A practical 10 Cents Ceramic tube hotend

Posted by beyondwind

|

Re: A practical 10 Cents Ceramic tube hotend February 15, 2019 04:59PM |

Registered: 5 years ago Posts: 7 |

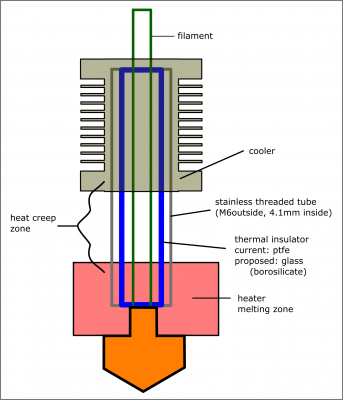

the bushing/liner have the purpose of keeping the heat out (down), there is pla filament inside, stainless tube outside

it always happens to those who switch to all metal (heat break) that they can't print pla anymore as it sticks to the stainless tube because it allow heat too go too high, it is called heat creep

i'll try to draw it with words, if it doesn't work i'll try an actual drawing :

:

it is like this : filament -> inside an insulator tube (ptfe now, borosilicate/glass on my sugestion) -> inside stainless throat/heat break

the target is to avoid heat to go up on the tube as this cause the heat creep, and insulation is much more preferable than cooling

edit: i am talking about standard configuration with aluminium hot end block at the bottom

Edited 4 time(s). Last edit at 02/15/2019 05:01PM by townkat.

it always happens to those who switch to all metal (heat break) that they can't print pla anymore as it sticks to the stainless tube because it allow heat too go too high, it is called heat creep

i'll try to draw it with words, if it doesn't work i'll try an actual drawing

:

:it is like this : filament -> inside an insulator tube (ptfe now, borosilicate/glass on my sugestion) -> inside stainless throat/heat break

the target is to avoid heat to go up on the tube as this cause the heat creep, and insulation is much more preferable than cooling

edit: i am talking about standard configuration with aluminium hot end block at the bottom

Edited 4 time(s). Last edit at 02/15/2019 05:01PM by townkat.

|

Re: A practical 10 Cents Ceramic tube hotend February 15, 2019 05:06PM |

Registered: 10 years ago Posts: 14,672 |

So the tube is both the heat break and the medium through which heat is transmitted? The ceramic hot ends I have seen have the heating element wound around the outside of the tube. If your design is like that, I suggest you calculate the minimum thermal conductivity you need in order to avoid excessive temperature drop between the outer wall where the heater is and the inner wall where the filament has to be melted.

Heat creep along the tube to the cold end is mitigated by the heatsink and fan assembly. Not ideal, but it works.

Edited 1 time(s). Last edit at 02/15/2019 05:06PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Heat creep along the tube to the cold end is mitigated by the heatsink and fan assembly. Not ideal, but it works.

Edited 1 time(s). Last edit at 02/15/2019 05:06PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: A practical 10 Cents Ceramic tube hotend February 15, 2019 05:39PM |

Registered: 5 years ago Posts: 7 |

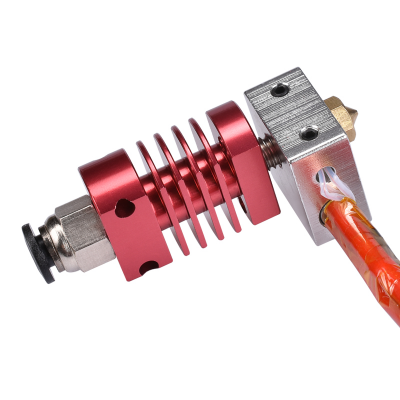

no, not ceramic hot end, a bushing/liner inside stainless threaded tube

i am talking about this

i am talking about this

|

Re: A practical 10 Cents Ceramic tube hotend February 15, 2019 05:48PM |

Registered: 10 years ago Posts: 14,672 |

OK, I misunderstood.

What do you think would be the advantage of a glass or ceramic heat break, compared to the traditional thin stainless steel one?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

What do you think would be the advantage of a glass or ceramic heat break, compared to the traditional thin stainless steel one?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: A practical 10 Cents Ceramic tube hotend February 15, 2019 06:34PM |

Registered: 5 years ago Posts: 7 |

usually printers come with ptfe lined stainless threaded throat/heat break

ptfe is not very heat resistant, it works but even at usual <250 Celsius it does change it's color and deteriorate over time

there is another all metal throat/heat break, which is identically stainless threaded tube but instead of 4.1mm inside hole it does have a 2mm hole so there is no liner used anymore, which works for higher glass temperature materials, but not for pla

this one also needs to be cooled more intensely, so the distance from heater block to cooler must be lower, this also is inconvenient in other ways too: more stress on heater element, slower heating time etc.. -> insulation is more preferable than cooling.

someone sugested that the shorter the melting zone, the more precise the extrusion/printing too

i am suggesting this as a solution which will work in both cases, high and low temp materials

Edited 6 time(s). Last edit at 02/15/2019 08:36PM by townkat.

|

Re: A practical 10 Cents Ceramic tube hotend February 15, 2019 06:36PM |

Registered: 5 years ago Posts: 148 |

With a heat break, there is no need to cool the top part of the assembly as the heat won't creep up the stem, or at least most of the heat shouldn't creep up the stem.

This means no more fans or heat sinking vanes etc above the nozzle and it's heating block. The heat stays concentrated in the bottom aluminium/copper block with the nozzle - where it's needed/wanted.

It also means you need less power to the nozzle heater because it's not being wasted up into the above heat-sinking/fan area. So everything becomes lighter and more efficient at doing what's it meant to do (heat the nozzle).

I've just tested a quick induction heater coil in place of the normal nozzle heater, it was a little tooo efficient though, like whatever was inside the induction coil started glowing red hot within 20 seconds or so .. need to down size the induction coil and use much smaller mosfets

This means no more fans or heat sinking vanes etc above the nozzle and it's heating block. The heat stays concentrated in the bottom aluminium/copper block with the nozzle - where it's needed/wanted.

It also means you need less power to the nozzle heater because it's not being wasted up into the above heat-sinking/fan area. So everything becomes lighter and more efficient at doing what's it meant to do (heat the nozzle).

I've just tested a quick induction heater coil in place of the normal nozzle heater, it was a little tooo efficient though, like whatever was inside the induction coil started glowing red hot within 20 seconds or so .. need to down size the induction coil and use much smaller mosfets

|

Re: A practical 10 Cents Ceramic tube hotend February 15, 2019 06:39PM |

Registered: 5 years ago Posts: 7 |

you may start printing with metal soon maybeQuote

Pippy

I've just tested a quick induction heater coil in place of the normal nozzle heater, it was a little tooo efficient though, like whatever was inside the induction coil started glowing red hot within 20 seconds or so .. need to down size the induction coil and use much smaller mosfets

|

Re: A practical 10 Cents Ceramic tube hotend February 15, 2019 06:47PM |

Registered: 5 years ago Posts: 148 |

|

Re: A practical 10 Cents Ceramic tube hotend February 17, 2019 06:15AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: A practical 10 Cents Ceramic tube hotend February 17, 2019 07:26AM |

Registered: 10 years ago Posts: 11 |

|

Re: A practical 10 Cents Ceramic tube hotend February 17, 2019 10:42AM |

Registered: 5 years ago Posts: 20 |

What about Water jet Focus tube for nozzle ? Don't now is this suitable, but I know it is very hard, it has super fine finish and it press fit in water jet head by default (for 4000 bar or more). It is expensive OTOH...

Edit:

Here is the link: [www.waterjet-shop.com]

Edited 1 time(s). Last edit at 02/17/2019 11:10AM by tabana.

Edit:

Here is the link: [www.waterjet-shop.com]

Edited 1 time(s). Last edit at 02/17/2019 11:10AM by tabana.

|

Re: A practical 10 Cents Ceramic tube hotend February 17, 2019 11:24PM |

Registered: 10 years ago Posts: 11 |

|

Re: A practical 10 Cents Ceramic tube hotend February 18, 2019 07:32AM |

Registered: 5 years ago Posts: 20 |

|

Re: A practical 10 Cents Ceramic tube hotend February 18, 2019 08:19AM |

Registered: 6 years ago Posts: 1,007 |

Quote

tabana

Sapphire (and ruby) are materials for water jet nozzle. I think focus tube is made of tungsten carbide, if it makes any difference.

I made this post just to give you another idea, maybe it's not worth to try it.

Can you explain the advantage of these materials for a heatbreak and how you would make it ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: A practical 10 Cents Ceramic tube hotend February 18, 2019 08:25AM |

Registered: 10 years ago Posts: 11 |

Quote

tabana

Sapphire (and ruby) are materials for water jet nozzle. I think focus tube is made of tungsten carbide, if it makes any difference.

I made this post just to give you another idea, maybe it's not worth to try it.

This is about ideas hopefully,normally just lurk here but some current stuff involves conductivity of very hard materials (electrical not thermal).

On the thermal conductivity bit WC itself is 110 W/mK but the binder (cobalt?) in "tungsten carbide" will reduce that

Edited to add

There is plenty of gemstone expertise around not so much with tungsten carbide

Edited 1 time(s). Last edit at 02/18/2019 08:32AM by jcamp.

|

Re: A practical 10 Cents Ceramic tube hotend February 18, 2019 09:12AM |

Registered: 10 years ago Posts: 11 |

|

Re: A practical 10 Cents Ceramic tube hotend February 18, 2019 11:47AM |

Registered: 6 years ago Posts: 1,007 |

Quote

jcamp

Quote

MKSA

[how you would make it ?

One off

Gemstone of ebay or local gemshow (cheaper uncut)

Diamond drill 1.5mm hole

Bolt or soldered rod through hole

Toolpost diamond grinder to desired OD

Lap/polish to desired ID with diamond paste

Fine, DO IT, show the results AND document the advantage compared to a SS or even Ti heatbreak as we keep asking !!!!!

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: A practical 10 Cents Ceramic tube hotend February 19, 2019 03:17AM |

Registered: 5 years ago Posts: 20 |

|

Re: A practical 10 Cents Ceramic tube hotend February 19, 2019 05:39AM |

Registered: 6 years ago Posts: 1,007 |

I don't care for "image", I care for REAL WORKING stuff !

Looking at your "image", have you ever made a working heatbreak, hot end ?

Edited 1 time(s). Last edit at 02/19/2019 11:29AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: A practical 10 Cents Ceramic tube hotend February 22, 2019 03:36AM |

Registered: 10 years ago Posts: 1,401 |

I haven't posted here in years but since I experimented a lot with my own design I will give you my ten cents.

Few years ago I designed a hotend that had a quartz tube surrounded with a ceramic body and a elaborate heater block, the quartz tube was about 27 dollars, the ceramic body was printed by shapeway around 60 dollars and the heater block was machined out of brass and it was around 45 dollars so roughly 132 dollars in reality since I did several iterations it was around 800 dollars that I spend on it.

The good: the quartz tube works like a charm, combined with the ceramic body there is no need for active cooling even when printing ABS the maximum temperature at the top of the hotend never exceeded 50 degrees. In theory you could print at very high temperatures.

The not so good: bulky and delicate, even though ceramic is very strong it could brake if you bump it hard enough and there is no universal mount for it so its design isn't as simple as regular aluminum ones.

The bad: EXPENSIVE, REALLY EXPENSIVE. unless you have a klin and machining tools available it is really hard to get it at reasonable cost, also in today's market when a really good and reliable hotend cost no more than 20 dollars and most of the people prints with PLA there is no place for this kind of hotends.

So once it broke because of my stupidity I put it to rest and went back to cheap and simple Chinese hotends.

Few years ago I designed a hotend that had a quartz tube surrounded with a ceramic body and a elaborate heater block, the quartz tube was about 27 dollars, the ceramic body was printed by shapeway around 60 dollars and the heater block was machined out of brass and it was around 45 dollars so roughly 132 dollars in reality since I did several iterations it was around 800 dollars that I spend on it.

The good: the quartz tube works like a charm, combined with the ceramic body there is no need for active cooling even when printing ABS the maximum temperature at the top of the hotend never exceeded 50 degrees. In theory you could print at very high temperatures.

The not so good: bulky and delicate, even though ceramic is very strong it could brake if you bump it hard enough and there is no universal mount for it so its design isn't as simple as regular aluminum ones.

The bad: EXPENSIVE, REALLY EXPENSIVE. unless you have a klin and machining tools available it is really hard to get it at reasonable cost, also in today's market when a really good and reliable hotend cost no more than 20 dollars and most of the people prints with PLA there is no place for this kind of hotends.

So once it broke because of my stupidity I put it to rest and went back to cheap and simple Chinese hotends.

Sorry, only registered users may post in this forum.