Best choices for Extruder and Hot End

Posted by JChicago

|

Best choices for Extruder and Hot End August 06, 2015 09:50AM |

Registered: 8 years ago Posts: 9 |

Hello, and greetings to everyone here! This post could have gone in several spots but one has to start somewhere, so here goes:

I recently acquired an essentially new Prusa 10 i3v off craigslist. It has a Greg's Wade's extruder and genuine E3D V6 hotend and works great at everything I can through at it. If there is one downside, it is that it's setup for 3mm filament. That's easily enough solved though. I'll give you a quick background of myself then ask my question(s). Although I'm relatively new to 3D printing, I have many years experience in all the separate elements that surround it (3d design, CAD/CAM, CNC, programming, electronics, Arduino et al, motors, computers, and so on...) I've built CNC mills and lathes but knew it was time to dive into printing. I did a fair amount of research before purchasing and was just going to buy an Ultimaker 2 but saw the deal on CL and couldn't pass it up, as it came with not only the 10" i3v, but a ton of filament, and a 6" Prusa kit as well for a couple hundred bucks total. Hard to pass up. As mentioned the working Prusa printed perfectly from the start and has done everything I can through at it perfectly. So this is my question for all the experts here: (I know there's no single correct answer but I welcome all your opinions, views, and expertise...) I've built the Prusa 6" up with frame, power supply, RAMPS 1.4, Marlin firmware, belts, pulleys...basically everything but the extruder and hot end. It also came with an 8" frame so it could be an 8" model with just a larger heat bed and firmware changes. I'd like to use this printer as my "experimental" unit so I can try various things, both hardware and software. From what I've read, to print 'anything', and fast, you need a high-temp hot end a direct-type extruder (opposed to Bowden). So.....What would you all suggest for a hot end and extruder? Since I saved so much money I have funds to get the good stuff here The E3D seems to be a real winner, and with their volcano pack their speed seems pretty respectable too...But I've seen all in one units like the Geeetech MK8 extruder/Hot end, the Hexagon units, There are J-heads, many extruder types you can print or buy....The list goes on and on, so I welcome any advise you can offer.

The E3D seems to be a real winner, and with their volcano pack their speed seems pretty respectable too...But I've seen all in one units like the Geeetech MK8 extruder/Hot end, the Hexagon units, There are J-heads, many extruder types you can print or buy....The list goes on and on, so I welcome any advise you can offer.

Thank you all in advance!

-Joseph

I recently acquired an essentially new Prusa 10 i3v off craigslist. It has a Greg's Wade's extruder and genuine E3D V6 hotend and works great at everything I can through at it. If there is one downside, it is that it's setup for 3mm filament. That's easily enough solved though. I'll give you a quick background of myself then ask my question(s). Although I'm relatively new to 3D printing, I have many years experience in all the separate elements that surround it (3d design, CAD/CAM, CNC, programming, electronics, Arduino et al, motors, computers, and so on...) I've built CNC mills and lathes but knew it was time to dive into printing. I did a fair amount of research before purchasing and was just going to buy an Ultimaker 2 but saw the deal on CL and couldn't pass it up, as it came with not only the 10" i3v, but a ton of filament, and a 6" Prusa kit as well for a couple hundred bucks total. Hard to pass up. As mentioned the working Prusa printed perfectly from the start and has done everything I can through at it perfectly. So this is my question for all the experts here: (I know there's no single correct answer but I welcome all your opinions, views, and expertise...) I've built the Prusa 6" up with frame, power supply, RAMPS 1.4, Marlin firmware, belts, pulleys...basically everything but the extruder and hot end. It also came with an 8" frame so it could be an 8" model with just a larger heat bed and firmware changes. I'd like to use this printer as my "experimental" unit so I can try various things, both hardware and software. From what I've read, to print 'anything', and fast, you need a high-temp hot end a direct-type extruder (opposed to Bowden). So.....What would you all suggest for a hot end and extruder? Since I saved so much money I have funds to get the good stuff here

The E3D seems to be a real winner, and with their volcano pack their speed seems pretty respectable too...But I've seen all in one units like the Geeetech MK8 extruder/Hot end, the Hexagon units, There are J-heads, many extruder types you can print or buy....The list goes on and on, so I welcome any advise you can offer.

The E3D seems to be a real winner, and with their volcano pack their speed seems pretty respectable too...But I've seen all in one units like the Geeetech MK8 extruder/Hot end, the Hexagon units, There are J-heads, many extruder types you can print or buy....The list goes on and on, so I welcome any advise you can offer.Thank you all in advance!

-Joseph

|

Re: Best choices for Extruder and Hot End August 06, 2015 10:11AM |

Registered: 9 years ago Posts: 425 |

|

Re: Best choices for Extruder and Hot End August 06, 2015 10:49AM |

Registered: 8 years ago Posts: 9 |

|

Re: Best choices for Extruder and Hot End August 06, 2015 11:28AM |

Registered: 9 years ago Posts: 977 |

"It has a Greg's Wade's extruder and genuine E3D V6 hotend and works great at everything I can through at it."

I am not sure exactly what you are trying to improve upon then. Could you please be more specific?

If you just want to use 1.75mm filament you can just change the E3D hotend for a 1.75mm version and print yourself a new Greg's Wade's Geared Extruder body and idler for 1.75mm filament.

I am not sure exactly what you are trying to improve upon then. Could you please be more specific?

If you just want to use 1.75mm filament you can just change the E3D hotend for a 1.75mm version and print yourself a new Greg's Wade's Geared Extruder body and idler for 1.75mm filament.

|

Re: Best choices for Extruder and Hot End August 06, 2015 12:01PM |

Registered: 9 years ago Posts: 425 |

One wont print flexibles very well (if at all) with a standard wades, even if modified the filament force path is still quite large (distance between hob exit and hotend entry), too large for some of the more flexible, flexible filaments (ie Filaflex).

But on the whole for standard printing with non exotics, such as ABS, PLA, Nylons, i do agree with the point AndrewBCN is making.

But on the whole for standard printing with non exotics, such as ABS, PLA, Nylons, i do agree with the point AndrewBCN is making.

|

Re: Best choices for Extruder and Hot End August 06, 2015 01:32PM |

Registered: 8 years ago Posts: 9 |

Thanks for the replies...This extruder/hot end will be for the other printer (which has none, it's a new build). So I'd like to set it up to print any type of filament (at the very least), and then [possibly] use it as a test bed for mods and such I can use on the larger, working unit. I don't want to mess with the working 10" until I've fully tested whatever mods I may want to make to it. This unit is a 6"-8" Prusa that has everything but a hot end and extruder on it. Since everything seems to be going to 1.75mm I'll start with that. I think the extruder is the biggest question mark. It's sounding like another E3d V6 (but setup for 1.75) would probably be the hot end of choice (???), but there are so many extruder options (build, print, buy... direct, geared, all-in-one) I don't know what the best choices might be given my goals. I suppose it can be summed up with one question: If you were building a printer and wanted to be able to print any material (and at fast speeds where possible), what extruder and hot end would you use?

Hopefully that makes some sense....

Thanks again,

-Joseph

Hopefully that makes some sense....

Thanks again,

-Joseph

|

Re: Best choices for Extruder and Hot End August 06, 2015 01:47PM |

Registered: 8 years ago Posts: 9 |

|

Re: Best choices for Extruder and Hot End August 06, 2015 03:04PM |

Registered: 9 years ago Posts: 977 |

Well, imho there is no perfect extruder that can be used with *any* kind of filament, otherwise we would know about it.

Greg's Wade's Geared Extruder is pretty much good at *most* things, this is why it's a classic choice. Obviously there are many other extruder designs available nowadays, but you have to accept that all of them are a compromise in one way or another.

Since you are going to have two (or more) 3D printers I would suggest you use them for different kinds of print jobs so as to maximize their use and printing possibilities.

Note that every time you change filaments there is a learning curve until you get as good prints as you were getting with the previous filament.

Greg's Wade's Geared Extruder is pretty much good at *most* things, this is why it's a classic choice. Obviously there are many other extruder designs available nowadays, but you have to accept that all of them are a compromise in one way or another.

Since you are going to have two (or more) 3D printers I would suggest you use them for different kinds of print jobs so as to maximize their use and printing possibilities.

Note that every time you change filaments there is a learning curve until you get as good prints as you were getting with the previous filament.

|

Re: Best choices for Extruder and Hot End August 06, 2015 11:41PM |

Registered: 9 years ago Posts: 425 |

Quote

AndrewBCN

Well, imho there is no perfect extruder that can be used with *any* kind of filament, otherwise we would know about it.

Ive not found anything in my testing, 1.75 or 3mm that the Flex3Drive cant handle, common and exotics and flexibles all run fine. (sorry i dont mean this to sound like blatant advertising), but just bringing awareness of this given your post above.

|

Re: Best choices for Extruder and Hot End August 07, 2015 10:54AM |

Registered: 8 years ago Posts: 49 |

Quote

Mutley3D

Quote

AndrewBCN

Well, imho there is no perfect extruder that can be used with *any* kind of filament, otherwise we would know about it.

Ive not found anything in my testing, 1.75 or 3mm that the Flex3Drive cant handle, common and exotics and flexibles all run fine. (sorry i dont mean this to sound like blatant advertising), but just bringing awareness of this given your post above.

How long is the flex shaft on the Flex3Drive?

|

Re: Best choices for Extruder and Hot End August 07, 2015 11:09AM |

Registered: 9 years ago Posts: 977 |

Quote

Mutley3D

Quote

AndrewBCN

Well, imho there is no perfect extruder that can be used with *any* kind of filament, otherwise we would know about it.

Ive not found anything in my testing, 1.75 or 3mm that the F******** cant handle, common and exotics and flexibles all run fine. (sorry i dont mean this to sound like blatant advertising), but just bringing awareness of this given your post above.

Sorry, but to be honest I personally could not care less about whether a commercial product claims to be able to handle any kind of filament perfectly, and I do find it disturbing that you manage to slip an advertisement about this commercial product in nearly every single one of your posts.

|

Re: Best choices for Extruder and Hot End August 07, 2015 01:01PM |

Registered: 9 years ago Posts: 425 |

Quote

AndrewBCN

Quote

Mutley3D

Quote

AndrewBCN

Well, imho there is no perfect extruder that can be used with *any* kind of filament, otherwise we would know about it.

Ive not found anything in my testing, 1.75 or 3mm that the F******** cant handle, common and exotics and flexibles all run fine. (sorry i dont mean this to sound like blatant advertising), but just bringing awareness of this given your post above.

Sorry, but to be honest I personally could not care less about whether a commercial product claims to be able to handle any kind of filament perfectly, and I do find it disturbing that you manage to slip an advertisement about this commercial product in nearly every single one of your posts.

AndrewBCN: Firstly, the original poster JChicago asked a question, i gave an honest answer, you made a comment about "no perfect extruder" so i proceeded to provide further information and knowledge for the benefit of awareness. I furthermore and equally apologised as I am very much aware of the sensitivity of such "advertising". Had someone else posted that comment, it would not be advertising, however i was providing factual info to a real question. I am genuinely sorry you find this "disturbing" but forums serve a purpose.

As for commercial product and advertising, I am not offering a different version of the same thing that others are making, i offer a unique product into which goes one heck of a lot of development and effort, and i also provide a backup to the product that is second to none with a full on warranty on all parts and when it comes to forums i do so with the greatest of sensitivity in regard to this aspect of things. I stand by my product, unlike a lot of other vendors (there are a lot of good vendors too), and i care greatly about my customers. Potentially this could also be described as sales bumph, but I am simply addressing the point that you raised with some hostility.

I also do not post onto every forum thread that is related to extruders for the very same reason, i have had this extruder in the market place for some time, i have a dedicated post to the subject with updates and support questions, new releases etc.

WFCook: In relation to your question about driveshaft length, standard lengths are 750, 850, 950, 1100 depending on the variant and printer the individual intends to fit to. I can also provide custom lengths depending on an individual requirement.

|

Re: Best choices for Extruder and Hot End August 07, 2015 01:42PM |

Registered: 9 years ago Posts: 1,873 |

There are lots of commercial parts in our repraps - most of us don't make our own hotends and nozzles, and who makes their own steppers? I don't see a problem with Mutley3D raising awareness of his product where appropriate, provided it is done in an appropriate manner. It might be best to add a signature just to make it clear that you are the manufacturer of the product and might have a certain understandable bias

|

Re: Best choices for Extruder and Hot End August 07, 2015 02:27PM |

Registered: 9 years ago Posts: 977 |

Quote

Mutley3D

AndrewBCN: Firstly, the original poster JChicago asked a question, i gave an honest answer, you made a comment about "no perfect extruder" so i proceeded to provide further information and knowledge for the benefit of awareness. I furthermore and equally apologised as I am very much aware of the sensitivity of such "advertising". Had someone else posted that comment, it would not be advertising, however i was providing factual info to a real question.

...

Sorry, any way I try to cut it, I still see most of your posts as advertising. And whether others are OK or not with that, I am not.

If you want to discuss how to make the path from the hobbed bolt or gear to the hotend inlet as short as possible to improve the performance of a direct drive or Greg's Wade's Geared extruder with flexible filaments, I am all for that kind of geeky, technical discussion.

However, any blanket statement that your $170 extruder has managed to push and retract every kind of filament that exists in the world, that just sounds like used car salesman talk to me.

|

Re: Best choices for Extruder and Hot End August 07, 2015 02:59PM |

Registered: 9 years ago Posts: 977 |

Quote

JamesK

There are lots of commercial parts in our repraps - most of us don't make our own hotends and nozzles, and who makes their own steppers?

That is true, James (and obvious). But you don't get the manufacturers of hotends, nozzles and steppers posting too often here in this forum either, making any claims about their products.

Quote

JamesK

I don't see a problem with Mutley3D raising awareness of his product where appropriate, provided it is done in an appropriate manner. It might be best to add a signature just to make it clear that you are the manufacturer of the product and might have a certain understandable bias

"... a certain understandable bias..." is a very, very polite way of putting it, really. It makes me realize how blunt I am sometimes...

Let me have a cold beer now...

Let me have a cold beer now...

Edited 1 time(s). Last edit at 08/07/2015 02:59PM by AndrewBCN.

|

Re: Best choices for Extruder and Hot End August 07, 2015 03:00PM |

Registered: 9 years ago Posts: 425 |

Quote

AndrewBCN

Quote

Mutley3D

AndrewBCN: Firstly, the original poster JChicago asked a question, i gave an honest answer, you made a comment about "no perfect extruder" so i proceeded to provide further information and knowledge for the benefit of awareness. I furthermore and equally apologised as I am very much aware of the sensitivity of such "advertising". Had someone else posted that comment, it would not be advertising, however i was providing factual info to a real question.

...

Sorry, any way I try to cut it, I still see most of your posts as advertising. And whether others are OK or not with that, I am not.

If you want to discuss how to make the path from the hobbed bolt or gear to the hotend inlet as short as possible to improve the performance of a direct drive or Greg's Wade's Geared extruder with flexible filaments, I am all for that kind of geeky, technical discussion.

However, any blanket statement that your $170 extruder has managed to push and retract every kind of filament that exists in the world, that just sounds like used car salesman talk to me.

AndrewBCN: nice to be nice.

i said "every filament i have tested with" which includes a lot of flexibles, not "every filament in the world".

Also No kickstarter (free money) here, no investor, just hard hard work, good design, lots of testing, innovation

Pricing is difficult, i wish it could be cheaper, plus exchange hits hard for US. Compared to other "performance" extruders, its competitive

The thing is having been a used car salesman ive come to be able to spot the tyre kickers

Peace!

Edited 1 time(s). Last edit at 08/08/2015 12:35AM by Mutley3D.

|

Re: Best choices for Extruder and Hot End August 07, 2015 03:48PM |

Registered: 8 years ago Posts: 49 |

Quote

AndrewBCN

Quote

JamesK

There are lots of commercial parts in our repraps - most of us don't make our own hotends and nozzles, and who makes their own steppers?

That is true, James (and obvious). But you don't get the manufacturers of hotends, nozzles and steppers posting too often here in this forum either, making any claims about their products.

Quote

JamesK

I don't see a problem with Mutley3D raising awareness of his product where appropriate, provided it is done in an appropriate manner. It might be best to add a signature just to make it clear that you are the manufacturer of the product and might have a certain understandable bias

"... a certain understandable bias..." is a very, very polite way of putting it, really. It makes me realize how blunt I am sometimes...Let me have a cold beer now...

Personally, I'd rather see more manufacturers chiming in here and posting things like this. In every forum I am a part of in all the hobbies in which I am active, their posts are some of the most informative and useful. And, frankly, Mutley3D was clear enough that it was his product. At least it seemed obvious to me. And it's not like he posted a bunch of links, pictures, and a 25MB brochure.

Quote

AndrewBCN

However, any blanket statement that your $170 extruder has managed to push and retract every kind of filament that exists in the world, that just sounds like used car salesman talk to me.

So you've never tried the product and don't know anything about it, but have a very strong opinion anyway.

You also, as I recall, have stated that anyone wishing to try their hand at a large format printer is wasting their time. I guess you feel that you can't make it work or aren't interested in it, so it's a waste of time and they shouldn't even try. Note that you don't know their application or requirements. Maybe they want to print large hobby rocket nose cones (low precision OK, high build volume necessary). Or maybe a boom crutch for their sailboat. Who are you to judge the feasibility of their goals?

Every hobby has people like this and I suggest you stop being the guy pounding his fist on the table and screaming "THIS IS HOW YOU REPRAP!" There are a lot of different ways to approach this hobby. Some of them may not apply to you. Get over it.

Personally, I find the idea of using a flex shaft instead of a long bowden tube interesting. There are a lot of technical hurdles there, the primary one being in finding a flexible drive cable with the right characteristics for precision control (they do exist) but also available at a realistic price and quantity (haven't found one myself). Why shouldn't he mention it? He has good concept drawings on his site. I can either buy one or attempt to develop it myself. But it is nice to see these new ideas.

Edited 1 time(s). Last edit at 08/07/2015 04:07PM by wfcook.

|

Re: Best choices for Extruder and Hot End August 10, 2015 08:41AM |

Registered: 8 years ago Posts: 9 |

Thanks Mutley3d and everyone else....I appreciate all the information, and I'll certainly check out what's been mentioned. Getting back to the original question, does anyone else have anything else to add as far as extruders and hot ends that will print a decent variety of filaments (flexible and newer ones most notably)? direct drive, bulldog, Wade's....? I think it was "YOU magazine" or possibly Thingiverse that has a simple 2-piece direct extruder you print that uses the same hardware from Greg's/Wade's and just adds a MK8 gear...Looks okay, anyone tried it?

-J

-J

|

Re: Best choices for Extruder and Hot End August 10, 2015 09:49AM |

Registered: 9 years ago Posts: 977 |

Quote

JChicago

... Thingiverse that has a simple 2-piece direct extruder you print that uses the same hardware from Greg's/Wade's and just adds a MK8 gear...Looks okay, anyone tried it?

-J

There are dozens of 2-piece direct drive extruders on Thingiverse, none of them uses the same hardware as a Greg's Wade's Geared Extruder, and most of them are for Bowden filament systems. Unless you are more specific it would be difficult for anybody to comment upon this. Also Bowden systems and flexible filaments usually don't go well together, you really want an extruder that directly feeds the flexible filament into the hotend i.e. an extruder that sits on the carriage.

This is one of the reasons I previously stated that there are no perfect extruders that will handle any kind of filament. Note that if you are going to use an E3D V6 hotend you can have the PTFE tube that runs down the body of the hotend go right up to the hobbed bolt on a Greg's Wade's geared extruder. In other words, you can modify a standard Greg's Wade's Geared Extruder to work with flexible filament.

But again, this is all theory, in practice how well you manage to print with flexible filament on a printer that you have yet to decide upon and build is another story altogether. Besides that, 99% of all RepRappers will never need to print anything except PLA and ABS.

|

Re: Best choices for Extruder and Hot End August 10, 2015 06:49PM |

Registered: 8 years ago Posts: 9 |

I had never planned on using a Bowden type, I may try one down the road but in my experiences so far, the E3D seems to print pretty fast and is flexible in what material it can handle. I haven't heard of a better hot end so far, but that's why I'm here. Below is the link to the direct drive that re-purposes the Greg's/Wade's hardware. I have a couple of the MK8 drive gears, both 3mm and 1.75 but from what I've read 3mm doesn't work well on a non-geared extruder due to torque limitations. This unit looks interesting and is pretty simple...Comments welcome.

[www.youmagine.com]

-J

[www.youmagine.com]

-J

|

Re: Best choices for Extruder and Hot End August 10, 2015 08:56PM |

Registered: 9 years ago Posts: 977 |

I recently posted a video of a very simple and easy to print extruder that uses an MK8 gear gear, [www.youtube.com] and the only thing I can say is that these direct drive extruders work well enough (and I suppose the one you linked to is the same in that respect), but they require a high-torque stepper and you have to run the stepper near its maximum rated current, meaning it will run hot.

Geared extruders are more complex and require more printed parts but they solve this problem: you can use smaller steppers and run them at 70% of their rated current and you still get more than twice as much torque as any direct drive extruder.

So again, this is why I wrote above that any extruder design is a compromise, between a number of desirable features such as simplicity, ease of maintenance, ease of filament swap, weight, cost, availability of parts, etc...

Nothing replaces hands-on experimenting so I suggest you print a couple of different direct drive extruders (a simple direct drive extruder is a $5 investment or so, excluding the stepper) and try them, to see if they do what you want them to do. The "best" extruder is going to be the one that works for you.

Geared extruders are more complex and require more printed parts but they solve this problem: you can use smaller steppers and run them at 70% of their rated current and you still get more than twice as much torque as any direct drive extruder.

So again, this is why I wrote above that any extruder design is a compromise, between a number of desirable features such as simplicity, ease of maintenance, ease of filament swap, weight, cost, availability of parts, etc...

Nothing replaces hands-on experimenting so I suggest you print a couple of different direct drive extruders (a simple direct drive extruder is a $5 investment or so, excluding the stepper) and try them, to see if they do what you want them to do. The "best" extruder is going to be the one that works for you.

|

Re: Best choices for Extruder and Hot End August 10, 2015 10:24PM |

Registered: 9 years ago Posts: 705 |

|

Re: Best choices for Extruder and Hot End August 19, 2015 11:44PM |

Registered: 12 years ago Posts: 187 |

Sorry to butt in here - but this thread came up in a search of my own. (I suspect my question has been asked and answered many times before - apologies if that is the case!)

I have a home-built Prusa Mendel, which was designed and built for 3 mm filament. It has an original Wade's Geared Extruder (which is still working fine), and it had the original PTFE-bodied "Geared Extruder Nozzle" [reprap.org] , which has failed by the metal tip shearing off the threaded PTFE neck at the bottom of the PTFE body. (I think the main cause of the failure was probably over-heating, because I didn't have a hot-end fan - I have since rectified this!)

I have purchased a replacement 3 mm J-Head, because I still have lots of 3 mm PLA stock, but I've noticed that a lot of new filaments are coming available in 1.75 mm only, and it got me to thinking: How much work does it take to put a 1.75 mm hot end onto the Wade's Extruder?

AndrewsBCN said:

"If you just want to use 1.75mm filament you can just change the E3D hotend for a 1.75mm version and print yourself a new Greg's Wade's Geared Extruder body and idler for 1.75mm filament."

Can I take it that in order to print with 1.75 mm filament, I can just install a 1.75 mm J-Head or similar onto the Wades Extruder, and change my software settings? Can a 3 mm Wade's Extruder push 1.75 mm filament reliably, without any other modifications?

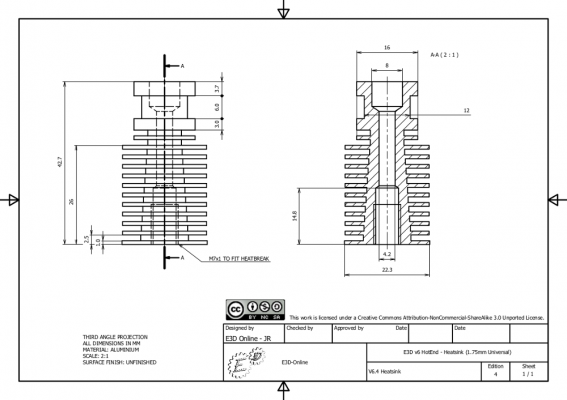

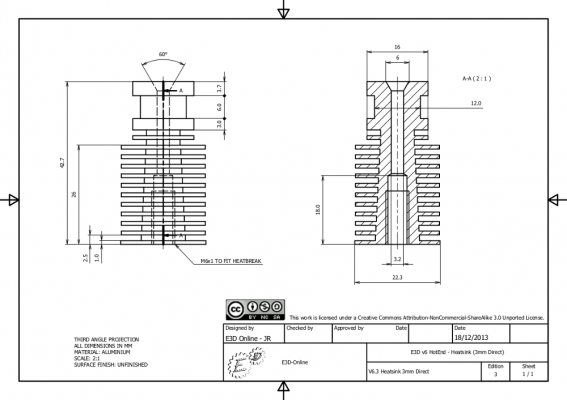

In the pictures that I have found, the set-screw at the top of the PEEK body (which retains the internal PTFE sleeve) sits flush with the PEEK in the 3 mm version, but stands proud on the 1.75 mm versions - see attached photos. I couldn't find a dimensioned drawing of this protruding screw - will it clear the filament hole in the Wade's Extruder body (4 mm diameter?)? (I guess I can ream out the hole in the Extruder Body if necessary, to provide more clearance?)

Are there any other tricks or traps I need to be aware of?

Thanks for all comments!

Follow my Mendel Prusa build here: [julianh72.blogspot.com]

I have a home-built Prusa Mendel, which was designed and built for 3 mm filament. It has an original Wade's Geared Extruder (which is still working fine), and it had the original PTFE-bodied "Geared Extruder Nozzle" [reprap.org] , which has failed by the metal tip shearing off the threaded PTFE neck at the bottom of the PTFE body. (I think the main cause of the failure was probably over-heating, because I didn't have a hot-end fan - I have since rectified this!)

I have purchased a replacement 3 mm J-Head, because I still have lots of 3 mm PLA stock, but I've noticed that a lot of new filaments are coming available in 1.75 mm only, and it got me to thinking: How much work does it take to put a 1.75 mm hot end onto the Wade's Extruder?

AndrewsBCN said:

"If you just want to use 1.75mm filament you can just change the E3D hotend for a 1.75mm version and print yourself a new Greg's Wade's Geared Extruder body and idler for 1.75mm filament."

Can I take it that in order to print with 1.75 mm filament, I can just install a 1.75 mm J-Head or similar onto the Wades Extruder, and change my software settings? Can a 3 mm Wade's Extruder push 1.75 mm filament reliably, without any other modifications?

In the pictures that I have found, the set-screw at the top of the PEEK body (which retains the internal PTFE sleeve) sits flush with the PEEK in the 3 mm version, but stands proud on the 1.75 mm versions - see attached photos. I couldn't find a dimensioned drawing of this protruding screw - will it clear the filament hole in the Wade's Extruder body (4 mm diameter?)? (I guess I can ream out the hole in the Extruder Body if necessary, to provide more clearance?)

Are there any other tricks or traps I need to be aware of?

Thanks for all comments!

Follow my Mendel Prusa build here: [julianh72.blogspot.com]

|

Re: Best choices for Extruder and Hot End August 20, 2015 12:02AM |

Registered: 9 years ago Posts: 517 |

I have never used a J-Head so not sure about it. I use the E3Dv6 and the bodies of the 3mm and 1.75mm are the same. So you wouldn't have to change the mounts. Any tubing you have that handles the 3mm filament will need to be replaced with tubing for 1.75mm. Based on the pictures you included, it looks like the two J-Heads use the same body so you should be able to use the same mount. If you aren't using a Bowden feed, then you could probably keep the tubing for the 3mm filament that is before the extruder motor (from the spool to the motor). But if you are using a Bowden, or if there is any tubing between the motor and the hotend, that will need to be replaced with the appropriate size tubing.

Clear as mud now?

Clear as mud now?

|

Re: Best choices for Extruder and Hot End August 20, 2015 01:55AM |

Registered: 9 years ago Posts: 977 |

Quote

julianh72

...

Can I take it that in order to print with 1.75 mm filament, I can just install a 1.75 mm J-Head or similar onto the Wades Extruder, and change my software settings? Can a 3 mm Wade's Extruder push 1.75 mm filament reliably, without any other modifications?

...

Well, a 3mm Greg's Wade's Geared Extruder should possibly be able to push 1.75mm filament, however it cannot be guaranteed to do so reliably, or as reliably as a 1.75mm one would. You have two solutions here:

1) Print yourself a 1.75mm Greg's Wade's Geared Extruder. That takes < 100g of filament and you can reuse all the metal parts (bearings, screws, hobbed bolt, etc) from your present extruder. Or...

2) Drill a 4mm hole through your 3mm Greg's Wade's body and insert a piece of 4mm OD, 2mm ID PTFE (Teflon) tube inside, going from the hobbed bolt right down to the Jhead.

I would suggest you just print yourself a new 1.75mm extruder and even buy all the metal parts for it. And then swap extruders on the X-carriage whenever you have to cycle through two different filament diameters.

|

Re: Best choices for Extruder and Hot End August 20, 2015 02:07AM |

Registered: 12 years ago Posts: 187 |

Clear as mud now?

Yes, I think so - thanks!

The Wades Extruder isn't a Bowden, and doesn't use any tubing, and I don't use any tubing from the spool to the top of the extruder drive. (Should I?)

The 1.75 mm and 3 mm J-Head have the same mounting detail, but the protruding set-screw in the top of the 1.75 mm version worries me a bit - it might foul the bottom of the Extruder body. If so, I think this would be easily fixed by reaming out a bit of a clearance hole for the set-screw.

There is a small hole in the extruder body (4 mm diameter by 25 mm deep, I think) below the hobbed bolt and pinch roller. The 3 mm filament goes through there straight into the top of the hot end. The only potential issue I can see is that the 3 mm filament is stable as it passes through this clearance-sized hole, but would the more flexible 1.75 mm filament tend to kink or buckle? Oh well - there's one sure way to find out - I might just buy a 1.75 mm J-Head, and see what happens! (As Jeremy Clarkson would say: "How hard can it be?" )

)

Follow my Mendel Prusa build here: [julianh72.blogspot.com]

Yes, I think so - thanks!

The Wades Extruder isn't a Bowden, and doesn't use any tubing, and I don't use any tubing from the spool to the top of the extruder drive. (Should I?)

The 1.75 mm and 3 mm J-Head have the same mounting detail, but the protruding set-screw in the top of the 1.75 mm version worries me a bit - it might foul the bottom of the Extruder body. If so, I think this would be easily fixed by reaming out a bit of a clearance hole for the set-screw.

There is a small hole in the extruder body (4 mm diameter by 25 mm deep, I think) below the hobbed bolt and pinch roller. The 3 mm filament goes through there straight into the top of the hot end. The only potential issue I can see is that the 3 mm filament is stable as it passes through this clearance-sized hole, but would the more flexible 1.75 mm filament tend to kink or buckle? Oh well - there's one sure way to find out - I might just buy a 1.75 mm J-Head, and see what happens! (As Jeremy Clarkson would say: "How hard can it be?"

)

)Follow my Mendel Prusa build here: [julianh72.blogspot.com]

|

Re: Best choices for Extruder and Hot End August 20, 2015 02:13AM |

Registered: 9 years ago Posts: 977 |

|

Re: Best choices for Extruder and Hot End August 20, 2015 02:29AM |

Registered: 12 years ago Posts: 187 |

You have two solutions here:

1) Print yourself a 1.75mm Greg's Wade's Geared Extruder. That takes < 100g of filament and you can reuse all the metal parts (bearings, screws, hobbed bolt, etc) from your present extruder. Or...

2) Drill a 4mm hole through your 3mm Greg's Wade's body and insert a piece of 4mm OD, 2mm ID PTFE (Teflon) tube inside, going from the hobbed bolt right down to the Jhead.

Thanks, AndrewBCN - that's what I needed to know. (I guess the issue is the risk of the 1.75 mm filament buckling / kinking inside the 4 mm filament duct - is that right?)

Is there a link to the CAD files for a 1.75 mm Wade's Extruder? The only version I can find seems to be detailed only for 3 mm filament. If not, is the only difference the diameter of the filament duct? (I could easily "fill in" the filament duct holes in the CAD model I have, and place new 2 mm holes. Does 2 mm give the right clearance for 1.75 mm filament?)

Thanks!

Follow my Mendel Prusa build here: [julianh72.blogspot.com]

1) Print yourself a 1.75mm Greg's Wade's Geared Extruder. That takes < 100g of filament and you can reuse all the metal parts (bearings, screws, hobbed bolt, etc) from your present extruder. Or...

2) Drill a 4mm hole through your 3mm Greg's Wade's body and insert a piece of 4mm OD, 2mm ID PTFE (Teflon) tube inside, going from the hobbed bolt right down to the Jhead.

Thanks, AndrewBCN - that's what I needed to know. (I guess the issue is the risk of the 1.75 mm filament buckling / kinking inside the 4 mm filament duct - is that right?)

Is there a link to the CAD files for a 1.75 mm Wade's Extruder? The only version I can find seems to be detailed only for 3 mm filament. If not, is the only difference the diameter of the filament duct? (I could easily "fill in" the filament duct holes in the CAD model I have, and place new 2 mm holes. Does 2 mm give the right clearance for 1.75 mm filament?)

Thanks!

Follow my Mendel Prusa build here: [julianh72.blogspot.com]

|

Re: Best choices for Extruder and Hot End August 20, 2015 07:16AM |

Registered: 9 years ago Posts: 977 |

I am guessing this would be close enough: Ultimate Greg's Wade's Geared Extruder - 30mm version

|

Re: Best choices for Extruder and Hot End August 20, 2015 08:51AM |

Registered: 8 years ago Posts: 49 |

Quote

ElmoC

I use the E3Dv6 and the bodies of the 3mm and 1.75mm are the same.

Not quite, there are some differences:

Sorry, only registered users may post in this forum.