New print surface material?

Posted by Mutley3D

|

Re: New print surface material? October 31, 2015 01:30AM |

Registered: 9 years ago Posts: 1,699 |

Nice description. Can you give me some hints of the tape? As I am also not finding a suitable tape here in Germany mainly caused by having not enough data as I cannot find something like vinyl as no company gives exact data of their parts so I still only can guess. I may have found one tape which is extra strong which is also suitable for underfloor heating but I am not sure.

Your review sounds good and if I have 1kg less waste it would also save much money.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Your review sounds good and if I have 1kg less waste it would also save much money.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? October 31, 2015 02:55AM |

Registered: 9 years ago Posts: 425 |

Quote

vendeta44

Side note: what i found worked well for leveling my print head with the printbite was getting it close then printing a large flat pane the size of my bed, after a few layers I could see what corners(4 point level bed) were lifting and I adjusted them then restarted the print and repeat. Maybe I'm crazy but it seems like the printbite wants the print head to be smooshed into it more so than glass.

You shouldnt need to print filament with as much squish as glass, you should be able to achieve a nice filament bead all around. Maybe tweak the temps, also if you are over extruding, as the print head works outwards and filament is pushed further out it can create a bit of a untidy outer line which would promote lift.

|

Re: New print surface material? October 31, 2015 03:30AM |

Registered: 9 years ago Posts: 425 |

Quote

Treito

Nice description. Can you give me some hints of the tape? As I am also not finding a suitable tape here in Germany mainly caused by having not enough data as I cannot find something like vinyl as no company gives exact data of their parts so I still only can guess. I may have found one tape which is extra strong which is also suitable for underfloor heating but I am not sure.

Your review sounds good and if I have 1kg less waste it would also save much money.

Tape for vinyl flooring, NOT vinyl tape. I think you misunderstood

|

Re: New print surface material? October 31, 2015 03:41AM |

Registered: 9 years ago Posts: 1,699 |

Quote

Mutley3D

Tape for vinyl flooring, NOT vinyl tape. I think you misunderstood

Yes it was too less sleep as printing on Kapton tape with ABS is not very successful. Maybe I found some sort of acrylic tape (a hint for others in my situation) that should fulfill the needs but it is a cheap company so I do not know much about the quality but according to the datasheet it should work (most comparable parts ends at 90°C).

[www.conrad.com]

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? October 31, 2015 10:18AM |

Registered: 10 years ago Posts: 25 |

A couple of days ago I listed some tape sold by a company called Affixit. They claimed the tape to be good for 140C.

Since then I believe I have found that the double sided tape is made by Tesa and goes under the name of Tesa (or just T) 4965.

It is quoted as able to be used up to 200C with a normal use temperature of 100C.

For Treito: They have a number of locations in Germany. Tesa Locations

Since then I believe I have found that the double sided tape is made by Tesa and goes under the name of Tesa (or just T) 4965.

It is quoted as able to be used up to 200C with a normal use temperature of 100C.

For Treito: They have a number of locations in Germany. Tesa Locations

|

Re: New print surface material? October 31, 2015 10:27AM |

Registered: 9 years ago Posts: 1,699 |

Thanks for this tip. Tesa is very common and a standard manufacturer so you are getting it everywhere here in Germany. I found this tape before and regarding the datasheet it can be only exposed up to 100°C and only for short times up tp 200°C. The other tape I posted above seems to be similiar and it is cheaper and suitable up to 160°C.

However I am afraid that I am the only person which cannot use PrintBite in the whole forum. Only because my printer has problems with hitting and damaging parts during the print process which is caused by warping of the edges and one sensor is crashing into it. PrintBite would probably prevent this but this circumstance seems to be a problem for buying it. I do net get this and I am really upset and nearly crying. So many thanks for this tip but it seems that I have to look somewhere else.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

However I am afraid that I am the only person which cannot use PrintBite in the whole forum. Only because my printer has problems with hitting and damaging parts during the print process which is caused by warping of the edges and one sensor is crashing into it. PrintBite would probably prevent this but this circumstance seems to be a problem for buying it. I do net get this and I am really upset and nearly crying. So many thanks for this tip but it seems that I have to look somewhere else.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? October 31, 2015 10:51AM |

Registered: 10 years ago Posts: 25 |

|

Re: New print surface material? October 31, 2015 10:58AM |

Registered: 9 years ago Posts: 1,699 |

The printbed itself is screwed down on it there is a 3 mm glass surface using clamps and onto the glass there is Kapton tape for the moment. I have BuildTak here but the sensor are incompatible with it. Blue Painters Tape also does not work at the moment. Only BuildTak, but I already damaged two pieces because of wrong settings due to the sensor and I do not want to risk to ruin a third one (black is not very reflective; I have optical sensors).

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? October 31, 2015 11:14AM |

Registered: 10 years ago Posts: 25 |

|

Re: New print surface material? October 31, 2015 11:15AM |

Registered: 10 years ago Posts: 25 |

|

Re: New print surface material? October 31, 2015 11:22AM |

Registered: 9 years ago Posts: 1,699 |

Quote

BriComp

I'm slightly confused. As I understand it you have the heated bed with Glasson the top of it held down with clamps. You then print onto Kapton tape which is stuck to the Glass.

Are you saying that the Glass is Warping, surely not?

Of course not. The edges of the printed parts have a slightly lift off by around 0.2mm. This is enough for the sensor to get caught at the printed part for several reasons. One is the Auto-bed-leviling-function and the fact that the sensor is not nearby the printhead, If you know everything how the auto-leveling works and where the sensor is placed it is logical but hard to explain yet.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? October 31, 2015 11:36AM |

Registered: 10 years ago Posts: 25 |

|

Re: New print surface material? October 31, 2015 11:46AM |

Registered: 9 years ago Posts: 12 |

I have upgraded the print head on my Ormerod 1 with the unit produced by DC42 and can confirm that the upgraded sensor head and five point auto levelling works fine with PrintBite. I've also added the aluminium X axis upgrade and replaced the wooden bed frame with the aluminium three point upgrade and the unit s now very stable.

|

Re: New print surface material? October 31, 2015 11:46AM |

Registered: 9 years ago Posts: 1,699 |

There is one simple solution more or less.

At first I need PrintBite which reduces the warping effect by better sticking. Besides if I have the target printing surface I can try to level the bed by hand. Problem solved. Even if I am not able to level the bed by hand the danger is less because the height difference would be less so the auto-leveling would not drive the sensor into the part. I currently have height differences of about 1mm. The controller can eliminate this but the sensor is let me say 5mm away from the nozzle. So if the nozzle moves on the head is moved up and down. but the FW does not know about the problem of the sensor. Regarding the z-height it is only some tenth mm higher than the nozzle. So you may imagine now that the height difference is limited which can be eliminated by software. Fixing this takes some time and I want to have the original surface as every surface differs.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

At first I need PrintBite which reduces the warping effect by better sticking. Besides if I have the target printing surface I can try to level the bed by hand. Problem solved. Even if I am not able to level the bed by hand the danger is less because the height difference would be less so the auto-leveling would not drive the sensor into the part. I currently have height differences of about 1mm. The controller can eliminate this but the sensor is let me say 5mm away from the nozzle. So if the nozzle moves on the head is moved up and down. but the FW does not know about the problem of the sensor. Regarding the z-height it is only some tenth mm higher than the nozzle. So you may imagine now that the height difference is limited which can be eliminated by software. Fixing this takes some time and I want to have the original surface as every surface differs.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? October 31, 2015 11:50AM |

Registered: 9 years ago Posts: 12 |

Quote

Treito

Quote

BriComp

I'm slightly confused. As I understand it you have the heated bed with Glasson the top of it held down with clamps. You then print onto Kapton tape which is stuck to the Glass.

Are you saying that the Glass is Warping, surely not?

Of course not. The edges of the printed parts have a slightly lift off by around 0.2mm. This is enough for the sensor to get caught at the printed part for several reasons. One is the Auto-bed-leviling-function and the fact that the sensor is not nearby the printhead, If you know everything how the auto-leveling works and where the sensor is placed it is logical but hard to explain yet.

Is it the sensor which is catching or the fan duct to the left of the nozzle?

I had the problem with the duct catching and initially put a shim along the length of the right side of the x axis plastic arm which the roller bearing rested against. That was enough to raise it clear of the printed material.

|

Re: New print surface material? October 31, 2015 12:05PM |

Registered: 9 years ago Posts: 425 |

BriComp,

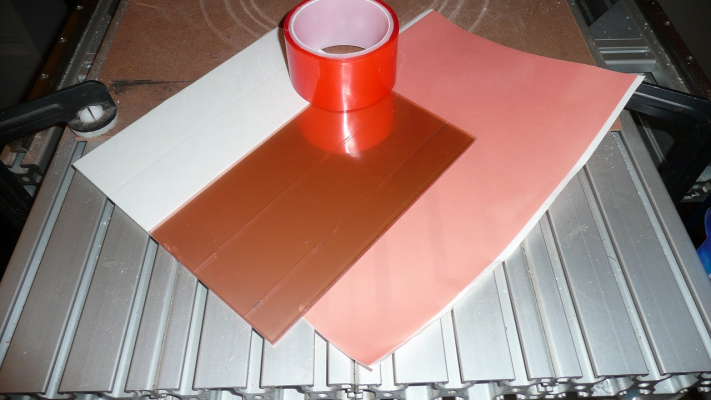

Good call on the tape, I didnt want to post about this until I had followed it up. I have received samples this morning which are on the machine and being tested. The liner is red. The actual adhesive film is transparent and clear. A roll is 50mtrs and expensive. Sheets are far more cost effective.

Printing without substrate should be a fundamental feature of 3d printing, especially given the duration of its existance to date, and should be low cost to do so.

Good call on the tape, I didnt want to post about this until I had followed it up. I have received samples this morning which are on the machine and being tested. The liner is red. The actual adhesive film is transparent and clear. A roll is 50mtrs and expensive. Sheets are far more cost effective.

Printing without substrate should be a fundamental feature of 3d printing, especially given the duration of its existance to date, and should be low cost to do so.

|

Re: New print surface material? October 31, 2015 12:36PM |

Registered: 10 years ago Posts: 25 |

Hi Mutley3D

Glad the info was useful,

Did you contact AllFix or Tesa, the manufacturers?

Is the sheet material the same as the rolls?

It is expensive though 12mm X 10M seems to be available on Amazon. That will mean a lot to put down in 12mm steps though!

I think if you can supply it, with a suitable mark up for yourself, that would be a great service for your customers.

Better still if PrintByte came with the adhesive film already applied ( as an option ). That might be a step too far though.

Regards

Bob

ReplikEo Ormerod2 waiting build.

Will be using Aluminium X Arm and DC24's Ormerod height sensor boards with the thermostatic fan control.

Glad the info was useful,

Did you contact AllFix or Tesa, the manufacturers?

Is the sheet material the same as the rolls?

It is expensive though 12mm X 10M seems to be available on Amazon. That will mean a lot to put down in 12mm steps though!

I think if you can supply it, with a suitable mark up for yourself, that would be a great service for your customers.

Better still if PrintByte came with the adhesive film already applied ( as an option ). That might be a step too far though.

Regards

Bob

ReplikEo Ormerod2 waiting build.

Will be using Aluminium X Arm and DC24's Ormerod height sensor boards with the thermostatic fan control.

|

Re: New print surface material? October 31, 2015 11:43PM |

Registered: 8 years ago Posts: 233 |

I am looking at some options for US buyers. What about these tapes???

[www.findtape.com]

[www.findtape.com]

[www.findtape.com]

[www.findtape.com]

[www.findtape.com]

[www.findtape.com]

[www.findtape.com]

[www.findtape.com]

|

Re: New print surface material? November 01, 2015 11:36AM |

Registered: 13 years ago Posts: 615 |

This surface seems interesting, I will give it a try too on my FoldaRap/Mondrian and make a report later

(mostly interested by the compatibility with nylon or PC)

I have used polyimide, pmma, buildtak, printEZ, glass, glue stick... and for the moment I prefer the simple kapton tape or bare glass to the various polymer stuff.

about // liberapay // flickr // wiki // thingiverse - github

(mostly interested by the compatibility with nylon or PC)

I have used polyimide, pmma, buildtak, printEZ, glass, glue stick... and for the moment I prefer the simple kapton tape or bare glass to the various polymer stuff.

about // liberapay // flickr // wiki // thingiverse - github

|

Re: New print surface material? November 01, 2015 04:04PM |

Registered: 9 years ago Posts: 705 |

|

Re: New print surface material? November 01, 2015 04:07PM |

Registered: 9 years ago Posts: 705 |

|

Re: New print surface material? November 01, 2015 05:18PM |

Registered: 9 years ago Posts: 425 |

Quote

elwood127

You know, you could add tape to order. That way we don't have 30 feet sitting around for years to come.

PrintBite is cheap and no frills but very effective. That is what people wish for, cheap, no frills, and effective. You could use 3M 468P tape, buy a sheet at greater expense and have none spare.

Edited 1 time(s). Last edit at 11/01/2015 05:38PM by Mutley3D.

|

Re: New print surface material? November 01, 2015 06:22PM |

Registered: 8 years ago Posts: 9 |

Lot of posts regarding Tape,

one of the main benefits of Printbite over the more known Buildtak is that it is NOT pre-applied with tape, I felt that my Buildtak was a one use product (in this case quite literately lol)

It is handy to have spare tape if you change / upgrade at a later date. or if your glass breaks.

Adding tape to the order separately also would greatly increase the cost as it would have to go in a different class of shipping.

Like i said previously I got a roll of Vinyl floor tape from local hardware store for a couple of quid, very cheap. Not a clue what its operating temp is but I have had the bed to 130c and had no problems.

B&Q Tape

one of the main benefits of Printbite over the more known Buildtak is that it is NOT pre-applied with tape, I felt that my Buildtak was a one use product (in this case quite literately lol)

It is handy to have spare tape if you change / upgrade at a later date. or if your glass breaks.

Adding tape to the order separately also would greatly increase the cost as it would have to go in a different class of shipping.

Like i said previously I got a roll of Vinyl floor tape from local hardware store for a couple of quid, very cheap. Not a clue what its operating temp is but I have had the bed to 130c and had no problems.

B&Q Tape

|

Re: New print surface material? November 01, 2015 08:03PM |

Registered: 9 years ago Posts: 1,699 |

Quote

Emmanuel

I have used polyimide, pmma, buildtak, printEZ, glass, glue stick... and for the moment I prefer the simple kapton tape or bare glass to the various polymer stuff.

What was your problem with BuildTak? For me it is the color (sensor does not work) and the fact that it is very sensitive.

To the tape: The most cheap tapes I found had a permanent operation temperature of only 90°C (3M) or 100°C (Tesa). I found one tape only with 19mm width and 50m length for about 15€ (there were also wider variantes, but the costs would be of course higher) which is suitable up to 160°C.

Besides that it seems like that mounting tape for mirrors could also be an alternative and regarding the adhesive surface of BuildTak they may have used somewhat in this direction (as I bought some for my car 16 years ago and it looks like the same).

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 02, 2015 10:11PM |

Registered: 9 years ago Posts: 517 |

For those looking for the Tesa tape, a couple words of warning. Amazon has a listing here. There is also a listing on ebay by xa-electronics.

*DO NOT ORDER FROM EITHER OF THESE LISTINGS*

What you get will not be Tesa 4965 tape, but an "equivalent" knock-off that does not meet the Tesa 4965 specifications. Xa-electronics listing is just a copy of Amazon's and if you order from them, they just order it from Amazon for you and charge you more than if you ordered it yourself.

I did find some 3M 468 sheets on Amazon here. This is actual 3M branded and you get 6 12"x12" sheets for $16.27. I just got it in and verified it. Now just need to get my PrintBite in to use it on it. The BuildTak sheet I have on my printer is on its last legs. Couple tears and several chucks have torn off. Having to print around the problems for now.

*DO NOT ORDER FROM EITHER OF THESE LISTINGS*

What you get will not be Tesa 4965 tape, but an "equivalent" knock-off that does not meet the Tesa 4965 specifications. Xa-electronics listing is just a copy of Amazon's and if you order from them, they just order it from Amazon for you and charge you more than if you ordered it yourself.

I did find some 3M 468 sheets on Amazon here. This is actual 3M branded and you get 6 12"x12" sheets for $16.27. I just got it in and verified it. Now just need to get my PrintBite in to use it on it. The BuildTak sheet I have on my printer is on its last legs. Couple tears and several chucks have torn off. Having to print around the problems for now.

|

Re: New print surface material? November 02, 2015 10:28PM |

Registered: 10 years ago Posts: 169 |

|

Re: New print surface material? November 02, 2015 11:02PM |

Registered: 9 years ago Posts: 517 |

|

Re: New print surface material? November 02, 2015 11:32PM |

Registered: 10 years ago Posts: 169 |

Here's one that goes to 93c....i'm sure there are others rated higher. 93° c rating

|

Re: New print surface material? November 03, 2015 12:47AM |

Registered: 9 years ago Posts: 1,699 |

Tesa 4965 only goes up to 100°C for permanent use.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 03, 2015 05:04AM |

Registered: 8 years ago Posts: 4 |

Sorry, only registered users may post in this forum.