Extruder drive/Cold End Suggestions with higher force capability?

Posted by patrickrio

|

Extruder drive/Cold End Suggestions with higher force capability? October 16, 2015 01:58PM |

Registered: 9 years ago Posts: 233 |

I have an ungeared 1.75mm Bowden setup with a 78oz-in 400 step motor that is very similar mechanically to this:

[printrbot.com]

I have a short 35cm bowden tube. I get a maximum print speed of about 200mm/sec at 0.4mm nozzle size before it gets difficult to tune my extruder mechanicals. The best I have done is 250mm/sec with extreme tweeking to keep the mechanicals from slipping or skipping steps and/or chewing up the filament. It gets worse with about 100mm/sec top speed with the 1.2mm nozzle. My build volume is 200x200x260mmm and it just seems really slow when printing big parts even at top speed currently. It is capable of better without the extruder limitation.

It is too bad, because my coreXY design can do much better speed and just completely outstrips the capability of my gearless solution. I am looking into some other designs that provide higher torque via gearing and/or dual sided tooth grip on the filament. What do people recommend?

I am listing my research in the topic below:

Flex3Drive flexible shaft system:

Flex3Drive

Flex3Drive Video

Bondtech Geared Extruder (seems like it may create the highest force, but expensive):

BondTech Extruder

Bondtech Video Review

PrintrBot Gear Head:

PrintrBot Gear Head

Gear Head Video

Wades Extruder and iterations

Wade's Extruder History & Variations

Wade's Reloaded Belted Extruder:

Wade's Belted

Modified Wade's Extruder:

Modified Wade's

Purchaseable kit Wade's Reloaded

[www.makergeeks.com]

[www.lulzbot.com]

Edited 5 time(s). Last edit at 10/16/2015 02:27PM by patrickrio.

[printrbot.com]

I have a short 35cm bowden tube. I get a maximum print speed of about 200mm/sec at 0.4mm nozzle size before it gets difficult to tune my extruder mechanicals. The best I have done is 250mm/sec with extreme tweeking to keep the mechanicals from slipping or skipping steps and/or chewing up the filament. It gets worse with about 100mm/sec top speed with the 1.2mm nozzle. My build volume is 200x200x260mmm and it just seems really slow when printing big parts even at top speed currently. It is capable of better without the extruder limitation.

It is too bad, because my coreXY design can do much better speed and just completely outstrips the capability of my gearless solution. I am looking into some other designs that provide higher torque via gearing and/or dual sided tooth grip on the filament. What do people recommend?

I am listing my research in the topic below:

Flex3Drive flexible shaft system:

Flex3Drive

Flex3Drive Video

Bondtech Geared Extruder (seems like it may create the highest force, but expensive):

BondTech Extruder

Bondtech Video Review

PrintrBot Gear Head:

PrintrBot Gear Head

Gear Head Video

Wades Extruder and iterations

Wade's Extruder History & Variations

Wade's Reloaded Belted Extruder:

Wade's Belted

Modified Wade's Extruder:

Modified Wade's

Purchaseable kit Wade's Reloaded

[www.makergeeks.com]

[www.lulzbot.com]

Edited 5 time(s). Last edit at 10/16/2015 02:27PM by patrickrio.

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 16, 2015 07:23PM |

Registered: 10 years ago Posts: 140 |

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 18, 2015 04:51PM |

Registered: 8 years ago Posts: 150 |

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 18, 2015 05:05PM |

Registered: 10 years ago Posts: 564 |

What layer thickness and line width are you using? With a 0.4mm nozzle, the maximum volumetric extrusion rate is about 10mm^3/sec before the extrusion forces get really high. I suppose you could go faster with more motor torque, but you'll create a lot more hysteresis in extrusion flow. I have no idea what the max. rate is for a 1.2mm nozzle, but again, you need to take into account the layer thickness and line width.

Also,do know that your hot-end is keeping up? If the heat chamber is too short, the filament won't have time to fully melt, even if the hot end is up to temp.

Also,do know that your hot-end is keeping up? If the heat chamber is too short, the filament won't have time to fully melt, even if the hot end is up to temp.

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 19, 2015 02:48PM |

Registered: 9 years ago Posts: 233 |

I am using a custom hot end that has the heated filament path going the long way through the block, like the Volcano. It seems to be able to melt much faster than I can extrude. I may have increased surface tension holding back my speed a bit though. Currently I am using a Peek heatbreak with teflon liner. I will hopefully someday switch to a metal or ceramic path from teflon.

When doing max extrusion tests, I try to increase layer height and width. With the 0.4 nozzle I do 0.5 width and 0.25 height. It is hard to get this layer and width setting to go above 200mm/sec.

I never really got close to a maximum using the 1.2mm nozzle, as I just can't get close to extruding fast enough.

When doing max extrusion tests, I try to increase layer height and width. With the 0.4 nozzle I do 0.5 width and 0.25 height. It is hard to get this layer and width setting to go above 200mm/sec.

I never really got close to a maximum using the 1.2mm nozzle, as I just can't get close to extruding fast enough.

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 19, 2015 02:54PM |

Registered: 9 years ago Posts: 233 |

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 19, 2015 03:34PM |

Registered: 11 years ago Posts: 5,780 |

I have printed exclusively ABS, so you may have different experience printing other materials, but my BullDogXL extruder and E3D v6 hot-end have been 100% reliable since December of last year when I put them on the machine. I print almost daily and in that time I have not had to clear a single jam or fix any other extruder/hot-end related problems. The BullDog XL can push either 1.75 mm or 3 mm filament (I use 1.75 mm) and has a 5:1 gear box. I print at relatively low speeds- 50mm/s typical maximum.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 19, 2015 09:55PM |

Registered: 10 years ago Posts: 564 |

Quote

patrickrio

I am using a custom hot end that has the heated filament path going the long way through the block, like the Volcano. It seems to be able to melt much faster than I can extrude. I may have increased surface tension holding back my speed a bit though. Currently I am using a Peek heatbreak with teflon liner. I will hopefully someday switch to a metal or ceramic path from teflon.

When doing max extrusion tests, I try to increase layer height and width. With the 0.4 nozzle I do 0.5 width and 0.25 height. It is hard to get this layer and width setting to go above 200mm/sec.

I never really got close to a maximum using the 1.2mm nozzle, as I just can't get close to extruding fast enough.

With 0.5mm line widths, 0.25mm layers and 200mm/s, you are trying to extrude 25mm^3/sec, which is consiiderably more than the 10mm^3/s max. that I has seen posted on an Ultimaker forum for a 0.4mm nozzle.

With your 1.2mm dia nozzle, if you were printing 1.5mm wide lines with 0.6mm layers at 100mm/sec, that would be 90mm^3/sec. With 1.75mm dia filament, this works out to an input filament speed of 37mm/sec. If your heat chamber is 20mm long (same length as a typical heater cartridge) then the filament is in the heat chamber for less than 1 second. before it gets squirted out. I doubt this is enough time to fully melt the filament, especially when you throw in the thermal resistance of the PTFE liner.

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 28, 2015 11:20AM |

Registered: 10 years ago Posts: 469 |

You may want to try my own extruder design. It doubles the torque of your stepper while still maintaining overall speed. [www.youmagine.com]

In my experimentation in the past with larger bore hot ends, I found that overall temp to extrude was not a significant problem, the main issue was thermal mass on the hot end. It caused the temperatures to vary wildly on the hot end leading to jams. Insulate the hot end block, and you may want to try going for a brass block instead of aluminum, this will ensure the temp is not dropping too much as you are taking away heat at a greater rate when the flow is greater.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

In my experimentation in the past with larger bore hot ends, I found that overall temp to extrude was not a significant problem, the main issue was thermal mass on the hot end. It caused the temperatures to vary wildly on the hot end leading to jams. Insulate the hot end block, and you may want to try going for a brass block instead of aluminum, this will ensure the temp is not dropping too much as you are taking away heat at a greater rate when the flow is greater.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 29, 2015 09:20AM |

Registered: 10 years ago Posts: 4 |

I have had numerous problems with my various cold end/extuders. The stepper motor had a tendency to slip fairly often and sometimes enough to grind a flat in the filament causing filament throughput to stop altogether. Very frustrating half way through a print when you start hearing the tell tale "extruder slip" notching sound.

My initial thought was that step stick driver was not set to a high enough current output so I increased it slightly. The next thought was that perhaps the driver was overheating causing momentary shutdown so I now always run it with a fan over the top of the driver chip with a heat-sink. The biggest improvement however was to dramatically reduce the speed of the motor in the EEPROM settings. I reduced it by a factor of about 10 and am now getting reliable printing.

Every time the extruder motor would slip my engineering head would start asking - surely this could be re-designed, all I need is a larger motor, more powerful driver and perhaps a better drive system since I know I can still feed the filament through since if I grab hold of it and push it with my hand it extrudes through the nozzle perfectly. I may still design my own but whilst it works it works.

If I do design my own I would start by thinking about my design goals; power, consistency and good filament "grip". I would probably start with a massively overpowered motor and work backwards to lower the cost, size etc, after eliminating other design issues.

My initial thought was that step stick driver was not set to a high enough current output so I increased it slightly. The next thought was that perhaps the driver was overheating causing momentary shutdown so I now always run it with a fan over the top of the driver chip with a heat-sink. The biggest improvement however was to dramatically reduce the speed of the motor in the EEPROM settings. I reduced it by a factor of about 10 and am now getting reliable printing.

Every time the extruder motor would slip my engineering head would start asking - surely this could be re-designed, all I need is a larger motor, more powerful driver and perhaps a better drive system since I know I can still feed the filament through since if I grab hold of it and push it with my hand it extrudes through the nozzle perfectly. I may still design my own but whilst it works it works.

If I do design my own I would start by thinking about my design goals; power, consistency and good filament "grip". I would probably start with a massively overpowered motor and work backwards to lower the cost, size etc, after eliminating other design issues.

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 29, 2015 09:35AM |

Registered: 10 years ago Posts: 14,672 |

It is good for the extruder to skip steps when the nozzle is temporarily obstructed. The alternative is for the extruder to grind a flat in the filament, which is worse because then extrusion doesn't restart when the obstruction is removed.

How good is your hobbed bolt or hobbed insert? The quality makes a lot of difference to the filament grip. I use these hobbed inserts: [reprappro.com].

You don't need a very powerful motor if you use a geared extruder drive with a ratio of about 3:1 for 1.75mm filament.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

How good is your hobbed bolt or hobbed insert? The quality makes a lot of difference to the filament grip. I use these hobbed inserts: [reprappro.com].

You don't need a very powerful motor if you use a geared extruder drive with a ratio of about 3:1 for 1.75mm filament.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 29, 2015 10:46AM |

Registered: 9 years ago Posts: 233 |

I have this Hobbed gear:

RobotDigg MK8 Gear

In this Bowden setup:

KISS Extruder on Thingiverse

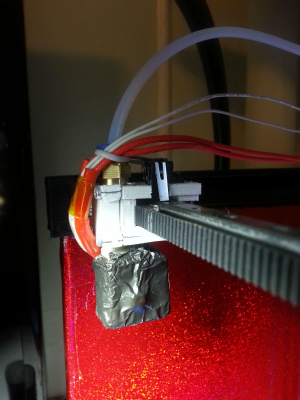

Here is a picture of my insulated Hot End and Carriage:

I am using a 400 step motor with 16 microsteps on the Duet controller, the 400 steps does functionally decrease the jerk forces to the filament so I actually get pretty good traction for a direct drive...It actually works pretty well at high speed with the 0.4mm nozzle, but I could go faster.

HOWEVER i need better grip/lower jerk forces if I want to extrude at high speeds with the 1.2mm nozzle. The failure point is filament grinding so I need to get a better grip I think.

Edited 1 time(s). Last edit at 10/29/2015 10:47AM by patrickrio.

RobotDigg MK8 Gear

In this Bowden setup:

KISS Extruder on Thingiverse

Here is a picture of my insulated Hot End and Carriage:

I am using a 400 step motor with 16 microsteps on the Duet controller, the 400 steps does functionally decrease the jerk forces to the filament so I actually get pretty good traction for a direct drive...It actually works pretty well at high speed with the 0.4mm nozzle, but I could go faster.

HOWEVER i need better grip/lower jerk forces if I want to extrude at high speeds with the 1.2mm nozzle. The failure point is filament grinding so I need to get a better grip I think.

Edited 1 time(s). Last edit at 10/29/2015 10:47AM by patrickrio.

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 29, 2015 03:30PM |

Registered: 10 years ago Posts: 469 |

I actually prefer the MK7 gear with a geared/belted extruder. I only tested the mk8 once and I have to say it works well for direct drive, but ground my filament to halt with a 2:1 ratio. I prefer the surface area of mk7, it is less willing to slip and grind than the mk8.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Extruder drive/Cold End Suggestions with higher force capability? October 29, 2015 03:35PM |

Registered: 9 years ago Posts: 233 |

Sorry, only registered users may post in this forum.