leadscrew nut with pla

Posted by deaconfrost

|

leadscrew nut with pla October 30, 2015 02:23PM |

Registered: 8 years ago Posts: 310 |

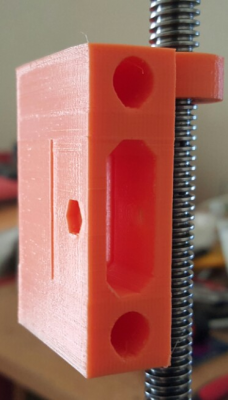

I made some 10mm leadscrew nuts with PLA, 80% infill, it seems very solid and doesn't look like it would wear too fast, I think I will try that on a Mega i3 with 10mm leadscrew which I already have

anyone else tried using PLA for this? how long did it last before you need to replace the nut?

when I turn the nut on the leadscrew it doesn't feels like it would wear any time soon, but again, I never know

I do have brass nuts there if I really need to use them, but printed ones would be ideal if they last long enough

also there is no backlash whatsoever which I like a lot

Edited 1 time(s). Last edit at 10/30/2015 02:25PM by deaconfrost.

anyone else tried using PLA for this? how long did it last before you need to replace the nut?

when I turn the nut on the leadscrew it doesn't feels like it would wear any time soon, but again, I never know

I do have brass nuts there if I really need to use them, but printed ones would be ideal if they last long enough

also there is no backlash whatsoever which I like a lot

Edited 1 time(s). Last edit at 10/30/2015 02:25PM by deaconfrost.

|

Re: leadscrew nut with pla October 30, 2015 03:31PM |

Registered: 9 years ago Posts: 483 |

|

Re: leadscrew nut with pla October 30, 2015 04:24PM |

Registered: 8 years ago Posts: 310 |

thanks for the tip, Im going to use it on the Z axis so there be very little movement, hopefully it last long enough till I get my new design finished, if not I just have to go back to the old parts, I can't use the brass nut on this without making Z top Z bottom and new X idler and motor mount as it is an i3, finger crossed

|

Re: leadscrew nut with pla October 31, 2015 07:44AM |

Registered: 8 years ago Posts: 310 |

its a good fit, smooth easy to turn no backlash, hope it last a while

going to draw the new parts to allow me to use a brass nut just in case the PLA get soften, but with such little movements on the Z axis Im hoping it won't come to that

printed at 0.1mm layer height without support

going to draw the new parts to allow me to use a brass nut just in case the PLA get soften, but with such little movements on the Z axis Im hoping it won't come to that

printed at 0.1mm layer height without support

|

Re: leadscrew nut with pla October 31, 2015 06:49PM |

Registered: 9 years ago Posts: 705 |

Nice. Do yourself a favor and add a belt tensioner. Makes assembly so much easier.

|

Re: leadscrew nut with pla October 31, 2015 06:56PM |

Registered: 8 years ago Posts: 310 |

yea I only though of that when I printed out the idler and in the middle of printing the motor mount now, a bit late

I be building a different design altogether after putting the leadscrew on, just so I have a perfect 190mm height for the parts I need to print, it be a 300mm x 300mm x 400mm print area with full leadscrew drive. anti backlash on all axis

Edited 1 time(s). Last edit at 10/31/2015 06:59PM by deaconfrost.

I be building a different design altogether after putting the leadscrew on, just so I have a perfect 190mm height for the parts I need to print, it be a 300mm x 300mm x 400mm print area with full leadscrew drive. anti backlash on all axis

Edited 1 time(s). Last edit at 10/31/2015 06:59PM by deaconfrost.

|

Re: leadscrew nut with pla October 31, 2015 10:27PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: leadscrew nut with pla November 01, 2015 05:32AM |

Registered: 8 years ago Posts: 310 |

|

Re: leadscrew nut with pla November 01, 2015 05:38PM |

Registered: 8 years ago Posts: 310 |

|

Re: leadscrew nut with pla November 01, 2015 06:43PM |

Registered: 8 years ago Posts: 1,671 |

I wonder if you added another Z lug at the bottom would it add further support, I know you not using brass inserts in this, but in the setup I'm using I can add 2 brass nuts and tighten things up which seems to take out any backlash, not the I'm noticing any backlash on the Z at the moment.

|

Re: leadscrew nut with pla November 01, 2015 06:54PM |

Registered: 8 years ago Posts: 310 |

the brass nut for 10mm is too big, I have the flange nut and the flange is 32mm diameter, the smooth rod is in the way, unless I draw new top and bottom as well as x end and x motor, otherwise its not possible to fit them, I do have 4 nuts and springs to make the anti backlash though.

but the pla parts have no backlash at all so far....

but the pla parts have no backlash at all so far....

|

Re: leadscrew nut with pla December 16, 2015 03:49PM |

Registered: 8 years ago Posts: 9 |

I found this on thingiverse and he said that the PLA has held up very well:

[www.thingiverse.com]

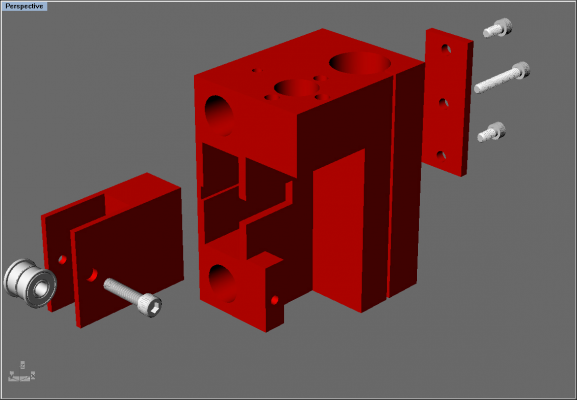

I'm currently designing my own leadscrew nut for a printer that uses 10mm threads. I haven't tested it yet, but the CAD model is here for now if you'd like to take a look at it:

[www.3dcontentcentral.com]

Edit: My version i'm not sure if the thread size is right as the hole looks much bigger than it should, but as an update the guy from Thingiverse has now uploaded a modified version of mine to his thingiverse page. So that's cool.

Edited 1 time(s). Last edit at 12/16/2015 06:42PM by BioLumo.

[www.thingiverse.com]

I'm currently designing my own leadscrew nut for a printer that uses 10mm threads. I haven't tested it yet, but the CAD model is here for now if you'd like to take a look at it:

[www.3dcontentcentral.com]

Edit: My version i'm not sure if the thread size is right as the hole looks much bigger than it should, but as an update the guy from Thingiverse has now uploaded a modified version of mine to his thingiverse page. So that's cool.

Edited 1 time(s). Last edit at 12/16/2015 06:42PM by BioLumo.

|

Re: leadscrew nut with pla December 17, 2015 09:24AM |

Registered: 8 years ago Posts: 9 |

I've now posted mine on Thingiverse:

[www.thingiverse.com]

It's still untested as of now, but i'm fairly sure it will work. Any feedback is welcome.

Edited 2 time(s). Last edit at 12/18/2015 08:44PM by BioLumo.

[www.thingiverse.com]

It's still untested as of now, but i'm fairly sure it will work. Any feedback is welcome.

Edited 2 time(s). Last edit at 12/18/2015 08:44PM by BioLumo.

|

Re: leadscrew nut with pla December 25, 2015 07:48PM |

Registered: 11 years ago Posts: 471 |

Idea: Two separate nuts, each with a little bit of backlash, with screws to pull them together (or apart), with some lever action to achieve fine tuning. This way, you can just tighten the screw as the plastic nuts wear, and you can tighten or loosen depending on whether you want precision or speed.

|

Re: leadscrew nut with pla January 02, 2016 07:55AM |

Registered: 8 years ago Posts: 310 |

Sorry, only registered users may post in this forum.