Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater?

Posted by NarimaanV

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 04, 2015 09:53AM |

Registered: 9 years ago Posts: 41 |

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 04, 2015 10:25AM |

Registered: 10 years ago Posts: 814 |

Using the NO (Normally Open) NPN sensor I have Wired Normally

Brown - 12v

Blue - Ground

Black - Signal

I get 11.5v No LED without metal near sensor. Bright LED and 0v with metal near sensor. Too much V to directly connect to RAMPS.

Wiring this way

Brown - 12v

Black - Ground

Blue - Signal

I get Dim LED 2.84v without metal near sensor. Bright LED and 0v with metal near sensor.

Wired this way, I connected the blue directly to RAMPS Zmin Signal and it worked.

Hope that helps clarify.

Brown - 12v

Blue - Ground

Black - Signal

I get 11.5v No LED without metal near sensor. Bright LED and 0v with metal near sensor. Too much V to directly connect to RAMPS.

Wiring this way

Brown - 12v

Black - Ground

Blue - Signal

I get Dim LED 2.84v without metal near sensor. Bright LED and 0v with metal near sensor.

Wired this way, I connected the blue directly to RAMPS Zmin Signal and it worked.

Hope that helps clarify.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 04, 2015 10:33AM |

Registered: 9 years ago Posts: 41 |

Quote

madmike8

Using the NO (Normally Open) NPN sensor I have Wired Normally

Brown - 12v

Blue - Ground

Black - Signal

I get 11.5v No LED without metal near sensor. Bright LED and 0v with metal near sensor. Too much V to directly connect to RAMPS.

Wiring this way

Brown - 12v

Black - Ground

Blue - Signal

I get Dim LED 2.84v without metal near sensor. Bright LED and 0v with metal near sensor.

Wired this way, I connected the blue directly to RAMPS Zmin Signal and it worked.

Hope that helps clarify.

What is the wiring layout of your sensor? Is it Brown = Power, Black = Output Signal, and Blue = Ground?

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 04, 2015 05:45PM |

Registered: 9 years ago Posts: 74 |

Quote

NarimaanV

Quote

madmike8

Using the NO (Normally Open) NPN sensor I have Wired Normally

Brown - 12v

Blue - Ground

Black - Signal

I get 11.5v No LED without metal near sensor. Bright LED and 0v with metal near sensor. Too much V to directly connect to RAMPS.

Wiring this way

Brown - 12v

Black - Ground

Blue - Signal

I get Dim LED 2.84v without metal near sensor. Bright LED and 0v with metal near sensor.

Wired this way, I connected the blue directly to RAMPS Zmin Signal and it worked.

Hope that helps clarify.

What is the wiring layout of your sensor? Is it Brown = Power, Black = Output Signal, and Blue = Ground?

That is how mine is wired. I get the same light setup which confused me for a while. It took me playing with a 9v battery to figure out how to actually wire it up as when I first hooked it up to my ramps I had nothing.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 04, 2015 07:13PM |

Registered: 9 years ago Posts: 41 |

Well I just tested the LJC18A3-H-Z/BX with my Arduino Uno (because if anything breaks, I'd rather it be that than my Mega and RAMPS board). Connected the sensor's power (brown) to 9V, the Ground (blue) to Ground, and the output (black) straight into a digital IO pin on the Uno. Then in a simple script, I enabled the internal pull-up resistor, and told it to light the internal LED of the Uno whenever the signal pin was LOW. Ran it and it all worked as expected! No smoke or broken Uno so I think that's definitive enough to say you don't need anything in between the sensor and a 5V board (for anyone who was still feeling a bit cautious). Doesn't hurt to have something in between, but also not a requirement either.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 05, 2015 10:24AM |

Registered: 8 years ago Posts: 30 |

I wasn't sure as I got 12V on the sensor output when testing. Just to be safe I connected to the voltage divider I'd previously used for my inductive sensor. Works so I'll leave it like that for now.

BTW the LJC18A3-H-Z/BX works great with my glass plate. Highly recommended. I just wish it was smaller like the 8mm diameter inductive sensor.

Edited 1 time(s). Last edit at 10/05/2015 10:26AM by JBFUK.

BTW the LJC18A3-H-Z/BX works great with my glass plate. Highly recommended. I just wish it was smaller like the 8mm diameter inductive sensor.

Edited 1 time(s). Last edit at 10/05/2015 10:26AM by JBFUK.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 05, 2015 10:45AM |

Registered: 9 years ago Posts: 41 |

Quote

JBFUK

I wasn't sure as I got 12V on the sensor output when testing. Just to be safe I connected to the voltage divider I'd previously used for my inductive sensor. Works so I'll leave it like that for now.

BTW the LJC18A3-H-Z/BX works great with my glass plate. Highly recommended. I just wish it was smaller like the 8mm diameter inductive sensor.

Yeah it never hurts to have some isolation/protection between the sensor and the RAMPS.

Curious though, when you say you had 12V on the signal output of the sensor when testing, how were you testing it? Did you have a pull-up resistor to 12V?

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 06, 2015 12:56PM |

Registered: 8 years ago Posts: 30 |

No I simply powered with 12v via the brown and blue wires and then measured the voltage between the black output wire and ground when activated. I take it this is not an accurate interpretation of what RAMPS would see if I connected that black wire directly to it? Wouldn't mind getting rid of the little voltage divider circuit if I could it would tidy things up a bit.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 06, 2015 09:26PM |

Registered: 9 years ago Posts: 41 |

Quote

JBFUK

No I simply powered with 12v via the brown and blue wires and then measured the voltage between the black output wire and ground when activated. I take it this is not an accurate interpretation of what RAMPS would see if I connected that black wire directly to it? Wouldn't mind getting rid of the little voltage divider circuit if I could it would tidy things up a bit.

So here's how I set mine up and if you can, try it as well and see if you get similar/same results: I wired the power to 9V (or 12V in your case), the the ground to ground, and the signal to 5V via a 10k resistor (i.e. a pull-up resistor). Then I connected the multimeter to ground and signal. When there's nothing near the sensor, my multimeter reads 5.6-5.7V (I have no idea where the extra 0.6-0.7 volts is coming from but I'd imagine Arduinos can still handle it since my Uno could). Then when there was something near the sensor, it read exactly 0V. If you try and get the same results, then you should be safe to wire it up straight (theoretically).

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 07, 2015 07:14AM |

Registered: 8 years ago Posts: 30 |

I see, the difference is connecting the black line to ground and using the blue line as the endstop input as opposed to the other way around which is what the sensor wiring diagram on the device itself shows. I'll switch to doing that once I've printed out a RAMPS enclosure and tidy up my wiring.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 07, 2015 03:36PM |

Registered: 9 years ago Posts: 41 |

Quote

JBFUK

I see, the difference is connecting the black line to ground and using the blue line as the endstop input as opposed to the other way around which is what the sensor wiring diagram on the device itself shows. I'll switch to doing that once I've printed out a RAMPS enclosure and tidy up my wiring.

I'm still a little confused about that, as others have mentioned doing that as well. Why connect the ground wire (blue) to signal and the signal wire (black) to ground? What's wrong with power-power, signal-signal and to 5V through a pull-up resistor, and ground to ground?

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 08, 2015 06:44AM |

Registered: 8 years ago Posts: 30 |

I'm not sure and to be honest I just don't want to have another broken component to replace. I already suffered a blown PSU and MOSFET on the bed feed when the heatbed managed to short itself out - the washers above the bed spring slowly wore through the PCB coating and resulted in a short via the frame! Could be a blessing in disguise as I replaced the MOSFET with a much higher rated component which doesn't even get warm in use. Still it's annoying to have to wait days for a replacement part, disassemble etc etc.

Think I'll leave it how it is for now and focus on tuning my prints. Very happy to be back on glass as opposed to an ali build plate.

Think I'll leave it how it is for now and focus on tuning my prints. Very happy to be back on glass as opposed to an ali build plate.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 08, 2015 06:59AM |

Registered: 9 years ago Posts: 41 |

Quote

JBFUK

I'm not sure and to be honest I just don't want to have another broken component to replace. I already suffered a blown PSU and MOSFET on the bed feed when the heatbed managed to short itself out - the washers above the bed spring slowly wore through the PCB coating and resulted in a short via the frame! Could be a blessing in disguise as I replaced the MOSFET with a much higher rated component which doesn't even get warm in use. Still it's annoying to have to wait days for a replacement part, disassemble etc etc.

Think I'll leave it how it is for now and focus on tuning my prints. Very happy to be back on glass as opposed to an ali build plate.

Wow that is an unfortunate sequence of events. Glad you got something good out of it though with the beefier MOSFET. And yeah, by all means, "if it ain't broke, don't fix it" with your current setup. Thanks for sharing your experience with the sensor so far!

Edited 1 time(s). Last edit at 10/08/2015 07:00AM by NarimaanV.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? October 09, 2015 07:26AM |

Registered: 8 years ago Posts: 3,525 |

Quote

NarimaanV

I think people use the inductive sensors for the advantages of a metal bed as well as opposed to just inductive vs capacitive. And if you already have a metal bed, I'd imagine inductive is probably better to go for than capacitive (don't know for sure, but I think capacitive is slightly open to interference by other stuff near the sensor where as inductive mainly pics up only metallic surfaces).

As for NPN vs PNP, I don't know exactly why they go for PNP, I think it might have to do with Printrbot's inductive sensor being infamous for being reliable and it happens to be a PNP sensor, so people might go for that over others because there are lots of reviews saying good things about it.

People go for PNP as it produces a normally closed output and is therefore a safety feature, if the sensor fails the z-endstop is triggered and the carriage stops, preventing a head/nozzle crash. I currently use an NPN sensor on an I3, it was much easier to set up. The sensor is wired directly to the 3 pin header for the z min endstop on RAMPS and works at 5v perfectly with approximately a 3mm detection distance to an aluminium mk3 heatbed. The LED on it doesn't light up but I'm not bothered. I have had some head crashes though, and I have to test the sensor before each printing session. With PNP you don't have to do this test and it fails-safe rather than failing dangerously. But you do have to reduce the signal voltage to 5v to prevent damage to your ramps board.

Edited 1 time(s). Last edit at 10/09/2015 07:26AM by DjDemonD.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 27, 2016 01:07PM |

Registered: 8 years ago Posts: 38 |

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 27, 2016 01:44PM |

Registered: 9 years ago Posts: 41 |

Quote

usen

Hi,

I use it in cartesian 3d printer type. I modified g-codes for Z-Probe with NPN Capacitive Proximity Sensor (LJC18A3-B-Z/BX).

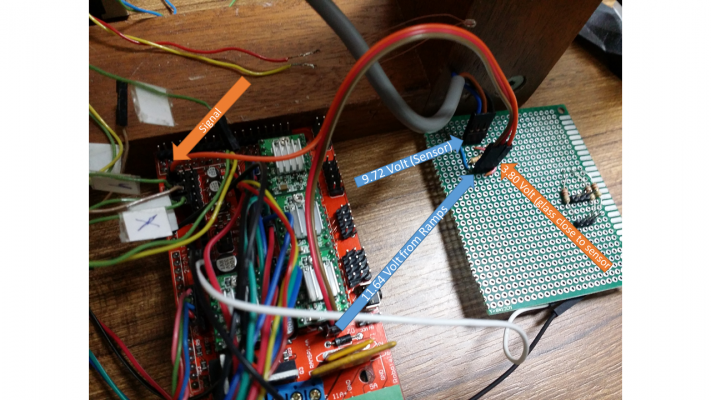

I measure capacitive sensor data from multimeter:

Input: 11.64 Volt

Signal: 3.80 Volt

Sensor Output: 9.72 Volt

Is there any problem?

Could you clarify what "Signal" vs "Sensor Output" is? If I'm interpreting that right and Sensor Output is what's going directly into your electronics, that's not great for them. Could you also post what electronics run your printer?

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 27, 2016 02:12PM |

Registered: 8 years ago Posts: 38 |

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 27, 2016 05:36PM |

Registered: 9 years ago Posts: 41 |

I see, that should be fine then as too little voltage can't harm your RAMPS board. Have you checked the Sensor Output voltage when it's not triggered to make sure it doesn't exceed 5V as well?

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 29, 2016 07:37AM |

Registered: 8 years ago Posts: 38 |

When it's not triggered, it is 0.91V. Is it enough (3,80 volt) when it is triggered? Because, capacitive sensor doesn't work well everytime.

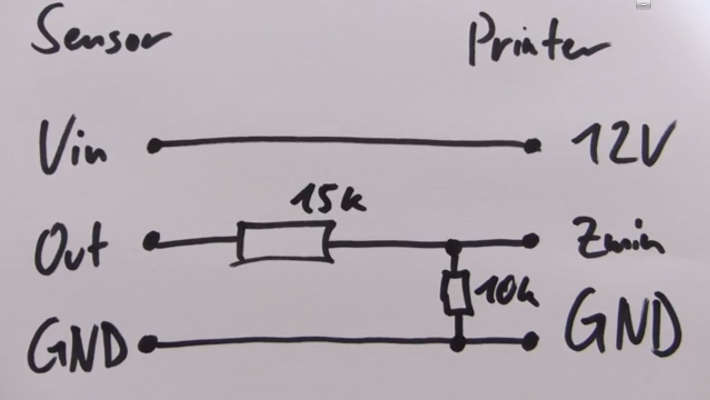

I watched this video: [www.youtube.com] and I use 15k and 10k resistors like below:

I watched this video: [www.youtube.com] and I use 15k and 10k resistors like below:

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 29, 2016 11:03AM |

Registered: 9 years ago Posts: 41 |

Quote

usen

When it's not triggered, it is 0.91V. Is it enough (3,80 volt) when it is triggered? Because, capacitive sensor doesn't work well everytime.

I watched this video: [www.youtube.com] and I use 15k and 10k resistors like below:

Well that assumes your sensor is putting out 12V when triggered, which it possibly might not considering your "reduced" voltage is as low as 3.8V. Have you measured the voltage coming out of the sensor before it reaches the voltage-reducer circuit you made?

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 30, 2016 06:05AM |

Registered: 8 years ago Posts: 38 |

When it is not triggered;

11,82V (Sensor Output) and 0,62V (Signal Output from Sensor)

11,84V (Sensor Output Reach to Ramps 1.4) and 0,92V (Signal Reach to Ramps 1.4)

When it is triggered;

9,31V (Sensor Output) and 2,66V (Signal Output from Sensor)

11,97V (Sensor Output Reach to Ramps 1.4) and 3,81V (Signal Reach to Ramps 1.4)

11,82V (Sensor Output) and 0,62V (Signal Output from Sensor)

11,84V (Sensor Output Reach to Ramps 1.4) and 0,92V (Signal Reach to Ramps 1.4)

When it is triggered;

9,31V (Sensor Output) and 2,66V (Signal Output from Sensor)

11,97V (Sensor Output Reach to Ramps 1.4) and 3,81V (Signal Reach to Ramps 1.4)

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 30, 2016 01:03PM |

Registered: 9 years ago Posts: 1,035 |

Hello, I was thinking of going capacitive for a while now but something doesn't click.

We need to measure bed level at nozzle height when nozzle is heated up right? How do you place such a bulky piece of hardware close enough to the nozzle so it performs its function properly? How far is too far?

That was for horizontal placement. Now for vertical placement and setup you should first know the offset from the heated nozzle tip. How do you measure that? And how do you factor in the sensor's own error?

I don't know why but this all probing and leveling should really be done between the heated nozzle tip and the bed. There should be a way to accurately measure when the nozzle touches the bed. Put current in the nozzle, current in the bed, at contact register ...Ok this might be overly simplistic and maybe naive/dangerous, but you get the point.

I have the Overlord Pro and although the auto-bed leveling is not performing as anticipated (I greatly put that on software), it's doing probeless auto-bed leveling quite smart. And now that is open source, maybe that can be replicated.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

We need to measure bed level at nozzle height when nozzle is heated up right? How do you place such a bulky piece of hardware close enough to the nozzle so it performs its function properly? How far is too far?

That was for horizontal placement. Now for vertical placement and setup you should first know the offset from the heated nozzle tip. How do you measure that? And how do you factor in the sensor's own error?

I don't know why but this all probing and leveling should really be done between the heated nozzle tip and the bed. There should be a way to accurately measure when the nozzle touches the bed. Put current in the nozzle, current in the bed, at contact register ...Ok this might be overly simplistic and maybe naive/dangerous, but you get the point.

I have the Overlord Pro and although the auto-bed leveling is not performing as anticipated (I greatly put that on software), it's doing probeless auto-bed leveling quite smart. And now that is open source, maybe that can be replicated.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 30, 2016 01:35PM |

Registered: 9 years ago Posts: 517 |

Check this video out on calibrating the sensor...

[www.youtube.com]

This is a Printrbot Simple with an inductive sensor, but the same procedure can be used with the capacitive one. The M212 command used in the video is for Marlin. Other firmware may do it differently, but they all function the same. It sets the height of the tip on the hotend from the bed when the sensor triggers. You adjust this value until the first layer is put down correctly.

[www.youtube.com]

This is a Printrbot Simple with an inductive sensor, but the same procedure can be used with the capacitive one. The M212 command used in the video is for Marlin. Other firmware may do it differently, but they all function the same. It sets the height of the tip on the hotend from the bed when the sensor triggers. You adjust this value until the first layer is put down correctly.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 30, 2016 02:07PM |

Registered: 9 years ago Posts: 41 |

Quote

usen

When it is not triggered;

11,82V (Sensor Output) and 0,62V (Signal Output from Sensor)

11,84V (Sensor Output Reach to Ramps 1.4) and 0,92V (Signal Reach to Ramps 1.4)

When it is triggered;

9,31V (Sensor Output) and 2,66V (Signal Output from Sensor)

11,97V (Sensor Output Reach to Ramps 1.4) and 3,81V (Signal Reach to Ramps 1.4)

I think you may have misunderstood my previous point. What's important in determining why your resistor-reduction circuit is making the signal only 3.8V to the ramps board is to determine what raw signal voltage is coming from the sensor when it's triggered. So literally put the multimeter's negative probe on ground and the positive probe on the output signal what normally would go to the RAMPS, except BEFORE it reaches the resistors.

Quote

realthor

Hello, I was thinking of going capacitive for a while now but something doesn't click.

We need to measure bed level at nozzle height when nozzle is heated up right? How do you place such a bulky piece of hardware close enough to the nozzle so it performs its function properly? How far is too far?

That was for horizontal placement. Now for vertical placement and setup you should first know the offset from the heated nozzle tip. How do you measure that? And how do you factor in the sensor's own error?

I don't know why but this all probing and leveling should really be done between the heated nozzle tip and the bed. There should be a way to accurately measure when the nozzle touches the bed. Put current in the nozzle, current in the bed, at contact register ...Ok this might be overly simplistic and maybe naive/dangerous, but you get the point.

I have the Overlord Pro and although the auto-bed leveling is not performing as anticipated (I greatly put that on software), it's doing probeless auto-bed leveling quite smart. And now that is open source, maybe that can be replicated.

Another nice video explaining the process as well: Youtube Video

The main idea process for calibrating the sensor according to the above is to first mount the sensor in such a way that when you home it, it triggers before your hotend touches the bed (doesn't matter by how much, just as long as there's some gap between the bed and the hotness and probe). Then you lower the z-axis in incriments of 1mm and 0.1mm until the hotend gives a little resistance to a sheet of paper sliding between it and the bed, and whatever your current height is becomes the z-probe offset (has to be a negative number).

Horizontally speaking, the sensor doesn't have to be THAT close to the hotend, as long as you tell the firmware what it's offset in the X and Y are you're fine. Determining that can be as simple as put a piece of paper with a dot on the bed, put the hotend directly above it, zero your coordinates, move the probe above the dot, then those coordinates are your offsets (positive or negative depending on the position).

And your idea is actually not naive at all. There are several 3D printers out there that implement that exact functionality. Some have a metal bed so it's just a matter of the hotend touching the bed, while some have precision spacers in the corners that are conductive and act as the probing points.

Quote

ElmoC

The M212 command used in the video is for Marlin. Other firmware may do it differently, but they all function the same. It sets the height of the tip on the hotend from the bed when the sensor triggers. You adjust this value until the first layer is put down correctly.

Does "vanilla" Marlin support M212 as well? From the RepRap wiki it seems that's something only Printrbot's branch added and the Marlin Github wiki doesn't list that as one of the G-Codes.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 30, 2016 03:59PM |

Registered: 10 years ago Posts: 14,672 |

On a delta printer it is vital to have the height sensor as close to the nozzle as possible. It also helps if it is very light. That is why I designed my mini differential IR sensor to be small enough to fit under the heatsink of an E3D V6 hot end. It will give you more reproducible results that a capacitive sensor, which is likely to be affected by temperature and humidity. See link in my signature for more.

Inductive sensors work OK on aluminium, as long as you have only a very thin film or sheet on top of it (so not a glass plate), but the are larger and heavier than IR sensors.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Inductive sensors work OK on aluminium, as long as you have only a very thin film or sheet on top of it (so not a glass plate), but the are larger and heavier than IR sensors.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 31, 2016 08:42PM |

Registered: 9 years ago Posts: 1,035 |

How necessary is a level compensation procedure on a cartesian printer? Even the cantilever beds can be quite accurately leveled mechanically and the rocking during printing on some of those beds is not accounted for anyway.

Does the bed loose leveling after once manually leveled to justify carrying a probe around and doing the leveling at each print?

I think people should better think this hard about a good structure before auto level compensation. I am sorry but all this focus on probes seems to me a good way for people to avoid the more painful thinking about what is in fact wrong.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Does the bed loose leveling after once manually leveled to justify carrying a probe around and doing the leveling at each print?

I think people should better think this hard about a good structure before auto level compensation. I am sorry but all this focus on probes seems to me a good way for people to avoid the more painful thinking about what is in fact wrong.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? January 31, 2016 08:53PM |

Registered: 9 years ago Posts: 41 |

Quote

realthor

Does the bed loose leveling after once manually leveled to justify carrying a probe around and doing the leveling at each print?

I think people should better think this hard about a good structure before auto level compensation. I am sorry but all this focus on probes seems to me a good way for people to avoid the more painful thinking about what is in fact wrong.

I think it depends on how rigid the printer is on how often it needs to be leveled. My university has one of those Replicator clones who's frame and connections are very rigid, so that has to be leveled maybe ever ~10 prints. My personal printer at home, a 10" Makerfarm Prusa i3v, is also quote rigid, but I find it needs to be re-leveled about every 2-3 prints, which is why I personally find the probe helpful.

And you're right, it probably is more beneficial to figure out a way to solve calibration issues instead of a mechanism that lets you get away with "working around" those issues.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? February 11, 2016 01:45AM |

Registered: 11 years ago Posts: 469 |

and dont forget auto bed leveling means the z axis will be constantly moving during a print !!! Im not confident that M5 threaded rod ( typical Prusa i3) and stock nut will handle that constant movement well.

Even on my Prusa Air 2 where i have ball screws on the Z axis im still on the fence as to the relative advantages of auto bed leveling . Just my 2 cents

Edited 1 time(s). Last edit at 02/11/2016 01:46AM by bigfilsing.

Even on my Prusa Air 2 where i have ball screws on the Z axis im still on the fence as to the relative advantages of auto bed leveling . Just my 2 cents

Edited 1 time(s). Last edit at 02/11/2016 01:46AM by bigfilsing.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? February 11, 2016 03:07AM |

Registered: 9 years ago Posts: 893 |

I have auto-levelling on my Prusa i3 - yesterday I printed a piece that was 198mm x 198mm and had no problems. The X axis screws don't move much as long as the bed is close to level in the first place - in my case, the bed is rigidly fixed to the Y carriage, but I did make efforts to level it with washers when fastening it down - all you can see is slight rotation of the motors as the hot-end moves around.

|

Re: Best Capacitive Proximity Sensor for Glass Sheet on PCB Heater? February 11, 2016 04:01AM |

Registered: 9 years ago Posts: 1,035 |

Quote

bigfilsing

and dont forget auto bed leveling means the z axis will be constantly moving during a print !!! Im not confident that M5 threaded rod ( typical Prusa i3) and stock nut will handle that constant movement well.

Even on my Prusa Air 2 where i have ball screws on the Z axis im still on the fence as to the relative advantages of auto bed leveling . Just my 2 cents

Maybe the whole point of bed leveling should be to warn you when the bed goes unleveled and then you should choose what the bed leveling should do in software: stop the printing process until you level or go for the Z-compensation. I would vote for the first variant and strive for a rigid frame. That way you'll have less problems down the road and Z will not constantly work so people can have cheaper components while still having great prints.

Offtopic: If these guys can do a concrete lathe, I wonder if we can't just design a concrete frame for a very rigid 3D printer.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.