New print surface material?

Posted by Mutley3D

|

Printbite - Love it! Hate it! February 25, 2018 07:13PM |

Registered: 9 years ago Posts: 53 |

Hate it! - I print exclusively with ABS and found the adhesion to be too fiddly. Had a print with lifted edges, but with central section stuck on so well I had to reheat the bed to 120C and slowly pry the softened part off. Was using Kean Strip Acetone purchased from a box store.

Love it! - Had suggestions from the forum to add in a touch of ABS juice when cleaning the surface. This helped a bit. Finally went to Elmers Xtreme Glue stick water slurry...and magic...no more lifting.. Even on parts that would be guaranteed to pull glass chips out of a Borosilicate glass bed. Really tough surface. Thought I was in heaven.

Hate it! - After 4 months of printing, gas pockets are beginning to form between the Printbite and glass as parts try to lift off the Printbite. I just ran a 20 hour print, and there was an outline of white bubbles around digital sundial. Upon cooling, I could feel the the bubbled surface was puckered/raised up. I've temperature cycled the bed a few times and about 3/4 of the white bubbles are gone and it does not feel puckered. I am glad it is more or less flat again, but the implications of what happened to the puckered material are not good. I am afraid the Xtreme Glue stick slurry attaches just too well to the Printbite and is causing it to separate from the glass bed. In the case of this print, the sundial just popped off the bed. I meticulously followed the Printbite installation instructions. This is the older 0.8mm thick Printbite surface.

Anyone else seeing similar issues with large ABS prints? Has anyone been successful in removing the adhesive backing and reattaching to a glass bed with 468MP?

Been trying to contact Printbite, but haven't gotten a reply. Made a post on the Printbite forum in early December suggesting to use glue stick, but it's status is "Your contribution is awaiting approval" with no response. Maybe I am on a black list.

Love it! - Had suggestions from the forum to add in a touch of ABS juice when cleaning the surface. This helped a bit. Finally went to Elmers Xtreme Glue stick water slurry...and magic...no more lifting.. Even on parts that would be guaranteed to pull glass chips out of a Borosilicate glass bed. Really tough surface. Thought I was in heaven.

Hate it! - After 4 months of printing, gas pockets are beginning to form between the Printbite and glass as parts try to lift off the Printbite. I just ran a 20 hour print, and there was an outline of white bubbles around digital sundial. Upon cooling, I could feel the the bubbled surface was puckered/raised up. I've temperature cycled the bed a few times and about 3/4 of the white bubbles are gone and it does not feel puckered. I am glad it is more or less flat again, but the implications of what happened to the puckered material are not good. I am afraid the Xtreme Glue stick slurry attaches just too well to the Printbite and is causing it to separate from the glass bed. In the case of this print, the sundial just popped off the bed. I meticulously followed the Printbite installation instructions. This is the older 0.8mm thick Printbite surface.

Anyone else seeing similar issues with large ABS prints? Has anyone been successful in removing the adhesive backing and reattaching to a glass bed with 468MP?

Been trying to contact Printbite, but haven't gotten a reply. Made a post on the Printbite forum in early December suggesting to use glue stick, but it's status is "Your contribution is awaiting approval" with no response. Maybe I am on a black list.

|

Re: Printbite - Love it! Hate it! February 25, 2018 11:48PM |

Registered: 8 years ago Posts: 126 |

Quote

to-the-nth

Has anyone been successful in removing the adhesive backing and reattaching to a glass bed with 468MP?

I moved my printbite a few days back.

Had to remove from an aluminium plate.

Got 1 corner to lift, then used a few thin bamboo skewers to gradually lift as I worked across, and prevented it from re-adhering on to the plate.

Adhesive was removed by wetting the adhesive with acetone, and while it was still very wet, gently scrape with a paint scraper. ( as soon as the acetone evaporates, the adhesive gets very tacky again )

|

Re: Printbite - Love it! Hate it! February 26, 2018 03:54AM |

Registered: 7 years ago Posts: 23 |

I initially struggled with ABS on PB as my i3 Plus had an over-temp cut out at 110C. Once I reflashed it so I could hit 115C, it's been printing ABS very well. Upgrading to a Micro Swiss hot end also helped as it cured the occasional under extrusion that was causing cracks in prints.

I haven't seen any bubbles but my PB was attached to very clean glass - might your glass have had anything on the surface that would prevent the glue working?

I've been using PB for 6-8 months and level is critical, as is wiping it with acetone every so often. I find some filament seems to leave something behind and I need to clean the glass after every print, but with others it's fine for days. I also find that you *must* leave the bed to cool before removing the print or again it's not as effective afterwards.

I haven't seen any bubbles but my PB was attached to very clean glass - might your glass have had anything on the surface that would prevent the glue working?

I've been using PB for 6-8 months and level is critical, as is wiping it with acetone every so often. I find some filament seems to leave something behind and I need to clean the glass after every print, but with others it's fine for days. I also find that you *must* leave the bed to cool before removing the print or again it's not as effective afterwards.

|

Re: Printbite - Love it! Hate it! February 26, 2018 12:27PM |

Registered: 9 years ago Posts: 53 |

Did you use 468MP to reattach? Would love to who you purchased from so I can try to duplicate. One option is to start with a fresh piece of glass for a new bed and get a new PB from Jason to do an A vs B comparison. Maybe a recommendation from flex3drive for reattaching? I have large prints that explosively release and are almost 1mm shorter because of cooling. There is a lot of force involved.Quote

DaveOB

I moved my printbite a few days back.

Had to remove from an aluminium plate.

Got 1 corner to lift, then used a few thin bamboo skewers to gradually lift as I worked across, and prevented it from re-adhering on to the plate.

Adhesive was removed by wetting the adhesive with acetone, and while it was still very wet, gently scrape with a paint scraper. ( as soon as the acetone evaporates, the adhesive gets very tacky again )

Quote

gadgetmind

I initially struggled with ABS on PB as my i3 Plus had an over-temp cut out at 110C. Once I reflashed it so I could hit 115C, it's been printing ABS very well. Upgrading to a Micro Swiss hot end also helped as it cured the occasional under extrusion that was causing cracks in prints.

I haven't seen any bubbles but my PB was attached to very clean glass - might your glass have had anything on the surface that would prevent the glue working?

I've been using PB for 6-8 months and level is critical, as is wiping it with acetone every so often. I find some filament seems to leave something behind and I need to clean the glass after every print, but with others it's fine for days. I also find that you *must* leave the bed to cool before removing the print or again it's not as effective afterwards.

I question the clean issue as well. But I did everything I could to clean it and followed the curing instructions. Application was tedious because I used the end of a round wooden dowel to press the PB against the glass as it was being applied to make sure there was no air pockets. Took almost an hour. I had a similar issue with PEI lifting with 468MP on a different bed 6 months earlier. When I peeled the PEI away, the 468MP had the consistency of cured rubbery contact adhesive, which is what it is. In sections, the 468MP was attached to PEI and sometimes to glass. I am afraid that the Xtreme glue slurry has so much better attach than just PB/ABS that it is stronger than the adhesive, and the Xtreme wins. The Xtreme pulled glass chips on a regular basis. Xtreme has the advantage of when a part is really "stuck" that I can water the edges, and the glue will dissolve within an hour.

I hear you about cooling the part back to room temp to get release. I did not try removing the bed and putting in a freezer. That part was BONDED, but still had lifted edges. Reading comments about lifted edges with PB, it seems like it is good, but there have always been disclaimers that it is no perfect and to expect a small amount of lifting. I'd love to do a controlled experiment between Xtreme and naked PB.

I was in denial seeing small white patches of delamination after some prints, because it tended to heal itself and completely disappear. But after being able to feel the raised bubbles, its clearly and issue I need to address.

Does it count as lifting if the part stays attached to the surface but the surface lifts?

|

Re: Printbite - Love it! Hate it! February 26, 2018 12:33PM |

Registered: 7 years ago Posts: 23 |

An hour? I've fitted two bits of PB and both times took only 10 mins or so to apply and then whatever the recommended heat cycle is.

To clean, I wipe with acetone when the bed is cold.

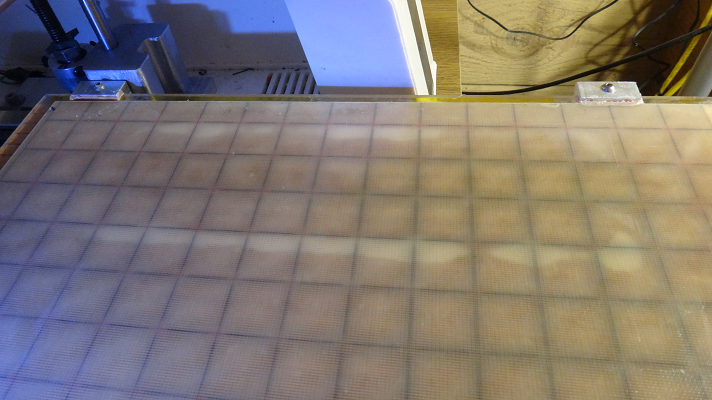

To check level, I have my own level test (it's on thingiverse under same username) and if these circles all print right, then I know the bed is level from edge to edge.

I won't claim that I still don't see lifting on *very* odd occasions, but it's usually a sharp corner that hasn't gone down right initially and I now check these and abort the print if it goes wrong. It's usually then time for a clean and level test, but TBH I often go for weeks doing noting but press print and leave the printer to it.

To clean, I wipe with acetone when the bed is cold.

To check level, I have my own level test (it's on thingiverse under same username) and if these circles all print right, then I know the bed is level from edge to edge.

I won't claim that I still don't see lifting on *very* odd occasions, but it's usually a sharp corner that hasn't gone down right initially and I now check these and abort the print if it goes wrong. It's usually then time for a clean and level test, but TBH I often go for weeks doing noting but press print and leave the printer to it.

|

Re: Printbite - Love it! Hate it! February 26, 2018 01:31PM |

Registered: 8 years ago Posts: 3,525 |

I've never had printbite lift from the substrate, but I don't use glass, I bond it directly to aluminium tooling plate. If a part is a high risk for lifting then I use ABS juice over the printbite before printing and put mouse ears on any sharp corners. I've never had a problem getting parts off printbite. Once they cool they lift off, sometimes if I have used ABS juice it takes a little blade under the corners to get them to begin to peel away. However I do all my ABS printing now in well enclosed machines (45 deg C at least), and this helps immensely to reduce shrinkage in the part.

I have recently started using AndOrNot own brand surface, mainly because its cheap. ABS does stick to it quite well, at the same temps as I'd use for printbite, (PLA and PETG stick at much lower temps, sometimes low-warping risk parts with PLA need no bed heat at all) but I have cracked an AndOrNot sheet with an ABS part contracting, and because it was bonded so well (seems AndOrNot needs to be cooler for the part to detach).

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I have recently started using AndOrNot own brand surface, mainly because its cheap. ABS does stick to it quite well, at the same temps as I'd use for printbite, (PLA and PETG stick at much lower temps, sometimes low-warping risk parts with PLA need no bed heat at all) but I have cracked an AndOrNot sheet with an ABS part contracting, and because it was bonded so well (seems AndOrNot needs to be cooler for the part to detach).

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Printbite - Love it! Hate it! February 27, 2018 12:45AM |

Registered: 9 years ago Posts: 53 |

Quote

gadgetmind

An hour? I've fitted two bits of PB and both times took only 10 mins or so to apply and then whatever the recommended heat cycle is.

...

I won't claim that I still don't see lifting on *very* odd occasions, but it's usually a sharp corner that hasn't gone down right initially and I now check these and abort the print if it goes wrong. It's usually then time for a clean and level test, but TBH I often go for weeks doing noting but press print and leave the printer to it.

Yup an hour. Pressed down mm by mm after the experience with the PEI. It would be interesting to bubble it up again and peel it off to see if the separation is on the glass side or PB side. Cringe, but the next time wonder if it would be worth sanding the glass with some 400 grit to roughen it up.. BTW you said your bed temp was 115C. Is that just first layer? I run 120C first layer then 95C.

Quote

DjDemonD

I've never had printbite lift from the substrate, but I don't use glass, I bond it directly to aluminium tooling plate. If a part is a high risk for lifting then I use ABS juice over the printbite before printing and put mouse ears on any sharp corners. I've never had a problem getting parts off printbite. Once they cool they lift off, sometimes if I have used ABS juice it takes a little blade under the corners to get them to begin to peel away. However I do all my ABS printing now in well enclosed machines (45 deg C at least), and this helps immensely to reduce shrinkage in the part.

I have recently started using AndOrNot own brand surface, mainly because its cheap. ABS does stick to it quite well, at the same temps as I'd use for printbite, (PLA and PETG stick at much lower temps, sometimes low-warping risk parts with PLA need no bed heat at all) but I have cracked an AndOrNot sheet with an ABS part contracting, and because it was bonded so well (seems AndOrNot needs to be cooler for the part to detach).

What bed temps do you run? My chamber runs 48-53C. I'm sensitive to ABS nano particle vapor so fishtank carbon filter & fan work well. Machine under construction has 330x330 tooling plate, and I have a sheet of the new thinner PB for it.

The AndOrNot looks interesting. Certainly cheaper. But as usual it is on the wrong side of the pond. They are using 468MP. No option for ABS juice "Do not use acetone or anything with a high % Isopropyl, this will damage the surface." Not a lot of info on their website.

Quote

DaveOB

I moved my printbite a few days back.

Had to remove from an aluminium plate.

DaveOB - Curious why did you have to (re)move your PB in the first place?

I am still impressed with the PB surface toughness (Love), if it just didn't bubble(Hate). The bubble stayed formed after the bed cooled down. So where did the extra material come from to make the bump? PB doesn't appear to be a thermoplastic and from cutting it to fit the bed, it seems to be glass filled. So did it just stretch when it formed the bubble? Why did it bubble remain after the bed was cool. Why has 3/4 of the bubble area disappeared?

468MP has a 24 month shelf life so could have been an old batch of adhesive on my PB?

Good to know that you three are not seeing problems, so it is probably something unique to my circumstances.

|

Re: New print surface material? March 01, 2018 08:24AM |

Registered: 8 years ago Posts: 3,525 |

I use 250 deg C nozzle and 115 deg C bed for abs. 225-240 nozzle and 80 deg C bed for petg and 215 deg C nozzle and 70 deg C bed for pla on PB old white one.

Edited 1 time(s). Last edit at 03/01/2018 08:25AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 03/01/2018 08:25AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: New print surface material? March 06, 2018 12:28AM |

Registered: 9 years ago Posts: 53 |

Your 115C with Aluminum Plate will probably be similar to my 120C glass. Thanks for the sanity check. Good reference numbers. Do you force cool the plate with a fan after the print? My 330x330 was taking over 1/2 hour to cool.Quote

DjDemonD

I use 250 deg C nozzle and 115 deg C bed for abs. 225-240 nozzle and 80 deg C bed for petg and 215 deg C nozzle and 70 deg C bed for pla on PB old white one.

Have this helpless feeling without my printer being fully functional. Afraid to make large prints. I need to build a back up bed with new surface.

So.....either place another order for PB, or for entertainment, try some FR4 from Amazon. two bed surfaces for $14.

Description isn't really clear if it is FR4 or G10, but found a reference "...FR4 is nearly always a suitable substitute for G10 except in rare applications like nuclear reactors" so probably no issues?

and then some 468MP from Amazon courtesy of GizmoDorks $3 per sheet

I saw a few threads on FR4. Seems like at worst just buff it up a bit with some fine grit sandpaper or steely wool. (or revert to gluestick slurry). Anybody have experience on ABS?

|

Re: New print surface material? April 14, 2018 08:49AM |

Registered: 10 years ago Posts: 35 |

I've been using my original printbite sheet for about 3 years now. its a little discolored from using some pretty high (> 125C) temps for polycarbonate, but it still works great!

I've successfully printed nylon, abs, polycarbonate, PLA, Bluprint, PETG.... occasionally I use a very light touch of gluestick.... if it stops working, I just scrub it down with household cleaner and its back to working like new.

I took my time installing it - super clean aluminum plate and no trapped air pockets when I installed it.

Thanks Mutley!

Edited 1 time(s). Last edit at 04/14/2018 08:50AM by dtwrv6.

I've successfully printed nylon, abs, polycarbonate, PLA, Bluprint, PETG.... occasionally I use a very light touch of gluestick.... if it stops working, I just scrub it down with household cleaner and its back to working like new.

I took my time installing it - super clean aluminum plate and no trapped air pockets when I installed it.

Thanks Mutley!

Edited 1 time(s). Last edit at 04/14/2018 08:50AM by dtwrv6.

|

Re: New print surface material? May 11, 2018 03:40AM |

Registered: 6 years ago Posts: 42 |

|

Re: Printbite - Love it! Hate it! May 19, 2018 04:31AM |

Registered: 7 years ago Posts: 15 |

Quote

to-the-nth

Has anyone been successful in removing the adhesive backing and reattaching to a glass bed with 468MP?

I did. I used a ceran surface scraper / cooktop scraper to scrape off the rest of the adhesive, then I used a paper towel and acetone to wipe the surface clean. It worked perfectly.

I tried acetone, brake cleaner, PB blaster penetrating oil and isopropyl before, but these did not work well.

Reason for removing the 468MP were air bubbles after one year of use with a FR4 build surface.

I printed PETG and ABS on FR4. ABS sticks ok at 100°C, detaches completely at around 60°C. Tried Nunus ABS blue and Extrudr ABS red. Occassionally the ABS detaches when the first layer is printed, then I clean the FR4 surface with isopropanol. If this does not help, I prepare the surface with abrasive paper, 180 grit. Edit:

Maybe one of ten prints detaches.

Cheers

David

Edited 2 time(s). Last edit at 05/19/2018 04:37AM by tody79.

|

Re: New print surface material? July 17, 2018 04:52AM |

Registered: 6 years ago Posts: 50 |

Any one printing standard Polycarbonate?

I normally print PC on PEI with a thin PVA layer (to act as a release agent as it micro fractures the PEI sheet all around the part edges and lifts the PEI from the glass bet on cool down otherwise) and print at 160*C bed temp and 305*C nozzle temp and enclosure temp at 60*C no fans no brim or raft but a 10 wall wide skirt 0.5mm from edge of print. The only downside of this setup is it sticks a little too well to PEI and slowly damages the surface as you really have to work to remove the part which is a real pain long-term and can result in lifting the PEI as well. I have tried from 90*C up to 140*C bed temp on PB but this does not work, the part comes off as soon as filament cools below 250*C which is usually on the second layer (bed deviation is 0.002 or less so no issue there)

Does anyone know what the max temp the glue on PB can take?

The reason I ask is most glues die around 135*C on bed surfaces and it has taken me a while to get PEI sheets that will remain stuck to the glass bed at 160*C and I don't want to push the PB any higher in temp until I can confirm what it will take. Any help with PC would be great, I am a little over wrestling with and replacing PEI sheets, the PB has worked so well for everything else I have tried (except I get occasional warping of PLA which I don't get on any of my other surfaces and also get curling on overhands close to the bed with PLA which I think is due to the black surface I went with for my IR sensor).

Going to give some PVA glue a spin tonight to see if that helps at all on the printbite, hopefully old mate will reply shortly to let me know what the max temp is on the glue they shipped on the PB and I can pump the be temp up to 160*C.

Edited 2 time(s). Last edit at 07/17/2018 04:58AM by Redemptioner.

I normally print PC on PEI with a thin PVA layer (to act as a release agent as it micro fractures the PEI sheet all around the part edges and lifts the PEI from the glass bet on cool down otherwise) and print at 160*C bed temp and 305*C nozzle temp and enclosure temp at 60*C no fans no brim or raft but a 10 wall wide skirt 0.5mm from edge of print. The only downside of this setup is it sticks a little too well to PEI and slowly damages the surface as you really have to work to remove the part which is a real pain long-term and can result in lifting the PEI as well. I have tried from 90*C up to 140*C bed temp on PB but this does not work, the part comes off as soon as filament cools below 250*C which is usually on the second layer (bed deviation is 0.002 or less so no issue there)

Does anyone know what the max temp the glue on PB can take?

The reason I ask is most glues die around 135*C on bed surfaces and it has taken me a while to get PEI sheets that will remain stuck to the glass bed at 160*C and I don't want to push the PB any higher in temp until I can confirm what it will take. Any help with PC would be great, I am a little over wrestling with and replacing PEI sheets, the PB has worked so well for everything else I have tried (except I get occasional warping of PLA which I don't get on any of my other surfaces and also get curling on overhands close to the bed with PLA which I think is due to the black surface I went with for my IR sensor).

Going to give some PVA glue a spin tonight to see if that helps at all on the printbite, hopefully old mate will reply shortly to let me know what the max temp is on the glue they shipped on the PB and I can pump the be temp up to 160*C.

Edited 2 time(s). Last edit at 07/17/2018 04:58AM by Redemptioner.

|

Re: New print surface material? July 17, 2018 11:57PM |

Registered: 6 years ago Posts: 50 |

So 145*C bed temp (160*C at machine) and a thin film of baked on PVA and I have good adhesion, was self released off the bed when it cooled but I can feel that it has stretched the Printbite slight as there is now a "ripple" in the area the print was attached. Will cycle the bed at that temp again today without a print to if it will heal itself.

|

Re: New print surface material? November 25, 2018 06:28AM |

Registered: 7 years ago Posts: 7 |

Im in need of a new print surface and am excited by Printbite+ but also worried that some here have experienced the same issues I have with my PEI sheet - bubbles !

And now it seems there are more choices:

LokBuild

AndOrNot

I also read that some users are adding elmers glue or ABS slurry to the print surface - this seems to contradict the whole point of using a print surface that claims to stick with heat and release when cold.

Since they all require considerable $$$ to ship them to me in the South pacific, Im looking for some guidance please.

And now it seems there are more choices:

LokBuild

AndOrNot

I also read that some users are adding elmers glue or ABS slurry to the print surface - this seems to contradict the whole point of using a print surface that claims to stick with heat and release when cold.

Since they all require considerable $$$ to ship them to me in the South pacific, Im looking for some guidance please.

|

Re: New print surface material? November 25, 2018 06:58AM |

Registered: 7 years ago Posts: 23 |

|

Re: New print surface material? November 25, 2018 08:23AM |

Registered: 6 years ago Posts: 50 |

Quote

gadgetmind

PrintBite is easy to fit to glass and bubbles aren't really an issue if you take care.

I print PLA, PETG, ABS and TPU straight onto it and all it takes to clean it is window cleaner or a wipe with acetone.

Level is important, but that's always the case.

I also print in multiple materials without any adhesive on the bed, I have a couple each of the black and opaque printebite+ on 350mmD x 3mm borosilicate glass. I use 70% isopropyl alcohol from a laboratory supply company and paper towel to clean the surface between each print and it works a charm without the harsh smell. No matter where I buy acetone from it never seems to do as good a job as the isopropyl alcohol does (leaves streaks behind you can easily see on the black surface).

PLA - 70*C first layer then 65*C, 10*C hotter for black

ABS - 115*C for OP, 120*C for blk

PETG - 80*C first layer then 75*C, 5*C hotter for black

TPU - 50*C for OP & Blk,

HK Flex - 60*C for OP & Blk

HIPS - 105*C first layer then 100*C , 5*C hotter for black

Nylon - 135*C on Black, have not tried on opaque

PC - 165*C on black, have not tried on opaque

With PC the heat cause the glue backing of the printbite to get soft and the PC is so strong as it shrinks it can pull the printbite away from the glass causing decent air bubbles between the glass and printbite that you can't get out (also seems to stretch the printebite). Running much hotter enclosure temp helps reduce this as well as letting the bed cool below 100*C before staging the enclosure temp down (let the adhesive backing cool off). On really large, long print PC parts I will rub a small amount of glue stick on the bed and then add a spray of isopropyl alcohol and rub it around while the bed heats up to put a super fine layer of PVA down. This is not to slick the PC to the bed, rather to act as a release agent when the bed and chamber start to cool down as it lets go of the print at a higher temp then the printbite normally does.

You can put you printbite down with some 20:1 windex and water solution, just soak the glass, lay the printpite down on the wet surface and squeegee out the water once you get it aligned. Then let it dry sitting on its edge for 24hrs, give it another squeegee working from the middle out, put it on the heated bed at 50*C for a couple hours, take it off and squeegee then do the normal heat cycle. No matter if you wet apply or not you want to give the bed a squeegee once when it first gets up to temp then again before just before you let it cool off, don't squeegee it while or after it is cooling off and only do it on the first full temp heat cycle.

Despite there technically being no difference between the opaque and black printebite, the opaque generally works better at a lower temp and seems to have a slightly rougher surface that is much more level than the black, in saying that both are very level considering they are applied with an adhesive backing by hand and are nearly identical in thickness so I have never had to worry about height calibration when swapping between the 2 surfaces.

Having warping issues and you are above normal bed temp for the material then you are probably too high in bed temp, for PLA especially try dropping the temp 5-10*C after the first or second layer and see if that fixes your issue. You can easily test what the bed temp should be, print a circle about 4 layers tick and around 50mm diameter, then while the bed is still running at temp, try to peel it off. You are looking for it to flex/bent a little but pop off mostly in the right shape, if it comes off all bent and warped then you have the bed too hot. The bed temp being too hot seemed to be more of an issue than it being to cold, especially for warping in PLA.

|

Re: New print surface material? January 13, 2020 04:34PM |

Registered: 7 years ago Posts: 168 |

I've been using the original Printbite for about 3 years, straight onto cast ally tool plate. Results have always been good with PLA/PETG, but hit and miss with ABS.

It seems this might be due to the fact that my IR probe doesn't seem to be reading it well. Z homing is consistent, but the bed leveling mesh looks awful and the bed is definitely that "lumpy".

Has anyone used the new matt black Printbite with (David Crockers) IR probe?

I love having a durable, permanent and self releasing surface, and unless there's some other permanent surface out there that is better with the IR probe, I'm more likely to change probes than surfaces.

While it's expensive, I'd also consider the Filaprint surface if it's self adhesive, IR compatible and long term durable. I don't want to jerk around with tape/spray/glue ever again!

It seems this might be due to the fact that my IR probe doesn't seem to be reading it well. Z homing is consistent, but the bed leveling mesh looks awful and the bed is definitely that "lumpy".

Has anyone used the new matt black Printbite with (David Crockers) IR probe?

I love having a durable, permanent and self releasing surface, and unless there's some other permanent surface out there that is better with the IR probe, I'm more likely to change probes than surfaces.

While it's expensive, I'd also consider the Filaprint surface if it's self adhesive, IR compatible and long term durable. I don't want to jerk around with tape/spray/glue ever again!

|

Re: New print surface material? January 14, 2020 05:04AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

hobbymods

I've been using the original Printbite for about 3 years, straight onto cast ally tool plate. Results have always been good with PLA/PETG, but hit and miss with ABS.

It seems this might be due to the fact that my IR probe doesn't seem to be reading it well. Z homing is consistent, but the bed leveling mesh looks awful and the bed is definitely that "lumpy".

Has anyone used the new matt black Printbite with (David Crockers) IR probe?

I love having a durable, permanent and self releasing surface, and unless there's some other permanent surface out there that is better with the IR probe, I'm more likely to change probes than surfaces.

While it's expensive, I'd also consider the Filaprint surface if it's self adhesive, IR compatible and long term durable. I don't want to jerk around with tape/spray/glue ever again!

Cast alloy tool plate? As in: not aluminium?

Then I would advice you to look at inductive proximity sensing. I even use it on aluminium but the sensing distance is really short. These sensors have worked the best out of every type of sensor I've ever used. These sensors don't look at the surface, but at the material underneath, and your tooling plate should be exactly flat. So the sensor should make for a perfectly flat mesh.

Dive into it, it's really good. Also, another option would be to use piezo sensing, but it is a lot more work to install and means you have to rebuild either your extruder or your heated bed when using underbed sensors.

An inductive sensor can easily be attached. You could print a simple holder and even glue the holder onto your X-carriage with some epoxy for example. The sensors have thread which allows for fine tuning and the initial tuning process is quite simple. Just keep in mind you have to set offsets in the config for the sensor location in relation to the nozzle.

Edited 1 time(s). Last edit at 01/14/2020 05:06AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: New print surface material? May 13, 2020 08:51AM |

Registered: 10 years ago Posts: 35 |

over 5 years on my first sheet of Printbite  160C bedtemps haven't hurt it one bit.

160C bedtemps haven't hurt it one bit.

I'm pretty hard on it - I've used acetone, mek, alcohol, vinegar and scrape it with a razor blade on occasion to clean it. It just keeps working.

Edited 1 time(s). Last edit at 05/13/2020 08:51AM by dtwrv6.

160C bedtemps haven't hurt it one bit.

160C bedtemps haven't hurt it one bit.I'm pretty hard on it - I've used acetone, mek, alcohol, vinegar and scrape it with a razor blade on occasion to clean it. It just keeps working.

Edited 1 time(s). Last edit at 05/13/2020 08:51AM by dtwrv6.

|

Re: New print surface material? May 14, 2020 04:40AM |

Registered: 10 years ago Posts: 231 |

Quote

dtwrv6

over 5 years on my first sheet of Printbite160C bedtemps haven't hurt it one bit.

I'm pretty hard on it - I've used acetone, mek, alcohol, vinegar and scrape it with a razor blade on occasion to clean it. It just keeps working.

Yeah, I'm probably about the same number of years. On original printbite, (not +). Have printed exclusively ABS meaning constantly heating/cooling the bed to 120-125C. I just wipe with Windex in between prints. Recently, I started printing some TPU. First tests stuck so bad, I had to scrape them off and use Acetone to get rid of the residue. When the instructions say don't smash the first layer, they mean it. Once I re-calibrated the Z height and adjusted my slicer settings to not make the first layer different or overextruded, TPU now works well. Don't even need to heat the bed which makes it really easy to start a new print right away.

|

Re: New print surface material? May 14, 2020 05:16AM |

Registered: 7 years ago Posts: 23 |

|

Re: New print surface material? May 14, 2020 06:10PM |

Registered: 10 years ago Posts: 35 |

I was pretty fussy when I put mine on. brand new aluminum build plate, sanded it with 120grit, scrubbed it with MEK, then cleaned with alcohol. I carefully put it on and cycled heat to it several times starting low and increasing temps and time.... no bubbles, and I suspect I'd need a heat gun to remove it.

|

Re: New print surface material? May 31, 2020 04:29AM |

Registered: 7 years ago Posts: 168 |

Sorry mate, haven't been here for ages.

Aussie slang, I said "ally" which is a tradesmans term for aluminium.

To be honest, I switched off the bed levelling and really set about leveling the bed mechanically with a feeler gauge, and I've never looked back. The IR probe gives very consistent nozzle height on homing, I'm tipping the Printbite was a bit more opaque in some places or it was picking up the grid pattern as the leveling mesh was a mess.

I've only just today discovered that Windex (the ammonia general purpose cleaning one) works much better for me than acetone. I've just tried it with PETG, and the adhesion is excellent. 90/240 first layer, 80/230 after that. No fan.

Edited 1 time(s). Last edit at 05/31/2020 06:47AM by hobbymods.

Aussie slang, I said "ally" which is a tradesmans term for aluminium.

To be honest, I switched off the bed levelling and really set about leveling the bed mechanically with a feeler gauge, and I've never looked back. The IR probe gives very consistent nozzle height on homing, I'm tipping the Printbite was a bit more opaque in some places or it was picking up the grid pattern as the leveling mesh was a mess.

I've only just today discovered that Windex (the ammonia general purpose cleaning one) works much better for me than acetone. I've just tried it with PETG, and the adhesion is excellent. 90/240 first layer, 80/230 after that. No fan.

Quote

Ohmarinus

Quote

hobbymods

I've been using the original Printbite for about 3 years, straight onto cast ally tool plate. Results have always been good with PLA/PETG, but hit and miss with ABS.

It seems this might be due to the fact that my IR probe doesn't seem to be reading it well. Z homing is consistent, but the bed leveling mesh looks awful and the bed is definitely that "lumpy".

Has anyone used the new matt black Printbite with (David Crockers) IR probe?

I love having a durable, permanent and self releasing surface, and unless there's some other permanent surface out there that is better with the IR probe, I'm more likely to change probes than surfaces.

While it's expensive, I'd also consider the Filaprint surface if it's self adhesive, IR compatible and long term durable. I don't want to jerk around with tape/spray/glue ever again!

Cast alloy tool plate? As in: not aluminium?

Then I would advice you to look at inductive proximity sensing. I even use it on aluminium but the sensing distance is really short. These sensors have worked the best out of every type of sensor I've ever used. These sensors don't look at the surface, but at the material underneath, and your tooling plate should be exactly flat. So the sensor should make for a perfectly flat mesh.

Dive into it, it's really good. Also, another option would be to use piezo sensing, but it is a lot more work to install and means you have to rebuild either your extruder or your heated bed when using underbed sensors.

An inductive sensor can easily be attached. You could print a simple holder and even glue the holder onto your X-carriage with some epoxy for example. The sensors have thread which allows for fine tuning and the initial tuning process is quite simple. Just keep in mind you have to set offsets in the config for the sensor location in relation to the nozzle.

Edited 1 time(s). Last edit at 05/31/2020 06:47AM by hobbymods.

|

Re: New print surface material? June 03, 2020 09:24AM |

Registered: 10 years ago Posts: 35 |

Sorry, only registered users may post in this forum.