How to split large wheel that doesn't fit the bed?

Posted by realthor

|

How to split large wheel that doesn't fit the bed? September 23, 2015 07:20AM |

Registered: 9 years ago Posts: 1,035 |

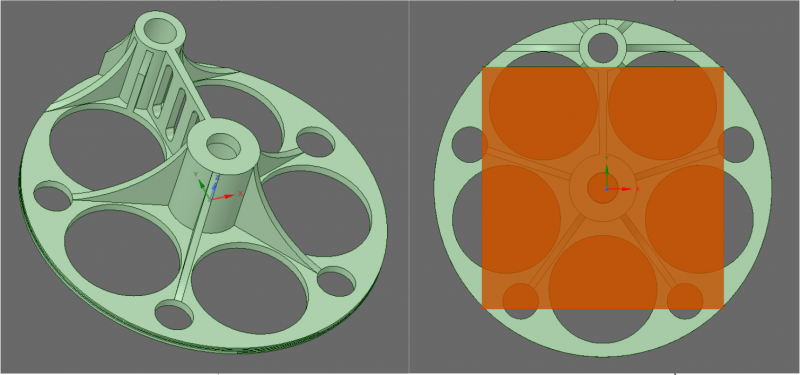

Hi guys, I need an opinion or even better, a solution for printing a large wheel/pulley that doesn't fit the bed of the printer. My main concern is that being a pulley that will use a timing belt, the pieces need to align pretty well.

Here's the pulley I have designed and how it compares to the usable working area of the bed (20x20 but i choose 18x18 to avoid collisions/etc ):

I could try to :

1) either have it sliced appropriately and printed in 3 parts: the area covered by the two hubs printed in one piece (this will chop off the tip of the lower ribs but that is of no concern really) and have the remaining piece split once more so each part it fits the bed; this will get me 3 parts that need to be bolted/glued/etc together, or

2) have the two hubs printed in one piece with a thin supporting layer and have the disk as an "external" part, not printed but perhaps laser cut from acrylic or some other plastic. I could then glue the hubs with the ribs to the disk or I could bolt them somehow.

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Here's the pulley I have designed and how it compares to the usable working area of the bed (20x20 but i choose 18x18 to avoid collisions/etc ):

I could try to :

1) either have it sliced appropriately and printed in 3 parts: the area covered by the two hubs printed in one piece (this will chop off the tip of the lower ribs but that is of no concern really) and have the remaining piece split once more so each part it fits the bed; this will get me 3 parts that need to be bolted/glued/etc together, or

2) have the two hubs printed in one piece with a thin supporting layer and have the disk as an "external" part, not printed but perhaps laser cut from acrylic or some other plastic. I could then glue the hubs with the ribs to the disk or I could bolt them somehow.

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? September 23, 2015 09:58AM |

Registered: 9 years ago Posts: 722 |

|

Re: How to split large wheel that doesn't fit the bed? September 23, 2015 11:40AM |

Registered: 9 years ago Posts: 1,035 |

Hi JM, thanks for your input. I wich I was that good at designing snap-fit connectors that would provide perfect match between the parts.

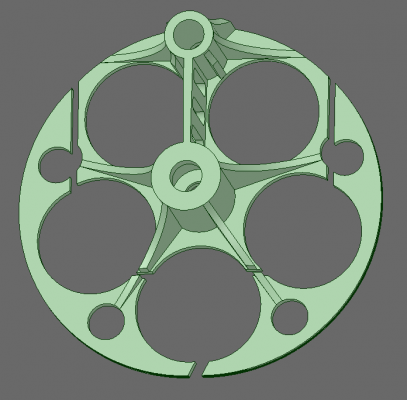

So far I have a split that would allow me to print it in 3 parts. All of these fit within the boundaries of the printing area:

I have split it this way because all the strain is going to be concentrated in the ribb-reinforced piece, all others only provide support for the timing belt and will only take the belt tension, which will actually press them together.

The pulley/disc layer is only 6mm thick and it gives me a hard time imagining how can I use snap-fit connectors or even ears with holes for small bolts. Can you suggest something or maybe direct me to a resource that I can use as a guide?

Besides snapping it together I would need to also glue them together as they are not supposed to be taken apart after being fixated together.

Edited 1 time(s). Last edit at 09/23/2015 11:42AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

So far I have a split that would allow me to print it in 3 parts. All of these fit within the boundaries of the printing area:

I have split it this way because all the strain is going to be concentrated in the ribb-reinforced piece, all others only provide support for the timing belt and will only take the belt tension, which will actually press them together.

The pulley/disc layer is only 6mm thick and it gives me a hard time imagining how can I use snap-fit connectors or even ears with holes for small bolts. Can you suggest something or maybe direct me to a resource that I can use as a guide?

Besides snapping it together I would need to also glue them together as they are not supposed to be taken apart after being fixated together.

Edited 1 time(s). Last edit at 09/23/2015 11:42AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? September 23, 2015 11:54AM |

Registered: 10 years ago Posts: 14,672 |

Alternatively, find someone in your local area who can print it in one piece for you. If you happen to be in southern UK, I have a Kossel with 300mm diameter print area that could probably do it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: How to split large wheel that doesn't fit the bed? September 23, 2015 01:11PM |

Registered: 9 years ago Posts: 1,035 |

I am based in Finland for a year or two and around here everything is sooo expensive so I'd rather buy a washing machine pulley which is about the same with what i need and modify that  .

.

Joking (almost joking) aside I would rather learn something new and do with what i have. Snap-fit connectors sound like fun to experiment with. On the other hand modularity is usually a good thing so learning how to design modulat is another plus.

It'll be some time before I can print anything because right now the printer I use is dissassembled waiting for new rods/bearings so I can continue this topic for a while if there is enough interest.

Cheers.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

.

.Joking (almost joking) aside I would rather learn something new and do with what i have. Snap-fit connectors sound like fun to experiment with. On the other hand modularity is usually a good thing so learning how to design modulat is another plus.

It'll be some time before I can print anything because right now the printer I use is dissassembled waiting for new rods/bearings so I can continue this topic for a while if there is enough interest.

Cheers.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? September 23, 2015 01:19PM |

Registered: 10 years ago Posts: 14,672 |

Perhaps you should rebuild your printer with a larger bed then? If the pulley is for a washing machine, I think it will be hard to make the joints between the 3 separate pieces strong enough.

Edited 1 time(s). Last edit at 09/23/2015 01:21PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 09/23/2015 01:21PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: How to split large wheel that doesn't fit the bed? September 23, 2015 05:34PM |

Registered: 9 years ago Posts: 1,035 |

No its not for a washing machine  , it has about the same dimensions though. But you might be right, maybe have to find a solution to have it in one piece : -/

, it has about the same dimensions though. But you might be right, maybe have to find a solution to have it in one piece : -/

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

, it has about the same dimensions though. But you might be right, maybe have to find a solution to have it in one piece : -/

, it has about the same dimensions though. But you might be right, maybe have to find a solution to have it in one piece : -/RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? September 23, 2015 07:20PM |

Registered: 9 years ago Posts: 483 |

If you print the hubs separately, is there enough room to shift the pulley part on the bed and print one side, then shift and print the other side(s)?

If you're using ABS, then glueing with Acetone will give you as strong a piece as if it were printed in one piece.

p.s. If you're using PLA, then you can print on Acrylic and be able to shift the Acrylic piece with the PLA piece still attached.

Edited 1 time(s). Last edit at 09/23/2015 07:22PM by etfrench.

If you're using ABS, then glueing with Acetone will give you as strong a piece as if it were printed in one piece.

p.s. If you're using PLA, then you can print on Acrylic and be able to shift the Acrylic piece with the PLA piece still attached.

Edited 1 time(s). Last edit at 09/23/2015 07:22PM by etfrench.

|

Re: How to split large wheel that doesn't fit the bed? September 23, 2015 08:25PM |

Registered: 9 years ago Posts: 1,035 |

Quote

etfrench

If you print the hubs separately, is there enough room to shift the pulley part on the bed and print one side, then shift and print the other side(s)?

p.s. If you're using PLA, then you can print on Acrylic and be able to shift the Acrylic piece with the PLA piece still attached.

Sorry etfrench I don't really follow. I can print the wheel in 3 parts and then glue them together. The ABS/acetone glueing would be best I admitt.

Could you explain a bit more your suggestion?

PS:I print on a solidoodle 1st gen.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? September 23, 2015 09:09PM |

Registered: 12 years ago Posts: 187 |

Thingiverse has a number of designs for segmented wheels which are bigger than the print bed - e.g. see:

"Modular Printable Spool" [www.thingiverse.com]

Basically, you split the rim into several pieces, and use spokes to join the rim segments to the hub. (Think of how a wagon-wheel is made.) Maybe you can get some design inspiration there?

Follow my Mendel Prusa build here: [julianh72.blogspot.com]

"Modular Printable Spool" [www.thingiverse.com]

Basically, you split the rim into several pieces, and use spokes to join the rim segments to the hub. (Think of how a wagon-wheel is made.) Maybe you can get some design inspiration there?

Follow my Mendel Prusa build here: [julianh72.blogspot.com]

|

Re: How to split large wheel that doesn't fit the bed? September 23, 2015 09:17PM |

Registered: 10 years ago Posts: 814 |

|

Re: How to split large wheel that doesn't fit the bed? September 24, 2015 12:03AM |

Registered: 9 years ago Posts: 978 |

|

Re: How to split large wheel that doesn't fit the bed? September 24, 2015 02:44AM |

Registered: 9 years ago Posts: 1,035 |

Folding 90 deg on the diagonal of the bed wouldn't cut it, it's a circle it is larger than the bed in all positions.

I've been thinking about it and I think I will go with printing the two hubs in one piece and then printing the pizza slices and bolt the hub to them in a sturdy fashion. This will take some belt tension so I must be sure it can take it.

Thanks all for your answers.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I've been thinking about it and I think I will go with printing the two hubs in one piece and then printing the pizza slices and bolt the hub to them in a sturdy fashion. This will take some belt tension so I must be sure it can take it.

Thanks all for your answers.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? September 24, 2015 03:40AM |

Registered: 12 years ago Posts: 187 |

Make a folded wheel as per the attached sketch - the hub lies flat on the print bed, and can be as big as your printable area. The 4 rim sectors are printed folded upwards at 90 degrees, but hinge down after printing. The hinge lines are printed thin enough to bend but with enough material to stay attached when they are bent flat. (You may need some "strong-back" pieces to hold the wheel rigid when it is folded flat.)

Could be an interesting design challenge...

If designing and printing hinges in a single print is too tricky, print it as 5 pieces and just fasten the 4 rim segments to the hub piece.

Follow my Mendel Prusa build here: [julianh72.blogspot.com]

Could be an interesting design challenge...

If designing and printing hinges in a single print is too tricky, print it as 5 pieces and just fasten the 4 rim segments to the hub piece.

Follow my Mendel Prusa build here: [julianh72.blogspot.com]

|

Re: How to split large wheel that doesn't fit the bed? September 24, 2015 04:27AM |

Registered: 9 years ago Posts: 483 |

The uprights on the printer would probably prevent you from shifting the print for each layer, otherwise you could use a separate glass (or other bed material) the same size as the pulley and shift it for each segment. Registering each move would be the hardest part.

I think the folded wheel is the best solution.

I think the folded wheel is the best solution.

|

Re: How to split large wheel that doesn't fit the bed? September 24, 2015 06:25AM |

Registered: 9 years ago Posts: 1,035 |

That's very ingenious indeed, the hinged flaps idea but with the current dimensions it would't work in the flapped position because the outside diameter barely touches the corners of the bed. If it would be smaller just a bit this would definitely work but my guess is that the 6mm disc is quite thin to try to design hinges that also have an axle.

In this particular situation printing separate parts (hinged or not) look like the best solution. I would also need a lockup solution, maybe a square axle/hole for the hinge. If someone would print a similar design in an flapped position with a square axle in one print, ans assuming one can take out the axle flat the disc and re-insert the square axle, it would stay perfectly flat.

Edit: I was wrong, it would work to flap it around a hinge on the perimeter of the current bed, I just had a hard time imagining it when I replied. However, my objection regarding the 6mm thickness remain... it is too thin for any plastic hinge, let alone square. At least this is where my skills are not on par with the challenge

Edited 1 time(s). Last edit at 09/24/2015 06:42AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

In this particular situation printing separate parts (hinged or not) look like the best solution. I would also need a lockup solution, maybe a square axle/hole for the hinge. If someone would print a similar design in an flapped position with a square axle in one print, ans assuming one can take out the axle flat the disc and re-insert the square axle, it would stay perfectly flat.

Edit: I was wrong, it would work to flap it around a hinge on the perimeter of the current bed, I just had a hard time imagining it when I replied. However, my objection regarding the 6mm thickness remain... it is too thin for any plastic hinge, let alone square. At least this is where my skills are not on par with the challenge

Edited 1 time(s). Last edit at 09/24/2015 06:42AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? September 24, 2015 11:59AM |

Registered: 10 years ago Posts: 466 |

|

Re: How to split large wheel that doesn't fit the bed? September 24, 2015 12:29PM |

Registered: 9 years ago Posts: 1,035 |

Yes that waas one of the previous ideas (piiza slices of the complete disc) and the 2 hubs that i can fit the bed would be joined with the slices but the hinge idea is awesome for the challenge.

I the pizza slices + hubs remains the most valid idea. Glueing them with acetone as opposed to screws is better but messier I guess. I have never worked with acetone before.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I the pizza slices + hubs remains the most valid idea. Glueing them with acetone as opposed to screws is better but messier I guess. I have never worked with acetone before.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? September 24, 2015 03:05PM |

Registered: 9 years ago Posts: 483 |

|

Re: How to split large wheel that doesn't fit the bed? September 24, 2015 05:51PM |

Registered: 11 years ago Posts: 5,780 |

If your goal is to make a wheel that works reliably, I'd say use something else to make it. 3D printing is great, but it isn't so great for things that are bigger than the machine's capacity.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How to split large wheel that doesn't fit the bed? September 24, 2015 06:08PM |

Admin Registered: 16 years ago Posts: 13,888 |

... best compromise would be a laser-cut disc with all the round openings and extra fixture holes -- and 3D-printing all the complex parts ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: How to split large wheel that doesn't fit the bed? September 24, 2015 06:55PM |

Registered: 9 years ago Posts: 1,035 |

Quote

VDX

... best compromise would be a laser-cut disc with all the round openings and extra fixture holes -- and 3D-printing all the complex parts ...

I completely aggree. Before opening the thread I was actually searching online to find a 20cm in diameter disc of some sort to get an idea of what I could use instead of printing the base disc and that's how I got to the washing machine pulley I was talking about at the begining of the thread.

BTW this pulley is not going to be used in daily operation, is just for some prototyping that I am planning.

What kind of material should I look for?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? September 25, 2015 03:23AM |

Admin Registered: 16 years ago Posts: 13,888 |

... you can try with lasercut plywood or acrylic -- but best would be milled POM or aluminium ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: How to split large wheel that doesn't fit the bed? September 25, 2015 05:21AM |

Registered: 9 years ago Posts: 1,035 |

I have to improvise it for now at least up to the point I see it works as I intend it to, after that I will look for better parts for the prototype. If I can get away with some store-bought disc of sorts and I bolt the printed hubs part I will be happy with it.

I have actually recalculated the gearing ratio between the motor and this disc and I can barely squeeze it on the existing bed without dropping below the limit. I will have to make it bigger nevertheless.

I was wondering the washing machine pulley, which is supposed to withstand tremendous amounts of torque and wear compared to mine, is it made out of injection molded ABS or some sorts of HDPE? The ones that are not made of aluminum of course.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I have actually recalculated the gearing ratio between the motor and this disc and I can barely squeeze it on the existing bed without dropping below the limit. I will have to make it bigger nevertheless.

I was wondering the washing machine pulley, which is supposed to withstand tremendous amounts of torque and wear compared to mine, is it made out of injection molded ABS or some sorts of HDPE? The ones that are not made of aluminum of course.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? September 25, 2015 06:44AM |

Admin Registered: 16 years ago Posts: 13,888 |

... the 'effective' torque depends on the caught teeth - the more teeth are in contact with the belt, the lower the local forces ... so a 100 teeth wheel can be made from styrofoam and driven with some ten Newtons of torque without breaking apart

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: How to split large wheel that doesn't fit the bed? September 25, 2015 07:20AM |

Registered: 9 years ago Posts: 1,035 |

so true

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? November 10, 2015 10:26AM |

Registered: 9 years ago Posts: 1,035 |

I am going to ressurect this thread to avoid opening a new one for a related question/idea.

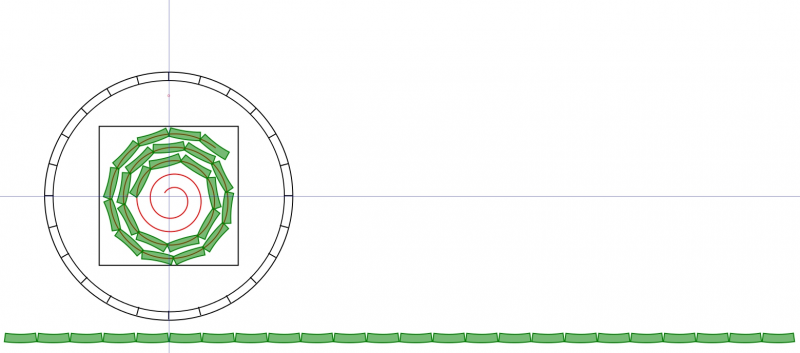

Is it possible (via a script maybe) to have a large ring segmented in such a way that there is still a very thin connecting strip (a la living hinge) between segments, on the outer edge, and to re-arange the segments in an Archimedean Spiral shape so that it all fits on the bed? Then the spiral will be reversed and the segments will form again the ring that will be iserted(rolled over) a bulk disk (wood/etc).

I find this idea intriguing because there will be no gaps on the outer surface. Here's a quick Inkscape sketch to demonstrate the concept:

The living hinge for PP and PE looks like this:

What do you think is this a good way to have a continuous outer surface on the ring or it would be better with an approache with as few as possible large chunks and a male/female approach for cvasi-seamless surface?

Edited 2 time(s). Last edit at 11/10/2015 10:49AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Is it possible (via a script maybe) to have a large ring segmented in such a way that there is still a very thin connecting strip (a la living hinge) between segments, on the outer edge, and to re-arange the segments in an Archimedean Spiral shape so that it all fits on the bed? Then the spiral will be reversed and the segments will form again the ring that will be iserted(rolled over) a bulk disk (wood/etc).

I find this idea intriguing because there will be no gaps on the outer surface. Here's a quick Inkscape sketch to demonstrate the concept:

The living hinge for PP and PE looks like this:

What do you think is this a good way to have a continuous outer surface on the ring or it would be better with an approache with as few as possible large chunks and a male/female approach for cvasi-seamless surface?

Edited 2 time(s). Last edit at 11/10/2015 10:49AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? November 11, 2015 04:46AM |

Registered: 8 years ago Posts: 3,525 |

|

Re: How to split large wheel that doesn't fit the bed? November 11, 2015 06:34AM |

Registered: 9 years ago Posts: 1,035 |

It think it would be close to impossible to choose the best way to segment a part because the designer always knows what its purpose is and can decide for the best (maybe tottally new) division format. In my example above I need a seamless outer edge for a ring that another wheel will be rotating against. If I would cut the whole disk in pizza slices and join them I wouldn't get a seamless surface on the rim. I have then to split the part in such a way that the outer ring is a different part than the inner disk/hub, which I can slice however I want given the strength/etc constrains of the design.

But I think a puzzle-like segmentation can be easily computed by the slicer along a split line defined by the user before slicing.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

But I think a puzzle-like segmentation can be easily computed by the slicer along a split line defined by the user before slicing.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: How to split large wheel that doesn't fit the bed? November 11, 2015 07:11AM |

Registered: 8 years ago Posts: 3,525 |

Sorry, only registered users may post in this forum.