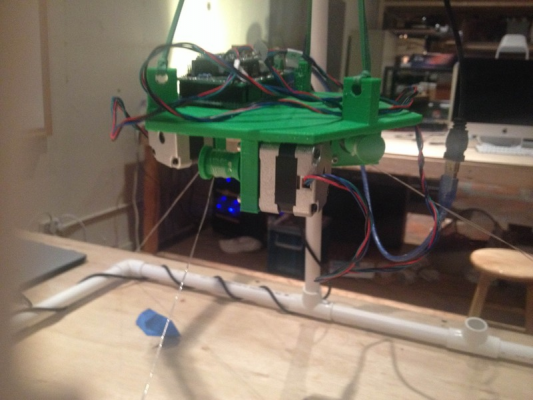

New Delta Printer - Look Ma, no rails!

Posted by LoboCNC

|

Re: New Delta Printer - Look Ma, no rails! July 13, 2015 07:44PM |

Registered: 10 years ago Posts: 564 |

One last modification for the time being: When I increased the spring force on the tension post, I started to see some wear in the fishing lines after a few hours of printing. I also noticed a slight degradation of the print surface finish due to the increased friction. Rather than go to pulleys (like a sensible person), I ran the fishing line thru a PTFE sleeve at every point where it slides over an eyelet. This has certainly reduced the wear on the fishing line (as well as the friction), but it's hard to tell how much wear there is on the PTFE. However, it's pretty easy to slide the PFTE sleeve over by 1mm every so often so that a new section starts to wear. I should be able to do this several dozen times, if necessary, before having to put in new pieces of sleeving altogether.

You'll also notice that I got rid of the guitar tuners, which I rather liked. They stuck out too far, and too many people wanted to twiddle them. The new system of winding up the slack at the fixed ends on a 4-40 screw doesn't allow for quite as much take-up, and it doesn't offer as hi-res tweaking, but it is good enough on both counts.

You'll also notice that I got rid of the guitar tuners, which I rather liked. They stuck out too far, and too many people wanted to twiddle them. The new system of winding up the slack at the fixed ends on a 4-40 screw doesn't allow for quite as much take-up, and it doesn't offer as hi-res tweaking, but it is good enough on both counts.

|

Re: New Delta Printer - Look Ma, no rails! July 14, 2015 03:30AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: New Delta Printer - Look Ma, no rails! July 14, 2015 10:37AM |

Registered: 10 years ago Posts: 564 |

Quote

o_lampe

I remember you have a ball shaped end on the tension post to the effector. There is some friction for sure?

Would you consider using a needle pin design centered in a dent of a hard plate?

-Olaf

Right now I've got a 0.375" dia nylon ball in a printed PLA socket. The socket needs to be pretty deep to accommodate the range of motion without popping out, so I thing you'd need more than a needle, but perhaps a smaller ball. Most of the friction, however, is from the fishing lines dragging over the eyelets. This is now greatly reduced with the PTFE sleeves.

|

Re: New Delta Printer - Look Ma, no rails! July 14, 2015 12:58PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: New Delta Printer - Look Ma, no rails! July 19, 2015 11:54AM |

Registered: 9 years ago Posts: 3 |

Actually this is a really really elegant solution! I really like it, I would love to try it out, maybe in a few weeks I can build a motion testing platform.

My only doubt is:

Why you say you loose resolution with longer lines? I can't catch that part of the deal. Also, rubber has a funny way to apply tension, if you use springs the tension will be more uniform. maybe that helps.

My only doubt is:

Why you say you loose resolution with longer lines? I can't catch that part of the deal. Also, rubber has a funny way to apply tension, if you use springs the tension will be more uniform. maybe that helps.

|

Re: New Delta Printer - Look Ma, no rails! July 19, 2015 12:43PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: New Delta Printer - Look Ma, no rails! July 19, 2015 12:50PM |

Registered: 10 years ago Posts: 564 |

Quote

echenlon

Actually this is a really really elegant solution! I really like it, I would love to try it out, maybe in a few weeks I can build a motion testing platform.

My only doubt is:

Why you say you loose resolution with longer lines? I can't catch that part of the deal. Also, rubber has a funny way to apply tension, if you use springs the tension will be more uniform. maybe that helps.

Thanks! Regarding resolution, in a Cartesian-type printer, the amount each motor has to move in order to move, say, 1mm is the same, independent of where you are in the workspace. In a non-Cartesian system like this, you have to solve non-linear equations to determine the motor positions from your XYZ coordinates. If you are at the top of the workspace, moving 1mm in the X direction might require Motor1 to move 150 steps. When you are at the bottom of the work space, with all the strings extended, moving 1mm might require Motor1 to only move 50 steps. As the 3 sets of strings become closer to parallel to each other, the number of steps becomes so coarse that you'll get significant errors in your print.

Regarding the springs, I agree - using metal springs will provide a more uniform tension. I started using silicone rubber tubing because I needed to experiment with lots of different spring lengths, and it's a lot easier to adjust the lengths with the tubing. I should go back and measure my rubber spring constant and replace them with metal springs. In my first version, the springs changed length quite a bit and this would be much more important. I the current design, though, the lengths remain more constant, so using more "linear" springs is not as important.

|

Re: New Delta Printer - Look Ma, no rails! July 20, 2015 01:53AM |

Registered: 11 years ago Posts: 364 |

|

Re: New Delta Printer - Look Ma, no rails! July 20, 2015 07:51AM |

Registered: 9 years ago Posts: 3 |

Quote

LoboCNC

Quote

echenlon

Actually this is a really really elegant solution! I really like it, I would love to try it out, maybe in a few weeks I can build a motion testing platform.

My only doubt is:

Why you say you loose resolution with longer lines? I can't catch that part of the deal. Also, rubber has a funny way to apply tension, if you use springs the tension will be more uniform. maybe that helps.

Thanks! Regarding resolution, in a Cartesian-type printer, the amount each motor has to move in order to move, say, 1mm is the same, independent of where you are in the workspace. In a non-Cartesian system like this, you have to solve non-linear equations to determine the motor positions from your XYZ coordinates. If you are at the top of the workspace, moving 1mm in the X direction might require Motor1 to move 150 steps. When you are at the bottom of the work space, with all the strings extended, moving 1mm might require Motor1 to only move 50 steps. As the 3 sets of strings become closer to parallel to each other, the number of steps becomes so coarse that you'll get significant errors in your print.

Regarding the springs, I agree - using metal springs will provide a more uniform tension. I started using silicone rubber tubing because I needed to experiment with lots of different spring lengths, and it's a lot easier to adjust the lengths with the tubing. I should go back and measure my rubber spring constant and replace them with metal springs. In my first version, the springs changed length quite a bit and this would be much more important. I the current design, though, the lengths remain more constant, so using more "linear" springs is not as important.

My bad, just now I realized how the physics wrk, it's like changing the length of the effectors on a delta, and the angle gets all wired. Anyway, if you enlarge the top and bottom pates proportional to the height the angles should keep consistent, instead of being a delta printer that can be as talla s you want, this has to keep a proportion.

Anyway, it's a cool design, I already have some ideas of how to make it my way, for sure I will upload some pictures. just be patient.

can you post a drawing or maybe a photo of that side bowden extruder you are using on the last video? that also seemed to be something interesting, but I was trying to figure out something more like this extruder on this video [www.youtube.com] witch I believe for that design is really good. (I don't care about the music, but there you can see that bowden really clear how it hangs in there)

Keep going! and thanks for sharing!

|

Re: New Delta Printer - Look Ma, no rails! July 20, 2015 12:53PM |

Registered: 10 years ago Posts: 564 |

Quote

ekaggrat

super cool... What firmware are you using?

I am using Marlin set up for a Delta printer, but I had to modify the calculate_delta() function in Marlin_main.cpp as shown below. In Configuration.h, the parameter DELTA_DIAGONAL_ROD is normally the fixed length of the pivoting arms. In my implementation DELTA_DIAGONAL_ROD should be set to the initial length of the diagonal strings when the carriage is at the zero position.

void calculate_delta(float cartesian[3])

{

float z_squared;

z_squared = sq(delta_z0 - cartesian[Z_AXIS]);

delta[X_AXIS] = sqrt( z_squared +

sq(-cartesian[X_AXIS]-delta_tower1_x) +

sq(-cartesian[Y_AXIS]-delta_tower1_y)

) - delta_diagonal_rod;

delta[Y_AXIS] = sqrt( z_squared +

sq(-cartesian[X_AXIS]-delta_tower2_x) +

sq(-cartesian[Y_AXIS]-delta_tower2_y)

) - delta_diagonal_rod;

delta[Z_AXIS] = sqrt( z_squared +

sq(-cartesian[X_AXIS]-delta_tower3_x) +

sq(-cartesian[Y_AXIS]-delta_tower3_y)

) - delta_diagonal_rod;

}

|

Re: New Delta Printer - Look Ma, no rails! July 21, 2015 04:06AM |

Registered: 9 years ago Posts: 1,035 |

I have to congratulate you, this is fantastic work.

Regarding the possibility to increase the XY printable surface instead of Z would actually work better for me and I guess for many other folks because most of the printed parts that I can think of should be printed horizontally for best strength. This is why I was all in with SCARA but your simple and effective design might change my mind. Please keep the iterations going and very soon you'll have many folks building and testing your design, which would only increase the speed of improving.

Again, mind blowing simplicity. If Morgan won a competition for a scara design this one should win one for the Deltas.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Regarding the possibility to increase the XY printable surface instead of Z would actually work better for me and I guess for many other folks because most of the printed parts that I can think of should be printed horizontally for best strength. This is why I was all in with SCARA but your simple and effective design might change my mind. Please keep the iterations going and very soon you'll have many folks building and testing your design, which would only increase the speed of improving.

Again, mind blowing simplicity. If Morgan won a competition for a scara design this one should win one for the Deltas.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: New Delta Printer - Look Ma, no rails! July 21, 2015 07:57AM |

Registered: 11 years ago Posts: 364 |

|

Re: New Delta Printer - Look Ma, no rails! July 21, 2015 04:17PM |

Registered: 12 years ago Posts: 4 |

Very clever design!

Two comments on the ball joint/Extruder location:

1.) Could you make a "virtual ball joint" by making a U-Joint with a large yoke - I guess you could call it a gimbal - that fits over and around the extruder head? Where the axes cross would be your center of rotation, and it should be able to be made quite low.

Perhaps using the top half of the blue frame, along with the full green ring, and mount the extruder head in the center of the inner gray ring.

2.) Going to a bowden style extruder, could you send the filament down through the single preload tube, right through the ball socket? Perhaps the preload tube could be a pushrod tube and the socket could be the mating socket from a lifter?

Alternately, I wonder if anyone has used 6 pushrods to make a more traditional delta machine. Could be a fun use for old pushrods, as they should be consistent in length, and are magnetic so they would work with magnetic sockets.

Just a couple more crazy ideas.

Keith

Two comments on the ball joint/Extruder location:

1.) Could you make a "virtual ball joint" by making a U-Joint with a large yoke - I guess you could call it a gimbal - that fits over and around the extruder head? Where the axes cross would be your center of rotation, and it should be able to be made quite low.

Perhaps using the top half of the blue frame, along with the full green ring, and mount the extruder head in the center of the inner gray ring.

2.) Going to a bowden style extruder, could you send the filament down through the single preload tube, right through the ball socket? Perhaps the preload tube could be a pushrod tube and the socket could be the mating socket from a lifter?

Alternately, I wonder if anyone has used 6 pushrods to make a more traditional delta machine. Could be a fun use for old pushrods, as they should be consistent in length, and are magnetic so they would work with magnetic sockets.

Just a couple more crazy ideas.

Keith

|

Re: New Delta Printer - Look Ma, no rails! July 22, 2015 10:23AM |

Registered: 10 years ago Posts: 564 |

|

Re: New Delta Printer - Look Ma, no rails! July 23, 2015 02:52PM |

Registered: 12 years ago Posts: 4 |

Regarding the tight bend radius of the line and using teflon tubing, could you instead just increase the radius over which the line travels?

There are all kinds of low cost guides for thread and sewing machines. Perhaps a ceramic thread guide similar to this would work:

It would create a large radius for the line, is very wear resistant, is cheap, and could be popped into a hole in the plate, perhaps one top and bottom of the plate. Concept image attached.

Even better may be putting a notch (1/2 a hole) in the side of the plate and installing one of these:

The line would be easy to run, and the plate still easy to make. The motors could be mounted from the bottom of the plate, and the spool on the motor shaft could stick up above the plate.

Perhaps some eyelet style ceramic loops could be used at the print head platform. Envision some slots in the hexagonal plate, and in each slot could be one of these:

inserted so only the loop stuck up through the hexagonal plate so the tension in the line would keep it in place. Some adhesive or a clamp from the bottom would also be a good idea.

I suppose this same trick could be used with some steel wire as well, or even a single wrap torsion spring.

Keith

There are all kinds of low cost guides for thread and sewing machines. Perhaps a ceramic thread guide similar to this would work:

It would create a large radius for the line, is very wear resistant, is cheap, and could be popped into a hole in the plate, perhaps one top and bottom of the plate. Concept image attached.

Even better may be putting a notch (1/2 a hole) in the side of the plate and installing one of these:

The line would be easy to run, and the plate still easy to make. The motors could be mounted from the bottom of the plate, and the spool on the motor shaft could stick up above the plate.

Perhaps some eyelet style ceramic loops could be used at the print head platform. Envision some slots in the hexagonal plate, and in each slot could be one of these:

inserted so only the loop stuck up through the hexagonal plate so the tension in the line would keep it in place. Some adhesive or a clamp from the bottom would also be a good idea.

I suppose this same trick could be used with some steel wire as well, or even a single wrap torsion spring.

Keith

|

Re: New Delta Printer - Look Ma, no rails! July 23, 2015 07:59PM |

Registered: 10 years ago Posts: 564 |

Keith, excellent suggestion with the thread guides for sewing machines. The tiniest ones might work pretty well. The only thing I'm worried about is that kinematic equations assume that the ends of the strings pivot about a single fixed point, as with a ball & socket joint. With any finite sized eyelet, though, the length of the string path changes slightly with the angle of the string. My gut feeling is that these deviations are insignificant for very small eyelets very tight bend radii (so that the toroidal surface of the eyelet approximates a ball & socket joint), but I don't have a feel for how big the eyelet hole or the eyelet radius can get before you start seeing errors in your print.

|

Re: New Delta Printer - Look Ma, no rails! July 24, 2015 07:30AM |

Registered: 11 years ago Posts: 364 |

this motor would be perfect for your extruder... weighs only 70 gms.. has a pull in torque of 3.5-4 kgcm with a ratio of 1:45 which is good enough for 1.75mm filament.. only downside is the shaft is 4mm

|

Re: New Delta Printer - Look Ma, no rails! July 24, 2015 04:48PM |

Registered: 10 years ago Posts: 564 |

|

Re: New Delta Printer - Look Ma, no rails! July 24, 2015 09:19PM |

Registered: 11 years ago Posts: 364 |

it is made by moons a chinese manufacturer and has no part number ... it is only available on taobao.. If you need my help to get it i can buy it for you and mail it to you...

taobao link

taobao link

|

Re: New Delta Printer - Look Ma, no rails! July 26, 2015 04:21PM |

Registered: 10 years ago Posts: 564 |

I just recently got some e-mail from Daniel Kunkel (tridprinting.com) who built a very similar delta printer back in February. It looks like I stumbled onto some of the very same solutions that he had come up with. He's even got a RepRap Wiki page: [reprap.org]

and some videos posted: [youtu.be]

and a pretty active discussion going on google groups: [groups.google.com]

Note that his SkyDelta printer is different from Brandon Heller's SkyDelta, although both are cable driven.

Daniel's SkyDelta looks to me somewhat more industrial than my printer, and may be of more interest to those following this thread who are interested in making really big printers.

and some videos posted: [youtu.be]

and a pretty active discussion going on google groups: [groups.google.com]

Note that his SkyDelta printer is different from Brandon Heller's SkyDelta, although both are cable driven.

Daniel's SkyDelta looks to me somewhat more industrial than my printer, and may be of more interest to those following this thread who are interested in making really big printers.

|

Re: New Delta Printer - Look Ma, no rails! July 26, 2015 06:30PM |

Registered: 10 years ago Posts: 1 |

First, hats off to Jeffrey... First for having a genius idea for a printer that is SUPER-SCALABLE, especially one including the super-gravity pole being tied directly to counterweight the motors, and second for doing a great job publicizing it. I think this design will be widely used for very large printers in the years to come.

There are quite a few issues worth discussing... Here's a start.

Line Choice

Various forms of Spectra line seem to be a much better choice than fishing line for their resistance to stretching.

Calibration

Jeffrey mentioned he really did not setup an exacting calibration technique. I have developed a technique using multi-variable minimization from z-probing. This allows for some really interesting possibilities including resetting the zero point of your bed to most any position on your bed. Alas, it's not bulletproof yet and I think I know why.

Super Gravity Pole

Standard springs work great for holding the tension of the super gravity pole. In our design, we used a dual motor with aluminum spools on each side for winding the string from the effector, and a single line with a spring going to the top of the super gravity pole. It works great!

Eyelets

So it turns out there can be a small radius error that is introduced in simple versions of these printers when using a rounded anchor point. It turns out that this error can cancelling the effect by using another anchor point.

Daniel - [www.TriDPrinting.com]

Daniel - [www.TriDPrinting.com]

There are quite a few issues worth discussing... Here's a start.

Line Choice

Various forms of Spectra line seem to be a much better choice than fishing line for their resistance to stretching.

Calibration

Jeffrey mentioned he really did not setup an exacting calibration technique. I have developed a technique using multi-variable minimization from z-probing. This allows for some really interesting possibilities including resetting the zero point of your bed to most any position on your bed. Alas, it's not bulletproof yet and I think I know why.

Super Gravity Pole

Standard springs work great for holding the tension of the super gravity pole. In our design, we used a dual motor with aluminum spools on each side for winding the string from the effector, and a single line with a spring going to the top of the super gravity pole. It works great!

Eyelets

So it turns out there can be a small radius error that is introduced in simple versions of these printers when using a rounded anchor point. It turns out that this error can cancelling the effect by using another anchor point.

Daniel - [www.TriDPrinting.com]

Daniel - [www.TriDPrinting.com]

|

Re: New Delta Printer - Look Ma, no rails! September 10, 2015 08:38AM |

Registered: 8 years ago Posts: 1 |

|

Re: New Delta Printer - Look Ma, no rails! October 05, 2015 11:24AM |

Registered: 12 years ago Posts: 4 |

I just saw this crazy motion simulator:

[www.youtube.com]

I know it is much more complexity with 8 winches, but I thought it may inspire more ideas.

Keith

[www.youtube.com]

I know it is much more complexity with 8 winches, but I thought it may inspire more ideas.

Keith

|

Re: New Delta Printer - Look Ma, no rails! October 05, 2015 12:44PM |

Registered: 10 years ago Posts: 564 |

Quote

NEATman

I just saw this crazy motion simulator:

[www.youtube.com]

I know it is much more complexity with 8 winches, but I thought it may inspire more ideas.

Keith

To hell with 3D printing - I want one of those!

|

Re: New Delta Printer - Look Ma, no rails! October 09, 2015 09:13PM |

Registered: 12 years ago Posts: 22 |

So I am working on a sort of inverted version of this. It shortens in the downward direction instead of upwards and has rubber bands pulling it upwards instead of pushing down.

It's still in the rough draft form so ignore some of the obvious problems in this design for now. I am going to work those out once I get the kinematics problem resolved.

Would these inverse kinematics work for my design if I multiplied the motion of the steppers by -1? What would I need to change here to adapt this modification of inverse kinematics in marlin to work with my machine? Any chance of getting someone to break this math down to me?

It's still in the rough draft form so ignore some of the obvious problems in this design for now. I am going to work those out once I get the kinematics problem resolved.

Would these inverse kinematics work for my design if I multiplied the motion of the steppers by -1? What would I need to change here to adapt this modification of inverse kinematics in marlin to work with my machine? Any chance of getting someone to break this math down to me?

|

Re: New Delta Printer - Look Ma, no rails! October 10, 2015 01:21AM |

Registered: 10 years ago Posts: 564 |

Quote

Linkreincarnate

So I am working on a sort of inverted version of this. It shortens in the downward direction instead of upwards and has rubber bands pulling it upwards instead of pushing down.

It's still in the rough draft form so ignore some of the obvious problems in this design for now. I am going to work those out once I get the kinematics problem resolved.

Would these inverse kinematics work for my design if I multiplied the motion of the steppers by -1? What would I need to change here to adapt this modification of inverse kinematics in marlin to work with my machine? Any chance of getting someone to break this math down to me?

It looks like you've only got 3 strings pulling the carriage downward against the rubber bands. This type of configuration does not constrain the orientation of the carriage. It will eventually settle into a minimum energy orientation against the rubber bands, but any motion will cause it to wobble all over. To kinematically constrain the carriage properly, you need 6 strings of known length pulling on the carriage - very similar to the 6 arms on a standard delta-style printer.

|

Re: New Delta Printer - Look Ma, no rails! October 10, 2015 01:02PM |

Registered: 10 years ago Posts: 401 |

Wow Linkreincarnate! Check out my Hangprinter on my blog. My firmware over at [github.com] has all the kinematics sorted out...

torbjornludvigsen.com

torbjornludvigsen.com

|

Re: New Delta Printer - Look Ma, no rails! October 10, 2015 05:53PM |

Registered: 12 years ago Posts: 22 |

|

Re: New Delta Printer - Look Ma, no rails! October 10, 2015 06:07PM |

Registered: 10 years ago Posts: 564 |

Quote

Linkreincarnate

Ok Thanks I kinda knew that but I've been putting off a redesign until I get it running as expected. Are there any rules about how they are constrained? I really want to keep the spools on the top and anchored to the bottom so I can put this in different sized frames.

Yes, there are very specific rules for fully constraining objects in space. In this case, the print head in space has 6 degrees of freedom (DOF), and each string provides a 1 DOF constraint. Therefore, you need 6 strings to to fully constrain the print head. Things get more complicated when you get near singularities which are configurations where 2 strings end up close to lying along the same line.

The clever thing about the delta printer style configuration is that you really want to just control the XYZ motion and you want the orientations fixed, and the 3 parallel rails with the 3 sets of parallel arms do just that. You really want to do the same thing with a string printer - operate pairs of strings together and make sure that the pairs of strings are always exactly parallel. There are all sorts of other ways to configure the strings, but the math can get really complicated for these more general approaches.

|

Re: New Delta Printer - Look Ma, no rails! October 10, 2015 10:53PM |

Registered: 12 years ago Posts: 22 |

Sorry, only registered users may post in this forum.