New print surface material?

Posted by Mutley3D

|

Re: New print surface material? November 03, 2015 09:57AM |

Registered: 10 years ago Posts: 25 |

Double Sided Tapes:

Bear in mind that these are designed to stay attached when used vertically. Think sticking car number plate on.

They will stay stuck with maximum shear force.

When being used to hold your bed surface on, there is very little shear force.

So don't worry too much about the temperature rating.

For instance with the Tesa T4965 it is rated that your "Number Plate" will not fall off at 100C and will even work OK with excursions up to 200C.

I haven't used this material yet but I would have no hesitation in using it when printing with a bed temperature up to 130C. Just imagine even if all it's "Stick Properties" were to disappear ( which it won't ) it would still not fall off since it is being used horizontally.

Bear in mind that these are designed to stay attached when used vertically. Think sticking car number plate on.

They will stay stuck with maximum shear force.

When being used to hold your bed surface on, there is very little shear force.

So don't worry too much about the temperature rating.

For instance with the Tesa T4965 it is rated that your "Number Plate" will not fall off at 100C and will even work OK with excursions up to 200C.

I haven't used this material yet but I would have no hesitation in using it when printing with a bed temperature up to 130C. Just imagine even if all it's "Stick Properties" were to disappear ( which it won't ) it would still not fall off since it is being used horizontally.

|

Re: New print surface material? November 03, 2015 10:04AM |

Registered: 9 years ago Posts: 517 |

It's not the sticky property that I worry about at use over rated temperature, but any possible fumes that might be generated because of the heat. I don't remember exactly what material it is but the liner used in some hot ends can produce toxic fumes when over heated. With some of these tapes, could this happen at higher temperatures? I don't know but would advise against such use without knowing for sure how the material will react.

|

Re: New print surface material? November 03, 2015 10:10AM |

Registered: 9 years ago Posts: 1,699 |

I am afraid of the sticky problem at first. i have this trouble with the Blue Painters Tape. The PrintBite could slide or lift for example. Besides the backing material (?) could melt. And if it melts it may generate not healthy fumes.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 03, 2015 12:58PM |

Registered: 12 years ago Posts: 153 |

Elmo, PTFE is the plastic you are thinking of that decomposes if the hotend goes over 350C and that does indeed cause pretty nasty fumes.

I've no idea for the adhesives however. I'd imagine that any significant decomposition would be noticed immediately as a bubbling or blistering of the print surface as there's nowhere for any evolved gasses to go.

Cheers,

Robin.

I've no idea for the adhesives however. I'd imagine that any significant decomposition would be noticed immediately as a bubbling or blistering of the print surface as there's nowhere for any evolved gasses to go.

Cheers,

Robin.

|

Re: New print surface material? November 03, 2015 01:42PM |

Registered: 10 years ago Posts: 25 |

|

Re: New print surface material? November 03, 2015 01:57PM |

Registered: 9 years ago Posts: 517 |

|

Re: New print surface material? November 03, 2015 02:18PM |

Registered: 12 years ago Posts: 153 |

Generally if something is going to break down then you will have a temperature at which significant breakdown occurs due to thermal energy exceeding some critical bond strength in the molecules.

Below that temperature you will have a very rapidly decreasing amount of breakdown that will probably never actually hit zero but will be many many times lower.

As Bricomp says, even the intermittent max temperature will be well below any actual breakdown point, and with (rule of thumb) chemical reaction speed doubling per 10C increase then at 100C there will be 1000 times less breakdown that at 200C.

Probably much less.

Unless you plan to house your printer in a sealed room then these (hypothetical) breakdown products are exceedingly unlikely to hit any concentration you need be concerned with.

But I am not an organic chemist and it's your house you plan to put this in, if you really want to find out then you will need to look at the COSHH (or whatever the equivalent government mandated chemical safety at work) data for the substance concerned.

The manufacturers should be able to supply this.

I'd be much more concerned about any filament fumes myself.

Perhaps there may be data about suitability of using the tape with underfloor heating, in the case of flooring tapes?

Edited 1 time(s). Last edit at 11/03/2015 02:20PM by Zedsquared.

Below that temperature you will have a very rapidly decreasing amount of breakdown that will probably never actually hit zero but will be many many times lower.

As Bricomp says, even the intermittent max temperature will be well below any actual breakdown point, and with (rule of thumb) chemical reaction speed doubling per 10C increase then at 100C there will be 1000 times less breakdown that at 200C.

Probably much less.

Unless you plan to house your printer in a sealed room then these (hypothetical) breakdown products are exceedingly unlikely to hit any concentration you need be concerned with.

But I am not an organic chemist and it's your house you plan to put this in, if you really want to find out then you will need to look at the COSHH (or whatever the equivalent government mandated chemical safety at work) data for the substance concerned.

The manufacturers should be able to supply this.

I'd be much more concerned about any filament fumes myself.

Perhaps there may be data about suitability of using the tape with underfloor heating, in the case of flooring tapes?

Edited 1 time(s). Last edit at 11/03/2015 02:20PM by Zedsquared.

|

Re: New print surface material? November 03, 2015 05:58PM |

Registered: 8 years ago Posts: 77 |

Sometimes I think we over complicate the matter.

Mine is stuck down with tape that cost 50p for 10metres and is 3 years old. I have no idea what it is made from, and nor do I care.

It holds the printbite fast at 65 deg, which is my optimum temp for PLA - has been on for a while and no evidence it needs replacing.

Mine is stuck down with tape that cost 50p for 10metres and is 3 years old. I have no idea what it is made from, and nor do I care.

It holds the printbite fast at 65 deg, which is my optimum temp for PLA - has been on for a while and no evidence it needs replacing.

|

Re: New print surface material? November 03, 2015 07:00PM |

Registered: 10 years ago Posts: 140 |

Quote

Phytone

Sometimes I think we over complicate the matter.

Mine is stuck down with tape that cost 50p for 10metres and is 3 years old. I have no idea what it is made from, and nor do I care.

It holds the printbite fast at 65 deg, which is my optimum temp for PLA - has been on for a while and no evidence it needs replacing.

Good for you. But it is more important for us who need 120-130C beds for Polycarbonate where the material you're using adhere is very important and . Just because something works well, doesn't mean we should ignore its operating temps or the material science behind it because its not visible, i.e. Teflon or PTFE lined hotends past 250 is pretty dangerous and can cause poly fume fever even if it doesn't visibly degrade.

The Tesa tape as well as the 3m 468 tapes seem to be able to handle the temps no problem.

|

Re: New print surface material? November 05, 2015 01:30AM |

Registered: 16 years ago Posts: 80 |

Out of curiosity, has anyone tried UV curing glue to hold their print surface to glass?

The glue is generally good to 180C so should be okay at printbed temperatures. It would be very easy to apply because you can spend all the time you want squeezing the air bubbles out and getting things aligned since it is a liquid before zapping it.

I ordered some cheap no name UV glue and will try it with my PEI/glass printbed.

If the cheap glue doesn't hold up well at temperature but seems promising otherwise then I will buy the expensive 3M stuff that is officially rated at 180C.

A random demo of UV curing glue, [www.youtube.com]

I think chemically it is similar to super glue (cyanoacrylate) except the polymerization is triggered by UV light rather than moisture.

The glue is generally good to 180C so should be okay at printbed temperatures. It would be very easy to apply because you can spend all the time you want squeezing the air bubbles out and getting things aligned since it is a liquid before zapping it.

I ordered some cheap no name UV glue and will try it with my PEI/glass printbed.

If the cheap glue doesn't hold up well at temperature but seems promising otherwise then I will buy the expensive 3M stuff that is officially rated at 180C.

A random demo of UV curing glue, [www.youtube.com]

I think chemically it is similar to super glue (cyanoacrylate) except the polymerization is triggered by UV light rather than moisture.

|

Re: New print surface material? November 05, 2015 02:03AM |

Registered: 9 years ago Posts: 1,699 |

I am no fan of a glue/ tape solution which you cannot remove without destroying the surface material (glass) as the glass is not cheap at all.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 05, 2015 02:10AM |

Registered: 10 years ago Posts: 169 |

Quote

John Meacham

Out of curiosity, has anyone tried UV curing glue to hold their print surface to glass?

The glue is generally good to 180C so should be okay at printbed temperatures. It would be very easy to apply because you can spend all the time you want squeezing the air bubbles out and getting things aligned since it is a liquid before zapping it.

I ordered some cheap no name UV glue and will try it with my PEI/glass printbed.

If the cheap glue doesn't hold up well at temperature but seems promising otherwise then I will buy the expensive 3M stuff that is officially rated at 180C.

A random demo of UV curing glue, [www.youtube.com]

I think chemically it is similar to super glue (cyanoacrylate) except the polymerization is triggered by UV light rather than moisture.

Will the UV light penetrate the PrintBite? Is line of sight for the rays necessary to cure? If it is...how do you get the UV to the glue between two opaque sheets?

|

Re: New print surface material? November 05, 2015 11:52AM |

Registered: 16 years ago Posts: 80 |

Quote

simspeed

Quote

John Meacham

Out of curiosity, has anyone tried UV curing glue to hold their print surface to glass?

The glue is generally good to 180C so should be okay at printbed temperatures. It would be very easy to apply because you can spend all the time you want squeezing the air bubbles out and getting things aligned since it is a liquid before zapping it.

I ordered some cheap no name UV glue and will try it with my PEI/glass printbed.

If the cheap glue doesn't hold up well at temperature but seems promising otherwise then I will buy the expensive 3M stuff that is officially rated at 180C.

A random demo of UV curing glue, [www.youtube.com]

I think chemically it is similar to super glue (cyanoacrylate) except the polymerization is triggered by UV light rather than moisture.

Will the UV light penetrate the PrintBite? Is line of sight for the rays necessary to cure? If it is...how do you get the UV to the glue between two opaque sheets?

I was thinking more the case when you were bonding something to glass, for which UV curable glues are pretty common.

Another choice might be heat curable adhesives, this one sounds just about perfect for attaching a heated bed to a print surface

[www.masterbond.com]

just put it between the two, squeegee out the bubbles and get it positioned correctly, then turn on the heated bed and the adhesive cures. It even is very thermally conductive and withstands thermal cycling. perfect.

I think the masterbond version is probably expensive, but there are lots of other makers of heat curing adhesives.

|

Re: New print surface material? November 05, 2015 02:08PM |

Registered: 9 years ago Posts: 483 |

|

Re: New print surface material? November 05, 2015 03:12PM |

Registered: 8 years ago Posts: 126 |

I got my PrintBite a week ago, so here's my opinion and experience :

I first saw mention of PrintBite on the reprap irc channel. Now we live in South Africa and I had just spent 3 days trying to track down a sheet of PEI. Please trust me when I tell you I got all the strange Mr Bean looks from everyone I asked about it - never even heard of it !

My printing on an i3 is exclusively ABS. I have been experimenting with different ways to keep the ABS prints on the aluminium bed.

I have tried, all with varying degrees of success, the Uhu Glue sticks, PVA white glue, blue printers tape, acetone with a puck, acetone + ABS slurry, and a few more.

I even tried printing on a scrap piece of acrylic sheet which stuck really well. VERY well - it is still stick on the sheet to this day.

The only thing that I found was working very well was the PVC removable clear flexible book covering plastic - until I found out that the smell from the PVC, or more specifically the 'C' was very very bad for me. Damn, and I thought I had a perfect solution.

So like many, I reverted back to the slurry method.

But I have 4 problems with the slurry that I don't like :

1. there is no set recipe as to how much ABS to acetone ratio should be used - I prefer science, not thumb suck.

2. there is no simple, easy and constant repeatable way to get the same thickness of slurry on the bed.

3. the slurry leaves a patchy color mark on the bottom of the print ( although this can be wiped off with acetone )

4. the slurry most often leaves a pattern, like sand dunes, in the bottom of the print.

So off I go again looking for a solution, and along comes PrintBite at just the right time.

I opted to have it couriered with DHL to South Africa. Using the postal service was out of the question, as a large number of parcels in our postal system disappear in to a massive worm hole, or the staff are constantly on strike waiting for the worm hole to widen.

So a few days later the DHL courier arrives with my parcel.

I was not too impressed with this whitish sheet of plastic. Didn't look too 'amazing' as I was expecting. I couldn't have been more wrong.

Took me a few minutes to clean up the bed and get the PrintBite stuck down.

I recall from the documentation that the bed temp should be increased, so up'd from 100 to 110C

Took me 3 or 4 prints of a first layer to get the height correct. I have Auto Bed Leveling using a manual endstop switch, so was able to very easily adjust the nozzle height by 0.01 each time in the starting gCode.

Once the height was correct, it wasn't a few hours until I had done away with the brim completely. I was able to print most of my items 'as is' on the bed.

I have found that the first line goes down and sticks perfectly every time. I even made a test model with a 0.25mm continuous line pattern which I used to test the first layer height, and even sharp corners would stay on the bed.

After using this for a week, I can honestly say that this PrintBite is the best print surface that I have ever used.

I wipe the PrintBite once with window cleaner, heat, ABL, print. No glue / tape / slurry - just print.

At the end of the print, I find I can lift the print with almost no effort whatsoever when the temp drops to around 70C.

My work area is now considerably neater - no jars of slurry, bottles of acetone, paint brushes, sponges, and all the tricks of the trade. Just 1 clean cloth and a spray bottle of window cleaner.

Bottom line is that PrintBite may not be cheap.

But it does cost less than the PEI that I found online.

And it does work - no doubt about that.

Was it worth the cost - hell YES. This is, for me, a game changer. This has taken all of my previous bed adhesion problems and niggles out of the equation, and left me confident that when I hit the Print command, it will start, it will print the first layer, it will stick to the bed, and I can concentrate on other things instead of doing the 'please stick, please stick' 3D printers chant for the first layer.

ps .. the bottom of my prints now look like glass. I can't even see the lines of the print. I even have to wipe some of then down with acetone to make them more dull to match the rest of the print.

I first saw mention of PrintBite on the reprap irc channel. Now we live in South Africa and I had just spent 3 days trying to track down a sheet of PEI. Please trust me when I tell you I got all the strange Mr Bean looks from everyone I asked about it - never even heard of it !

My printing on an i3 is exclusively ABS. I have been experimenting with different ways to keep the ABS prints on the aluminium bed.

I have tried, all with varying degrees of success, the Uhu Glue sticks, PVA white glue, blue printers tape, acetone with a puck, acetone + ABS slurry, and a few more.

I even tried printing on a scrap piece of acrylic sheet which stuck really well. VERY well - it is still stick on the sheet to this day.

The only thing that I found was working very well was the PVC removable clear flexible book covering plastic - until I found out that the smell from the PVC, or more specifically the 'C' was very very bad for me. Damn, and I thought I had a perfect solution.

So like many, I reverted back to the slurry method.

But I have 4 problems with the slurry that I don't like :

1. there is no set recipe as to how much ABS to acetone ratio should be used - I prefer science, not thumb suck.

2. there is no simple, easy and constant repeatable way to get the same thickness of slurry on the bed.

3. the slurry leaves a patchy color mark on the bottom of the print ( although this can be wiped off with acetone )

4. the slurry most often leaves a pattern, like sand dunes, in the bottom of the print.

So off I go again looking for a solution, and along comes PrintBite at just the right time.

I opted to have it couriered with DHL to South Africa. Using the postal service was out of the question, as a large number of parcels in our postal system disappear in to a massive worm hole, or the staff are constantly on strike waiting for the worm hole to widen.

So a few days later the DHL courier arrives with my parcel.

I was not too impressed with this whitish sheet of plastic. Didn't look too 'amazing' as I was expecting. I couldn't have been more wrong.

Took me a few minutes to clean up the bed and get the PrintBite stuck down.

I recall from the documentation that the bed temp should be increased, so up'd from 100 to 110C

Took me 3 or 4 prints of a first layer to get the height correct. I have Auto Bed Leveling using a manual endstop switch, so was able to very easily adjust the nozzle height by 0.01 each time in the starting gCode.

Once the height was correct, it wasn't a few hours until I had done away with the brim completely. I was able to print most of my items 'as is' on the bed.

I have found that the first line goes down and sticks perfectly every time. I even made a test model with a 0.25mm continuous line pattern which I used to test the first layer height, and even sharp corners would stay on the bed.

After using this for a week, I can honestly say that this PrintBite is the best print surface that I have ever used.

I wipe the PrintBite once with window cleaner, heat, ABL, print. No glue / tape / slurry - just print.

At the end of the print, I find I can lift the print with almost no effort whatsoever when the temp drops to around 70C.

My work area is now considerably neater - no jars of slurry, bottles of acetone, paint brushes, sponges, and all the tricks of the trade. Just 1 clean cloth and a spray bottle of window cleaner.

Bottom line is that PrintBite may not be cheap.

But it does cost less than the PEI that I found online.

And it does work - no doubt about that.

Was it worth the cost - hell YES. This is, for me, a game changer. This has taken all of my previous bed adhesion problems and niggles out of the equation, and left me confident that when I hit the Print command, it will start, it will print the first layer, it will stick to the bed, and I can concentrate on other things instead of doing the 'please stick, please stick' 3D printers chant for the first layer.

ps .. the bottom of my prints now look like glass. I can't even see the lines of the print. I even have to wipe some of then down with acetone to make them more dull to match the rest of the print.

|

Re: New print surface material? November 06, 2015 02:53AM |

Registered: 9 years ago Posts: 1,699 |

Quote

DaveOB

Took me 3 or 4 prints of a first layer to get the height correct. I have Auto Bed Leveling using a manual endstop switch, so was able to very easily adjust the nozzle height by 0.01 each time in the starting gCode.

What printer do you use and how does this work? My optical proximity switch is something about 0.3mm higher than my nozzle and due to the auto bed leveling operation it tends to crash into the printed part. It seems there is one side effect I can use to switch to a microswitch. Maybe I can use another side effect on my second printer as it uses another nozzle.

Besides I found comparable and they costs 2 or even 3 times more than PrintBite except for one, but this does not stick very well. It is better than direct printing on Glass but much more worst than Kapton tape (using PLA). So I am really curious. Even though a black one would have been more interesting but for adjusting a bright one is more suitable for my current sensor.

My parcel is in Germany "already"

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 07, 2015 03:07PM |

Registered: 8 years ago Posts: 126 |

Hi Treito

I have an i3 printer.

I do not use an optical switch. I just took the mechanical end stop micro switch with the long arm from the Z axis and put it in a drop down arm. Attached the arm to my X carriage. There is an arm on the far right of the X axis that flicks the micro switch arm upwards after the auto bed level.

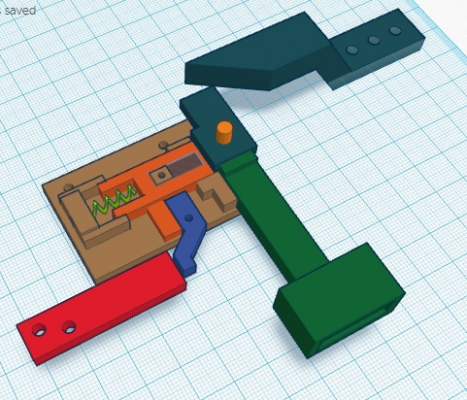

The design is basically like this :

All I have to do is remember to lower the arm again before I start the next print.

The PrintBite has, for me, been a big step forward. I am now glad that I could not get PEI in our country. Just remember to run your bed at a higher temperature than usual. I increased bed temp for ABS from 100 to 110C and parts sticking perfectly, and only release after bed cools to below 80C.

I have an i3 printer.

I do not use an optical switch. I just took the mechanical end stop micro switch with the long arm from the Z axis and put it in a drop down arm. Attached the arm to my X carriage. There is an arm on the far right of the X axis that flicks the micro switch arm upwards after the auto bed level.

The design is basically like this :

All I have to do is remember to lower the arm again before I start the next print.

The PrintBite has, for me, been a big step forward. I am now glad that I could not get PEI in our country. Just remember to run your bed at a higher temperature than usual. I increased bed temp for ABS from 100 to 110C and parts sticking perfectly, and only release after bed cools to below 80C.

|

Re: New print surface material? November 07, 2015 03:59PM |

Registered: 9 years ago Posts: 1,699 |

Quote

DaveOB

and only release after bed cools to below 80C.

Hi Dave,

Many thanks for the answer. That is why I ordered to pieces for each printer so I can exchange the surface after a print. Unfortunately your design cannot be convert for my printers but for my Ormerod 2 I have an idea or more than one but this will be too off-topic.

I am afraid that I will not get my Printbites before Wednesday in the evening because the parcel was not transported today (other companies do transport even on Saturdays) and as I am probably not at home on Monday I can make a date for catching up the parcel at the depot not for Wednesday. Luckily the depot is nearby my work So I have an extra travel of about 200 metres by car.

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 07, 2015 04:12PM |

Registered: 8 years ago Posts: 126 |

Quote

Treito

Quote

DaveOB

and only release after bed cools to below 80C.

Hi Dave,

Many thanks for the answer. That is why I ordered to pieces for each printer so I can exchange the surface after a print. Unfortunately your design cannot be convert for my printers but for my Ormerod 2 I have an idea or more than one but this will be too off-topic.

I am afraid that I will not get my Printbites before Wednesday in the evening because the parcel was not transported today (other companies do transport even on Saturdays) and as I am probably not at home on Monday I can make a date for catching up the parcel at the depot not for Wednesday. Luckily the depot is nearby my work So I have an extra travel of about 200 metres by car.

Best regards,

Sven

I found that adding a sheet or cork below my aluminium bed helps the heat up time, but then it also slows the cooling time. But that is not a bad thing, as I prefer to have the ABS parts cool slowly, say over 5 - 10 minutes, rather than risk them warping from rapid cooling.

I also like to wipe the PrintBite with a little window cleaner before each print, and I find I can do this if the temp is 80C or lower.

For the Z sensor used in ABL, I did see a number of designs online for using a small servo to lower and raise the sensor using the sensor pins on Ramps controlled with gCode.

Regards

Dave

Edited 1 time(s). Last edit at 11/07/2015 04:15PM by DaveOB.

|

Re: New print surface material? November 08, 2015 03:28AM |

Registered: 9 years ago Posts: 1,699 |

I saw this servo mechanism, too on YT, but I have no RAMPS (also there should be an output?). But I can use a side effect due to the printer design as another person already does here in this forum: If the nozzle touches the bed and you lower the z-axis further the printer head tilts to one direction. It is always the same and the angle seems to be that good related to the height that you can use this for a precise z-axis homing and ABL. Luckily you can reach a mechanical operation nearby and my FW also accepts negative values for z-axis-homing.

Yesterday I received cork plates of a size of 190mm x 190mm. Okay they are a little bit too small but it should isolate better than cardboard only. If I would have liked to cool down the print on the printer so that I cannot print during this time I probably would have not needed PrintBite as I should be able to print directly on my bed. At least this is for my Ormerod 2 as long as my Ormerod 1 is not equipped with its new heated bed. (I hope I got the temps not wrong). But I did not test yet to print directly onto the aluminium heated bed.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Yesterday I received cork plates of a size of 190mm x 190mm. Okay they are a little bit too small but it should isolate better than cardboard only. If I would have liked to cool down the print on the printer so that I cannot print during this time I probably would have not needed PrintBite as I should be able to print directly on my bed. At least this is for my Ormerod 2 as long as my Ormerod 1 is not equipped with its new heated bed. (I hope I got the temps not wrong). But I did not test yet to print directly onto the aluminium heated bed.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 08, 2015 03:33AM |

Registered: 8 years ago Posts: 126 |

|

Re: New print surface material? November 08, 2015 03:59AM |

Registered: 9 years ago Posts: 1,699 |

Okay I never used ABS slurry and I never will use it as I do not like this kind of solution. And I was also never thinking that printing onto the bed surface would work suitable. I imagined it would be like printing directly onto glass: it can work but the adhesion would not be very height not comparable with Kapton tape for example.

So I still have to wait at least until Wednesday or even longer.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

So I still have to wait at least until Wednesday or even longer.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 12, 2015 03:46AM |

Registered: 9 years ago Posts: 1,699 |

Hello,

luckily I was able to achieve the parcel on Tuesday using a little trick. Never mind. Because of some little healthy problems I was only able to run a short test this morning. This material is amazing.

The PrintBite was applied with some tape. I used a new and unused borosilicate glass and a version with the standard tape of Mutley3D. (I also have one with a test version of another tape). The appliance was not as easy as BuildTak as BT is flexible and the PrintBite was applied with strips. The structure is a little bit irregular with some small scratches on the surface. This does not affect the function but I would like to mention it as you will see this on the printed part. It is also kind of transparent and not very thick.

My Ormerod 2 is broken at the moment (nozzle damage) so I used my Ormerod 1. For the moment it is equipped with a non-modulated proximity sensor. The maximum value I achieved was about 500. White paper achieves 950 and BuildTak only 130 so that is why the sensor does not work with BT correctly.

I started a short print with PLA at 200°C and a bed temperature of only 60°C (as I did not change my file). The nozzle was a lillte bit too deep but I continued printing. At this point I would have destroyed any BuildTak, for me it is important to mention this. During the leck of time I canceled the print but I kept the bed on. I was able to remove the part but it was stuck very good on the bed. It was better than any other surface I tested before including BT, Kapton Tape, FiberGlass from Replikeo and Blue Painters Tape. According to the information here I would even get a better stuck if I increase the bed temperature.

I am curious about ABS printing.

Of course you can see the structure on the printed part but this is not a big deal and looks at the end not bad.

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

luckily I was able to achieve the parcel on Tuesday using a little trick. Never mind. Because of some little healthy problems I was only able to run a short test this morning. This material is amazing.

The PrintBite was applied with some tape. I used a new and unused borosilicate glass and a version with the standard tape of Mutley3D. (I also have one with a test version of another tape). The appliance was not as easy as BuildTak as BT is flexible and the PrintBite was applied with strips. The structure is a little bit irregular with some small scratches on the surface. This does not affect the function but I would like to mention it as you will see this on the printed part. It is also kind of transparent and not very thick.

My Ormerod 2 is broken at the moment (nozzle damage) so I used my Ormerod 1. For the moment it is equipped with a non-modulated proximity sensor. The maximum value I achieved was about 500. White paper achieves 950 and BuildTak only 130 so that is why the sensor does not work with BT correctly.

I started a short print with PLA at 200°C and a bed temperature of only 60°C (as I did not change my file). The nozzle was a lillte bit too deep but I continued printing. At this point I would have destroyed any BuildTak, for me it is important to mention this. During the leck of time I canceled the print but I kept the bed on. I was able to remove the part but it was stuck very good on the bed. It was better than any other surface I tested before including BT, Kapton Tape, FiberGlass from Replikeo and Blue Painters Tape. According to the information here I would even get a better stuck if I increase the bed temperature.

I am curious about ABS printing.

Of course you can see the structure on the printed part but this is not a big deal and looks at the end not bad.

Best regards,

Sven

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 15, 2015 10:53AM |

Registered: 9 years ago Posts: 425 |

Treito, I am really pleased to hear that the PrintBite arrived safely and is already making such a positive difference for you. Given the difficulties in the past with alternative print surfaces and tapes etc, to know that you are having such stonking success now is great news

Edited 1 time(s). Last edit at 11/15/2015 10:54AM by Mutley3D.

Edited 1 time(s). Last edit at 11/15/2015 10:54AM by Mutley3D.

|

Re: New print surface material? November 15, 2015 11:46AM |

Registered: 9 years ago Posts: 1,699 |

Thanks for your answer but I have to pull out your tooth like we German say (even the translation is not 100% possible). ABS was not working at the moment and BuildTak is not far away but it is much more sensitive. But BuildTak looks better in black

But I am sure if I find the right parameters ABS will work, too

Now I am trying to build a test part which allows me to swap to mechanical end stops and mechanical auto bed leveling to assist this effect and help to make the bed even more accurate leveled.

Besides I tested today the PrintBite with my Ormerod 2 and PLA. It was nearly perfect. After cooling down the part was already freed. So the MK3 heated bed seems to support the PrintBite much better. Maybe the other printer only hit the needed temperature better.

The next two tests would be printing on ABS and applying the test strips.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

But I am sure if I find the right parameters ABS will work, too

Now I am trying to build a test part which allows me to swap to mechanical end stops and mechanical auto bed leveling to assist this effect and help to make the bed even more accurate leveled.

Besides I tested today the PrintBite with my Ormerod 2 and PLA. It was nearly perfect. After cooling down the part was already freed. So the MK3 heated bed seems to support the PrintBite much better. Maybe the other printer only hit the needed temperature better.

The next two tests would be printing on ABS and applying the test strips.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 15, 2015 12:04PM |

Registered: 9 years ago Posts: 425 |

Treito, Ah well never mind. As the website sayss, PrintBite is NOT a cure for insufficent heating, poor leveling and other issues. However you do need to run a slightly warmer bed (110-120) for PrintBite and run the nozzle a bit hotter for bottom layer of ABS aswell, then it will stick without problem.

|

Re: New print surface material? November 15, 2015 12:13PM |

Registered: 9 years ago Posts: 1,699 |

I already tried 115°C bed temperature and 260°C nozzle temperature with my Ormerod 1. I was then able to print a part (3DBenchy), but it did not stick very well and also warped but like I said I was not finished (but I am open for tips).

Regarding the small size bed leveling for example should not be a big deal as the skirt proved this.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Regarding the small size bed leveling for example should not be a big deal as the skirt proved this.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 15, 2015 12:21PM |

Registered: 9 years ago Posts: 425 |

Treito, in your previous posts you talk of various issues on your machines, I think you need to get these sorted correctly. Also make sure the PrintBite is fully adhered without air pockets underneath. Try adjusting the Z-zero height aswell. Also clean PB with window cleaner (or acetone if no window cleaner) but avoid ispropyl alcohol as this can leave a film on the surface.

|

Re: New print surface material? November 15, 2015 12:31PM |

Registered: 9 years ago Posts: 1,699 |

Thanks for the answer. I do not want to argue in any way, I would like to pronounce that, but you mix something up. Okay it is hard as I have two machines. My Ormerod 1 is really problematic like auto bed leveling, broken controllers and so on. So that is why I switched now to the Ormerod 2. It only suffered from a broken nozzle as the PLA found two other exits besides the nozzle output.

To be honest the bed leveling is not perfect but it is enough to be able to print. We are talking about 0.2mm for this printer which is calculated wrong about the whole distance of the bed (for my Ormerod 1 we are talking about 0.5mm up to 1mm).

That is why I would like to test other methods for ABL, but this has nothing to do with the ABS print failures. My Ormerod 2 produces a really nice skirt.

And I only can repeat myself: ABS is not working now for me, but I am sure it will soon work, too.

Edited 1 time(s). Last edit at 11/15/2015 12:33PM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

To be honest the bed leveling is not perfect but it is enough to be able to print. We are talking about 0.2mm for this printer which is calculated wrong about the whole distance of the bed (for my Ormerod 1 we are talking about 0.5mm up to 1mm).

That is why I would like to test other methods for ABL, but this has nothing to do with the ABS print failures. My Ormerod 2 produces a really nice skirt.

And I only can repeat myself: ABS is not working now for me, but I am sure it will soon work, too.

Edited 1 time(s). Last edit at 11/15/2015 12:33PM by Treito.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? November 15, 2015 12:38PM |

Registered: 9 years ago Posts: 517 |

Quote

Mutley3D

avoid ispropyl alcohol as this can leave a film on the surface.

I'm confused here. You say not to use isopropyl alcohol, but in your application instructions, you say it is fine to use.

2. Clean the surface of your print bed with a degreasing agent (Isopropyl Alcohol, Acetone, Windex etc) 3. Clean the chosen underside of your PrintBite sheet in a similar way. Both sides of the PrintBite material are the same so it has no upper or lower surface.

While step 2 applies to the bed, step 3 says to clean PrintBite in a similar way, i.e. Isopropyl Alcohol is fine.

I have 91% isopropyl alcohol with contains 91% alcohol and 9% purified water. Are you saying one of these two ingredients leave a film of some sort? Or are you referring to other packaging that may contain other ingredients? Like how nail polish remover is mainly acetone, but has other ingredients added that makes it unsuitable for cleaning.

You also referred to acetone being "should be ok" in your message to Fatlab. Has it been verified that there is no long term negative effect on PrintBite from acetone?

Sorry, only registered users may post in this forum.