and dampen your obvious enthusiasm with this project, however I have a few objections about it that i would like to convey here.

The first thing is, this is clearly a closed source project by a company that uses open source hardware and firmware in its products, however has returned very little or even nothing to the open source RepRap community.

Second thing is, you are clearly posting this thread as a promotional stunt, since the design and build of a 1-meter FDM is clearly beyond the means and practical use by 99.99% of all RepRappers. And personally I find that the promotion of a closed source product in an open source forum is very disturbing.

The third thing is, as has been noted before in this thread, your project as it stands has very little technical merit, and I would even argue that you are setting a very bad example with your "design as we go" build method. For example, deflection of an aluminum profile can be calculated in advance, yet there is no indication or mention that you have done any engineering calculations in advance for your project, before your build started.

Doh!

The fourth thing is, apparently this one meter cube bot is a dumb (sorry, no other way of putting it) linear upscale of your 60cm cube bot main product. This gives the false impression that 3D printers can be easily upscaled, which is an absolute fallacy.

The fifth thing is, I have serious doubts that current FDM printer technology is even remotely practical for objects that exceed 30cm in any direction, not to mention 60cm. At the 1 meter scale, there are no doubts, it is a certainty: current FDM technology is useless.

Summarizing, I really think you should create a blog on your company's website and post about your closed source commercial project in it. Then simply post a link in this forum to your blog, for those that may eventually be interested, however uninformative and misleading your blog may be.

I don't want to sound like a sourpuss and dampen your obvious enthusiasm with this project, however I have a few objections about it that i would like to convey here.

The first thing is, this is clearly a closed source project by a company that uses open source hardware and firmware in its products, however has returned very little or even nothing to the open source RepRap community.

Second thing is, you are clearly posting this thread as a promotional stunt, since the design and build of a 1-meter FDM is clearly beyond the means and practical use by 99.99% of all RepRappers. And personally I find that the promotion of a closed source product in an open source forum is very disturbing.

The third thing is, as has been noted before in this thread, your project as it stands has very little technical merit, and I would even argue that you are setting a very bad example with your "design as we go" build method. For example, deflection of an aluminum profile can be calculated in advance, yet there is no indication or mention that you have done any engineering calculations in advance for your project, before your build started.

Quote

oak1477

If our design is not stiff enough we will be changing it.

Doh!

The fourth thing is, apparently this one meter cube bot is a dumb (sorry, no other way of putting it) linear upscale of your 60cm cube bot main product. This gives the false impression that 3D printers can be easily upscaled, which is an absolute fallacy.

The fifth thing is, I have serious doubts that current FDM printer technology is even remotely practical for objects that exceed 30cm in any direction, not to mention 60cm. At the 1 meter scale, there are no doubts, it is a certainty: current FDM technology is useless.

Summarizing, I really think you should create a blog on your company's website and post about your closed source commercial project in it. Then simply post a link in this forum to your blog, for those that may eventually be interested, however uninformative and misleading your blog may be.

|

Re: 1 Meter bot project July 14, 2015 08:19AM |

Registered: 9 years ago Posts: 1,873 |

Just to offer a different opinion, I'm delighted to see this project discussed here. Everything I do is heavily cost constrained and I think it's fascinating to see a project undertaken with the resources of a printer manufacturer behind it.

I know there are always emotional and political issues at stake in the open vs closed arena, but I don't see any actual harm in this thread being here. And I can't help but feel that some of those issues may be colouring your response to the project itself. If I understand correctly this is an internship project conducted by a capable but less experienced person and likely within a limited time-span. Under that scenario some of your objections regarding approach and technique seem a little unreasonable.

I'm confused about your suggestion of 30cm as an upper limit for FDM. The use cases and characteristics may be different from smaller printers but I'm curious why you think it is "useless"?

I know there are always emotional and political issues at stake in the open vs closed arena, but I don't see any actual harm in this thread being here. And I can't help but feel that some of those issues may be colouring your response to the project itself. If I understand correctly this is an internship project conducted by a capable but less experienced person and likely within a limited time-span. Under that scenario some of your objections regarding approach and technique seem a little unreasonable.

I'm confused about your suggestion of 30cm as an upper limit for FDM. The use cases and characteristics may be different from smaller printers but I'm curious why you think it is "useless"?

|

Re: 1 Meter bot project July 14, 2015 08:49AM |

Registered: 9 years ago Posts: 977 |

Quote

JamesK

Just to offer a different opinion, I'm delighted to see this project discussed here. Everything I do is heavily cost constrained and I think it's fascinating to see a project undertaken with the resources of a printer manufacturer behind it.

I know there are always emotional and political issues at stake in the open vs closed arena, but I don't see any actual harm in this thread being here. And I can't help but feel that some of those issues may be colouring your response to the project itself. If I understand correctly this is an internship project conducted by a capable but less experienced person and likely within a limited time-span. Under that scenario some of your objections regarding approach and technique seem a little unreasonable.

I'm confused about your suggestion of 30cm as an upper limit for FDM. The use cases and characteristics may be different from smaller printers but I'm curious why you think it is "useless"?

James,

Everybody is free to have their own opinions and express them politely. So thanks for expressing yours.

There is no upper theoretical limit for FDM, you can print a km long object if you want to. However, in practical terms, the vast majority of 3D printable designs are limited to a 1l cube, as you can observe by yourself by checking the thousands of designs available on Thingiverse.

The reasons for this could be the object of a separate thread with several pages of arguments and counter arguments, so I'll stop here. If you want to dig further into this issue, just create a thread in the forum of your choice and I'll contribute as my time allows.

|

Re: 1 Meter bot project July 16, 2015 07:24PM |

Registered: 10 years ago Posts: 580 |

Lets keep it positive guys.

This thread is valuable - as long as you continue posting about your experiences and the required fixes After the build is complete - what happens when you actually attempt to print big with it is what's important.

Many people want to build large and need to know the pitfalls. Having built a large printer entirely from scratch I know this process is not easy, so I applaud your efforts!

I see several issues you will have to deal with:

- Resonance from your stepper drivers with Nema 23's - you will likely need tune-able drivers. Make sure the manufacturer has up-to-date software to tune them - that they support, and a cable that will connect to a modern computer ( USB ).

- Bed flatness. If you are using a cast aluminum tooling plate then you might be OK. A rolled-aluminum plate that large is going to warp when you heat it (or you could just print PLA).

- Accurate bed leveling - but you would know this already from your other large models.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

This thread is valuable - as long as you continue posting about your experiences and the required fixes After the build is complete - what happens when you actually attempt to print big with it is what's important.

Many people want to build large and need to know the pitfalls. Having built a large printer entirely from scratch I know this process is not easy, so I applaud your efforts!

I see several issues you will have to deal with:

- Resonance from your stepper drivers with Nema 23's - you will likely need tune-able drivers. Make sure the manufacturer has up-to-date software to tune them - that they support, and a cable that will connect to a modern computer ( USB ).

- Bed flatness. If you are using a cast aluminum tooling plate then you might be OK. A rolled-aluminum plate that large is going to warp when you heat it (or you could just print PLA).

- Accurate bed leveling - but you would know this already from your other large models.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: 1 Meter bot project July 16, 2015 08:17PM |

Registered: 11 years ago Posts: 5,780 |

I don't think that upscaling a printer is quite the difficult thing that some make it out to be (I did it on a smaller scale than this). I think FDM can be useful in any size as long as you can live with the limitations. I doubt the intent is to print 50um layers with this beast, so if it flexes a little, it really doesn't mean it's useless, it just means they'll need to use thicker layers- but at this size, thicker layers are in order anyway so that print times don't become impractically long.

What difference does the closed/open source nature of the company's other products make in relation to this build for which they are providing detailed information on their successes and failures as they progress? I am thankful to see how they are doing things because I may one day decide to build something like this. Knowing some of the problems and their solutions in advance will save myself and others a lot of time, effort, and money. Who would be against that?

Finally, this forum isn't just for people who can only afford $300 kits- I'll bet there are plenty of people here with the resourcefulness/finances that would allow a build like this. Anyone who finds this thread offensive to their sensibilities has the option of simply ignoring it.

What difference does the closed/open source nature of the company's other products make in relation to this build for which they are providing detailed information on their successes and failures as they progress? I am thankful to see how they are doing things because I may one day decide to build something like this. Knowing some of the problems and their solutions in advance will save myself and others a lot of time, effort, and money. Who would be against that?

Finally, this forum isn't just for people who can only afford $300 kits- I'll bet there are plenty of people here with the resourcefulness/finances that would allow a build like this. Anyone who finds this thread offensive to their sensibilities has the option of simply ignoring it.

|

Re: 1 Meter bot project July 18, 2015 11:49AM |

Registered: 10 years ago Posts: 102 |

|

Re: 1 Meter bot project July 18, 2015 09:47PM |

Registered: 10 years ago Posts: 32 |

|

Re: 1 Meter bot project July 21, 2015 10:41AM |

Registered: 11 years ago Posts: 5,780 |

Sorry, only registered users may post in this forum.

. Keep up the good work, coming along nicely.

. Keep up the good work, coming along nicely.