New print surface material?

Posted by Mutley3D

|

Re: New print surface material? August 20, 2016 03:51AM |

Registered: 7 years ago Posts: 17 |

I'm trying to get a question answered regarding this print surface. My company ha a 3d printer with a 1meter x 1meter print surface. Since the largest size of printbite available is 500mm by 500 mm, I'll need to put on 4 sheets to cover the whole surface. I am worried however that needing multiple sheets will cause issues. Specifically that the four sheets will expand as the bed heats and cause stresses and possibly delamination in the sheets next to them. Does anyone have any idea or experience with using multiple sheets of printbite. Do you think it would be a problem? Or is the expansion very small?

|

Re: New print surface material? August 22, 2016 01:58AM |

Registered: 7 years ago Posts: 168 |

|

Re: New print surface material? August 22, 2016 03:42PM |

Registered: 8 years ago Posts: 77 |

Quote

Phytone

After going through PLA, ABS and PETG with great results - I'm trying Nylon (3DPrima Nylon)

Have cooked the Nylon for 10 hours in the oven to make sure it is dry, but every time the print gets more than 0.8mm thick, the darn thing lifts off the bed.

Have cleaned with Acetone - nope

Have put down a coat of hairspray - nope

Have put down a coat of PVA/water - nope

Have played around with nozzle heights, from well and truly squished to a nice bead - nope

Bed Temperatures between 70 - 100 deg - nope

Extruder temp is 250 and it comes out nice.

So can anyone share their setup for Print Bite and Nylon?

Thanks in advance!

Kevin

Solved : Bed at 60 degrees and application of Pritt Stick onto the Print Bite.

|

Re: New print surface material? August 23, 2016 07:05AM |

Registered: 10 years ago Posts: 231 |

I haven't seen anyone mention using denatured alcohol as a possible cleaning solution for PrintBite. Just curious if anyone had tried it or if there was some reason it wouldn't work? When I worked in a photo lab many years ago, we used to use denatured alcohol for cleaning negatives, prints, whatever and it was really effective at removing any fingerprints, grease, etc.

|

Re: New print surface material? October 27, 2016 06:32PM |

Registered: 8 years ago Posts: 601 |

Recently had some frustrations with printbite and so I thought I'd put my troubles up in case anyone else gets this problem.

I had printbite dialled in perfectly. Its been going for months and months, nearly 12 hours or more a day with little to no problems and then all of a sudden NO prints would stick. even simple calibration cubes had trouble sticking. This had me stumped for a whole week, and I messed around with Z offsets, calibrations, temps, flow rate, all to no avail. Then my paper towel ran out that I use to wipe the surface with acetone. I bought some new ones (Mega jumbo kitchen towel for anyone in the UK) and it STICKS again!

My theory? acetone was breaking down the paper towel in some way and actually leaving residues rather then cleaning it up. I was using Tesco non-branded cheap kitchen roll. I've figured out that a clean printbite surface will actually feel rough when you wipe with the towel. It should have a slight amount of friction, a bit like mild sand paper. If you can move the kitchen towel smoothly and effortlessly, it's probably greasy.

I had printbite dialled in perfectly. Its been going for months and months, nearly 12 hours or more a day with little to no problems and then all of a sudden NO prints would stick. even simple calibration cubes had trouble sticking. This had me stumped for a whole week, and I messed around with Z offsets, calibrations, temps, flow rate, all to no avail. Then my paper towel ran out that I use to wipe the surface with acetone. I bought some new ones (Mega jumbo kitchen towel for anyone in the UK) and it STICKS again!

My theory? acetone was breaking down the paper towel in some way and actually leaving residues rather then cleaning it up. I was using Tesco non-branded cheap kitchen roll. I've figured out that a clean printbite surface will actually feel rough when you wipe with the towel. It should have a slight amount of friction, a bit like mild sand paper. If you can move the kitchen towel smoothly and effortlessly, it's probably greasy.

|

Re: New print surface material? October 27, 2016 07:16PM |

Registered: 7 years ago Posts: 168 |

Quote

hobbymods

Hi Mutley,

I made an inquiry through your website some time back, regarding getting a couple of your Printbite sheets cut to 240x240mm and posted to Australia.

No reply at this stage....can it be done?

Here I am again....I sent another email a few days back just asking it the items have been dispatched (after this first post here you contacted me and said it was in hand) and if I could get a tracking number.

I really hate to nag, but it's been a while and the communication is sparse.

Could you please let me know where we're at, and send me a tracking number?

Thank you

Edited 1 time(s). Last edit at 10/27/2016 07:16PM by hobbymods.

|

Re: New print surface material? October 27, 2016 08:18PM |

Registered: 9 years ago Posts: 425 |

I will PM you to resolve this urgently. Did you email the old mutley3d.com or new flex3drive.com domain?

Edited 1 time(s). Last edit at 10/27/2016 10:43PM by Mutley3D.

Quote

hobbymods

Quote

hobbymods

Hi Mutley,

I made an inquiry through your website some time back, regarding getting a couple of your Printbite sheets cut to 240x240mm and posted to Australia.

No reply at this stage....can it be done?

Here I am again....I sent another email a few days back just asking it the items have been dispatched (after this first post here you contacted me and said it was in hand) and if I could get a tracking number.

I really hate to nag, but it's been a while and the communication is sparse.

Could you please let me know where we're at, and send me a tracking number?

Thank you

Edited 1 time(s). Last edit at 10/27/2016 10:43PM by Mutley3D.

|

Re: New print surface material? October 28, 2016 12:18AM |

Registered: 7 years ago Posts: 168 |

I probably used the old address as you did mention a change to your system and what not.

Not having a big hissy fit or anything, just might be time we chased it up as it's taking a while.

I'm pretty mellow mate, let's just get a tracking number and see what these bloody posties are up to

Not having a big hissy fit or anything, just might be time we chased it up as it's taking a while.

I'm pretty mellow mate, let's just get a tracking number and see what these bloody posties are up to

|

Re: New print surface material? November 05, 2016 05:53AM |

Registered: 7 years ago Posts: 168 |

And we're all good, it arrived during the week.

Post has been consistently about 3-4 weeks out of the UK lately to Oz, so nothing too strange there.

Thanks for getting back to me.

Post has been consistently about 3-4 weeks out of the UK lately to Oz, so nothing too strange there.

Thanks for getting back to me.

Quote

Mutley3D

I will PM you to resolve this urgently. Did you email the old mutley3d.com or new flex3drive.com domain?

Quote

hobbymods

Quote

hobbymods

Hi Mutley,

I made an inquiry through your website some time back, regarding getting a couple of your Printbite sheets cut to 240x240mm and posted to Australia.

No reply at this stage....can it be done?

Here I am again....I sent another email a few days back just asking it the items have been dispatched (after this first post here you contacted me and said it was in hand) and if I could get a tracking number.

I really hate to nag, but it's been a while and the communication is sparse.

Could you please let me know where we're at, and send me a tracking number?

Thank you

|

Re: New print surface material? November 29, 2016 04:44AM |

Registered: 9 years ago Posts: 288 |

Finally getting a clean print on the printbite without extra nonsense.

My bed is flexing during the initial home height probe and giving odd results to the firmware (uses z endstop for probing )

)

Having to reissue the autobed command before printing and having to use a raft to compensate for the unlevel bed.

Once I sorted out that and the z-offset issue, printbite really bites my prints.

Thank you Mutley 3D

My bed is flexing during the initial home height probe and giving odd results to the firmware (uses z endstop for probing

)

)Having to reissue the autobed command before printing and having to use a raft to compensate for the unlevel bed.

Once I sorted out that and the z-offset issue, printbite really bites my prints.

Thank you Mutley 3D

|

Re: New print surface material? December 02, 2016 12:48PM |

Registered: 7 years ago Posts: 7 |

Hello,

I use a 3d delta SPIDERBOT printer, with an original E3d-V6 HotEnds plus steel thermocouple on HotEnds and heating bed.

I replaced the PEI bed with the PRINTBITE.

No problem for printing PLA, ABS, PET or PETG.

But for the POLYCARBONATE (PC) I have problems of warping or no grip on the first layer.

I have adjusted the gap from HotEnds and bed to 0.12mm, i tried from 0.05 to 0.3 but was no good.

Printing layers at 0.25mm,

Very reduced speed for the first layer.

The temperature of the heating bed is at 150-155°C in the repeater host, but I measured 137-140. I don't know if i can go more up without a PSU failure.

I tried for HotEnds from 280 to 320°C but still have problems of warping.

I use the PC ESUN,

What do you advise me to do, to get PC print ?

THX

I use a 3d delta SPIDERBOT printer, with an original E3d-V6 HotEnds plus steel thermocouple on HotEnds and heating bed.

I replaced the PEI bed with the PRINTBITE.

No problem for printing PLA, ABS, PET or PETG.

But for the POLYCARBONATE (PC) I have problems of warping or no grip on the first layer.

I have adjusted the gap from HotEnds and bed to 0.12mm, i tried from 0.05 to 0.3 but was no good.

Printing layers at 0.25mm,

Very reduced speed for the first layer.

The temperature of the heating bed is at 150-155°C in the repeater host, but I measured 137-140. I don't know if i can go more up without a PSU failure.

I tried for HotEnds from 280 to 320°C but still have problems of warping.

I use the PC ESUN,

What do you advise me to do, to get PC print ?

THX

|

Re: New print surface material? December 02, 2016 09:46PM |

Registered: 10 years ago Posts: 35 |

|

Re: New print surface material? December 02, 2016 10:37PM |

Registered: 9 years ago Posts: 425 |

@stephi - I have not tried ESUN PC so I cant comment on this particular brand. I do however print Polymaker PC with no issues on a bed @120 with nozzle @ 275/280

I suspect that your bed temp of 140+ is possibly too high so drop this to 120 and try again.

Please also note that since ESUN is a budget brand it may not adhere aswell as others, however as per dtwrv6 suggests, you could try applying some glue stick to the cold bed, but then wipe it off with a wet kitchen towel (water) to clean it off before printing. leaving only a feint trace of glue stick on the surface. Done correctly this should increase your success with the ESUN PC.

Flex3Drive.com

I suspect that your bed temp of 140+ is possibly too high so drop this to 120 and try again.

Please also note that since ESUN is a budget brand it may not adhere aswell as others, however as per dtwrv6 suggests, you could try applying some glue stick to the cold bed, but then wipe it off with a wet kitchen towel (water) to clean it off before printing. leaving only a feint trace of glue stick on the surface. Done correctly this should increase your success with the ESUN PC.

Flex3Drive.com

|

Re: New print surface material? December 03, 2016 04:27PM |

Registered: 7 years ago Posts: 7 |

|

Re: New print surface material? December 05, 2016 06:27PM |

Registered: 10 years ago Posts: 35 |

I've found that the machine setup is an order of magnitude more critical on polycarbonate than on any of the other materials you mentioned. Don't expect 100% success with PC unless you are willing to invest a lot of time tuning and tweaking your machine (even replacing parts with better parts) before you get something to work reliably. Printbite is one piece of a working solution, but there are a hundred other variables that you have to master to make it work. It's trial by error mostly, along with some outside help and some intuition. But it does work great when you have everything dialed in right.

If you don't have a heated enclosure for your printer, you had better start there. You might get away without it for ABS, but I don't see how you will print PC unless you heat the chamber.

Good Luck!

Edited 1 time(s). Last edit at 12/05/2016 06:34PM by dtwrv6.

If you don't have a heated enclosure for your printer, you had better start there. You might get away without it for ABS, but I don't see how you will print PC unless you heat the chamber.

Good Luck!

Edited 1 time(s). Last edit at 12/05/2016 06:34PM by dtwrv6.

|

Re: New print surface material? December 07, 2016 04:41PM |

Registered: 7 years ago Posts: 7 |

@dtwrv6 Thx for your reply

out of topic on.

I have this 3d printer V1.5 with heated enclosure. now is V2.2.

[www.spiderbot.eu]

Lots of tunings Like, E3D-v6 HotEnd including a semi rigid Stainless Steel thermocouples type K (1100ºC)

[www.tcdirect.com]

I will replace this thermocouple by the new Type K Thermocouple Cartridge from E3D, more easy for maintenance.

All metal extruder 2300 steps/mm [micron-eme.com]

Hiwin linear guideways, enhanced pulley and ball-bearing, and lot of little things.

So if you have advise for another good tuning regarding delta printer, i will be very happy to try.

I am thinking to replace belts along the linear guideways by 8mm lead screw-2mm pitch for more accuracy, driving it by 60 and 12 Tooth Pulleys, as nema motors are on botton of the printer, the little belts on 60 and 12 pulleys never hot when you heat the chamber.

out of topic off.

@Mutley3D

So i have tried to drop the bed temps to 120 and it don't work, there is completely no grip on the bed, the PC slides on the bed. test with hotend at 260-270-280.....310.

maybe that my ESUN PC have a lot of moisure, I will try to put it in an oven at 60°C during few hours.

I am waiting for my order of a spool of Polymaker PC.

Sorry for my bad English

Edited 1 time(s). Last edit at 12/07/2016 04:47PM by stephi.

out of topic on.

I have this 3d printer V1.5 with heated enclosure. now is V2.2.

[www.spiderbot.eu]

Lots of tunings Like, E3D-v6 HotEnd including a semi rigid Stainless Steel thermocouples type K (1100ºC)

[www.tcdirect.com]

I will replace this thermocouple by the new Type K Thermocouple Cartridge from E3D, more easy for maintenance.

All metal extruder 2300 steps/mm [micron-eme.com]

Hiwin linear guideways, enhanced pulley and ball-bearing, and lot of little things.

So if you have advise for another good tuning regarding delta printer, i will be very happy to try.

I am thinking to replace belts along the linear guideways by 8mm lead screw-2mm pitch for more accuracy, driving it by 60 and 12 Tooth Pulleys, as nema motors are on botton of the printer, the little belts on 60 and 12 pulleys never hot when you heat the chamber.

out of topic off.

@Mutley3D

So i have tried to drop the bed temps to 120 and it don't work, there is completely no grip on the bed, the PC slides on the bed. test with hotend at 260-270-280.....310.

maybe that my ESUN PC have a lot of moisure, I will try to put it in an oven at 60°C during few hours.

I am waiting for my order of a spool of Polymaker PC.

Sorry for my bad English

Edited 1 time(s). Last edit at 12/07/2016 04:47PM by stephi.

|

Re: New print surface material? December 08, 2016 01:10PM |

Registered: 9 years ago Posts: 425 |

|

Re: New print surface material? December 08, 2016 02:56PM |

Registered: 7 years ago Posts: 7 |

|

Re: New print surface material? December 12, 2016 10:41AM |

Registered: 7 years ago Posts: 2 |

|

Re: New print surface material? December 13, 2016 04:58AM |

Registered: 9 years ago Posts: 288 |

Quote

UnicronNL

@stephi

I use PC from hobbyking, print-bed 170c and nozzle 315c, no warping problems with these temps

(my printbite is slowly turning brownish)

I use ABS print-bed 100c and nozzle 240c get temp related adhesion issues (cold air blowing trough room)

Mine is turning brown

I am wondering about removing the glass and putting the bite directly to the aluminium heatbed.

|

Re: New print surface material? December 13, 2016 07:19AM |

Registered: 7 years ago Posts: 2 |

Quote

GRAYWOLF

I use ABS print-bed 100c and nozzle 240c get temp related adhesion issues (cold air blowing trough room)

Mine is turning brown

I am wondering about removing the glass and putting the bite directly to the aluminium heatbed.

I have it directly on alu bed, only it's a milled tooling plate 6mm thick. also i have 500Watt silicon heater from KEENOVO

Edited 1 time(s). Last edit at 12/13/2016 07:20AM by UnicronNL.

|

Re: New print surface material? December 13, 2016 07:25AM |

Registered: 8 years ago Posts: 601 |

More praise for Mutley after I got a new sheet of custom PrintBite at no extra cost! Great service, would happily pay more for it.

I've recently had problems with my old print bite actually. It turns out the bed was warping over my overly large heater cables. This resulted in an uneven surface and all my prints were popping off. This hadn't happened before but it seems I had over tightened the leveling screws so my cheap pcb heater bent. I heightened the bed over the wires and I'm back to perfect prints! The lesson here is to persevere... And build a better machine

I've recently had problems with my old print bite actually. It turns out the bed was warping over my overly large heater cables. This resulted in an uneven surface and all my prints were popping off. This hadn't happened before but it seems I had over tightened the leveling screws so my cheap pcb heater bent. I heightened the bed over the wires and I'm back to perfect prints! The lesson here is to persevere... And build a better machine

|

Re: New print surface material? January 20, 2017 10:26PM |

Registered: 8 years ago Posts: 367 |

Has anyone had luck with nGen on PrintBite? I haven't found settings that work well. It does stick, but not very firmly, and so print sometimes end up peeling away from the print bed after a while. I am using 220C on a bed at 80C, but have varied both values up and down from this.

See my blog at [moosteria.blogspot.com].

See my blog at [moosteria.blogspot.com].

|

Re: New print surface material? January 20, 2017 11:59PM |

Registered: 9 years ago Posts: 425 |

Quote

animoose

Has anyone had luck with nGen on PrintBite? I haven't found settings that work well. It does stick, but not very firmly, and so print sometimes end up peeling away from the print bed after a while. I am using 220C on a bed at 80C, but have varied both values up and down from this.

You absolutely need to be running hotter on the nozzle. 220c is too low. Probably need to increase bed temp aswell to 90+. Tweak your Z zero adjustment aswell up or down. Keep at it and you will find the sweetspot. If it doest stick, increase heat (note that doesnt necassarily mean increase temps)

Are you running a print cooling fan?

Try a detached brim / insulation skirt. Will help maintain bed temp around the part. Set skirt to 20+ lines depending on part size, but set skirt "distance to part" 0.5-1mm distance from the part so it is not fused to the printed part.

Edited 1 time(s). Last edit at 01/20/2017 11:59PM by Mutley3D.

Flex3Drive.com

|

Re: New print surface material? January 21, 2017 12:13AM |

Registered: 8 years ago Posts: 367 |

I am running a print cooling fan.

Thanks for the suggestions. I'll give them a go. BTW, I've been using PrintBite with PLA (205 on 80 works well), PETG and some other materials and it's excellent. It's made a huge difference in the quality of my prints and how easy it is to make them work.

See my blog at [moosteria.blogspot.com].

Thanks for the suggestions. I'll give them a go. BTW, I've been using PrintBite with PLA (205 on 80 works well), PETG and some other materials and it's excellent. It's made a huge difference in the quality of my prints and how easy it is to make them work.

See my blog at [moosteria.blogspot.com].

|

Re: New print surface material? January 21, 2017 07:07AM |

Registered: 8 years ago Posts: 601 |

|

Re: New print surface material? January 28, 2017 10:42PM |

Registered: 8 years ago Posts: 367 |

Quote

Origamib

I've found good results for nGen with 90c first layer, then 80. Nozzle temps at 250/230c. Cooling fan should be as low as possible as nGen does warp a little, especially on larger pieces.

Thanks, I tried 235/85 and that is working quite well. 235/80 gave me a lot of warping.

See my blog at [moosteria.blogspot.com].

|

Re: New print surface material? January 31, 2017 05:22AM |

Registered: 7 years ago Posts: 168 |

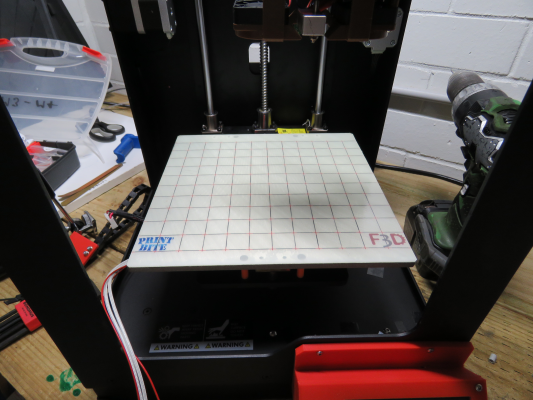

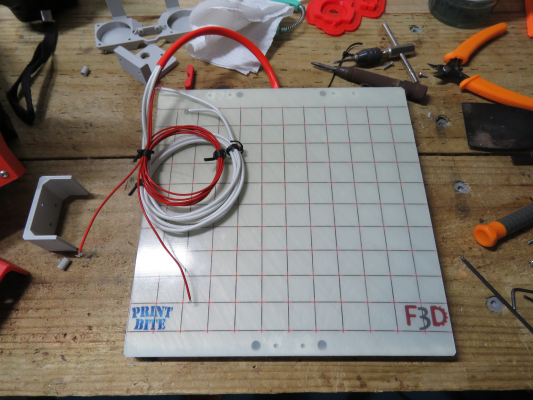

Been a bit slack/busy to be doing much with my printers other than just use them, but here's my new bed finally for my converted Zortrax.

I'll get the whole machine permanently assembled in the coming weeks, and dial it all right in.

I'll get the whole machine permanently assembled in the coming weeks, and dial it all right in.

|

Re: New print surface material? January 31, 2017 07:04AM |

Registered: 7 years ago Posts: 321 |

|

Re: New print surface material? January 31, 2017 08:00AM |

Registered: 9 years ago Posts: 425 |

@Animoose - That difference between 80c and 85c  I think you have demonstrated very well that it can be a matter of just a few degrees to switch that adhesion on. Glad to hear you got a win there.

I think you have demonstrated very well that it can be a matter of just a few degrees to switch that adhesion on. Glad to hear you got a win there.

@hobbymods - Looking very nice there indeed. Bravo.

@DragonFire - You could always throw a Hopka, donning your Shapka, to the print release Gods.

Flex3Drive.com

I think you have demonstrated very well that it can be a matter of just a few degrees to switch that adhesion on. Glad to hear you got a win there.

I think you have demonstrated very well that it can be a matter of just a few degrees to switch that adhesion on. Glad to hear you got a win there.@hobbymods - Looking very nice there indeed. Bravo.

@DragonFire - You could always throw a Hopka, donning your Shapka, to the print release Gods.

Flex3Drive.com

Sorry, only registered users may post in this forum.