Gap between lines...not sure what is wrong

Posted by jobzombi

|

Gap between lines...not sure what is wrong October 13, 2015 12:12PM |

Registered: 9 years ago Posts: 34 |

I checked the Print Troubleshooting Pictorial Guide and either there was nothing, or it was worded in a way that made it hard for me to find the same problem. It seems to happen with my white filament and not my black filament.

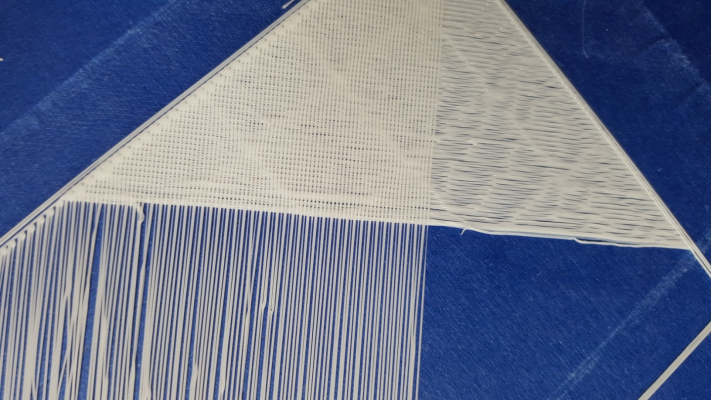

I uploaded this picture showing the issue in various conditions. Starting from the blue (bare) section, going counter-clockwise, I have the first layer at .2mm 180Celcius. This layer is flat, but the gaps seen there are 2-dimensional aberations; it also sticks pretty well to the plate. The next section is layer 2, .15mm 140Celcius, you can see the obvious gaps in the lines here too. Lastly, the last section I took out the first layer. You can see when the lines go from the previous section to this section that it has gaps. When I make the first layer 200+Celcius, it shows no gaps, it shows instead the usual stuff you see when the filament is too hot. Thinking it may have been due to not extruding enough filament, since Slic3r calculates the width based on the layer height and nozzle diameter, I figured if I lower the input filament diameter, it would compensate for volume by increasing the feedrate, to maintain the same extruded volume. The measured diameter for the filament is 1.76mm, but I lowered it to 1.66mm. Nothing changed. Am I wrong somewhere? Like I said, it does not do this with the black filament, but it does the same thing with a glow in the dark filament I have.

I uploaded this picture showing the issue in various conditions. Starting from the blue (bare) section, going counter-clockwise, I have the first layer at .2mm 180Celcius. This layer is flat, but the gaps seen there are 2-dimensional aberations; it also sticks pretty well to the plate. The next section is layer 2, .15mm 140Celcius, you can see the obvious gaps in the lines here too. Lastly, the last section I took out the first layer. You can see when the lines go from the previous section to this section that it has gaps. When I make the first layer 200+Celcius, it shows no gaps, it shows instead the usual stuff you see when the filament is too hot. Thinking it may have been due to not extruding enough filament, since Slic3r calculates the width based on the layer height and nozzle diameter, I figured if I lower the input filament diameter, it would compensate for volume by increasing the feedrate, to maintain the same extruded volume. The measured diameter for the filament is 1.76mm, but I lowered it to 1.66mm. Nothing changed. Am I wrong somewhere? Like I said, it does not do this with the black filament, but it does the same thing with a glow in the dark filament I have.

|

Re: Gap between lines...not sure what is wrong October 13, 2015 01:33PM |

Registered: 9 years ago Posts: 74 |

|

Re: Gap between lines...not sure what is wrong October 13, 2015 02:31PM |

Registered: 9 years ago Posts: 34 |

|

Re: Gap between lines...not sure what is wrong October 13, 2015 02:40PM |

Registered: 9 years ago Posts: 74 |

I read that somewhere as well and dealt with it for a long time but recently went through Slic3rs defaults and realized they recommend the layer height being equal to the nozzle diameter. It is night and day

[manual.slic3r.org]

[manual.slic3r.org]

|

Re: Gap between lines...not sure what is wrong October 13, 2015 03:50PM |

Registered: 10 years ago Posts: 14,672 |

I use a first layer height around half the nozzle diameter.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Gap between lines...not sure what is wrong October 13, 2015 07:28PM |

Registered: 8 years ago Posts: 541 |

First of all, did you calibrate your extruder? Then, did you change the configuration.h file to reflect the result and save it to the printer?

Have you leveled your bed to 0.1 mm or the thickness of a sheet of paper or about .004" feeler gauge? My first layer is 0.3 mm. The 0.3 plus the bed calibration of 0.1 would equal the 0.4. After that it depends on your quality as far as layer height goes. I set my first layer at 150%. If you do those things, problem gone. I'm new to this but these things were a must to get a good solid first few layers. Gotta calibrate that extruder!

Edited 2 time(s). Last edit at 10/13/2015 07:35PM by tjnamtiw.

Have you leveled your bed to 0.1 mm or the thickness of a sheet of paper or about .004" feeler gauge? My first layer is 0.3 mm. The 0.3 plus the bed calibration of 0.1 would equal the 0.4. After that it depends on your quality as far as layer height goes. I set my first layer at 150%. If you do those things, problem gone. I'm new to this but these things were a must to get a good solid first few layers. Gotta calibrate that extruder!

Edited 2 time(s). Last edit at 10/13/2015 07:35PM by tjnamtiw.

|

Re: Gap between lines...not sure what is wrong October 16, 2015 12:14PM |

Registered: 9 years ago Posts: 159 |

just been through something similar..

the exstrusion rates need to be close (steps for E motor)

after that theres an adjuster in the slicer setting that tweeksthe exstrusion width,to the desired or what you can acheive is subject to quolity..unfortunatly.

after the extrusions right, watch the plastic as it comes out the end, ideally it comes out like ice cream and 'pours' almost ahead of time, what you dont want is it apparently dragging onto the bed/layer

if it does, slow the travel rates (and the excelration, dont forget the accelerasion is tied into how fast its going, i.e. at 500mm/s for a 2mm move? it'll never reach the 500 in time with a teleportation device lol)

i use a large 100 by 100mm square rim, draw it up as 2x what ever your extrusion width is and set the speed accordingly, to fast it goes a couple layers then starts to round on the corners then starts pulling off.

an added note to this one is, if you use larger and larger nozzles it can pingoff like elastic because its going too fast, from your picture theres big spaces in between, so eather your traveliing at very high speeds or my gues would be the extrusion width and height coupled with exstruder motor steps and the slicer exstrution factor adjuster.(as the prints get longer/larger the plastic has to travel further,exspansion contraction plays up more the further, so small 20mm cubes will be fine a 200mm will spew up all the more wtshtf).

when you get the extrution to stick side to side, you may start getting little lines showing every so often, thats an unleval bed, just as a side note for the next step.

theres like a triangle thing going on, extrusion height to width, too hi its to 'thin' to stick on the top and bottom and side to side, then comes the layer height 'setting', for the same exstrution factors, lowering the height may well sort it out,then the temperature changes it slightly again, if all yu setting are right.if not, then you'll enter the triangle of baldness, its a scarey premature loss of hair as yu pull it out! change this change that then the other fudges up so yu change this yu change that then that fudges up..its usualy about the calibrating faize. i tried all ways.. i'm bolding lol...always, i mean always came back to calibrating, being it steps, exstrutions or temperature...then theres the bed on top, or below lol.

btw, when everything is set very very close to right, you can actually gett a lovely looking print, alas its like a harp, every layer is not stuck to the next, pluck yu fingers allong and every string pings.(looks the same as your pick, only theyre closer together).

Edited 2 time(s). Last edit at 10/16/2015 12:21PM by munchit1.

the exstrusion rates need to be close (steps for E motor)

after that theres an adjuster in the slicer setting that tweeksthe exstrusion width,to the desired or what you can acheive is subject to quolity..unfortunatly.

after the extrusions right, watch the plastic as it comes out the end, ideally it comes out like ice cream and 'pours' almost ahead of time, what you dont want is it apparently dragging onto the bed/layer

if it does, slow the travel rates (and the excelration, dont forget the accelerasion is tied into how fast its going, i.e. at 500mm/s for a 2mm move? it'll never reach the 500 in time with a teleportation device lol)

i use a large 100 by 100mm square rim, draw it up as 2x what ever your extrusion width is and set the speed accordingly, to fast it goes a couple layers then starts to round on the corners then starts pulling off.

an added note to this one is, if you use larger and larger nozzles it can pingoff like elastic because its going too fast, from your picture theres big spaces in between, so eather your traveliing at very high speeds or my gues would be the extrusion width and height coupled with exstruder motor steps and the slicer exstrution factor adjuster.(as the prints get longer/larger the plastic has to travel further,exspansion contraction plays up more the further, so small 20mm cubes will be fine a 200mm will spew up all the more wtshtf).

when you get the extrution to stick side to side, you may start getting little lines showing every so often, thats an unleval bed, just as a side note for the next step.

theres like a triangle thing going on, extrusion height to width, too hi its to 'thin' to stick on the top and bottom and side to side, then comes the layer height 'setting', for the same exstrution factors, lowering the height may well sort it out,then the temperature changes it slightly again, if all yu setting are right.if not, then you'll enter the triangle of baldness, its a scarey premature loss of hair as yu pull it out! change this change that then the other fudges up so yu change this yu change that then that fudges up..its usualy about the calibrating faize. i tried all ways.. i'm bolding lol...always, i mean always came back to calibrating, being it steps, exstrutions or temperature...then theres the bed on top, or below lol.

btw, when everything is set very very close to right, you can actually gett a lovely looking print, alas its like a harp, every layer is not stuck to the next, pluck yu fingers allong and every string pings.(looks the same as your pick, only theyre closer together).

Edited 2 time(s). Last edit at 10/16/2015 12:21PM by munchit1.

Sorry, only registered users may post in this forum.