A practical 10 Cents Ceramic tube hotend

Posted by beyondwind

|

A practical 10 Cents Ceramic tube hotend July 28, 2015 04:42PM |

Registered: 8 years ago Posts: 1 |

Details and instructions:

[beyondwind.duckdns.org]

Youtube video demo:

[youtu.be]

Edited 1 time(s). Last edit at 07/29/2015 01:25AM by beyondwind.

|

Re: A practical 10 Cents Ceramic tube hotend July 28, 2015 04:56PM |

Registered: 8 years ago Posts: 396 |

thats funny.

I actually came up with this same approach, using the ceramic fuse, but didn't get as far as you did with the implementation. The tube is too big for my 1.75 filament.

fixed your video link:

[www.youtube.com]

but that's only the first few layers in the video. would like to see what happens after a more lengthy print...

Edited 1 time(s). Last edit at 07/28/2015 04:58PM by thetazzbot.

I actually came up with this same approach, using the ceramic fuse, but didn't get as far as you did with the implementation. The tube is too big for my 1.75 filament.

fixed your video link:

[www.youtube.com]

but that's only the first few layers in the video. would like to see what happens after a more lengthy print...

Edited 1 time(s). Last edit at 07/28/2015 04:58PM by thetazzbot.

|

Re: A practical 10 Cents Ceramic tube hotend August 03, 2015 03:50AM |

Registered: 9 years ago Posts: 1,035 |

Interesting. Any design that would work for 1.75mm filament? How does it handle the cooling gradient? Ceramic is an insulator, are the metal parts that screw onto each other enough to dissipate the heat?

Keep it up.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Keep it up.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: A practical 10 Cents Ceramic tube hotend August 03, 2015 04:42AM |

Registered: 11 years ago Posts: 1,592 |

|

Re: A practical 10 Cents Ceramic tube hotend August 03, 2015 01:55PM |

Registered: 8 years ago Posts: 396 |

Seems the original poster just posts and vanishes.. Love it when they do that.

Conceptually, you should not get any leaks since it is compression fitting.

If the nozzle and heat break end of the male compression fitting meet in the middle of the heat block, you should not have any leaks there either.

I have bravely tested this concept by holding a piece of ceramic fuse tube on one end while heating the other with a hot air gun. I did not feel it get too hot, but i may have chickened out too soon. Need to attach a thermocouple probe to one end and heat the other to see if there is heat creep.

according to thermal-conduction charts,

[www.engineeringtoolbox.com]

[www.engineeringtoolbox.com]

[www.coorstek.com]

Stainless steel has a thermal conductivity of 7-26 (the lower the number the more it resists heat)

Aluminum: 124

Copper: 200+

Brass: 100

Ceramic: (Technically called Alumina) between 16 and 30

So, as you can see, theoretically, Stainless steel is actually better at the job than the ceramic in this context. You can buy ceramic tube from mcmaster-carr, it is expensive. I bought a couple to experiment with about a month or two ago and haven't gotten anywhere until i saw this posting...it gave me some ideas to play with. The ceramic tube is very hard stuff, and very smooth. You need a diamond blade on a dremel to cut it.

Or you could use the fuses from an autoparts store. Just heat them with a heat gun and the glue that holds the metal ends on will melt and they will fall off. Inside is a powdery dust, don't breath that dust. The tube I bought was sized for 1.75 mm filament. They do have smallish fuses that will work (inside diameter) but the length is too short i think.

I plan on playing with this idea a bit more as I'd like to get rid of the fan and heat sink on my mini kossel

Edited 1 time(s). Last edit at 08/03/2015 01:56PM by thetazzbot.

Conceptually, you should not get any leaks since it is compression fitting.

If the nozzle and heat break end of the male compression fitting meet in the middle of the heat block, you should not have any leaks there either.

I have bravely tested this concept by holding a piece of ceramic fuse tube on one end while heating the other with a hot air gun. I did not feel it get too hot, but i may have chickened out too soon. Need to attach a thermocouple probe to one end and heat the other to see if there is heat creep.

according to thermal-conduction charts,

[www.engineeringtoolbox.com]

[www.engineeringtoolbox.com]

[www.coorstek.com]

Stainless steel has a thermal conductivity of 7-26 (the lower the number the more it resists heat)

Aluminum: 124

Copper: 200+

Brass: 100

Ceramic: (Technically called Alumina) between 16 and 30

So, as you can see, theoretically, Stainless steel is actually better at the job than the ceramic in this context. You can buy ceramic tube from mcmaster-carr, it is expensive. I bought a couple to experiment with about a month or two ago and haven't gotten anywhere until i saw this posting...it gave me some ideas to play with. The ceramic tube is very hard stuff, and very smooth. You need a diamond blade on a dremel to cut it.

Or you could use the fuses from an autoparts store. Just heat them with a heat gun and the glue that holds the metal ends on will melt and they will fall off. Inside is a powdery dust, don't breath that dust. The tube I bought was sized for 1.75 mm filament. They do have smallish fuses that will work (inside diameter) but the length is too short i think.

I plan on playing with this idea a bit more as I'd like to get rid of the fan and heat sink on my mini kossel

Edited 1 time(s). Last edit at 08/03/2015 01:56PM by thetazzbot.

|

Re: A practical 10 Cents Ceramic tube hotend August 03, 2015 06:01PM |

Registered: 9 years ago Posts: 1,035 |

Ceramic is very hard stuff. I was reading some weeks back how carbon fibre reinforced filament destroys a nozzle in a day's worth of printing with the stuff. If there was a way to use this thinking for a nozzle we could have tough nozzles for tough prints. Just an idea, maybe too unrealistic?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: A practical 10 Cents Ceramic tube hotend August 04, 2015 04:02PM |

Registered: 8 years ago Posts: 396 |

|

Re: A practical 10 Cents Ceramic tube hotend August 04, 2015 07:35PM |

Registered: 8 years ago Posts: 45 |

|

Re: A practical 10 Cents Ceramic tube hotend August 05, 2015 09:48AM |

Registered: 8 years ago Posts: 396 |

|

Re: A practical 10 Cents Ceramic tube hotend August 05, 2015 06:19PM |

Registered: 8 years ago Posts: 45 |

Thanks I searched every compression fitting on ebay, I may have just found right fitting eBay Seller - context-pneumatic-supplies-cpm

6mm x 1/4 Bsp Male Stud 6mm x 1/4 Bsp Male Stud

6mm x 1/4 Bsp Male Stud 6mm x 1/4 Bsp Male Stud

|

Re: A practical 10 Cents Ceramic tube hotend August 05, 2015 11:07PM |

Registered: 8 years ago Posts: 396 |

|

Re: A practical 10 Cents Ceramic tube hotend August 06, 2015 08:40PM |

Registered: 8 years ago Posts: 45 |

There is a B&Q, all their stuff is expensive. screwfix have a range of brass couplings only smallest was Male Coupler 8mm x ¼"

The ebay seller, responded

"they dont make a compression with 6mm thread but i can do that with an adpater i stock m6 male to 1/8 & 1/4 Female to which we can fasten any range of fitting"

I just added a few pics, of this ceramic break design. should hear soon.

The ebay seller, responded

"they dont make a compression with 6mm thread but i can do that with an adpater i stock m6 male to 1/8 & 1/4 Female to which we can fasten any range of fitting"

I just added a few pics, of this ceramic break design. should hear soon.

|

Re: A practical 10 Cents Ceramic tube hotend August 07, 2015 07:40PM |

Registered: 8 years ago Posts: 396 |

|

Re: A practical 10 Cents Ceramic tube hotend November 03, 2015 05:53AM |

Registered: 9 years ago Posts: 1,035 |

Quote

thetazzbot

Unless you could make a nozzle out of carbon fiber

Read about how carbon fiber is madeIt's interesting that ABS and Carbon fiber start out with the same base polymer and end up in drastically different places..

Sorry if this seems to be comming from nowhere but I've just stumbled on this nozzle made with sapphire: http://www.dura-gem.com/how-it-work.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: A practical 10 Cents Ceramic tube hotend November 03, 2015 07:14AM |

Registered: 8 years ago Posts: 1,671 |

Wondering if these could be worked into a design

http://www.ebay.co.uk/itm/VARIOUS-SIZES-CERAMIC-HIGH-TEMP-CONNECTOR-BLOCKS-1-4-POLE-32A-76A-4mm-16mm-/140992173543?var=&hash=item20d3c9d5e7:m:miBFX2aaOKNWmv1Hc3mcbYQ

http://www.ebay.co.uk/itm/VARIOUS-SIZES-CERAMIC-HIGH-TEMP-CONNECTOR-BLOCKS-1-4-POLE-32A-76A-4mm-16mm-/140992173543?var=&hash=item20d3c9d5e7:m:miBFX2aaOKNWmv1Hc3mcbYQ

|

Re: A practical 10 Cents Ceramic tube hotend November 06, 2015 04:49AM |

Registered: 9 years ago Posts: 1,035 |

There is another reprap thread for a ceramic hotend i don't know if you are aware but nontheless here it is:

http://forums.reprap.org/read.php?94,195507

Question: isn't ceramic too porous to have the filament slide through its inside? I think it whould be glazed on the inside hole (or at least very finely polished somehow).

Edit: OK, I just now watched the linked video and website and realized there's a Teflon tube inside the ceramic. So basically he replaced the aluminum heatsink that dissipates the heat in a normal hotend with a compression fitting and the ceramic tube. Quite clever. As far as I can see the ceramic tube's job is to support the hotend in the clamping bracket (because it's very strong material) and prevent heat from the compression fitting to reach the teflon (because ceramic heats up very slowly)?

The last part, "ceramic heats up very slowly", is a two-edged sword: current printers print for a long time and as slow as it heats up it will release that heat also very slow. I wonder how hot does this get after 10-15h of printing. The contact between the aluminum heating block and the compression fitting is quite substantial from the tiny heatbreak we're used to so there will be much more heat conducted into the stainless fitting, potentially heating the ceramic slowly but with much more heat than the original aluminum hotend transmitts into the pfte tube.

I also have my doubts about plastic creeping out but from the drawing section it looks quite confined. I wonder if that is accurate to the real inside dimensions of the compression fitting.

Having said this, I find the cost saving worth the potential downsides.

Edited 4 time(s). Last edit at 11/06/2015 07:09AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

http://forums.reprap.org/read.php?94,195507

Question: isn't ceramic too porous to have the filament slide through its inside? I think it whould be glazed on the inside hole (or at least very finely polished somehow).

Edit: OK, I just now watched the linked video and website and realized there's a Teflon tube inside the ceramic. So basically he replaced the aluminum heatsink that dissipates the heat in a normal hotend with a compression fitting and the ceramic tube. Quite clever. As far as I can see the ceramic tube's job is to support the hotend in the clamping bracket (because it's very strong material) and prevent heat from the compression fitting to reach the teflon (because ceramic heats up very slowly)?

The last part, "ceramic heats up very slowly", is a two-edged sword: current printers print for a long time and as slow as it heats up it will release that heat also very slow. I wonder how hot does this get after 10-15h of printing. The contact between the aluminum heating block and the compression fitting is quite substantial from the tiny heatbreak we're used to so there will be much more heat conducted into the stainless fitting, potentially heating the ceramic slowly but with much more heat than the original aluminum hotend transmitts into the pfte tube.

I also have my doubts about plastic creeping out but from the drawing section it looks quite confined. I wonder if that is accurate to the real inside dimensions of the compression fitting.

Having said this, I find the cost saving worth the potential downsides.

Edited 4 time(s). Last edit at 11/06/2015 07:09AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: A practical 10 Cents Ceramic tube hotend November 06, 2015 06:46AM |

Registered: 8 years ago Posts: 1,671 |

Yes heats up slowly doesn't mean it doesn't heat up(same with silicone), maybe that also means you could cool it quicker, I feel ceramic might have a use just not sure where, is it any easier to cool than aluminium, I was wondering if the terminal blocks could be used in the transition/melt zone, above copper or ali' heater block, or between throat & ali' cooling fins, if it helps or hinders. Just seen those jewel tipped nozzles, they look interesting, anyone got any spare blood diamonds.

Visited that thread but no convo going on and the guy's site is down, the blog is up, been there before some interesting tests going on there.

Edited 2 time(s). Last edit at 11/06/2015 07:02AM by MechaBits.

Visited that thread but no convo going on and the guy's site is down, the blog is up, been there before some interesting tests going on there.

Edited 2 time(s). Last edit at 11/06/2015 07:02AM by MechaBits.

|

Re: A practical 10 Cents Ceramic tube hotend November 06, 2015 08:05AM |

Registered: 9 years ago Posts: 1,035 |

From my pov the ceramic tube should be the very heatbreak that connects to the aluminum heating block. Not sure about a way to connect ceramic to the aluminum bloc because you don't/can't have threads on ceramic but that would be its best use in a hotend.

I might be completely off the charts here but I believe the PFTE tube is not desired and any segmentation of the plastic filament enclosure dow to the nozzle is a bad thing. So we must have the lease amount of parts making up a nozzle, ideally a heating element and a heat-break/support structure. Also the transition between the two, on the inside, should be conical, forcing the upper cone into the lower cone as you screw the heatbreak in the aluminum.

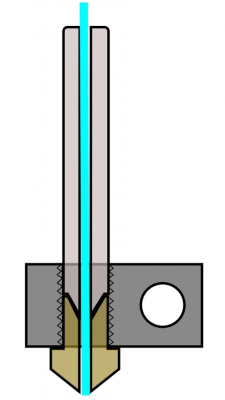

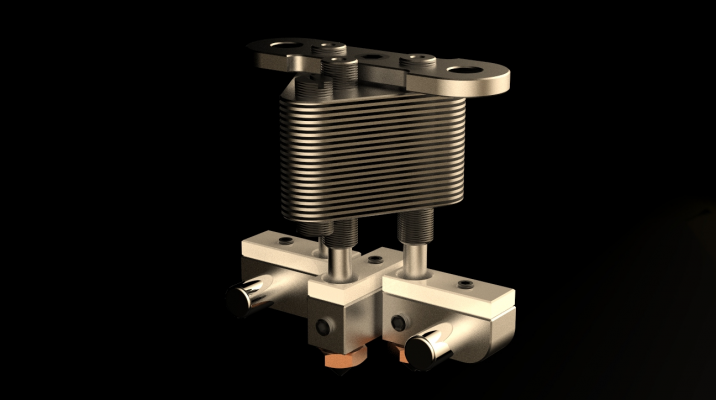

In my (ignorant?) logic, this is how a hotend should look:

Here the yellowish is copper/brass/stainless nozzle, the grey is aluminum (can be copper/etc?) and the pinkish hue is alumina tube or some other material that can be threaded so it fits the current breed of heatblocks. The nozzle should have a negative cone at the upper end and the heat break should be pointy with the same geometry/size cone. The inner diameter is that of the plastic filament so it must be very well polished/glazed on the inside hole.

Edited 1 time(s). Last edit at 11/06/2015 11:11AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I might be completely off the charts here but I believe the PFTE tube is not desired and any segmentation of the plastic filament enclosure dow to the nozzle is a bad thing. So we must have the lease amount of parts making up a nozzle, ideally a heating element and a heat-break/support structure. Also the transition between the two, on the inside, should be conical, forcing the upper cone into the lower cone as you screw the heatbreak in the aluminum.

In my (ignorant?) logic, this is how a hotend should look:

Here the yellowish is copper/brass/stainless nozzle, the grey is aluminum (can be copper/etc?) and the pinkish hue is alumina tube or some other material that can be threaded so it fits the current breed of heatblocks. The nozzle should have a negative cone at the upper end and the heat break should be pointy with the same geometry/size cone. The inner diameter is that of the plastic filament so it must be very well polished/glazed on the inside hole.

Edited 1 time(s). Last edit at 11/06/2015 11:11AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 03:23AM |

Registered: 8 years ago Posts: 1,671 |

So a ceramic block(nasa tile) could be put on the top of the ali block to help keep the heat directed downwards but would still creep up the steel throat.

Wonder if the coating that is applied to some Ali heatblocks to minimize hotend crusting could be applied to the throats too.

Going to rearrange the Trilobyte into a triangular Toblerone version (must be my sweet tooth, and all the talk of honeycombs)

with nozzles 18mm apart, ceramic heat shield, and see how that turns out.

Wonder if the coating that is applied to some Ali heatblocks to minimize hotend crusting could be applied to the throats too.

Going to rearrange the Trilobyte into a triangular Toblerone version (must be my sweet tooth, and all the talk of honeycombs)

with nozzles 18mm apart, ceramic heat shield, and see how that turns out.

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 05:00AM |

Registered: 9 years ago Posts: 1,035 |

The heat will creep up the steel throath and will have nowhere to go since around the throat of the stainless steelbreak it only finds the insulating ceramic tube. The heatbreak should only be in contact with another metal to dissipate the heat into the environment. Or ceramic as a heatbreak and no stainless steel tube. Hence my picture above...

Edited 1 time(s). Last edit at 11/07/2015 05:01AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Edited 1 time(s). Last edit at 11/07/2015 05:01AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 05:41AM |

Registered: 8 years ago Posts: 1,671 |

Yes ceramic tube if used as heatbreak, as in your picture, but i was thinking of keeping steel tube for now and cold end heatsink,

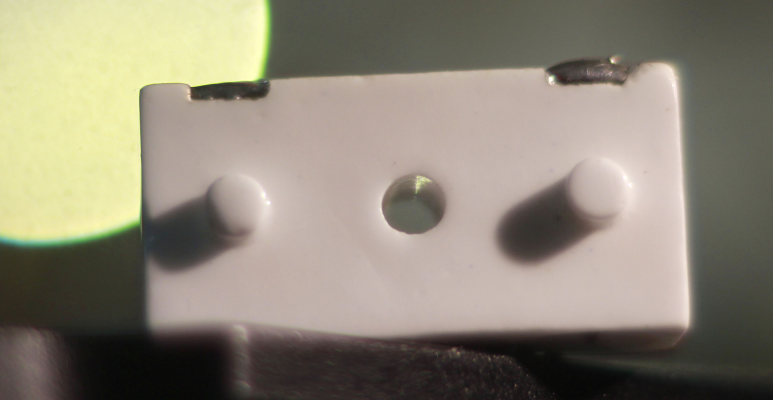

as i cant be sure I could find or make the ceramic part with right properties, ie a nicely reamed hole, or smooth glaze, correct volume melt zone, I have a smooth ceramic terminal block with a tiny hole in it, looks bigger than 1mm less than 2, though I cant tell how things are inside that hole, looks smooth to me, though a little dimpled.

Edited 1 time(s). Last edit at 11/07/2015 06:21AM by MechaBits.

as i cant be sure I could find or make the ceramic part with right properties, ie a nicely reamed hole, or smooth glaze, correct volume melt zone, I have a smooth ceramic terminal block with a tiny hole in it, looks bigger than 1mm less than 2, though I cant tell how things are inside that hole, looks smooth to me, though a little dimpled.

Edited 1 time(s). Last edit at 11/07/2015 06:21AM by MechaBits.

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 05:57AM |

Registered: 9 years ago Posts: 1,035 |

How would you intercalate the ceramic block in between the al block and the steel heatbreak cause those two screw into each other. I think I am missing something here.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 06:35AM |

Registered: 8 years ago Posts: 1,671 |

Now there's a word i'll have to look up "intercalate"

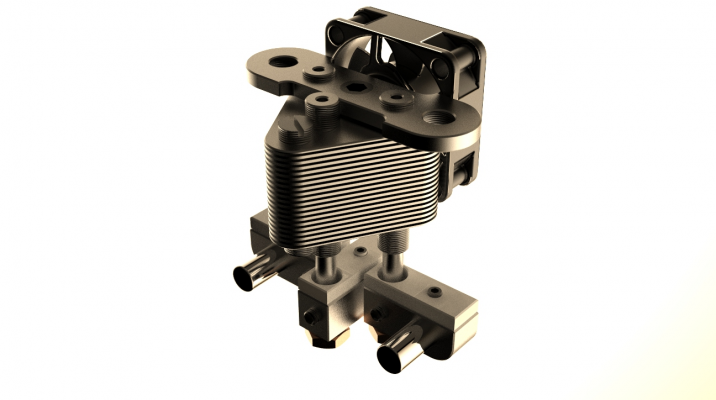

The renders when done might show this easier, but while there are minimal parts with only a few combinations of assembly

I had wondered the same thing, I hope to take away any heat in the steel tube asap with heatsink

heatblock with ceramic ontop to try to stop rising radiant heat from block, so the most direct route for heat would be the up steel tube

So if I can get another piece of ceramic in there or other insulating/crack sealing stuff between nozzle & tube, I'll give it a go.

Dont worry we may both be missing something, but only by looking might we find it.

Edited 1 time(s). Last edit at 11/07/2015 06:36AM by MechaBits.

The renders when done might show this easier, but while there are minimal parts with only a few combinations of assembly

I had wondered the same thing, I hope to take away any heat in the steel tube asap with heatsink

heatblock with ceramic ontop to try to stop rising radiant heat from block, so the most direct route for heat would be the up steel tube

So if I can get another piece of ceramic in there or other insulating/crack sealing stuff between nozzle & tube, I'll give it a go.

Dont worry we may both be missing something, but only by looking might we find it.

Edited 1 time(s). Last edit at 11/07/2015 06:36AM by MechaBits.

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 06:56AM |

Registered: 9 years ago Posts: 1,035 |

yup, waiting for the renders although in this case working on it straight away might be quicker  .

.

I'll have a run in the hardware store to see what ceramic insulators might do the job. There must be something. They usually look like this:

If only the holes would be the right size , which I doubt ... but another aspect of this reprap thing is that soon we'll have filament extruders so we will be able to make custom diameter filaments

, which I doubt ... but another aspect of this reprap thing is that soon we'll have filament extruders so we will be able to make custom diameter filaments  .

.

The following look plenty smooth maybe on the inside it's the same. Not sure how readily available they are though. If ceramic doesn't trnsmit heat then even a 3d printed holder can be designed around those rings.

These are called "standoff ceramic insulators", again not sure about availability:

Edited 4 time(s). Last edit at 11/07/2015 07:09AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

.

.I'll have a run in the hardware store to see what ceramic insulators might do the job. There must be something. They usually look like this:

If only the holes would be the right size

, which I doubt ... but another aspect of this reprap thing is that soon we'll have filament extruders so we will be able to make custom diameter filaments

, which I doubt ... but another aspect of this reprap thing is that soon we'll have filament extruders so we will be able to make custom diameter filaments  .

.The following look plenty smooth maybe on the inside it's the same. Not sure how readily available they are though. If ceramic doesn't trnsmit heat then even a 3d printed holder can be designed around those rings.

These are called "standoff ceramic insulators", again not sure about availability:

Edited 4 time(s). Last edit at 11/07/2015 07:09AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 07:25AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 04:14PM |

Registered: 9 years ago Posts: 483 |

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 05:21PM |

Registered: 9 years ago Posts: 1,035 |

The solution of the vanishing poster is quite goot at bringing the costs down. I can't think of any way to directly attach the ceramic tube to the aluminum block.

For the ceramic tube interior, I would take a larger diameter tube, fill it with some cement, put a 1.75mm smooth rod inside and let it cure. After curing I would polish the interior with some sort of wick dipped in concrete polishing and sealing solution (they are sold everywhere I guess). This will prepare the interior tube to receive the plastic without pfte. There will be no heat creeping up. Now we need the cement to be the more flexible type and to flos completely to the brass nozzle so that there is a continuous path for the plastic filament without anyway for the liquid plastic to creep up.

How do we attach the aluminum block to the ceramic tube? The attachement should be strong enough but not excessivley strong because the nozzle doesn't take any force it only rubs against viscous plastic. The ceramic tube will then be clamped in the hotend mount.

Maybe we shouldn't think of the hotend in terms of the classic design. Let's put together another stack of parts that can work for our requirements. But it will be difficult because there are so many smart guys working on current designs and because they ended up like this I would think it is a smart solution. But it is never a bad thing to do some exercises outside the box.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

For the ceramic tube interior, I would take a larger diameter tube, fill it with some cement, put a 1.75mm smooth rod inside and let it cure. After curing I would polish the interior with some sort of wick dipped in concrete polishing and sealing solution (they are sold everywhere I guess). This will prepare the interior tube to receive the plastic without pfte. There will be no heat creeping up. Now we need the cement to be the more flexible type and to flos completely to the brass nozzle so that there is a continuous path for the plastic filament without anyway for the liquid plastic to creep up.

How do we attach the aluminum block to the ceramic tube? The attachement should be strong enough but not excessivley strong because the nozzle doesn't take any force it only rubs against viscous plastic. The ceramic tube will then be clamped in the hotend mount.

Maybe we shouldn't think of the hotend in terms of the classic design. Let's put together another stack of parts that can work for our requirements. But it will be difficult because there are so many smart guys working on current designs and because they ended up like this I would think it is a smart solution. But it is never a bad thing to do some exercises outside the box.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 05:55PM |

Registered: 8 years ago Posts: 1,671 |

there are a number of ways to approach it,I'm not suggesting I've solved anything yet,

the part where the materials meet is the one of the many areas I have little practical experience with

I'm just trying a design based on the space I have to work with, hoping some other bright spark will rip off the design

and produce it in china cheaper than I can make it, or they work out some other tiny way of doing this.

if there was such thing as a heater nozzle things might be a little easier,

if the cartridge heaters where toroid instead of cylindrical,

or a way to pass a current from one place to other controlling the heat localisation

if 3 separate temps where not needed, some other way of controlling dribble,

or if mixing into one nozzle, the arrangement would be different,

obviously sometimes same filament same temps different colours,

or totally different materials in each, support + 2 others

If the tube was tapered and the heater just dropped on and wedged itself in place

I wonder could something create a nice controllable heat gradient between top n bottom

or bottom & specific point above

would be cool if something visual could be seen on screen.

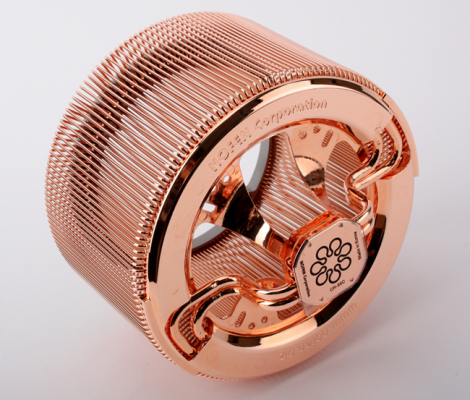

I have a few more changes to incorporate, one of them to change the heater blocks for something like this

Edited 3 time(s). Last edit at 11/07/2015 06:08PM by MechaBits.

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 06:40PM |

Registered: 9 years ago Posts: 1,035 |

For a completely new approach I have some very interesting ideas but really I am worried they will be patented by some company that has more R&D power than I have and would hate that. They are nothing new, please don't take it like I have such a good opinion about myself. Not at all, if there was a way to make it "prior art" that counts I'd post it there with no objections. I don't want to patent them myself, I hate petenters more than I hate cloners and rip-offs.

If you have any idea where I can post this ideas so that it would invalidate any patent attampt on it I am more than happy to go on with it. I don't have more than the ideas so I can't work on and show a prototype either.

Otherwise I am still trying to design a cheap solution based on current design.

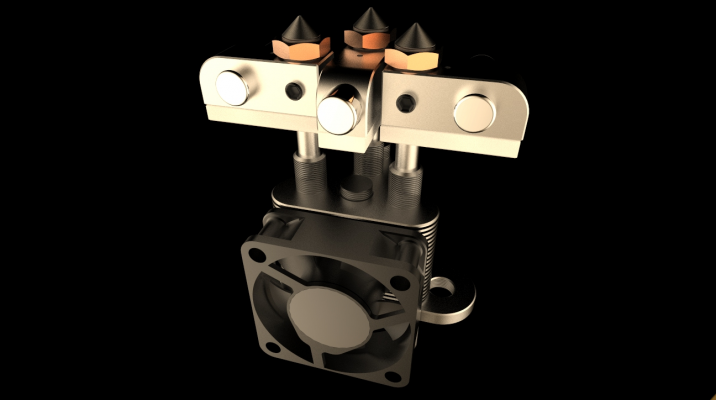

BTW, found this on a .ir website (http://ultishop.ir/products/204394), thought it might be interesting:

Edited 4 time(s). Last edit at 11/07/2015 07:16PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

If you have any idea where I can post this ideas so that it would invalidate any patent attampt on it I am more than happy to go on with it. I don't have more than the ideas so I can't work on and show a prototype either.

Otherwise I am still trying to design a cheap solution based on current design.

BTW, found this on a .ir website (http://ultishop.ir/products/204394), thought it might be interesting:

Edited 4 time(s). Last edit at 11/07/2015 07:16PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: A practical 10 Cents Ceramic tube hotend November 07, 2015 07:03PM |

Registered: 8 years ago Posts: 1,671 |

yes i agree the patent system is not fit for purpose, costs a fortune to litigate, no one will help, lawyers will try to take your money, and even if you win, getting compo would be another battle, the way of the wen encourages sharing, but sometimes just one time it would be nice to see some payback for time & effort & ideas, not sure how to fix that one, but you have some design rights, but they are not as long as what songwriters get, a couple of years max...then people would still alter, take the extra mile, and voila you see your work staring back at you.

keep it to yourself the only good advice, sad but true,

I seem to have taken a 10 cent idea and ruined it.

I wonder would anyone pay $300 for a hotend?

if it was small and performed flawlessly, I might?

I seen a cool cpu cooler the other day all copper beautiful but was a £100

keep it to yourself the only good advice, sad but true,

I seem to have taken a 10 cent idea and ruined it.

I wonder would anyone pay $300 for a hotend?

if it was small and performed flawlessly, I might?

I seen a cool cpu cooler the other day all copper beautiful but was a £100

Sorry, only registered users may post in this forum.