New print surface material?

Posted by Mutley3D

|

Re: New print surface material? May 11, 2016 09:40AM |

Registered: 9 years ago Posts: 1,699 |

I am using dc42 mini height sensor board with PrintBite. Works as good as a direct contact switch.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? May 11, 2016 09:42AM |

Registered: 9 years ago Posts: 425 |

Quote

leadinglights

I am about to try PrintBite on two of my printers but Anna & Karl's question about sensors made me think: Is PrintBite O.K. with brief contact with a hot end? The reason I ask is that I am using a piezoelectric sensor for bed leveling and Z contact detect [forums.reprap.org]

Contact force is less than 100 grams and duration is less than 20ms. With the hot end at 260°C and the bed at 115°C there is no visible trace left on Kapton tape.

Mike

This will be no problem.

|

Re: New print surface material? May 11, 2016 09:53AM |

Registered: 12 years ago Posts: 1,450 |

I have one of dc42s sensors and I am delighted with it, but the Piezoelectric sensor is user transparent, it corrects for changed nozzles and beds without having to have a fudge factor entered. The Piezoelectric sensors also have no X or Y offset.Quote

Treito

I am using dc42 mini height sensor board with PrintBite. Works as good as a direct contact switch.

Mike.

p.s., as an afterthought, had PrintBite not been robust I would have used both - the piezo to automatically set Z height on one corner and the IR sensor for leveling the rest of the bed.

|

Re: New print surface material? May 11, 2016 11:30AM |

Registered: 10 years ago Posts: 104 |

I just want to relay my experience with PrintBite. Initially I had a few issues being unable to get stuff to stick but Mutley3D was very helpful and in the end it turned out I simply didn't have my bed at the suggest temperature for the material I was using. I did set the bed to the correct temperature but the surface wasn't reaching that temperature, Cranking the heat up a bit solved all the issues and now sticks amazingly well. I would say the only downside, if you can even call it that, is I have to wait until the bed has cooled to 40c before I can even think of getting the prints off without prying them off which I dont want to do fo fear of damaging the print or the surface. I don't need a brim or anything even for the smallest parts and the bottom is brilliantly smooth and flat.

|

Re: New print surface material? May 11, 2016 12:45PM |

Registered: 10 years ago Posts: 14,672 |

Quote

ElmoC

Quote

Anna & Karl

Does anyone have any indications how PrintBite behaves with capacitive proximity sensors? I am thinking about installing one and would be interested in your experiences. What about inductive sensors with aluminium under the PrintBite - would that be likely to work?

I would avoid using a capacitive sensor. They can be effected by temperature and humidity so are really not a good choice for 3D printers.

I used an inductive sensor with PrintBite. However, because of the thickness of the material (0.7mm IIRC), that reduced the height difference between the nozzle and sensor and I was having issues with the sensor catching on the part if the edge of the print curled up any. This was with the standard 4mm approach sensor. If you can use the 8mm version (it has a wider barrel), that should take care of the issue.

My differential IR sensor works well with PrintBite, and unlike the heavy inductive sensors, weight only 2g so it doesn't add significantly to the mass of the hot end. See [miscsolutions.wordpress.com] for details.

Edited 1 time(s). Last edit at 05/11/2016 12:45PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New print surface material? May 11, 2016 04:19PM |

Registered: 9 years ago Posts: 1,699 |

I love this sensor.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: New print surface material? May 13, 2016 12:18PM |

Registered: 7 years ago Posts: 9 |

Hi, i also got a PrintBite and testing it in my Rasie3D N1. I mostly print with ABS and buildtak does a real good job holding it stuck to the plate real hard. But after like 50 prints my buildtak was getting worse and then i decided to try PrintBite out. I have read the whole thread so i started with Z-ABS that i normally print with at 280c and set it 290c and bed at 100c. ABS did not stick very good at all. So next test was i did set bed at 110c but pretty much the same thing. Next was 120c and still did not stick very good. I cleaned the plate with window cleaner and acetone. It was abit better with window cleaner i think.

So i was kind off sad and i did what i don't really want to do. I put abs-slurry on the PrintBite and ofcourse it helped alot as it does on any surface. After a few prints i wped the slurry off with clean acetone and tried again and it was actuallly alot better then my first tests. Not as good as buildtak, but if i have full enclosure it can work.

I will do some more testing but for ABS not the best surface to have imo. Doing a 8 hour print as we speak but that one is not to hard..

So i was kind off sad and i did what i don't really want to do. I put abs-slurry on the PrintBite and ofcourse it helped alot as it does on any surface. After a few prints i wped the slurry off with clean acetone and tried again and it was actuallly alot better then my first tests. Not as good as buildtak, but if i have full enclosure it can work.

I will do some more testing but for ABS not the best surface to have imo. Doing a 8 hour print as we speak but that one is not to hard..

|

Re: New print surface material? May 13, 2016 01:41PM |

Registered: 9 years ago Posts: 425 |

Trhuster - what bed construction do you have there - looks like round magnets? My thought is simply regarding your true top surface temp - maybe you need to increase bed temp a touch more, sounds like you almost have the adhesion fully switched on. is your heater in direct contact with surface underneath.

Printing ABS at 290 is going to degrade/decompose the ABS if it actually is 290 - Are you 100% sure it is a real 290c, and not a temp calibration/thermistor issue going on there.

Printing ABS at 290 is going to degrade/decompose the ABS if it actually is 290 - Are you 100% sure it is a real 290c, and not a temp calibration/thermistor issue going on there.

|

Re: New print surface material? May 13, 2016 01:59PM |

Registered: 7 years ago Posts: 9 |

Quote

Mutley3D

Trhuster - what bed construction do you have there - looks like round magnets? My thought is simply regarding your true top surface temp - maybe you need to increase bed temp a touch more, sounds like you almost have the adhesion fully switched on. is your heater in direct contact with surface underneath.

Printing ABS at 290 is going to degrade/decompose the ABS if it actually is 290 - Are you 100% sure it is a real 290c, and not a temp calibration/thermistor issue going on there.

The black spots are just some markings on heated plate. I have Printbite on a glass plate because no way it is flat all over if i put it on the heated plate directly. So yes we lose some heat there. My ir-temp reader says 96c when bed is set at 110c. Not sure how exact it is. The ABS i used at first Z-ABS and are made for high temp printing. Zortrax uses around 280c on their M200.

The one in the pic is total oppsite and needs low temp and i print it at 230c.

Edited 1 time(s). Last edit at 05/13/2016 01:59PM by Trhuster.

|

Re: New print surface material? May 13, 2016 02:27PM |

Registered: 10 years ago Posts: 104 |

|

Re: New print surface material? May 13, 2016 02:31PM |

Registered: 9 years ago Posts: 425 |

Quote

Trhuster

Quote

Mutley3D

Trhuster - what bed construction do you have there - looks like round magnets? My thought is simply regarding your true top surface temp - maybe you need to increase bed temp a touch more, sounds like you almost have the adhesion fully switched on. is your heater in direct contact with surface underneath.

Printing ABS at 290 is going to degrade/decompose the ABS if it actually is 290 - Are you 100% sure it is a real 290c, and not a temp calibration/thermistor issue going on there.

The black spots are just some markings on heated plate. I have Printbite on a glass plate because no way it is flat all over if i put it on the heated plate directly. So yes we lose some heat there. My ir-temp reader says 96c when bed is set at 110c. Not sure how exact it is. The ABS i used at first Z-ABS and are made for high temp printing. Zortrax uses around 280c on their M200.

The one in the pic is total oppsite and needs low temp and i print it at 230c.

Yes good it is on glass plate which is recommended, for the reason you mention, flatness

OK so your some 14-15 degrees undertemp according to IR gun on the bed.

In your case I would advise printing the bottom layer on your low temp ABS at 245, then you can drop to 230 if you need to, but also increase the bed temp so your getting 110-120 on the bed surface.

No two machines are the same, so it is a case of dialling in. Your very close. As someone mentions above, if it doesnt stick, increase temps. Top surface temp is *important*, actually no, it is critical, to getting the good adhesion.

|

Re: New print surface material? May 13, 2016 02:38PM |

Registered: 7 years ago Posts: 9 |

Quote

Mutley3D

Quote

Trhuster

Quote

Mutley3D

Trhuster - what bed construction do you have there - looks like round magnets? My thought is simply regarding your true top surface temp - maybe you need to increase bed temp a touch more, sounds like you almost have the adhesion fully switched on. is your heater in direct contact with surface underneath.

Printing ABS at 290 is going to degrade/decompose the ABS if it actually is 290 - Are you 100% sure it is a real 290c, and not a temp calibration/thermistor issue going on there.

The black spots are just some markings on heated plate. I have Printbite on a glass plate because no way it is flat all over if i put it on the heated plate directly. So yes we lose some heat there. My ir-temp reader says 96c when bed is set at 110c. Not sure how exact it is. The ABS i used at first Z-ABS and are made for high temp printing. Zortrax uses around 280c on their M200.

The one in the pic is total oppsite and needs low temp and i print it at 230c.

Yes good it is on glass plate which is recommended, for the reason you mention, flatness

OK so your some 14-15 degrees undertemp according to IR gun on the bed.

In your case I would advise printing the bottom layer on your low temp ABS at 245, then you can drop to 230 if you need to, but also increase the bed temp so your getting 110-120 on the bed surface.

No two machines are the same, so it is a case of dialling in. Your very close. As someone mentions above, if it doesnt stick, increase temps. Top surface temp is *important*, actually no, it is critical, to getting the good adhesion.

Well 120c on the bed is as high my printer will go so mabey 105c real temp then. I must do some more tests, i have not given up yet. What is the real temp sweet spot for ABS on PrintBite?

|

Re: New print surface material? May 13, 2016 02:48PM |

Registered: 8 years ago Posts: 126 |

If I may add my 2 cents worth here for you to consider :

I placed a sheet of cork, around 2mm thick, under the bed and heater, and added some corrugated card under that to keep the top of the cork in contact with the bottom of the heater pad.

Cork is very safe for this application and is an excellent heat insulator.

So the cork prevents you losing heat from below the bed, and effectively deflects that heat back to the bed. Heat-up times for the bed reduced considerably, and I very easily reach and maintain 120C for printing ABS. Have not had a warped or loose print since.

I placed a sheet of cork, around 2mm thick, under the bed and heater, and added some corrugated card under that to keep the top of the cork in contact with the bottom of the heater pad.

Cork is very safe for this application and is an excellent heat insulator.

So the cork prevents you losing heat from below the bed, and effectively deflects that heat back to the bed. Heat-up times for the bed reduced considerably, and I very easily reach and maintain 120C for printing ABS. Have not had a warped or loose print since.

|

Re: New print surface material? May 13, 2016 03:15PM |

Registered: 9 years ago Posts: 425 |

Trhuster - one thing you could do if you fall just shy of optimum temp, is cover the bed with something while its heating, this can help keep the heat in the bed and soak a higher temp into the top surface. Remove and print, whilst it may cool slightly, it should remain hot enough for that bottom layer to get firmly stuck. Otherwise as justmentioned by DaveOB, some insulation below might also help.

I would also keep an eye on your heatbed wiring, making sure they dont get warm from the electrical current. If they do, might be worth increasing wire guage slightly allowing more current to flow to the heater. Also check if your MOSFET for the bed is getting hot, if it is, some active cooling will help if not already in place.

HTH

I would also keep an eye on your heatbed wiring, making sure they dont get warm from the electrical current. If they do, might be worth increasing wire guage slightly allowing more current to flow to the heater. Also check if your MOSFET for the bed is getting hot, if it is, some active cooling will help if not already in place.

HTH

|

Re: New print surface material? May 13, 2016 03:22PM |

Registered: 9 years ago Posts: 517 |

Get rid of the IR temp sensor. They are practically useless. They only give an average temperature of the surrounding area. Best to use a contact type thermometer like a thermocouple. Tape it down to the bed with kapton tape and take the temperature that way. You can also do the same thing with the hotend. Tape the thermocouple close to the nozzle and check the temp there.

|

Re: New print surface material? May 13, 2016 03:45PM |

Registered: 8 years ago Posts: 126 |

|

Re: New print surface material? May 14, 2016 04:32AM |

Registered: 8 years ago Posts: 601 |

I'm surprised people have issues with this stuff, I received mine a few days ago and tried it out for the first time last night and wow does it stick!

What I've noticed is that you need to level the bed slightly closer to get it to stick, normally I use gauges to level the hot end to 0.08mm away, but with this it's more like 0.06 is needed. I never liked the paper method, far too inexact.

What I've noticed is that you need to level the bed slightly closer to get it to stick, normally I use gauges to level the hot end to 0.08mm away, but with this it's more like 0.06 is needed. I never liked the paper method, far too inexact.

|

Re: New print surface material? May 14, 2016 05:35AM |

Registered: 7 years ago Posts: 9 |

Quote

Origamib

I'm surprised people have issues with this stuff, I received mine a few days ago and tried it out for the first time last night and wow does it stick!

What I've noticed is that you need to level the bed slightly closer to get it to stick, normally I use gauges to level the hot end to 0.08mm away, but with this it's more like 0.06 is needed. I never liked the paper method, far too inexact.

Many things can be different between users. Z-ABS is abit different to most other brands off ABS for one thing. What filament do you use?

|

Re: New print surface material? May 14, 2016 07:13AM |

Registered: 8 years ago Posts: 601 |

Quote

Trhuster

Quote

Origamib

I'm surprised people have issues with this stuff, I received mine a few days ago and tried it out for the first time last night and wow does it stick!

What I've noticed is that you need to level the bed slightly closer to get it to stick, normally I use gauges to level the hot end to 0.08mm away, but with this it's more like 0.06 is needed. I never liked the paper method, far too inexact.

Many things can be different between users. Z-ABS is abit different to most other brands off ABS for one thing. What filament do you use?

I'm using the E3D basics brand of PLA and ABS. My heated bed is not the greatest, so I actually start at 110c and slowly ramp it up to 120 c as it prints for ABS. First layer temp of 250c, then 230c thereafter.

It sticks so hard that it doesn't even come away when cooled, although you can see it is starting to from underneath the plate. A quick tap on the side of the table and the parts actually *pop* off like an elastic band. Maybe I'm printing at too high of a temp? or perhaps it will get better after a few more heat cycles. either way, this method is much more efficient then the alternatives like kapton, glue and ABS slurry.

EDIT: The print I'm doing right now has actually warped. It is a batch of 9 pegs for a pegboard, and the largest item in the very corner of the heated bed has very slightly lifted. It hasn't continued to lift though, like it would on kapton. I imagine the edge of my heated bed is colder (no surprise, its just a mk2a heatbed).

Edited 1 time(s). Last edit at 05/14/2016 07:18AM by Origamib.

|

Re: New print surface material? May 14, 2016 07:22AM |

Registered: 7 years ago Posts: 9 |

I will start testing this in a better way. Using this warp test part. [www.thingiverse.com] I will post about my findings when i am done.

|

Re: New print surface material? May 14, 2016 07:31AM |

Registered: 8 years ago Posts: 601 |

Quote

Trhuster

I will start testing this in a better way. Using this warp test part. [www.thingiverse.com] I will post about my findings when i am done.

That's a good idea, I'll see if I can do the same.

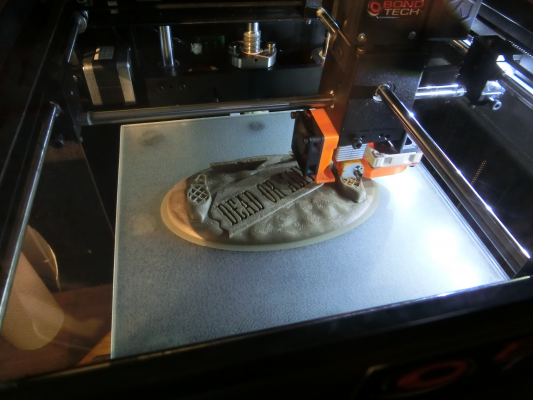

Here's a picture of the warping:

I'm pretty impressed still, as its most likely a cold spot there so its an issue with my machine and not PrintBite. What I do find impressive is that it didnt run down the rest of the print, it stopped there and the rest was still stuck hard. This was the only item to warp.

Edited 1 time(s). Last edit at 05/14/2016 07:32AM by Origamib.

|

Re: New print surface material? May 14, 2016 04:00PM |

Registered: 7 years ago Posts: 9 |

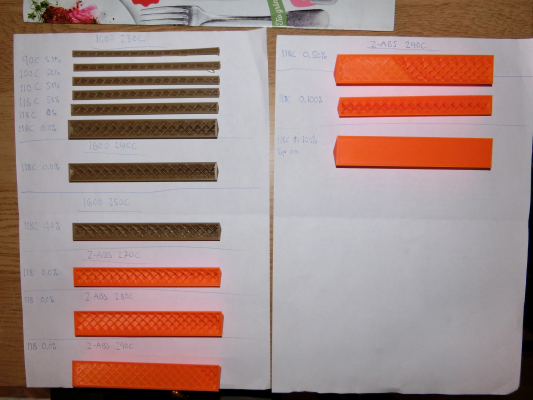

So dedicated my whole day for this. My main goal was to see how good my ABS would stick to the plate so i did not use the top on the printer for those tests.

First i tested Igoo3d ABS and it did stick better the hotter the plate was. 118c is max because when it reach 120c heated plate shuts off. Hotend temp did not help at all, 230, 240,250c was the same.

Second i tested Z-ABS and only at 118c on the bed plate. It was different and it was stuck abit better when raising the hotend temp. After each part strated warping i removed the print before the bed cooled down and it was very easy to remove. Not same as with Buildtak at all that part is really stuck to the plate, sometimes too hard and very hard to remove the part.

Mabey it will get better if bed plate is warmer but i doubt it will be even close to same stick as on Buildtak.

Last test i put on top and test completed with just a tiny warp but this is just because off the hotetr build chamber temp, not the actuall stick to the plate. I will use it abit more, i guess abs-slurry can be used when needed. Best part with PrintBite it is the durabilty and easy off part removal.

First i tested Igoo3d ABS and it did stick better the hotter the plate was. 118c is max because when it reach 120c heated plate shuts off. Hotend temp did not help at all, 230, 240,250c was the same.

Second i tested Z-ABS and only at 118c on the bed plate. It was different and it was stuck abit better when raising the hotend temp. After each part strated warping i removed the print before the bed cooled down and it was very easy to remove. Not same as with Buildtak at all that part is really stuck to the plate, sometimes too hard and very hard to remove the part.

Mabey it will get better if bed plate is warmer but i doubt it will be even close to same stick as on Buildtak.

Last test i put on top and test completed with just a tiny warp but this is just because off the hotetr build chamber temp, not the actuall stick to the plate. I will use it abit more, i guess abs-slurry can be used when needed. Best part with PrintBite it is the durabilty and easy off part removal.

|

Re: New print surface material? May 14, 2016 05:10PM |

Registered: 10 years ago Posts: 104 |

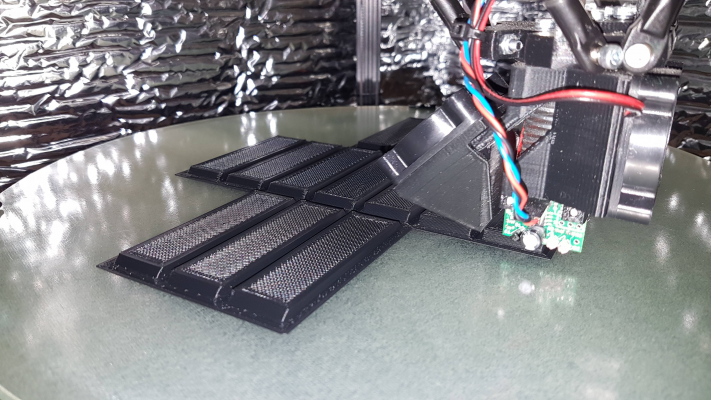

The thing is there is a certain temperature around 120c where the adhesion skyrockets. when you hit that point you simply cannot remove the part, I have a print going at the moment which is very wide and flat and as you can see isnt warping at all. I couldnt pry this off the bed with a chisel without damaging the surface.

|

Re: New print surface material? May 14, 2016 07:02PM |

Registered: 9 years ago Posts: 425 |

MightyMouth - Nice work and great example!

Trhuster - Given your bed shuts off at 120 meaning you have to limit to 118, can you increase your temp limit in firmware? Sounds like you are just shy of the temp threshold as your top surface temp may be -10ish from thermistor reading

Origamib - looks like your bit of lift there is from where the edge of the heatbed is not as hot, or possibly even finger grease, but nice work also.

Comparisons to buildtak - a relatively soft material, with adhesion so severe it is common to damage the sheet during part removal - hence sold in multipacks. PrintBite targets a different approach, being extremely durable with the single sheet lasting the lifetime of the printer, fit and forget!

Trhuster - Given your bed shuts off at 120 meaning you have to limit to 118, can you increase your temp limit in firmware? Sounds like you are just shy of the temp threshold as your top surface temp may be -10ish from thermistor reading

Origamib - looks like your bit of lift there is from where the edge of the heatbed is not as hot, or possibly even finger grease, but nice work also.

Comparisons to buildtak - a relatively soft material, with adhesion so severe it is common to damage the sheet during part removal - hence sold in multipacks. PrintBite targets a different approach, being extremely durable with the single sheet lasting the lifetime of the printer, fit and forget!

|

Re: New print surface material? May 14, 2016 11:39PM |

Registered: 8 years ago Posts: 916 |

How are you guys combating the lower wall cave in you get with a high bed temperature when printing ABS?

I know that I need to have my bed surface at 90 degrees or lower to prevent this effect from happening (calibrated with thermocouple) on my printer with a PEI build surface. If I have it set to 95 or higher then the lower wall cave in effect starts happening. I normally print with the first layer at 95 for good adhesion, then subsequent layers are printed at 90 degrees. This is surface temperature, my thermistor is on the bottom so my printer thinks that it's set to 105 / 100 degrees.

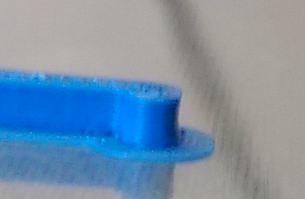

I can see that those blue parts that Origamib is printing has quite a bit of this effect showing.

The recommendations above are to have the bed surface at 110-120 degrees for the first layer. What is the recommendation for subsequent layers? Are you supposed to then drop the temperature to 90 degrees? Or just live with the cave in?

Edited 3 time(s). Last edit at 05/14/2016 11:44PM by nebbian.

I know that I need to have my bed surface at 90 degrees or lower to prevent this effect from happening (calibrated with thermocouple) on my printer with a PEI build surface. If I have it set to 95 or higher then the lower wall cave in effect starts happening. I normally print with the first layer at 95 for good adhesion, then subsequent layers are printed at 90 degrees. This is surface temperature, my thermistor is on the bottom so my printer thinks that it's set to 105 / 100 degrees.

I can see that those blue parts that Origamib is printing has quite a bit of this effect showing.

The recommendations above are to have the bed surface at 110-120 degrees for the first layer. What is the recommendation for subsequent layers? Are you supposed to then drop the temperature to 90 degrees? Or just live with the cave in?

Edited 3 time(s). Last edit at 05/14/2016 11:44PM by nebbian.

|

Re: New print surface material? May 15, 2016 02:06AM |

Registered: 7 years ago Posts: 9 |

Quote

Mutley3D

MightyMouth - Nice work and great example!

Trhuster - Given your bed shuts off at 120 meaning you have to limit to 118, can you increase your temp limit in firmware? Sounds like you are just shy of the temp threshold as your top surface temp may be -10ish from thermistor reading

Origamib - looks like your bit of lift there is from where the edge of the heatbed is not as hot, or possibly even finger grease, but nice work also.

Comparisons to buildtak - a relatively soft material, with adhesion so severe it is common to damage the sheet during part removal - hence sold in multipacks. PrintBite targets a different approach, being extremely durable with the single sheet lasting the lifetime of the printer, fit and forget!

I don't think PrintBite is bad and i am not in love with Buildtak either. I just compared the adhesion with Buildtak becuase it was fitted on the printer when i got it. Worst part with Buildtak is that adhesion get worse after you used it for a while and you need to change it. If Rasie3d releases the latest fw i will try and change max temp to 130c and isolate the underside off the bedplate.

|

Re: New print surface material? May 15, 2016 02:14AM |

Registered: 8 years ago Posts: 601 |

Quote

nebbian

I can see that those blue parts that Origamib is printing has quite a bit of this effect showing.

The recommendations above are to have the bed surface at 110-120 degrees for the first layer. What is the recommendation for subsequent layers? Are you supposed to then drop the temperature to 90 degrees? Or just live with the cave in?

Can't say I've seen this problem? the pieces above are almost a finished print. they are just pegs to hold up tools on a pegboard. What I have seen though is bad surface finishes due to heat curl on small pieces, especially overhangs. Like MightyMouth said adhesion skyrockets at 120c, but you can print lower. I did some tests as well printing a simple model of a gecko on Thingiverse. (http://www.thingiverse.com/thing:1363148)

At 120c, no lift, no brim needed. At 90c, it lifted with a brim, but at 100/110c I could print with a small brim and have zero curling. I printed a set of camera mounts for someone yesterday that were fairly large and square, with no noticeable collapse.

At some point I plan to do tests to see if 120c is needed for the whole print, or just to get a very good adhesion at the start. I say this, because it's impossible to remove until it reaches 50c after the print, so maybe this is true for mid-print?

|

Re: New print surface material? May 15, 2016 03:33AM |

Registered: 7 years ago Posts: 9 |

|

Re: New print surface material? May 15, 2016 03:52AM |

Registered: 8 years ago Posts: 916 |

Quote

Origamib

Can't say I've seen this problem? the pieces above are almost a finished print. they are just pegs to hold up tools on a pegboard.

It is hard to tell from the picture, perhaps you could take a closeup of this area on that blue piece?

I just know that parts that have thin walls and sharp corners suffer from the problem, especially with a hot heatbed. I simply can't see how you can get around this issue when using a print surface that requires such high heat to 'turn on'.

|

Re: New print surface material? May 15, 2016 06:28AM |

Registered: 10 years ago Posts: 104 |

Quote

nebbian

How are you guys combating the lower wall cave in you get with a high bed temperature when printing ABS?

I know that I need to have my bed surface at 90 degrees or lower to prevent this effect from happening (calibrated with thermocouple) on my printer with a PEI build surface. If I have it set to 95 or higher then the lower wall cave in effect starts happening. I normally print with the first layer at 95 for good adhesion, then subsequent layers are printed at 90 degrees. This is surface temperature, my thermistor is on the bottom so my printer thinks that it's set to 105 / 100 degrees.

I can see that those blue parts that Origamib is printing has quite a bit of this effect showing.

The recommendations above are to have the bed surface at 110-120 degrees for the first layer. What is the recommendation for subsequent layers? Are you supposed to then drop the temperature to 90 degrees? Or just live with the cave in?

I havent really printed anything that this would be noticable on I dont think and most of my prints have been functional rather that asthetic anyway. I suspect you could print the first couple layers at 120 then drop it down as when I have tried to remove a failed print before the bed was properly cool I have been unable to.

Interestingly the print above is the first print I have left to print overnight and to cool completely before removing, usually I wait until 30c or 40 c then the print can be persuaded to come off, when I cam to remove the print it was completely free.

Sorry, only registered users may post in this forum.