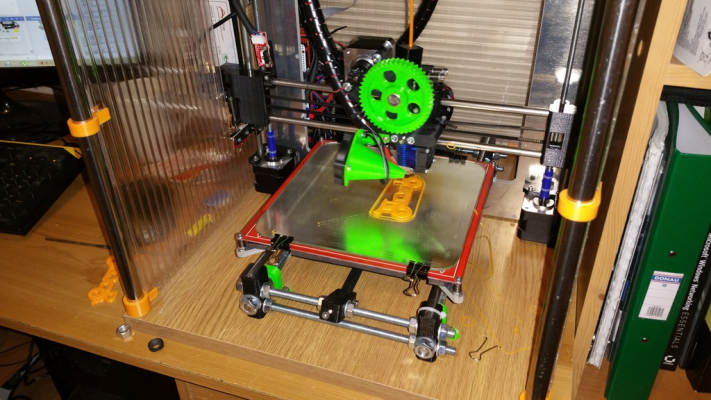

Prusa i3 Z axis problems help

Posted by [email protected]

|

Prusa i3 Z axis problems help June 13, 2015 07:49AM |

Registered: 9 years ago Posts: 6 |

Hi all I have had my prusa about 3 months now(first printer). I'm pretty familiar with it and could now not do without it. My only gripe with it is that I am continually losing steps on one of the z axis motors. I have spent hours tweaking the pot on the driver with no solution. I can get probably 2-3 small prints before it has gone to far off level.

The only solution I can see is running them separately and adding another end stop on the other side. Is this possible? What else would you suggest

If it wasn't for this I the printer would be 100% reliable.

The only solution I can see is running them separately and adding another end stop on the other side. Is this possible? What else would you suggest

If it wasn't for this I the printer would be 100% reliable.

|

Re: Prusa i3 Z axis problems help June 13, 2015 01:08PM |

Registered: 9 years ago Posts: 125 |

Can you swap one x-motor and z-motor and try? Have you checked z-motor connectors or wire resistance? Have you checked the threaded rods and nuts on Z? Z threaded rods and plastic couplers, do they "bend" equally or slip. I have the aluminium ones...

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

Prusa i3, Ramps 1.4. Catnozzle 0.4mm

SketchUp - Enveloping Globoid Worm Gear - Part One - 3D Printed: [youtu.be]

DesignSpark Mechanical & more precise screw thread: [youtu.be]

Nicer Screw Thread In SketchUp ( Bolts,Nuts): [youtu.be]

How To Model A Heart Shape In SketchUp: [youtu.be]

How To Draw 3D Printable Snap Fit Ball Joint In SketchUp: [youtu.be]

|

Re: Prusa i3 Z axis problems help June 15, 2015 04:46AM |

Registered: 9 years ago Posts: 6 |

No iv not checked resistance, but the is defiantly no slip. I think the driver is stuggerling to power two motors. All of the other motors sing lovely if for example I tell them to move 10mm as with the z motors unless I only move a step at a time the judder and don't move. I have spent hours tweeking the driver with no improving at best they "work" while printing as its only moving a few steps at a time. Hence my idea of running them separate and each time I home even if they lose a step they would realign when homing so long as I had an end stop on both sides. I don't know if the internal software has options for that. Obviously others don't have this issue so something must no be right but I defiantly know there is no binding so it is either a motor or power problem.

|

Re: Prusa i3 Z axis problems help June 15, 2015 05:34AM |

Registered: 9 years ago Posts: 198 |

I am interested to see what the solution is to this as i have the same problem. I have tried slowing down the homing speed changed the stepper driver and tweaked the pot but with no real results. I did think that the threaded rods might be to blame but after checking they seem fine.

thanks Nikki

thanks Nikki

|

Re: Prusa i3 Z axis problems help June 17, 2015 03:33AM |

Registered: 8 years ago Posts: 59 |

I had the same problem with my i3.

I made some changes in my configuration.h file (presumeably you are using Marlin). I think the one that fixed it was reducing DEFAULT_MAX_FEEDRATE for the Z-axis. I think it was originally 25mm/sec (though I'm not 100% sure), I changed it to 3mm/sec!

I also changed a couple of other things:

DEFAULT_MAX_FEEDRATE set to 50 for the Z-axis (down from 100), and

DEFAULT_ACCELERATION set to 1500 down from 3000,

... but I think it was the change to DEFAULT_MAX_FEEDRATE that did it.

let us know how you go.

I made some changes in my configuration.h file (presumeably you are using Marlin). I think the one that fixed it was reducing DEFAULT_MAX_FEEDRATE for the Z-axis. I think it was originally 25mm/sec (though I'm not 100% sure), I changed it to 3mm/sec!

I also changed a couple of other things:

DEFAULT_MAX_FEEDRATE set to 50 for the Z-axis (down from 100), and

DEFAULT_ACCELERATION set to 1500 down from 3000,

... but I think it was the change to DEFAULT_MAX_FEEDRATE that did it.

let us know how you go.

|

Re: Prusa i3 Z axis problems help June 21, 2015 12:13PM |

Registered: 9 years ago Posts: 6 |

|

Re: Prusa i3 Z axis problems help June 21, 2015 05:43PM |

Registered: 11 years ago Posts: 5,780 |

If you want to actually fix the problem, which is poor design, the real solution is to dump the two-motor set up and put a belt on it so both screws are driven by a single motor. They'll never get out of sync again. You'll never waste another minute trying to relaign the X axis. The guy who sold you the kit knew you'd be spending your time realigning the X axis, but by taking a short cut- using 2 motors instead of 1 motor with a belt, he was able to sell you the machine for $300 instead of $325 or $350.

I'll bet that if you had known what a PITA it was going to be to keep the X axis aligned, you'd have opted for a printer that used a single motor with a belt to drive both screws, even if it cost a few $ more.

Every dollar they take out turns into hours of your valuable time spent trying to make the thing work. Is your time really worth so little?

I'll bet that if you had known what a PITA it was going to be to keep the X axis aligned, you'd have opted for a printer that used a single motor with a belt to drive both screws, even if it cost a few $ more.

Every dollar they take out turns into hours of your valuable time spent trying to make the thing work. Is your time really worth so little?

|

Re: Prusa i3 Z axis problems help June 21, 2015 07:22PM |

Registered: 9 years ago Posts: 1,873 |

I'm not even sure that the belt option is more expensive, at least using budget parts. Deleting one motor saves about $16. I paid $2 for a 424 tooth belt and $4 for the pulleys. Plus about $3 for the bearings to make up the mounting blocks. The main issue is ensuring the mounts are strong enough to handle the radial force from the belt tension and the axial force from the weight of the X axis. Admittedly I ended up with a few spares, but they'll either come in handy or I can sell them on.

|

Re: Prusa i3 Z axis problems help June 21, 2015 08:09PM |

Registered: 13 years ago Posts: 68 |

I had issues like that on my mm 1.5+ when cranking the speed up. My solution was to turn the acceleration almost in half for Z. if it binds, then you are likely trying to go too fast. That and other factors. You have 4 rods between X and Z. Its easier to balance a 3 legged chair than a 4 legged one. Your binding might have to do with the X axis not being level, increasing friction. Maybe try some lube too. I moved to a linear rail for X, fixed the constant X axis binding I had.

Edited 1 time(s). Last edit at 06/21/2015 08:11PM by L4nce0.

Edited 1 time(s). Last edit at 06/21/2015 08:11PM by L4nce0.

|

Re: Prusa i3 Z axis problems help January 06, 2016 07:01AM |

Registered: 8 years ago Posts: 11 |

I know this thread is old, but I would like feedback on this idea. I wonder if a simple fix is to join the two leadscrews with a gt2 belt and pulleys, leaving both motors. This would force them into synch, give the power of two motors. I would add bearings on the top plates for the threaded rod, add pulleys on each rod and a tensioner and a belt.

Thoughts....

Thoughts....

|

Re: Prusa i3 Z axis problems help January 06, 2016 10:17PM |

Registered: 9 years ago Posts: 705 |

|

Re: Prusa i3 Z axis problems help January 06, 2016 11:59PM |

Registered: 8 years ago Posts: 11 |

|

Re: Prusa i3 Z axis problems help January 07, 2016 06:24AM |

Registered: 9 years ago Posts: 1,873 |

One should be plenty, the lead screw provides plenty of mechanical advantage, and there's little benefit to rapidly accelerating the Z axis. On the other hand, if you are starting with two motors already there, I'm not sure that there is a huge advantage from removing one of them, except that you'd have it as a spare or could use it in another project. I'm using a single Z motor with a fairly heavy X axis and not feeling the need for more power there.

|

Re: Prusa i3 Z axis problems help January 07, 2016 01:50PM |

Registered: 8 years ago Posts: 200 |

|

Re: Prusa i3 Z axis problems help January 07, 2016 04:05PM |

Registered: 8 years ago Posts: 11 |

|

Re: Prusa i3 Z axis problems help January 07, 2016 04:10PM |

Registered: 9 years ago Posts: 1,873 |

Sorry, only registered users may post in this forum.