First Print.

Posted by Geartech

|

First Print. August 02, 2015 07:25AM |

Registered: 8 years ago Posts: 29 |

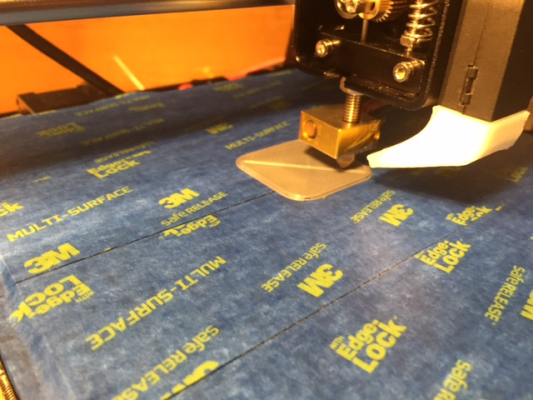

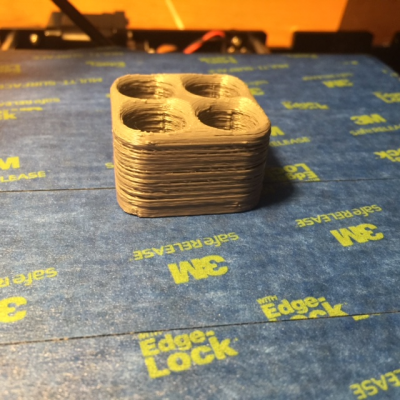

Got my Hesine 505/Prusa i3 done the other night, ran my first pint with pretty good results.

There are some problems with material deposition in places that I need to figure out

But so far its worked pretty well for my first attempt at this.

A lot of the credit goes to the reading and setup ideas I got from here.

There are some problems with material deposition in places that I need to figure out

But so far its worked pretty well for my first attempt at this.

A lot of the credit goes to the reading and setup ideas I got from here.

|

Re: First Print. August 03, 2015 09:34AM |

Registered: 10 years ago Posts: 56 |

|

Re: First Print. August 03, 2015 11:01AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: First Print. August 03, 2015 04:37PM |

Registered: 8 years ago Posts: 29 |

Thanks Olaf, thats the kind of info I need. I have gotten much better prints after doing a little more setup

of the bed and temps.

Layer height was .2mm

temp was 195 c

dont remember the speed.

I went back thru and measured the filament and corrected that in Cura, also checked the feed rate and had to add a few steps.

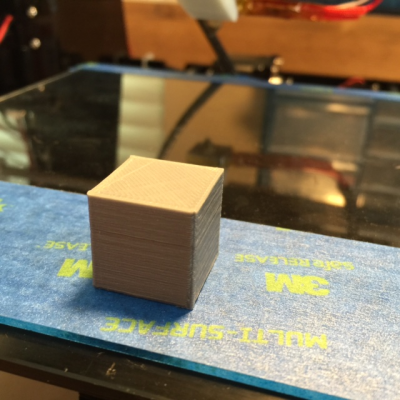

My second print came out like this.

that was .1mm layer

temp 205c

speed 45mm/s

Edited 1 time(s). Last edit at 08/03/2015 04:39PM by Geartech.

of the bed and temps.

Layer height was .2mm

temp was 195 c

dont remember the speed.

I went back thru and measured the filament and corrected that in Cura, also checked the feed rate and had to add a few steps.

My second print came out like this.

that was .1mm layer

temp 205c

speed 45mm/s

Edited 1 time(s). Last edit at 08/03/2015 04:39PM by Geartech.

|

Re: First Print. August 03, 2015 09:45PM |

Registered: 8 years ago Posts: 29 |

|

Re: First Print. August 04, 2015 01:06AM |

Registered: 8 years ago Posts: 5,232 |

Quote

Geartech

Moved the print head feed tube further up till it almost touched the extruder drive.

in that position I lost feed. It appear to bind somewhere. I think the tube is misaligned in the

frame.

dropped it down 2 turns and that seems to fix it.

I remember, I had to add a washer on the idler and also realign the drive gear.

Make sure the M6 nut doesn´t touch the hot-end.

-Olaf

|

Re: First Print. August 04, 2015 01:06PM |

Registered: 8 years ago Posts: 29 |

Got it working again but I had to drop the threaded tube down a few more turns so it wasnt so

close to the drive wheel.

The hole for the tube is drilled to far foward and when its close to the wheel it causes it to bind as it needs that

space inbetween the tube and wheel to flex .

I ordered a different extruder frame asym to see if is any difference and also will allow me to play with making a

new frame or fixing the position of the drilled hole without fear of runing it.

close to the drive wheel.

The hole for the tube is drilled to far foward and when its close to the wheel it causes it to bind as it needs that

space inbetween the tube and wheel to flex .

I ordered a different extruder frame asym to see if is any difference and also will allow me to play with making a

new frame or fixing the position of the drilled hole without fear of runing it.

Sorry, only registered users may post in this forum.