Local makerspace gone mad :-D

Posted by boelle

|

Local makerspace gone mad :-D September 03, 2015 10:13AM |

Registered: 9 years ago Posts: 93 |

Hi all

The local makerspace has gone mad

They want to build a 3d printer that has a 600*600 build plate and 600mm movement for the Z axis

Insane yes, but at least its not my idea, but i want to play along just for the fun of it

With that size plate it cant be a moving one as it will be to much mass to move

So far i have thought of a delta or a H bot.... for the delta's a i have looked at open beam etc but there are not many plans or scripts that can provide a build plan

Any pointers etc are much welcome

BTW speed is not the goal... the goal is producing quality prints.... and yes large prints takes time i know

The local makerspace has gone mad

They want to build a 3d printer that has a 600*600 build plate and 600mm movement for the Z axis

Insane yes, but at least its not my idea, but i want to play along just for the fun of it

With that size plate it cant be a moving one as it will be to much mass to move

So far i have thought of a delta or a H bot.... for the delta's a i have looked at open beam etc but there are not many plans or scripts that can provide a build plan

Any pointers etc are much welcome

BTW speed is not the goal... the goal is producing quality prints.... and yes large prints takes time i know

|

Re: Local makerspace gone mad :-D September 03, 2015 01:13PM |

Registered: 9 years ago Posts: 569 |

I believe that SeeMeCNC built a large scale delta with a pellet feeder rather than traditional filament. Not sure how big it was, but they printed a small, lifesize boy out. They might be able to provide you with some information or plans.

I think a few rostock or kossel printers on Thingiverse come with OpenSCAD plans that you can scale up.

I think a few rostock or kossel printers on Thingiverse come with OpenSCAD plans that you can scale up.

|

Re: Local makerspace gone mad :-D September 03, 2015 01:35PM |

Registered: 11 years ago Posts: 5,780 |

I don't see anything insane about it, unless they're going to use MDF or laser cut acrylic for the frame.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Local makerspace gone mad :-D September 03, 2015 01:46PM |

Registered: 9 years ago Posts: 93 |

|

Re: Local makerspace gone mad :-D September 03, 2015 02:32PM |

Registered: 8 years ago Posts: 150 |

|

Re: Local makerspace gone mad :-D September 03, 2015 02:41PM |

Registered: 10 years ago Posts: 14,672 |

To build a delta with 600mm build diameter (so not quite 600x600), you will need diagonal rods about 700mm long. To get 600mm build height, you need a machine height of about 600 + 700 + 200mm = 1.5m. Not too high to be practical, but pushing the envelope. If you want to build it as a delta, take a look at scaling up the large (300mm diameter x about 500mm high) design described in my blog (see my signature). Some points to note:

- With a delta of that size, 2020 extrusions are probably too small. Go for 2040 or 2060 instead.

- Likewise, you should use thicker carbon fibre tubes.

- Don't even consider using printed corners. Go for metal corners. Robotdigg sells expensive solid aluminum ones, and I am told they have a version for 2040 extrusion now. Alternatively, check out this thread [groups.google.com] for less expensive sheet metal corners.

- Increase the spacing of the diagonal rods to about 90-110mm, to increase the rigidity of the effector.

You may be better off choosing an H-bot design, but I have no experience of those.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

- With a delta of that size, 2020 extrusions are probably too small. Go for 2040 or 2060 instead.

- Likewise, you should use thicker carbon fibre tubes.

- Don't even consider using printed corners. Go for metal corners. Robotdigg sells expensive solid aluminum ones, and I am told they have a version for 2040 extrusion now. Alternatively, check out this thread [groups.google.com] for less expensive sheet metal corners.

- Increase the spacing of the diagonal rods to about 90-110mm, to increase the rigidity of the effector.

You may be better off choosing an H-bot design, but I have no experience of those.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Local makerspace gone mad :-D September 06, 2015 10:10PM |

Registered: 11 years ago Posts: 471 |

|

Re: Local makerspace gone mad :-D September 07, 2015 03:37AM |

Registered: 9 years ago Posts: 93 |

|

Re: Local makerspace gone mad :-D September 07, 2015 07:58AM |

Registered: 11 years ago Posts: 5,780 |

4 words:

Life size Yoda heads!

You don't have to wait for someone to post a life-size model on Thingiverse- just use the scale function in your slicing software. If you have a large format printer you can print it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Life size Yoda heads!

You don't have to wait for someone to post a life-size model on Thingiverse- just use the scale function in your slicing software. If you have a large format printer you can print it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Local makerspace gone mad :-D September 07, 2015 08:01AM |

Registered: 9 years ago Posts: 93 |

|

Re: Local makerspace gone mad :-D September 07, 2015 08:31AM |

Registered: 10 years ago Posts: 67 |

Something else to consider: Electronics.

A bigger delta means you will at least triple the mass of the arms. This will require stronger steppers and probably will result in currents higher than your standard arduino printer electronics drivers can handle. I would also be leary of any material for delta arms at that length. Almost anything other than chromed linear rods will start flexing.

A H-bot or CoreXY will require the gantries to use larger diameter rods, but thats about all. You should not need larger steppers. The Z table will be much bigger, but since it moves so slow you can get away using a gearbox on that stepper without increasing current.

Of course you can always use CNC stepper controllers. Personally, I would prefer to tackle one thing at a time. In this case, tackle the stability issues you face and not worry about non-standard electronics, firmwares, and software problems for another project.

Oh, another thing: Heated bed. Your best bet is to use AC voltage heating bars and drive them with an SSR. You will not be able to find a DC heater big enough (unless you power the heater from a separate PSU).

"Never argue with stupid people, they will drag you down to their level and then beat you with experience."

A bigger delta means you will at least triple the mass of the arms. This will require stronger steppers and probably will result in currents higher than your standard arduino printer electronics drivers can handle. I would also be leary of any material for delta arms at that length. Almost anything other than chromed linear rods will start flexing.

A H-bot or CoreXY will require the gantries to use larger diameter rods, but thats about all. You should not need larger steppers. The Z table will be much bigger, but since it moves so slow you can get away using a gearbox on that stepper without increasing current.

Of course you can always use CNC stepper controllers. Personally, I would prefer to tackle one thing at a time. In this case, tackle the stability issues you face and not worry about non-standard electronics, firmwares, and software problems for another project.

Oh, another thing: Heated bed. Your best bet is to use AC voltage heating bars and drive them with an SSR. You will not be able to find a DC heater big enough (unless you power the heater from a separate PSU).

"Never argue with stupid people, they will drag you down to their level and then beat you with experience."

|

Re: Local makerspace gone mad :-D September 07, 2015 09:29AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Hazer

A bigger delta means you will at least triple the mass of the arms. This will require stronger steppers and probably will result in currents higher than your standard arduino printer electronics drivers can handle. I would also be leary of any material for delta arms at that length. Almost anything other than chromed linear rods will start flexing.

No way should you use metal rods to connect the effector of a delta. Use carbon fibre tube. 6mm tube is stiff enough for the 350mm arms of my delta, and stiffness varies with the cube of the diameter AFAIR. I think 10mm tube should be plenty stiff enough if you decide to go the delta route. You can stick with Nema 17 stepper motors. You will need a very stiff frame, but that goes for any large printer.

Quote

Hazer

Oh, another thing: Heated bed. Your best bet is to use AC voltage heating bars and drive them with an SSR. You will not be able to find a DC heater big enough (unless you power the heater from a separate PSU).

I agree. My delta uses a mains powered heated bed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Local makerspace gone mad :-D September 07, 2015 09:34AM |

Registered: 9 years ago Posts: 93 |

heat bed.. yeah the other hackers said "we just chain up 9 mk2 beds"

i laughed and asked them how much current that would be

they thought at it for 1 min and came up with a approx 80A number and i told them to say 15A * 9 and asked where they would get a 12V psu rated that much at an fair price

before they could answer i added the bonus Q: why not use a 230V silicone heater and a SSR with zero point detection build in..... they humble accepted defeat :-D

But yes i i'm more and more convinced about a H bot... delta could be done... but the arms yes... it will be problematic to say it mild

let's see, we only meet weekly so it will not be until the end of week i know what they decide on

i laughed and asked them how much current that would be

they thought at it for 1 min and came up with a approx 80A number and i told them to say 15A * 9 and asked where they would get a 12V psu rated that much at an fair price

before they could answer i added the bonus Q: why not use a 230V silicone heater and a SSR with zero point detection build in..... they humble accepted defeat :-D

But yes i i'm more and more convinced about a H bot... delta could be done... but the arms yes... it will be problematic to say it mild

let's see, we only meet weekly so it will not be until the end of week i know what they decide on

|

Re: Local makerspace gone mad :-D September 08, 2015 02:27AM |

Registered: 8 years ago Posts: 5,232 |

Maybe they meant to put them in series and feed 110V~ (US-) mains to them? Has anyone done that before? ( and survived ? )Quote

boelle

the other hackers said "we just chain up 9 mk2 beds"

I like the idea of using multiple heatbeds. It saves energy, when you print small parts.

But to be consequent, the heatspreader should be split too, which is a nightmare to level.

-Olaf

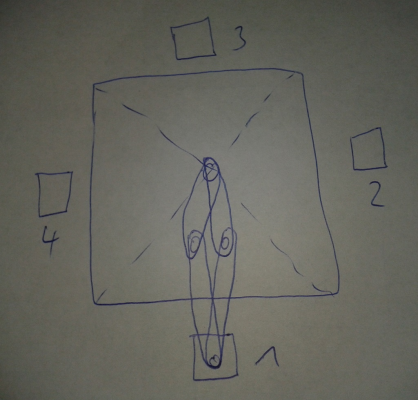

PS: I´m currently thinking about an " 4 SCARA arms printer " I have a "SCARA"-design in mind which only requires linear/polar math. ( the design is not shown in this pic, it´s an early napkin sketch )

|

Re: Local makerspace gone mad :-D September 09, 2015 04:18PM |

Registered: 10 years ago Posts: 580 |

I wish you the best on your endeavor.

I exhibited my printer (which was built at our makerspace called Vocademy in Riverside CA) in the booth next to SeeMeCNC at the World 3D Printer Expo in Burbank, so I got to see their big delta working over a couple days.

Unfortunately, that printer is good for only one thing - getting press (and yes the local news did come to film it).

There was no retraction so there was a lot of stringing.

The pellet feeder makes the effector so heavy that the entire machine flexes with every move.

Eventually the nozzle would hit the print and knock it, and it would be off - making biggest spaghetti you've ever seen, and not one good print the entire weekend.

So what I took away from that is - if you are going to build a big delta, then make it very rigid indeed, and the effector must be just as light as you can make it.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I exhibited my printer (which was built at our makerspace called Vocademy in Riverside CA) in the booth next to SeeMeCNC at the World 3D Printer Expo in Burbank, so I got to see their big delta working over a couple days.

Unfortunately, that printer is good for only one thing - getting press (and yes the local news did come to film it).

There was no retraction so there was a lot of stringing.

The pellet feeder makes the effector so heavy that the entire machine flexes with every move.

Eventually the nozzle would hit the print and knock it, and it would be off - making biggest spaghetti you've ever seen, and not one good print the entire weekend.

So what I took away from that is - if you are going to build a big delta, then make it very rigid indeed, and the effector must be just as light as you can make it.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Local makerspace gone mad :-D September 09, 2015 04:26PM |

Registered: 9 years ago Posts: 93 |

mains whatever its 230 or 115 does not matter much....

what is important is the isolation between tracks on the PCB... next how "accessible" the tracks are to fingers, of course the solder terminals are the worst spot...

but i bet the isolation distance between the tracks are so poor you risk jumps from one track to the other and hence maybe the resistance gets so low it will blow a fuse....

i would not worrie about getting shocked.... mains is not dangerous at all... its the lack of respect for mains that kills :-D

money wise i bet 9 pcb's cost more than a custom silicone heater from china.... so it would not make much sence anyway :-D

what is important is the isolation between tracks on the PCB... next how "accessible" the tracks are to fingers, of course the solder terminals are the worst spot...

but i bet the isolation distance between the tracks are so poor you risk jumps from one track to the other and hence maybe the resistance gets so low it will blow a fuse....

i would not worrie about getting shocked.... mains is not dangerous at all... its the lack of respect for mains that kills :-D

money wise i bet 9 pcb's cost more than a custom silicone heater from china.... so it would not make much sence anyway :-D

|

Re: Local makerspace gone mad :-D September 09, 2015 04:35PM |

Registered: 9 years ago Posts: 93 |

|

Re: Local makerspace gone mad :-D September 09, 2015 06:17PM |

Registered: 11 years ago Posts: 5,780 |

I wouldn't try to do that. I wouldn't try to go any bigger than it already is. Too much moving mass in the Y axis. If i were building a cartesian machine that had a 600 x 600 bed, I'd probably look at CoreXY or similar design with the bed only moving in the Z axis.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Local makerspace gone mad :-D September 09, 2015 07:04PM |

Registered: 8 years ago Posts: 338 |

Quote

boelle

heat bed.. yeah the other hackers said "we just chain up 9 mk2 beds"

i laughed and asked them how much current that would be

they thought at it for 1 min and came up with a approx 80A number and i told them to say 15A * 9 and asked where they would get a 12V psu rated that much at an fair price

before they could answer i added the bonus Q: why not use a 230V silicone heater and a SSR with zero point detection build in..... they humble accepted defeat :-D

But yes i i'm more and more convinced about a H bot... delta could be done... but the arms yes... it will be problematic to say it mild

let's see, we only meet weekly so it will not be until the end of week i know what they decide on

you can get 12v 100amp psu's for around 30 dollars on amazon... (not saying that the idea is practicable, but that they arent crazy expensive) look up a Server power supply

Edited 1 time(s). Last edit at 09/09/2015 07:05PM by Qdeathstar.

Sorry, only registered users may post in this forum.