Nozzle sealing

Posted by leadinglights

|

Nozzle sealing July 23, 2015 07:18AM |

Registered: 12 years ago Posts: 1,450 |

What is the best method of sealing a screw on brass nozzle from leaking around the threads?

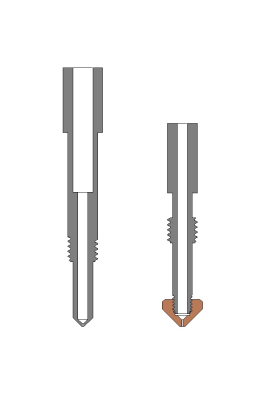

Further info:- I have previously made the nozzles for my 4 printers as on the section on the left in the drawing below. My next printer will have 5 or more hot ends and quick changing of the whole hot end is no longer a viable option so I have opted to use a more standard threaded nozzle as shown on the right

Thanks for any input,

Mike.

Further info:- I have previously made the nozzles for my 4 printers as on the section on the left in the drawing below. My next printer will have 5 or more hot ends and quick changing of the whole hot end is no longer a viable option so I have opted to use a more standard threaded nozzle as shown on the right

Thanks for any input,

Mike.

|

Re: Nozzle sealing July 23, 2015 07:31AM |

Registered: 9 years ago Posts: 977 |

|

Re: Nozzle sealing July 23, 2015 08:40AM |

Registered: 12 years ago Posts: 1,450 |

To cover a wide range of materials I need a maximum temperature as high as I can get it, or at least 300C which precludes PTFE tape. With the coefficients of expansion of brass at 18ppm and stainless steel at 17.3ppm I don't think that the joint would be reliably self sealing.

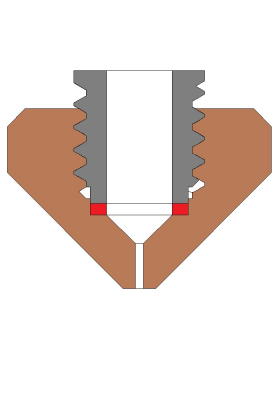

Has anybody used a soft metal gasket as marked in red in the drawing below.

The best material for this would be 24kt gold, but I think you can understand my reticence to use that here.

Mike.

Has anybody used a soft metal gasket as marked in red in the drawing below.

The best material for this would be 24kt gold, but I think you can understand my reticence to use that here.

Mike.

|

Re: Nozzle sealing July 23, 2015 10:51AM |

Registered: 9 years ago Posts: 977 |

If you really want to use a ring seal as in your latest diagram, then a simple copper ring would work fine imho. And these are available just about anywhere in standard sizes and very inexpensive too.

However, I still believe that heat expansion of the steel/brass thread joint will probably provide a good enough seal for the relatively viscous molten filament - I mean, we are not talking about a gas tight seal here.

Again, a simple 10 minutes test would demonstrate whether I am right or wrong.

However, I still believe that heat expansion of the steel/brass thread joint will probably provide a good enough seal for the relatively viscous molten filament - I mean, we are not talking about a gas tight seal here.

Again, a simple 10 minutes test would demonstrate whether I am right or wrong.

|

Re: Nozzle sealing July 23, 2015 11:16AM |

Admin Registered: 16 years ago Posts: 13,886 |

... for UHV sealing we regularly used aluminium rings ... gold rings only for special problems, where the costs were negligible

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Nozzle sealing July 23, 2015 11:21AM |

Registered: 12 years ago Posts: 1,450 |

Thanks Andrew, I didn't know that copper ring seals were available: Can you tell me of any stockists of small ones in small quantities? The reason that I am getting a bit paranoid is that with 5 or more hot ends something like 5 times the opportunity exists for something to leak.

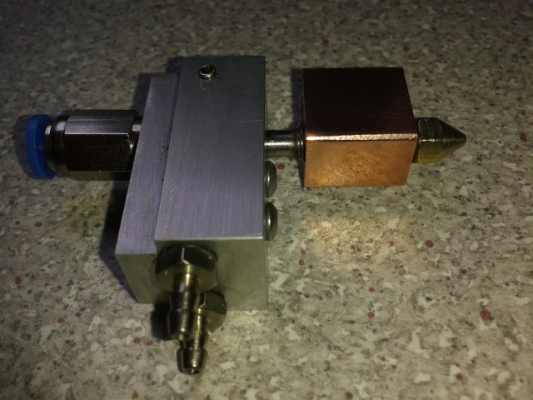

Picture below of one of the hot end assemblies.

Mike

Picture below of one of the hot end assemblies.

Mike

|

Re: Nozzle sealing July 23, 2015 11:34AM |

Registered: 12 years ago Posts: 1,450 |

|

Re: Nozzle sealing July 23, 2015 01:47PM |

Registered: 9 years ago Posts: 977 |

I bought 10 small copper sealing rings at a local hardware store here in Barcelona, Spain, a few weeks ago. They had them in various sizes, and unit cost was about $0.20. As Viktor wrote above, failing copper, you could use aluminum rings, I don't think it would make any difference in your particular application and cost should be about the same. However, I would expect aluminum rings to be a little bit harder to find.

|

Re: Nozzle sealing July 23, 2015 01:51PM |

Admin Registered: 16 years ago Posts: 13,886 |

... here's a check at ebay Germany - should be the same at your location too:

[www.ebay.de]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[www.ebay.de]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Nozzle sealing July 30, 2015 12:30PM |

Registered: 12 years ago Posts: 1,450 |

Thanks AndrewBCN and VDX. Unfortunately the size of 'O' rings that I wanted were not available on any web site I could find. 3mm OD, 2mm ID is about half the size of their smallest so I had to make my own. Cut from K&S tubing with a 22mm circular saw blade in a Proxxon micromot mounted in a 10" lathe. Cut to 0.6mm lengths in both copper and aluminium - the copper is annealed to dead soft just before installation. Initial trials show they seal don't leak with 200kPa of air pressure.

Metal 'O' rings compared to a U.K. 5p coin.

Mike

Metal 'O' rings compared to a U.K. 5p coin.

Mike

|

Re: Nozzle sealing July 30, 2015 12:47PM |

Registered: 9 years ago Posts: 977 |

Sorry, only registered users may post in this forum.