Calculate torque to move printer components / microstepping

Posted by Crowner

|

Calculate torque to move printer components / microstepping June 16, 2015 06:58PM |

Registered: 8 years ago Posts: 2 |

Hi,

I want to build a big printer (print head around 4kg, 600mm travelling distance, 300mm/s travelling speed) and therefore did a couple of calculations to determine the required torque for the stepper motors. If anybody knows of a similar project, please let me know. Im planning to use a Rack & Pinion or ball screw ball mechanism (Not sure about belts because of the high loads?) To check my calculations i tried to determine the torque required for the most common RepRap printers.

To keep things simple, I started with a mass of 0.7 kg for the Extruder. The force required to accelerate this mass (using a= 5000mm/s²) would be F=m*a =0.7*5=3.5 N. Using a pulley with 14 mm Diameter, the required torque would be M=F*d/2 =3.5*0.007=2.45 Ncm.

Most of the NEMA 17 motors used, have 50 Ncm or more, so around 25x as much as calculated, or am I overlooking sth? (To simplify the calculations i didnt take into account pulley and rotor intertia).

I do have some friction, but how does it come that the motors are so much bigger than expected?

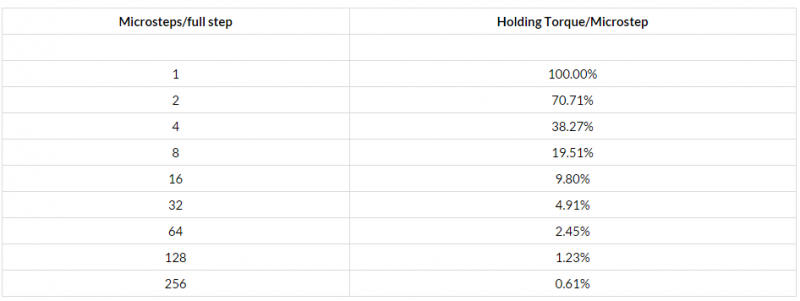

The other question i have is to what extend micro stepping is used to attain the desired resolution for reprap printers and how well does it work? I wanted my printer to be direct driven, but i cant get to my required resolution (0.1mm) using full steps. But people discouraged me to use micro stepping because there wouldnt be a significant gain in accuracy especially at high loads and i would loose a lot of torque. (i read about drivers who compensate the current loss by adding more current to the right coil, but couldn't find them getting used anywhere ). There are also a couple of articles like this one here: [www.micromo.com]

Or is the reason for the oversized motors of the repraps the loss in torque through microstepping? With 1/16 microstepping there would be only 10% of the initial torque left, what would explain the big torque values of the NEMA 17 motors.

I would be really glad if somebody could answer those questions because i have been searching on the net for a while and could only find general information.

Thanks a lot!

I want to build a big printer (print head around 4kg, 600mm travelling distance, 300mm/s travelling speed) and therefore did a couple of calculations to determine the required torque for the stepper motors. If anybody knows of a similar project, please let me know. Im planning to use a Rack & Pinion or ball screw ball mechanism (Not sure about belts because of the high loads?) To check my calculations i tried to determine the torque required for the most common RepRap printers.

To keep things simple, I started with a mass of 0.7 kg for the Extruder. The force required to accelerate this mass (using a= 5000mm/s²) would be F=m*a =0.7*5=3.5 N. Using a pulley with 14 mm Diameter, the required torque would be M=F*d/2 =3.5*0.007=2.45 Ncm.

Most of the NEMA 17 motors used, have 50 Ncm or more, so around 25x as much as calculated, or am I overlooking sth? (To simplify the calculations i didnt take into account pulley and rotor intertia).

I do have some friction, but how does it come that the motors are so much bigger than expected?

The other question i have is to what extend micro stepping is used to attain the desired resolution for reprap printers and how well does it work? I wanted my printer to be direct driven, but i cant get to my required resolution (0.1mm) using full steps. But people discouraged me to use micro stepping because there wouldnt be a significant gain in accuracy especially at high loads and i would loose a lot of torque. (i read about drivers who compensate the current loss by adding more current to the right coil, but couldn't find them getting used anywhere ). There are also a couple of articles like this one here: [www.micromo.com]

Or is the reason for the oversized motors of the repraps the loss in torque through microstepping? With 1/16 microstepping there would be only 10% of the initial torque left, what would explain the big torque values of the NEMA 17 motors.

I would be really glad if somebody could answer those questions because i have been searching on the net for a while and could only find general information.

Thanks a lot!

|

Re: Calculate torque to move printer components / microstepping June 17, 2015 02:31AM |

Registered: 8 years ago Posts: 5,232 |

50Ncm is the holding torque?

Microstepping helps the rotor to "lean in the right direction". Then only a small push is necessary to tick in the next position.

The reason for such big steppers is, that the mass isn´t standing still but is often moving in the opposite direction. This adds a lot of inertia.

-Olaf

Edited 3 time(s). Last edit at 06/17/2015 02:54AM by o_lampe.

Microstepping helps the rotor to "lean in the right direction". Then only a small push is necessary to tick in the next position.

The reason for such big steppers is, that the mass isn´t standing still but is often moving in the opposite direction. This adds a lot of inertia.

-Olaf

Edited 3 time(s). Last edit at 06/17/2015 02:54AM by o_lampe.

|

Re: Calculate torque to move printer components / microstepping June 17, 2015 05:41AM |

Registered: 8 years ago Posts: 2 |

|

Re: Calculate torque to move printer components / microstepping June 17, 2015 09:14AM |

Registered: 11 years ago Posts: 5,780 |

I have used http://www.orientalmotor.com/support/motor-sizing.html to calculate stepper motor torque required for my printer.

|

Re: Calculate torque to move printer components / microstepping June 17, 2015 09:24AM |

Registered: 9 years ago Posts: 1,873 |

Interesting questions. I took the motor recommendations on faith without looking at the math. I'm guessing that the sizes used have been found to work well in practice. Connecting up the logic would suggest that the apparent over-spec correlates with several factors: reduced per-step torque due to micro-stepping, most motors are run well under spec to avoid heat problems, missed steps are really bad for 3d printing, so you want to have a good margin of safety to avoid them.

|

Re: Calculate torque to move printer components / microstepping June 17, 2015 10:51AM |

Registered: 11 years ago Posts: 5,780 |

The OP intends to build a machine with a 4kg extruder carriage and expects to run it at 300mm/sec. He has to do the math...

My machine has a ball screw in the Y axis. I don't recall exact numbers I used, but moving mass was close to 2 kg, and I spec'd it for 1000mm/sec^2 acceleration with print speed of 50 mm/sec and positioning accuracy of 0.01 mm. That led to a final torque of about 380 oz-in. I use a 425 oz-in motor with a DSP driver and 32V power supply and it performs as intended.

My machine has a ball screw in the Y axis. I don't recall exact numbers I used, but moving mass was close to 2 kg, and I spec'd it for 1000mm/sec^2 acceleration with print speed of 50 mm/sec and positioning accuracy of 0.01 mm. That led to a final torque of about 380 oz-in. I use a 425 oz-in motor with a DSP driver and 32V power supply and it performs as intended.

|

Re: Calculate torque to move printer components / microstepping June 17, 2015 11:24AM |

Registered: 8 years ago Posts: 5,232 |

Quote

Crowner

Thanks for the answer, 50 Ncm is the holding torque but at 400 rpm i still have 80% of the holding torque. And a mass changing direction would first decelarate and then accelerate as calculated above, why would that require more torque?

Isn´t it the deceleration that requires so much torque? Because you want to decelerate with the same value "a= 5000mm/s²)

But now the virtual mass is much bigger, due to the speed?

Ignore me, I´m just thinking out loud, what my gutts tell me

-Olaf

|

Re: Calculate torque to move printer components / microstepping June 17, 2015 11:54AM |

Registered: 11 years ago Posts: 335 |

Anyone who claims that microstepping materially decreases motor torque is incorrect. Hobbiysts misunderstood the following chart (confusing incremental torque for stall torque) and the idea has refused to die for years.

[www.micromo.com]

It is pretty obvious that running 1/16 steps does not reduce your torque by 90% or nobody would do it. Many high-end stepper drivers have a fixed microstep count (Ex: Gecko) which would also not be a case if there were major drawbacks to using microstepping.

The high motor torque you have calculated is the result of specifying an unrealistic accleration (5m/s^2). Most printers are sub 1m/s^2.

Note that high acceleration will apply massive forces to the frame under acceleration. At 0.5G you will be seeing 20N on the frame which is likely to bend it enough to influence print quality.

I would recommend belts or rack and pinion over ball screws. A ball screw is very difficult to accelerate since it is attached pre-reduction. If you do the math, a few grams of ballscrew adds the same inertia as several hundred grams on the carriage.

There are belt driven systems that can hold 0.01mm under large loads but you need to put them under a lot of tension. Stratasys uses the H-Bot belt path in most of their machines, I think the 900mc has fast travel ballscrews.

Edited 2 time(s). Last edit at 06/17/2015 11:56AM by 691175002.

[www.micromo.com]

It is pretty obvious that running 1/16 steps does not reduce your torque by 90% or nobody would do it. Many high-end stepper drivers have a fixed microstep count (Ex: Gecko) which would also not be a case if there were major drawbacks to using microstepping.

The high motor torque you have calculated is the result of specifying an unrealistic accleration (5m/s^2). Most printers are sub 1m/s^2.

Note that high acceleration will apply massive forces to the frame under acceleration. At 0.5G you will be seeing 20N on the frame which is likely to bend it enough to influence print quality.

I would recommend belts or rack and pinion over ball screws. A ball screw is very difficult to accelerate since it is attached pre-reduction. If you do the math, a few grams of ballscrew adds the same inertia as several hundred grams on the carriage.

There are belt driven systems that can hold 0.01mm under large loads but you need to put them under a lot of tension. Stratasys uses the H-Bot belt path in most of their machines, I think the 900mc has fast travel ballscrews.

Edited 2 time(s). Last edit at 06/17/2015 11:56AM by 691175002.

|

Re: Calculate torque to move printer components / microstepping June 17, 2015 12:04PM |

Registered: 9 years ago Posts: 1,873 |

Sorry, only registered users may post in this forum.