New print surface material?

Posted by Mutley3D

|

Re: New print surface material? May 16, 2016 12:25AM |

Registered: 9 years ago Posts: 425 |

Nebbian - There are several reasons one can have such artifact as you described, Depending on cause there may be several ways around it. The link you refer to is not a blanket "all in" case given the infinite combinations of materials, objects, printer setups, user ability and experience etc.

Many factors beyond just reducing bed temp may come into play, including nozzle temps, cooling, material type and quality, layer heights, part size and dimensions, even colour pigment can affect how a material behaves.

The link in your post about the issue refers to a PLA part that has caved in which actually shows some lift aswell. The contraction of the material creates the potential for warp. If the part hadn't lifted/warped, would the cave-in be to the same extent if any, possibly not.

I am aware of the issue you are trying to highlight. In unfavourable conditions, this can occur. There are a variety of measures one can take to avoid this if it happens, which may involve dropping bed and or nozzle temp after the first layer has been put down as the linked article suggests and as is suggested in this thread. A different layer height may also affect this. I print ABS @ 0.12mm layer height and cant say I suffer this issue.

In the photo clipping where you have magnified of Origamib's blue part, the problem appears to occur on one piece on the edge of a bed full of other identical looking pieces that dont appear to have the same issue, so possibly it could be a cooling issue of some sort, even a slight draft from someone walking by at the wrong time can cause some momentary rapid material contraction. Possibly the bed on that location is offering just the right conditions for the issue to occur, ie slightly cooler causing material above that area to contract a little more than warmer areas? It also appears very minor.

Many factors beyond just reducing bed temp may come into play, including nozzle temps, cooling, material type and quality, layer heights, part size and dimensions, even colour pigment can affect how a material behaves.

The link in your post about the issue refers to a PLA part that has caved in which actually shows some lift aswell. The contraction of the material creates the potential for warp. If the part hadn't lifted/warped, would the cave-in be to the same extent if any, possibly not.

I am aware of the issue you are trying to highlight. In unfavourable conditions, this can occur. There are a variety of measures one can take to avoid this if it happens, which may involve dropping bed and or nozzle temp after the first layer has been put down as the linked article suggests and as is suggested in this thread. A different layer height may also affect this. I print ABS @ 0.12mm layer height and cant say I suffer this issue.

In the photo clipping where you have magnified of Origamib's blue part, the problem appears to occur on one piece on the edge of a bed full of other identical looking pieces that dont appear to have the same issue, so possibly it could be a cooling issue of some sort, even a slight draft from someone walking by at the wrong time can cause some momentary rapid material contraction. Possibly the bed on that location is offering just the right conditions for the issue to occur, ie slightly cooler causing material above that area to contract a little more than warmer areas? It also appears very minor.

|

Re: New print surface material? May 29, 2016 02:52PM |

Registered: 8 years ago Posts: 88 |

So, few days with PrintBite (had PEI sheet before).

Same setup as PEI (220-240 deg. ABS, 100 deg. bed), works as PEI with one improvement: very easy to remove the parts after printing is done.

My "100 deg bed" is around 85-87 real (read with a thermal imager) because of the 3mm glass between aluminium hotbed and PrintBite. Didn't have the guts to glue it to the bed directly

The other big advantage of PrintBite is that is easily sourceable in EU. PEI was a huge effort (money) to get from US.

Let's see how PrintBite handles usage. PEI was used for 3 months, sanded and washed 4 times (to remove scratches) and it was like new. I assume sanding PrintBite is a nono, right?

Same setup as PEI (220-240 deg. ABS, 100 deg. bed), works as PEI with one improvement: very easy to remove the parts after printing is done.

My "100 deg bed" is around 85-87 real (read with a thermal imager) because of the 3mm glass between aluminium hotbed and PrintBite. Didn't have the guts to glue it to the bed directly

The other big advantage of PrintBite is that is easily sourceable in EU. PEI was a huge effort (money) to get from US.

Let's see how PrintBite handles usage. PEI was used for 3 months, sanded and washed 4 times (to remove scratches) and it was like new. I assume sanding PrintBite is a nono, right?

|

Re: New print surface material? May 30, 2016 06:36AM |

Registered: 8 years ago Posts: 93 |

|

Re: New print surface material? May 30, 2016 06:40AM |

Registered: 8 years ago Posts: 126 |

Quote

sigxcpu

I assume sanding PrintBite is a nono, right?

I am reasonably certain that any sanding is going to damage the surface of the PrintBite.

Mine has been on my printer for around 6 months and doesn't have a mark on it. This product has totally transformed my 3D printing in to a very easy 'no-hassle' experience.

Without reservation, I can say that this is by far the best 'upgrade' that I did to my printer.

|

Re: New print surface material? May 30, 2016 10:45AM |

Registered: 8 years ago Posts: 475 |

I think we shall get a precise recommendation for a cleaner product.

'Glass cleaner' may have different composition and additive which are always unknown. I have two kind of glass cleaner and none mention any component other than perfume ! Brand recommendation is not quite possible as cleaning products brands are generally local.

Common solvents are methanol, white spirit and white gas. I might be quite tempted by white gas as it is less 'greasy' than white spirit and supposedly immune for plastic.

Mutley3D, can you please confirm there is no risk to use white gas as a cleaner or that simple methanol is sufficient ?

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

'Glass cleaner' may have different composition and additive which are always unknown. I have two kind of glass cleaner and none mention any component other than perfume ! Brand recommendation is not quite possible as cleaning products brands are generally local.

Common solvents are methanol, white spirit and white gas. I might be quite tempted by white gas as it is less 'greasy' than white spirit and supposedly immune for plastic.

Mutley3D, can you please confirm there is no risk to use white gas as a cleaner or that simple methanol is sufficient ?

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

|

Re: New print surface material? May 30, 2016 12:23PM |

Registered: 8 years ago Posts: 93 |

|

Re: New print surface material? May 30, 2016 01:18PM |

Registered: 10 years ago Posts: 104 |

|

Re: New print surface material? May 30, 2016 05:12PM |

Registered: 8 years ago Posts: 475 |

Asbo and MightyMouth, Thank you.

I have acetone in my remote workshop, but I print in my flat and was not very found using it as it is quite a dangerous chemical, hence was not in my list. Will use it if this is the only positive report, anyway.

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

I have acetone in my remote workshop, but I print in my flat and was not very found using it as it is quite a dangerous chemical, hence was not in my list. Will use it if this is the only positive report, anyway.

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

|

Re: New print surface material? May 30, 2016 05:37PM |

Registered: 9 years ago Posts: 425 |

Hi Pierre

Acetone + kitchen towel is most effective. It removes greasey residue without smearing or leaving a thin film behind. A non smearing window cleaner will also work.

Please avoid Isopropyl alcohol, White Spirit/White gas/Methanol as they will leave a residue/thin film. These chemicals could be considered more hazardous than Acetone, which at worst has a smell but it not known as a carcinogen.

Alternatively you could use a natural soap/water solution with kitchen towel. Instructions can be downloaded here

Hope this helps

Acetone + kitchen towel is most effective. It removes greasey residue without smearing or leaving a thin film behind. A non smearing window cleaner will also work.

Please avoid Isopropyl alcohol, White Spirit/White gas/Methanol as they will leave a residue/thin film. These chemicals could be considered more hazardous than Acetone, which at worst has a smell but it not known as a carcinogen.

Alternatively you could use a natural soap/water solution with kitchen towel. Instructions can be downloaded here

Hope this helps

|

Re: New print surface material? May 30, 2016 05:48PM |

Registered: 8 years ago Posts: 126 |

Hi Mutley3D

Personally, I am a big fan of the window cleaner option. I buy the generic 'no name brand' from our local superstore.

I do see from research that one of the most common ingredients of home made window cleaner is white vinegar.

Do you have any info about using vinegar on PrintBite ?

As it is acidic in nature, it should remove finger prints well, as long as it is safe on the PrintBite material ?

Personally, I am a big fan of the window cleaner option. I buy the generic 'no name brand' from our local superstore.

I do see from research that one of the most common ingredients of home made window cleaner is white vinegar.

Do you have any info about using vinegar on PrintBite ?

As it is acidic in nature, it should remove finger prints well, as long as it is safe on the PrintBite material ?

|

Re: New print surface material? May 30, 2016 05:58PM |

Registered: 9 years ago Posts: 425 |

DaveOB

I was actually going to suggest a diluted white vinegar solution, 50:50 with water. I knew it cleans windows really well without smears, but I havent tested it on PB...yet! (and local co-op didnt have any when i went down there for some)

So I erred on the side of caution and didnt suggest it in case someone said "but it will smell like a chip shop", but it would certainly be what I would describe as the "organic" option. I will update more on this tomorrow once I get some from in town.

I was actually going to suggest a diluted white vinegar solution, 50:50 with water. I knew it cleans windows really well without smears, but I havent tested it on PB...yet! (and local co-op didnt have any when i went down there for some)

So I erred on the side of caution and didnt suggest it in case someone said "but it will smell like a chip shop", but it would certainly be what I would describe as the "organic" option. I will update more on this tomorrow once I get some from in town.

|

Re: New print surface material? May 31, 2016 06:57AM |

Registered: 8 years ago Posts: 88 |

I always use Isopropyl alcohol because it is a degreaser. The plastic remnants are easily removed mechanically and my fingers marks with alcohol. Same was used for PEI without any issues.

One time I had to use cleaners because I was oiling the mechanics and touched the PEI surface with them.

My real problem is not the first layer but the upper layers delamination because of the stupid filament I'm trying to get rid of (read consumed fast) right now.

One time I had to use cleaners because I was oiling the mechanics and touched the PEI surface with them.

My real problem is not the first layer but the upper layers delamination because of the stupid filament I'm trying to get rid of (read consumed fast) right now.

|

Re: New print surface material? May 31, 2016 07:30AM |

Registered: 8 years ago Posts: 93 |

|

Re: New print surface material? May 31, 2016 08:21PM |

Registered: 9 years ago Posts: 517 |

Got the new heater for my printer and the PrintBite arrived at the same time. Yea! So, got everything hooked up and ran some temperature tests. When I set my bed for 60C, the surface of the PrintBite measured 60C. I was expecting more insulating effect. So I went ahead and did a test print. A 50x50x5mm cube. Ran the hot end at 200 for PLA like I normally do. It stuck great other than a little lifting on a couple corners. Will try upping the bed temperature a bit and see if that helps. Waiting for the bed temp to drop to remove it. At 40C, it popped right off.

|

Re: New print surface material? May 31, 2016 08:41PM |

Registered: 9 years ago Posts: 425 |

|

Re: New print surface material? May 31, 2016 10:02PM |

Registered: 9 years ago Posts: 517 |

|

Re: New print surface material? May 31, 2016 10:07PM |

Registered: 9 years ago Posts: 517 |

Well this is interesting. Seems the lifting is happening after the printing is done and the bed is cooling. At the end of the last print, I checked and saw no lifting. Even tried slipping a paint knife under an edge and it would not go. I just checked again when the temp was down to 55 and all four corners (printing a 50x50x5 cube) had lifted enough for the paint knife to slide under.

|

Re: New print surface material? June 01, 2016 03:57PM |

Registered: 8 years ago Posts: 88 |

|

Re: New print surface material? June 01, 2016 05:26PM |

Registered: 9 years ago Posts: 425 |

Quote

sigxcpu

Maybe odd question: any chance to unglue the PrintBite from the glass bed? I want to transfer it on the aluminium hotbed, if possible (yes, I've made a mistake).

Dont think you have made a mistake. On glass it should be fine. Do you easily reach temp? if so, I maybe wouldnt worry.

|

Re: New print surface material? June 01, 2016 08:21PM |

Registered: 9 years ago Posts: 517 |

Still having issues with the lifting after I finish printing. I have tried several different spools of PLA, all with the same results. I am experimenting with lowing the nozzle a bit to get a better squish to start with. The bed has had a good cleaning with acetone. Not sure what else to do other than turning up the heat on the bed or hotend, but think that would just make the problem worse.

|

Re: New print surface material? June 02, 2016 04:26AM |

Registered: 8 years ago Posts: 88 |

Quote

Mutley3D

Quote

sigxcpu

Maybe odd question: any chance to unglue the PrintBite from the glass bed? I want to transfer it on the aluminium hotbed, if possible (yes, I've made a mistake).

Dont think you have made a mistake. On glass it should be fine. Do you easily reach temp? if so, I maybe wouldnt worry.

Glass is 210x210x3mm, so it adds a bit of weight to the already heavy aluminium heatbed and steel carriage (P3 Steel) and now, replacing PEI with this would've been a good opportunity to get rid of that extra weight.

|

Re: New print surface material? June 02, 2016 07:28PM |

Registered: 9 years ago Posts: 517 |

Just wanted to post a follow up on getting my printer dialed in to work with PrintBite. I had used it in the past on my Printrbot Simple Metal so new it worked. The problem with the Printrbot is it only has a 4mm inductive probe which required it to be fairly low. When I took out the thickness of the PrintBite, the distance from the bottom of the probe to the bed was too low. While it cleared, if there was any curling on an edge of a print, it could catch on it and pull the print off the bed.

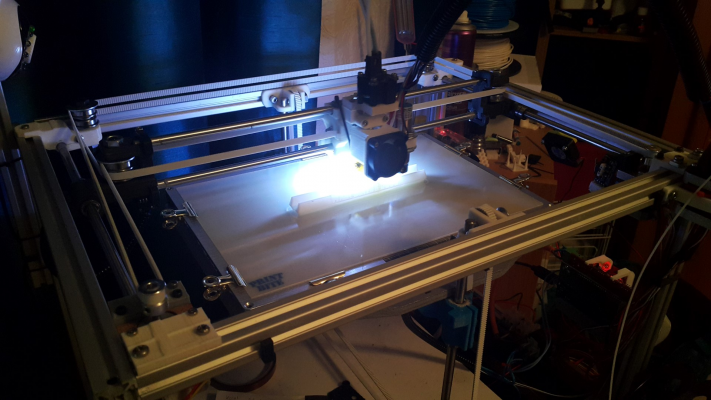

I have built a 300x200mm CoreXY printer and wanted to use Print Bite on it. At the time, I had already put down a layer of BuildTak so was going to wait until it had to be replaced before putting the PrintBite on. Unfortunately, my 600W 110V Keenovo heater failed. But since it was only 5 months old, Keenovo sent me a replacement (Their customer service was great to work with). So since I was having to wait for the heater, I went ahead and order the PrintBite.

After I got the new heater and Print Bite installed, I started doing some test prints. The bed on the printer is a 1/4" (6mm) piece of aluminum tooling plate. I mounted the thermistor by drilling a hole on the side (the 6mm high part) and embedded it with some thermal epoxy. I then adjusted out the beta value of the thermistor so it was reading true surface temperature with the BuildTak. When I went to check the temp difference using PrintBite, I found there was none. When the thermistor said it was 60C, my external thermocouple thermometer read 60C on the PrintBite surface. I was expecting more of an insulating effect from the PrintBite but was happy with it being what it was.

I first started out printing some 50x50x5mm test cubes using my current PLA settings. Bed at 60C and Nozzle at 200C. The first cube printed great. But shortly after the print finished, I noticed the corners were lifting. My second try I upped the nozzle and bed temps (210/65). It again printed fine but started to lift shortly after printing finished. I tried a couple other settings and finally got a good cube with very little corner lift. So I decided to try a larger part. While I was getting ready to test things out, Mutley3D messaged me with some suggestions. We tossed some ideas around while I was printing this larger part.

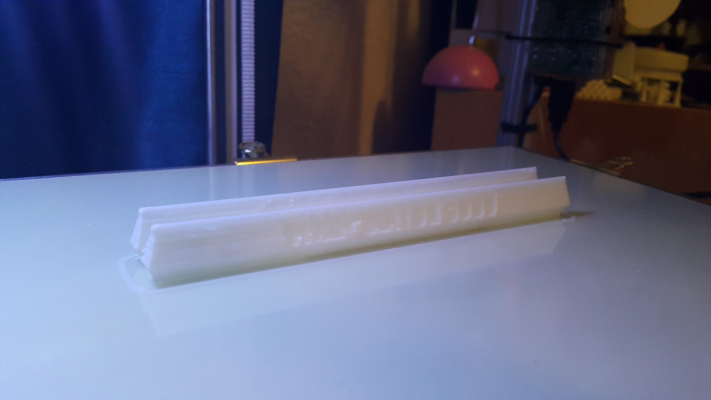

Running the bed at 70C and nozzle at 210 produced this wonderful part...

The print hadn't even finished. We tried increasing the bed temp up, but the hotter we went, the quicker the lifting started. When I tried at 90, it was lifting off the bed before the first layer was done. This is when I discovered another issue. When I was using BuildTak, it adheres to the part very well. Maybe a bit too well. In order to be able to remove the part after it finishes printing, I had backed the nozzle away from the board some. When I took the part off that was printed at 90C, I noticed the parallel traces on the first layer were not adhere to each other. They were like individual wires.

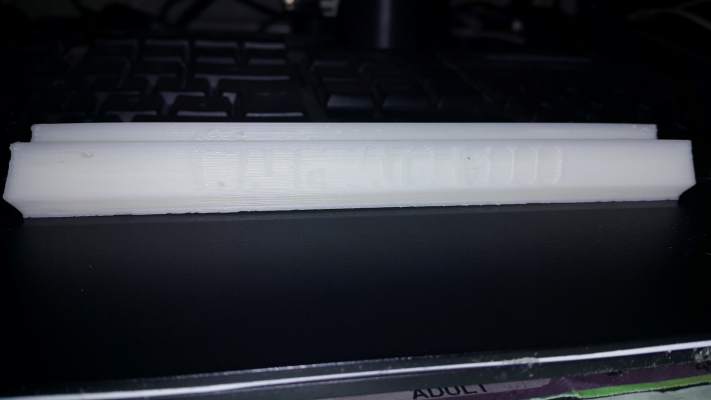

After making this discovery, I readjusted the nozzle and tried the print again. Because the lifting had been getting worse as the bed temp went up, I decided to try a print with the bed temp at 55. The part printed with no lifting and stayed well attached to the bed until it had cooled to about 35C when it slipped right off.

So it looked like I had found a good setting. However, the next part I went to print had some adhesion issues on the first layer. It was late so shut it all down for the night. This morning, I started the part with the bed temp set to 65C. The first layer stuck like it should have so I let it go while I headed into work. After getting home, I check the part. It printed flat with no lifting and came right off the bed. I have since printed several more parts at the 65/210 settings and they have all come out perfect.

So for those who are having some issues, check your nozzle height in addition to using a bit more heat than normal. That was the key to getting it to work for me.

I have built a 300x200mm CoreXY printer and wanted to use Print Bite on it. At the time, I had already put down a layer of BuildTak so was going to wait until it had to be replaced before putting the PrintBite on. Unfortunately, my 600W 110V Keenovo heater failed. But since it was only 5 months old, Keenovo sent me a replacement (Their customer service was great to work with). So since I was having to wait for the heater, I went ahead and order the PrintBite.

After I got the new heater and Print Bite installed, I started doing some test prints. The bed on the printer is a 1/4" (6mm) piece of aluminum tooling plate. I mounted the thermistor by drilling a hole on the side (the 6mm high part) and embedded it with some thermal epoxy. I then adjusted out the beta value of the thermistor so it was reading true surface temperature with the BuildTak. When I went to check the temp difference using PrintBite, I found there was none. When the thermistor said it was 60C, my external thermocouple thermometer read 60C on the PrintBite surface. I was expecting more of an insulating effect from the PrintBite but was happy with it being what it was.

I first started out printing some 50x50x5mm test cubes using my current PLA settings. Bed at 60C and Nozzle at 200C. The first cube printed great. But shortly after the print finished, I noticed the corners were lifting. My second try I upped the nozzle and bed temps (210/65). It again printed fine but started to lift shortly after printing finished. I tried a couple other settings and finally got a good cube with very little corner lift. So I decided to try a larger part. While I was getting ready to test things out, Mutley3D messaged me with some suggestions. We tossed some ideas around while I was printing this larger part.

Running the bed at 70C and nozzle at 210 produced this wonderful part...

The print hadn't even finished. We tried increasing the bed temp up, but the hotter we went, the quicker the lifting started. When I tried at 90, it was lifting off the bed before the first layer was done. This is when I discovered another issue. When I was using BuildTak, it adheres to the part very well. Maybe a bit too well. In order to be able to remove the part after it finishes printing, I had backed the nozzle away from the board some. When I took the part off that was printed at 90C, I noticed the parallel traces on the first layer were not adhere to each other. They were like individual wires.

After making this discovery, I readjusted the nozzle and tried the print again. Because the lifting had been getting worse as the bed temp went up, I decided to try a print with the bed temp at 55. The part printed with no lifting and stayed well attached to the bed until it had cooled to about 35C when it slipped right off.

So it looked like I had found a good setting. However, the next part I went to print had some adhesion issues on the first layer. It was late so shut it all down for the night. This morning, I started the part with the bed temp set to 65C. The first layer stuck like it should have so I let it go while I headed into work. After getting home, I check the part. It printed flat with no lifting and came right off the bed. I have since printed several more parts at the 65/210 settings and they have all come out perfect.

So for those who are having some issues, check your nozzle height in addition to using a bit more heat than normal. That was the key to getting it to work for me.

|

Re: New print surface material? June 03, 2016 12:51AM |

Registered: 10 years ago Posts: 104 |

|

Re: New print surface material? June 03, 2016 03:28AM |

Registered: 8 years ago Posts: 126 |

Quote

MightyMouth

It's all about getting it dialled in, Temperature, Nozzle Height and Extrusion Settings are all important, but for me (once my printer was set up right) Printbite has been the best 3D Printing purchase I have made other than the printer itself.

I have to agree with this statement 100%

PrintBite is not a magic fix for a poorly calibrated printer, but once I had it dialed in, it is producing exact results every time. Best investment I made for my printer.

|

Re: New print surface material? June 05, 2016 03:37PM |

Registered: 8 years ago Posts: 601 |

Quote

MightyMouth

It's all about getting it dialled in, Temperature, Nozzle Height and Extrusion Settings are all important, but for me (once my printer was set up right) Printbite has been the best 3D Printing purchase I have made other than the printer itself.

I can vouch for this as well. Nozzle height was a surprising issue for me, found by an accidental discovery when I switched slicers. Bit of tinkering later, and every material sticks well now. I've also found it important to dial in slicer settings to make sure a good even layer is placed, without too many gaps.

I've now printed several large pieces in both ABS and PLA, with print times ranging from 3 to 10 hours, all successful. Also, I cant remember who asked but the last picture I posted on this thread of small blue ABS parts, I can confirm that their was lower part cave in, but only with this colour of ABS. I have since fixed this by printing @ 120c first layer, 110 after. I can print as low as 100c bed temp for small parts with no lift/warp. I sometimes print the first two layers at 120c on larger items to avoid warping, although I'm not sure how necessary this is.

Baasicly, anyone worried about the excessive heat, it's not a huge issue. Just takes a bit of dialling in for your specific ABS. The results are worth it.

|

Re: New print surface material? June 10, 2016 06:23PM |

Registered: 8 years ago Posts: 3,525 |

So I recently got a sheet of Printbite 300x200mm for my enlarged SmartRapCore Alu (no heated chamber - yet). Found that it appears to be improved, though I am not sure what the change is. Improved adhesion, and ABS parts remain stuck down until it cools to around 66 deg C whereas the previous sheets I've tried would release at 88 deg C so there must be more adhesion in this newer sheet.

Decided to print the diabolical Warpinator 5000 from Angus at Maker's Muse and got a perfectly flat print, no lift at all.

Using Excelvan ABS at 255 deg C first layer and 240 deg C 2nd and subsequent layers. Bed 120 deg C first layer 115 deg C after that.

Well impressed so far. In fact just peeled off a brim still a little sticky at room temperature, before it would just slide off.

Now looking for an even more warp prone model to test any suggestions?

If I have any concern it's that Petg might be very difficult to remove if it sticks proportionally as well as abs does.

I emailed Angus at Maker's Muse and he confirmed that this is in his words "one of the very few flat ABS warpinator 5000's in existence".

Edited 4 time(s). Last edit at 06/12/2016 05:06PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Decided to print the diabolical Warpinator 5000 from Angus at Maker's Muse and got a perfectly flat print, no lift at all.

Using Excelvan ABS at 255 deg C first layer and 240 deg C 2nd and subsequent layers. Bed 120 deg C first layer 115 deg C after that.

Well impressed so far. In fact just peeled off a brim still a little sticky at room temperature, before it would just slide off.

Now looking for an even more warp prone model to test any suggestions?

If I have any concern it's that Petg might be very difficult to remove if it sticks proportionally as well as abs does.

I emailed Angus at Maker's Muse and he confirmed that this is in his words "one of the very few flat ABS warpinator 5000's in existence".

Edited 4 time(s). Last edit at 06/12/2016 05:06PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: New print surface material? June 20, 2016 10:54AM |

Registered: 7 years ago Posts: 4 |

|

Re: New print surface material? June 20, 2016 11:14AM |

Registered: 8 years ago Posts: 601 |

|

Re: New print surface material? June 20, 2016 12:30PM |

Registered: 9 years ago Posts: 425 |

|

Re: New print surface material? June 30, 2016 06:43PM |

Registered: 8 years ago Posts: 367 |

This is a question from idle curiosity: I can see why you would need to use a higher bed temperature with PrintBite (it's a bit more insulation between the heater and the surface), but why does the hot end need to be hotter as well? Shouldn't that just affect the viscosity of the extruded plastic?

Disclaimer: I am not a chemical engineer and probably talk nonsense about such things.

See my blog at [moosteria.blogspot.com].

Disclaimer: I am not a chemical engineer and probably talk nonsense about such things.

See my blog at [moosteria.blogspot.com].

Sorry, only registered users may post in this forum.