plastic (composite) frame for reprap printers?

Posted by realthor

|

Re: plastic (composite) frame for reprap printers? November 04, 2015 10:40AM |

Registered: 9 years ago Posts: 1,035 |

Quote

J-Max

For example, Instead of printing honneycomb pannels,

can't we print on foam to make usable and connectable pannels at low cost ?

++JM

Depends if there is a foam material that doesn't emitt fumes when near a heated chamber. Most foams that i know of are not good with heat and with all the discussions going on about yet another source of fine particles in our homes from the 3D printing I wouldn't just want to add up to that.

Wood will be affected by humidiy over time and the MDF/HDF variety is just not healthy to havearound kids, family so the other candidate for frames is metal. To make a cheap enclosed frame with metal you need aluminum extrusions at least, if not steel sheet or corners like the solidoodle and a way to weld/rivet/bolt them together. Aluminum extrusions are not available where I live but it might differ for other places. They will become easier to find with time by means of demand and offer but still the cost is not small for a decent aluminum cube frame with one additional bracing. Then you also need some facets material of sorts.

There are WPCs (wood plastic composites) like those the decking boards are made of or even cement fiberboard that can be used as a mass produced material that can be readily available. I've seen the latter used more and more in architecture.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 04, 2015 06:42PM |

Registered: 8 years ago Posts: 1,671 |

Quote

realthor

in my case I would like the capability to create closed hexagonal chambers (at least by creating another skin every X mm in height but I'd like those to be random for each hexagonal tube, not all at the same height) rather than continuous tubes.

Something like this:

[attachment 65282 screenshot.426.jpg]

Imagine if half of those chambers where linked with holes in the walls, so you could dip the thing in some sort resin(expensive & messy) and it would soak into it through the network of pores. I know probably tricky due to size of the pores & viscosity, but if it could be done, the panels or parts could be quite interesting maybe even useful. Using 3D printing to print skeletal support lattices of some material that can be cured further or for use as a catalyst to react some other infill material could make for some interesting diversion from the choices available at the moment.

Edited 1 time(s). Last edit at 11/04/2015 06:43PM by MechaBits.

|

Re: plastic (composite) frame for reprap printers? November 04, 2015 07:39PM |

Registered: 9 years ago Posts: 1,035 |

Quote

MechaBits

Imagine if half of those chambers where linked with holes in the walls, so you could dip the thing in some sort resin(expensive & messy) and it would soak into it through the network of pores. I know probably tricky due to size of the pores & viscosity, but if it could be done, the panels or parts could be quite interesting maybe even useful. Using 3D printing to print skeletal support lattices of some material that can be cured further or for use as a catalyst to react some other infill material could make for some interesting diversion from the choices available at the moment.

This needs more explanation from your side

... sounds intriguing. What properties do you want from the resin so that the 3D printed part would only work as a skeletal support? Or maybe we can inject some foaming liquid to make insulated walls.

... sounds intriguing. What properties do you want from the resin so that the 3D printed part would only work as a skeletal support? Or maybe we can inject some foaming liquid to make insulated walls.Found this on a web search for "Structural Foam": http://www.polycel.com/why.html whcih is interesting but it requires quite high temps.

Edited 2 time(s). Last edit at 11/04/2015 08:18PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 04, 2015 08:59PM |

Registered: 8 years ago Posts: 1,671 |

Hmm more explanation, I cant explain the materials they may or may not exist yet(Super Honey), just having the ability to do it, even if we have to wait for right materials. I'm not sure i said the printed part is ONLY a skelington.... like I wouldn't say what holds us up is only a load of old bones, it's only a chassis, sub frame, or any other of those things we hardly ever see, like carbon fibre without the fibre. What i did say was it could be part of a reactive process that might happen when dipped. maybe it just melts away and your left with a capillary system, not much use in supporting a 3D printer I admit, but I'm pretty sure something like this will be going on at some point, if not already.

It's fun trying to design stuff that works in plastic...but as mentioned above, probably pure folly.

I love metal parts more than plastic ones, I would rather have a load of metal bits lying around for years than plastic toys,

they both hurt the same when you tread on them so I go for metal whenever possible,

the only place for plastic toys is in the grinder to make more plastic parts...

but hopefully some material will come along and change all that, sugar glass, metal molasses, crystal rods, carbon candyfloss

some material we could easily bake at home would be the ideal.

Time to take that thinking cap off.

Edited 4 time(s). Last edit at 11/04/2015 09:13PM by MechaBits.

It's fun trying to design stuff that works in plastic...but as mentioned above, probably pure folly.

I love metal parts more than plastic ones, I would rather have a load of metal bits lying around for years than plastic toys,

they both hurt the same when you tread on them so I go for metal whenever possible,

the only place for plastic toys is in the grinder to make more plastic parts...

but hopefully some material will come along and change all that, sugar glass, metal molasses, crystal rods, carbon candyfloss

some material we could easily bake at home would be the ideal.

Time to take that thinking cap off.

Edited 4 time(s). Last edit at 11/04/2015 09:13PM by MechaBits.

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 04:59AM |

Registered: 8 years ago Posts: 3,525 |

I understand the OP intending that this discussion be focused on the practical solutions to self replication, not the philosophy but the philosophy is very interesting. The idea of these machines self replicating, and not relying heavily on manufactured components is a wonderful concept and potentially very enabling, but in a sense haven't the people decided, that what the majority really want is a machine that can make plastic objects but not necessarily itself. Reprap has evolved but evolved into a part-manufactured, part-3d printed - 3d printer.

This is not a bad thing and it's still incredibly enabling, and if a reliable, long lasting, manufactured 3d printer is readily available and affordable and since reprap is a huge part of bringing this about, then many of its original aims will have been met without true self replication being achieved or indeed required. We all love the Star Trek replicator, and would all love an instant cup of "tea Earl Gray hot" but isn't that just a flight of fancy like 80's kids growing up believing they will all be driving flying cars by now? I recently drove my father who is 65 years old to my house in my electric car and designed and printed him a part with his name on on my 3d printer and he was blown away by technology being used. Whereas my 18 month old son might look back fondly at the primordial, primitive devices I have shown him in my workshop as quaint old fashioned 3d-printers from back in the 2010's!

I've come to 3d printing a long way after the original repraps, I started with an i3 and now also have a kossel mini, and am thinking about building a corexy. The idea I could print myself a set of spare parts was an extremely satisfying thing to do with the i3 after I first got it working. But would I have any qualms about buying a metal or injection moulded part for some component that functioned poorly or proved to be unreliable if it is currently a 3d printed part - none whatsoever. We were always going to have to buy (or salvage) the electronics, motors, cables and some of the structural components of a 3d printer because whist we could potentially make them given enough time and energy, this will always be much more difficult than having them manufactured.

Edited 1 time(s). Last edit at 11/05/2015 05:01AM by DjDemonD.

This is not a bad thing and it's still incredibly enabling, and if a reliable, long lasting, manufactured 3d printer is readily available and affordable and since reprap is a huge part of bringing this about, then many of its original aims will have been met without true self replication being achieved or indeed required. We all love the Star Trek replicator, and would all love an instant cup of "tea Earl Gray hot" but isn't that just a flight of fancy like 80's kids growing up believing they will all be driving flying cars by now? I recently drove my father who is 65 years old to my house in my electric car and designed and printed him a part with his name on on my 3d printer and he was blown away by technology being used. Whereas my 18 month old son might look back fondly at the primordial, primitive devices I have shown him in my workshop as quaint old fashioned 3d-printers from back in the 2010's!

I've come to 3d printing a long way after the original repraps, I started with an i3 and now also have a kossel mini, and am thinking about building a corexy. The idea I could print myself a set of spare parts was an extremely satisfying thing to do with the i3 after I first got it working. But would I have any qualms about buying a metal or injection moulded part for some component that functioned poorly or proved to be unreliable if it is currently a 3d printed part - none whatsoever. We were always going to have to buy (or salvage) the electronics, motors, cables and some of the structural components of a 3d printer because whist we could potentially make them given enough time and energy, this will always be much more difficult than having them manufactured.

Edited 1 time(s). Last edit at 11/05/2015 05:01AM by DjDemonD.

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 06:11AM |

Registered: 9 years ago Posts: 1,035 |

I would not have anything against large scale manufacturing and mass production if:

a) the environment wouldn't pay what we don't in the end product's price (green energy, sustainable cradle to cradle manufacturing, non-toxic processes, local production, no pollution),

b) people would be paid fair and have happy thriving communities and

c) the mass production would be paired with mass-customization so that the creative juices in people are encouraged rather than stiffled with a one-size fits all communist ideas.

As long as all the mass manufacturing is done overseas, with pollution galore, people being basically slaves for our cheap mass manufactured stuff and our people being layd off and losing confidence and community strength as a result and as long as we don't yet have the clean energy to power the mining of iron and its production process I can't with an open heart and a smile on my face support neither non-local production nor local production that is hurting the future. We are buying using money we don't have and borrowing from the health of the environment of the future generations. Not cool.

That is why I love reprap which states that even if we can't do everything without metal we should minimize vitamin count (in which metal parts are included as long as we currently can only print thermoplastics).

That's why I love bio-based plastics that take a lot less energy to produce than metal.

That's why I love fiber-reinforced bio-based plastics (nanocellulose PLA?) or whatever higher-tech materials will pop up down the road that will be able to take the job of many metal parts, as is the current trend in high-tech industries.

So I might buy a metal 3D printer but my focus will always be the philosophy I've just described. And I believe in community inovation, collective brainpower rather than individual oportunistic happy discoveries that are being patented.

I see that this thread is going into philosophical discussions more than actual engineering work and I am forced to defend my drive for this every few posts ... I wonder if anybody else cares about this stuff. Maybe metal is all we deserve.

... I wonder if anybody else cares about this stuff. Maybe metal is all we deserve.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

a) the environment wouldn't pay what we don't in the end product's price (green energy, sustainable cradle to cradle manufacturing, non-toxic processes, local production, no pollution),

b) people would be paid fair and have happy thriving communities and

c) the mass production would be paired with mass-customization so that the creative juices in people are encouraged rather than stiffled with a one-size fits all communist ideas.

As long as all the mass manufacturing is done overseas, with pollution galore, people being basically slaves for our cheap mass manufactured stuff and our people being layd off and losing confidence and community strength as a result and as long as we don't yet have the clean energy to power the mining of iron and its production process I can't with an open heart and a smile on my face support neither non-local production nor local production that is hurting the future. We are buying using money we don't have and borrowing from the health of the environment of the future generations. Not cool.

That is why I love reprap which states that even if we can't do everything without metal we should minimize vitamin count (in which metal parts are included as long as we currently can only print thermoplastics).

That's why I love bio-based plastics that take a lot less energy to produce than metal.

That's why I love fiber-reinforced bio-based plastics (nanocellulose PLA?) or whatever higher-tech materials will pop up down the road that will be able to take the job of many metal parts, as is the current trend in high-tech industries.

So I might buy a metal 3D printer but my focus will always be the philosophy I've just described. And I believe in community inovation, collective brainpower rather than individual oportunistic happy discoveries that are being patented.

I see that this thread is going into philosophical discussions more than actual engineering work and I am forced to defend my drive for this every few posts

... I wonder if anybody else cares about this stuff. Maybe metal is all we deserve.

... I wonder if anybody else cares about this stuff. Maybe metal is all we deserve.RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 06:21AM |

Registered: 8 years ago Posts: 3,525 |

I apologise and I don't want to hijack your thread, if you wish I will happily delete my comment and change it to "moved to xxx" and start a new thread if you prefer, as I see from the discussion above, which is also very interesting, some good ideas are being exchanged.

I am inspired and impressed with your desire to do things in a better way to the way we do them now, hopefully I will try to think more along these lines myself.

I am inspired and impressed with your desire to do things in a better way to the way we do them now, hopefully I will try to think more along these lines myself.

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 06:40AM |

Registered: 9 years ago Posts: 722 |

Hi guys,

I believe there's a lot of fantasmagoria about 3d printing.

I love my reprap, maybe too much, and I often realize I'm using it too much for what it's not suitable for.

I'm now convicted we don't want to be able to print anything. Just today's example.

Last two days I spent 2x 14 hours of printing time to get a single post to hold a thing.

That means a lot of energy, some plastic (which has a bill full of carbon too), including computer time to design and customize.

The first one was not perfectly sized and not as ridgid as I thought. It brokes.

The second one was better, but still not strong enough for my needs, even if I made it realy big and thick.

Then I get two blocks of wood in my offcuts bin, saw two corners, drill two holes, glued them together, and it was just ideal.

A bit of sanding, some spray paint later it was nice and clean, strong like a tree !

Looking at my watch, it took me 15 minutes. Obviously it cost me close to nothing in raw material and energy.

I get that wood grown localy. My filament comes at last from 600km away from my home, by trucks.

And what about my printer made out of chinese stuff ?

I promiss I will pay attention to never use my printer for things I can get better by another way.

That's why I will leave the topic. Definitely, a 3d printer can't print anything.

If theoricaly it can, for many applications it should not.

Future applications and materials may increase the existing range of application, but it's still a reduced range.

It's surely not the single and ultimate way to fight mass production and globalization.

The truth is : guy with a handsaw and a chisel in his garage can do as much than anybody with a reprap.

Most of 3d printers prints yodas that glows in the dark, let's be honnest.

I'm glad to own a Reprap and to make things with it,

and mostly things I can't do without it, like a peristaltic pump for example.

And the opensource community opened a lot of perspectives.

I downloaded and printed that pump !

But should I realy print anything with it ? Probably not.

++JM

Edited 1 time(s). Last edit at 11/05/2015 06:44AM by J-Max.

I believe there's a lot of fantasmagoria about 3d printing.

I love my reprap, maybe too much, and I often realize I'm using it too much for what it's not suitable for.

I'm now convicted we don't want to be able to print anything. Just today's example.

Last two days I spent 2x 14 hours of printing time to get a single post to hold a thing.

That means a lot of energy, some plastic (which has a bill full of carbon too), including computer time to design and customize.

The first one was not perfectly sized and not as ridgid as I thought. It brokes.

The second one was better, but still not strong enough for my needs, even if I made it realy big and thick.

Then I get two blocks of wood in my offcuts bin, saw two corners, drill two holes, glued them together, and it was just ideal.

A bit of sanding, some spray paint later it was nice and clean, strong like a tree !

Looking at my watch, it took me 15 minutes. Obviously it cost me close to nothing in raw material and energy.

I get that wood grown localy. My filament comes at last from 600km away from my home, by trucks.

And what about my printer made out of chinese stuff ?

I promiss I will pay attention to never use my printer for things I can get better by another way.

That's why I will leave the topic. Definitely, a 3d printer can't print anything.

If theoricaly it can, for many applications it should not.

Future applications and materials may increase the existing range of application, but it's still a reduced range.

It's surely not the single and ultimate way to fight mass production and globalization.

The truth is : guy with a handsaw and a chisel in his garage can do as much than anybody with a reprap.

Most of 3d printers prints yodas that glows in the dark, let's be honnest.

I'm glad to own a Reprap and to make things with it,

and mostly things I can't do without it, like a peristaltic pump for example.

And the opensource community opened a lot of perspectives.

I downloaded and printed that pump !

But should I realy print anything with it ? Probably not.

++JM

Edited 1 time(s). Last edit at 11/05/2015 06:44AM by J-Max.

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 07:06AM |

Registered: 9 years ago Posts: 1,035 |

@DjDemonD: not at all, all contributions are appreciated and I consider all and maybe even bow to the ideas I don't quite aggree with. But I wouldn't mind some ideas even if a compromise is made. So I am welcoming your ideas too.

@JM: completely aggree with the minimlistic approach. I don't want a 3D printer to become one of those asking himself every day "what should I print today?". I really want to have a printer to stay in its corner until something breaks and I need replacement, until I want to make something and test a prototype, until I want a new toy for my (eventual) kids. I am ok with wood or anything "sensible" about the world we live in. Stuff isn't my main goal.

Wanting a 3D printer made primarily from plastic or wood or stone or ice or glass or metal it's ok with me but I am trying to use the least harmful to myself, my family, my yard, my humanity, my soul material. I would be happy to talk about wood and what wood to choose to perform to the specific job. But MDF stuff is too chemically-laden and too sensible to humidity.

We don't yet have perfect bio-based plastics but we can work with what plastics we have so that when those will be commonplace we will have designs for them.

Should we really print anything with the reprap printer we want to design? Probably not, but it's a good thing to have in case we need it. It's not for everyone, granted.

Sorry to hear I somehow shuned you away from this thread, not my intention by all means. I want more in not out.

For continuation of this thread:

Idea: wood is prone to humidity; plastic is not so much; not all people have in their house the tools to route channels and what not in wood. I know wood can be primed, painted to prevent humidity infiltrating. How can we use wood and plastic to build sturdy frames? Maybe embed square wood pieces in plastic? Print on a rotating wood dowel to embed it in plastic? Print the connectors right on the embedding shell? Bad idea? What is a better one?

Edited 2 time(s). Last edit at 11/05/2015 07:11AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

@JM: completely aggree with the minimlistic approach. I don't want a 3D printer to become one of those asking himself every day "what should I print today?". I really want to have a printer to stay in its corner until something breaks and I need replacement, until I want to make something and test a prototype, until I want a new toy for my (eventual) kids. I am ok with wood or anything "sensible" about the world we live in. Stuff isn't my main goal.

Wanting a 3D printer made primarily from plastic or wood or stone or ice or glass or metal it's ok with me but I am trying to use the least harmful to myself, my family, my yard, my humanity, my soul material. I would be happy to talk about wood and what wood to choose to perform to the specific job. But MDF stuff is too chemically-laden and too sensible to humidity.

We don't yet have perfect bio-based plastics but we can work with what plastics we have so that when those will be commonplace we will have designs for them.

Should we really print anything with the reprap printer we want to design? Probably not, but it's a good thing to have in case we need it. It's not for everyone, granted.

Sorry to hear I somehow shuned you away from this thread, not my intention by all means. I want more in not out.

For continuation of this thread:

Idea: wood is prone to humidity; plastic is not so much; not all people have in their house the tools to route channels and what not in wood. I know wood can be primed, painted to prevent humidity infiltrating. How can we use wood and plastic to build sturdy frames? Maybe embed square wood pieces in plastic? Print on a rotating wood dowel to embed it in plastic? Print the connectors right on the embedding shell? Bad idea? What is a better one?

Edited 2 time(s). Last edit at 11/05/2015 07:11AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 07:58AM |

Registered: 11 years ago Posts: 5,780 |

What's wrong with aluminum? Unlike the plastics we print with, it's almost 100% recycleable.

You can see how many people are concerned about the environmental impact of their printers, the anti mass production sentiment, and the "keep the jobs here" ideas by the number of people who buy $300 printer kits from China. People don't care about philosophy, the environment, jobs or any of that other stuff. All they know is they want to print Yoda and they want to do it as cheaply as possible.

I sleep fine at night knowing a bunch of the parts I put into my printer were recovered from scrapped industrial machines. I was able to do some basic milling operations because most of the machinist jobs went to other places leaving the US chock full of milling machines (and other machines like the ones my parts came from) that have been idled and are being sold for scrap. We have three of them at the makerspace right now. We also have a bunch of ex and current part-time machinists as members of the makerspace, who are happy to teach anyone their trade. When I start a new project, my first stop is the local scrap yards to see what sort of useful stuff I can find. I talk to people at the makerspace to see what sorts of stuff they might have squirreled away.

I have always advocated for quality printer construction using scrapped parts where possible and pointed out that they are often cheaper and usually much better quality-wise than the alternatives, and recommended that people find and get involved in their local makerspaces but 99.9% of people don't want to make that much effort. People don't care about any of that stuff any more than they care about your favorite topics. They want that Yoda head and they want it now, and that $300 is burning a hole in their pockets. The most effort you can expect from them is a post asking which is the "best" $300 printer kit (equivalent of asking which is the best - cow, sheep, or chicken poop?), assembling a poorly designed kit of low quality parts, followed by dozens of posts about why the motors won't turn or the prints won't stick to the bed or any of the hundreds of other problems that plague cheap machines.

If you're really concerned about pollution, jobs, local sourcing, etc., take up kite flying instead of 3D printing. 3D printing is inherently environmentally unfriendly, as is almost everything else humans do.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You can see how many people are concerned about the environmental impact of their printers, the anti mass production sentiment, and the "keep the jobs here" ideas by the number of people who buy $300 printer kits from China. People don't care about philosophy, the environment, jobs or any of that other stuff. All they know is they want to print Yoda and they want to do it as cheaply as possible.

I sleep fine at night knowing a bunch of the parts I put into my printer were recovered from scrapped industrial machines. I was able to do some basic milling operations because most of the machinist jobs went to other places leaving the US chock full of milling machines (and other machines like the ones my parts came from) that have been idled and are being sold for scrap. We have three of them at the makerspace right now. We also have a bunch of ex and current part-time machinists as members of the makerspace, who are happy to teach anyone their trade. When I start a new project, my first stop is the local scrap yards to see what sort of useful stuff I can find. I talk to people at the makerspace to see what sorts of stuff they might have squirreled away.

I have always advocated for quality printer construction using scrapped parts where possible and pointed out that they are often cheaper and usually much better quality-wise than the alternatives, and recommended that people find and get involved in their local makerspaces but 99.9% of people don't want to make that much effort. People don't care about any of that stuff any more than they care about your favorite topics. They want that Yoda head and they want it now, and that $300 is burning a hole in their pockets. The most effort you can expect from them is a post asking which is the "best" $300 printer kit (equivalent of asking which is the best - cow, sheep, or chicken poop?), assembling a poorly designed kit of low quality parts, followed by dozens of posts about why the motors won't turn or the prints won't stick to the bed or any of the hundreds of other problems that plague cheap machines.

If you're really concerned about pollution, jobs, local sourcing, etc., take up kite flying instead of 3D printing. 3D printing is inherently environmentally unfriendly, as is almost everything else humans do.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 08:18AM |

Registered: 9 years ago Posts: 722 |

Hi again,

Oh, I just leave because I probably won't help that much on this specific topic...

Each raw material own strengths and weaknesses. Even in each subdivision.

We know PLA suits some applications, ABS others, Nylon too.

And it's the same about metals, stones, whatever.

For wood it's the same. We know wood expands and contracts with moisture.

But there's also a lot of woods that can stay oudoor with no wear at all.

Mixing materials are a special science because any raw material's properties must not oppose the ones of the other raw material.

For example, metal expands with heat a little bit in any direction, while wood contracts when it's dry in a single direction.

So mixing natural wood with metal is often a bad idea, but is still possible with particule boards or plywood.

Probably a mix of plastic and metal can work. We have some examples with Dibond for example.

Maybe there's a lot of possible applications with some fabrics, even glass or carbon fibre fabrics.

We could experiment, laying some fibreglass on our heatbeds, then print at last several layers, then flip it back for other layers.

Or sandwich several layers of fibreglass within several coats of plastic.

If you want to mix wood and plastics you should consider wood grain direction and/or use filaments that can expand and contract a bit like nylon.

About our plastics, we should experiment those which have a good bond togeter (or not! it can be usefull sometimes).

We could experiment mixing different plastics for mecanical applications.

Imagine Flexible A filament don't stick on B plastic, and C plastic sticks to both A and B filaments,

so we should be able to build printable pumps, absorbers, gas springs, and many other things.

Aside from that, I've nothing got to offer...

++JM

Oh, I just leave because I probably won't help that much on this specific topic...

Each raw material own strengths and weaknesses. Even in each subdivision.

We know PLA suits some applications, ABS others, Nylon too.

And it's the same about metals, stones, whatever.

For wood it's the same. We know wood expands and contracts with moisture.

But there's also a lot of woods that can stay oudoor with no wear at all.

Mixing materials are a special science because any raw material's properties must not oppose the ones of the other raw material.

For example, metal expands with heat a little bit in any direction, while wood contracts when it's dry in a single direction.

So mixing natural wood with metal is often a bad idea, but is still possible with particule boards or plywood.

Probably a mix of plastic and metal can work. We have some examples with Dibond for example.

Maybe there's a lot of possible applications with some fabrics, even glass or carbon fibre fabrics.

We could experiment, laying some fibreglass on our heatbeds, then print at last several layers, then flip it back for other layers.

Or sandwich several layers of fibreglass within several coats of plastic.

If you want to mix wood and plastics you should consider wood grain direction and/or use filaments that can expand and contract a bit like nylon.

About our plastics, we should experiment those which have a good bond togeter (or not! it can be usefull sometimes).

We could experiment mixing different plastics for mecanical applications.

Imagine Flexible A filament don't stick on B plastic, and C plastic sticks to both A and B filaments,

so we should be able to build printable pumps, absorbers, gas springs, and many other things.

Aside from that, I've nothing got to offer...

++JM

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 08:30AM |

Registered: 9 years ago Posts: 1,035 |

Quote

the_digital_dentist

What's wrong with aluminum? Unlike the plastics we print with, it's almost 100% recycleable.

If there is a way to use wood that can replace aluminum I prefer wood. If there is a way to combine wood and plastic over aluminum I prefer that combination. If those two fail, I'll choose aluminum.

[/quote]Quote

the_digital_dentist

If you're really concerned about pollution, jobs, local sourcing, etc., take up kite flying instead of 3D printing. 3D printing is inherently environmentally unfriendly, as is almost everything else humans do.

By that logic everybody trying to straighten up the wrongdoings of humankind should be flying. I prefer to stay and fight

. If nothing else at least mentalities

. If nothing else at least mentalities .

.@J-Max: what about printing plastic on roughed wood? Could that work?

Edited 1 time(s). Last edit at 11/05/2015 08:30AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 09:02AM |

Registered: 8 years ago Posts: 3,525 |

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 09:49AM |

Registered: 9 years ago Posts: 1,035 |

Quote

DjDemonD

Quote

the_digital_dentist

What's wrong with aluminum? Unlike the plastics we print with, it's almost 100% recycleable

Indeed - why aren't we extruding aluminium in our printers and making metal objects?

http://3dprinting.com/3dprinters/vader-molten-metal-3d-printer/

High-temp materials are easier to machine and the actual fabrication of bulk material to take place in factories. The energy usage just makes more sense. In order to 3d print in aluminum there should be an alloy that lowers its melting point to below 400C maybe below 300C (I am guessing) which would make it softer and more plastic-like. For aluminum our 3D printers should be able to mill it because we usually need structural aluminum parts like brackets, holders, etc, not so much intricate stuff. For that plastic is good enough (another guess).

Edited 1 time(s). Last edit at 11/05/2015 09:51AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 10:21AM |

Registered: 11 years ago Posts: 5,780 |

The reason we don't print aluminum is first and foremost its melting temperature. If there was an easy way to achieve the heat required we'd be sintering aluminum powder. A laser that can produce sufficient heat requires huge power input and is very expensive and remember, almost no one is willing to pay more than $300 for a printer, even if it can produce an aluminum Yoda head.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 11:08AM |

Registered: 9 years ago Posts: 1,035 |

Quote

the_digital_dentist

[...] and remember, almost no one is willing to pay more than $300 for a printer, even if it can produce an aluminum Yoda head.

Epic

))

))Aluminum extrusions are a comfortable way to quickly build a frame, it's tried and true. Unless not available in your area and metal shipping costs are huge. Try to live in Northern Europe and you'll see why you want wodd/plastic alternatives. Even hardware store parts are expensive. And with the language barrier no makerspace, no scrap yards, almost nothing but what you can build with few tools.

And when I see my long-term BT and the situation i'm in I recognize a lot more people that: 1) either don't have enough tools 2) don't have enough room for tools (rented studio?) or 3) can't afford the tools or a precise, industrial-grade, aluminum extrusion frame 3d printer or 4) there are countless other situations where you would like a reprap plastic/wood+as little metal as possible 3d printer. There comes funbot

which is great little 3D printer from sweden. But I started a SCARA design and now I have the SCARA stage built with only some threaded rod to keep things together, some threaded rod for the Spectra drive and bearings for the rotating parts.

which is great little 3D printer from sweden. But I started a SCARA design and now I have the SCARA stage built with only some threaded rod to keep things together, some threaded rod for the Spectra drive and bearings for the rotating parts.So I decided to go this route and try to come up with something that anybody would find more facile to do. Find a friend with a 3D printer, go to the hardware store, go to Ikea and there's the printer...Yes it's not ideal, yes it's not industrial grade, yes it's not perfect. But there are many more pretentious designs out there.

Edited 2 time(s). Last edit at 11/05/2015 11:19AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 12:45PM |

Registered: 9 years ago Posts: 722 |

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 03:26PM |

Registered: 10 years ago Posts: 73 |

All this talk about PVC pipe is amusing...I built a nice size CoreXY machine recently and the frame seems plenty strong: [forums.reprap.org]

More discussion here: [groups.google.com]

More discussion here: [groups.google.com]

|

Re: plastic (composite) frame for reprap printers? November 05, 2015 05:02PM |

Registered: 9 years ago Posts: 1,035 |

Do you still use it as a primary machine? I liked the PVC pipe connector set on thingiverse when I first saw it but don't fancy too much PVC in the apartment (I live in a studio for a while). I would try the same approach with wood dowels.

BTW, did you think about enclosing it to maybe be able to print with other filament than PLA?

One more: isn't it too light? Maybe fill the PVC pipes with sand or some vibration absorbtion material?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

BTW, did you think about enclosing it to maybe be able to print with other filament than PLA?

One more: isn't it too light? Maybe fill the PVC pipes with sand or some vibration absorbtion material?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 06, 2015 05:09PM |

Registered: 10 years ago Posts: 73 |

Quote

realthor

Do you still use it as a primary machine? I liked the PVC pipe connector set on thingiverse when I first saw it but don't fancy too much PVC in the apartment (I live in a studio for a while). I would try the same approach with wood dowels.

BTW, did you think about enclosing it to maybe be able to print with other filament than PLA?

One more: isn't it too light? Maybe fill the PVC pipes with sand or some vibration absorbtion material?

No, its not the primary machine. It's an experimental, proof of concept type of printer. I wanted to see if the PVC could make a viable frame and which of the printed parts would fail, and how they would fail (too early to tell). I'm in a studio apartment and don't mind the PVC. The main issue is the printer is too big for my tight living quarters...

I wouldn't trust the PVC in an enclosure; it softens readily in boiling water (100C). I don't plan on using PLA; the metal hot end is too fiddly. Once the heatbed is hooked up it will be PET, HIPS, or other stuff. But I have different extruders and hot ends I plan on testing.

I don't think it's too light... was thinking about sand in the lower structure, but it's around 45 pounds now. Plenty heavy for the time being; I can always add weight later.

|

Re: plastic (composite) frame for reprap printers? November 06, 2015 06:04PM |

Registered: 9 years ago Posts: 1,035 |

What would be the downsides or upsides? of a wood dowel similarly built strcture?

of a wood dowel similarly built strcture?

My personal opinion is that for apartments and for every home to have a 3d printer in 10 years as they predict the printers will either be a mini-fridge-size cool looking applicances lie any other applicance in the home or they will be unoptrusively embedded in the furniture. I just measured a wardrobe/cupboard shelf and it's 60cm deep and 50cm wide, with the height adjustable by the shelf pins. Pne can make a box fit that space and you got an enclosed printer. Of course the cupboard must be sturdy enough but they are usually by the wall so they are easy to bolt to the wall and it won't even show.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

of a wood dowel similarly built strcture?

of a wood dowel similarly built strcture?My personal opinion is that for apartments and for every home to have a 3d printer in 10 years as they predict the printers will either be a mini-fridge-size cool looking applicances lie any other applicance in the home or they will be unoptrusively embedded in the furniture. I just measured a wardrobe/cupboard shelf and it's 60cm deep and 50cm wide, with the height adjustable by the shelf pins. Pne can make a box fit that space and you got an enclosed printer. Of course the cupboard must be sturdy enough but they are usually by the wall so they are easy to bolt to the wall and it won't even show.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 06, 2015 09:30PM |

Registered: 9 years ago Posts: 233 |

as a cheap alternative to PVC that doesnt melt, what about steel electrical conduit as a frame material. Maker Faire NYC had a guy this year that designed fittings to turn conduit into structural frames. I will see if I can find a link.

Found the link:

Maker Pipe Connectors

Pretty sure that some acceptable connectors could be 3D printed too....

I think that this solution is obviously inferior to aluminum extrusion for structural integrity, but it should definitely be available at every hardware store for relatively cheap. It won't melt like PVC. Another option would be to use Ikea table or chair legs.....

Edited 1 time(s). Last edit at 11/06/2015 09:39PM by patrickrio.

Found the link:

Maker Pipe Connectors

Pretty sure that some acceptable connectors could be 3D printed too....

I think that this solution is obviously inferior to aluminum extrusion for structural integrity, but it should definitely be available at every hardware store for relatively cheap. It won't melt like PVC. Another option would be to use Ikea table or chair legs.....

Edited 1 time(s). Last edit at 11/06/2015 09:39PM by patrickrio.

|

Re: plastic (composite) frame for reprap printers? November 07, 2015 05:24AM |

Registered: 9 years ago Posts: 1,035 |

I like the idea with electrical conduit connectors. And it's cheap. And it should be reliable too since there is a much lauded CNC that uses it for linear elements (http://www.3ders.org/articles/20150728-ryan-zellars-shares-designs-for-impressive-mostly-3d-printed-reprap-cnc-machine.html).

There is also the UConduit h-bot 3D Printer which uses conduit for framing and its own design connector: http://reprap.org/wiki/File:Ucon_compression.jpg

IKEA steel powder coated round legs go for 2.5Eur/leg around here. I would use IKEA tables with steel legs only if I find them discounted or in the returned area (nothing new either: http://forums.reprap.org/read.php?2,354189,470428#msg-470428).

Edited 1 time(s). Last edit at 11/07/2015 05:24AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

There is also the UConduit h-bot 3D Printer which uses conduit for framing and its own design connector: http://reprap.org/wiki/File:Ucon_compression.jpg

IKEA steel powder coated round legs go for 2.5Eur/leg around here. I would use IKEA tables with steel legs only if I find them discounted or in the returned area (nothing new either: http://forums.reprap.org/read.php?2,354189,470428#msg-470428).

Edited 1 time(s). Last edit at 11/07/2015 05:24AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 07, 2015 04:46PM |

Registered: 10 years ago Posts: 73 |

Quote

realthor

What would be the downsides or upsides?of a wood dowel similarly built strcture?

My personal opinion is that for apartments and for every home to have a 3d printer in 10 years as they predict the printers will either be a mini-fridge-size cool looking applicances lie any other applicance in the home or they will be unoptrusively embedded in the furniture. I just measured a wardrobe/cupboard shelf and it's 60cm deep and 50cm wide, with the height adjustable by the shelf pins. Pne can make a box fit that space and you got an enclosed printer. Of course the cupboard must be sturdy enough but they are usually by the wall so they are easy to bolt to the wall and it won't even show.

I can't think of any compelling reason why wood dowels wouldn't work just fine except for dimensional stability issues involving changes in temperature and humidity. It is certainly worth exploring.

Your idea of incorporating a printer in furniture is exactly what I've been considering...made this part to do it: [www.thingiverse.com]

Any sturdy box structure should suffice...was thinking that the old TV consoles from the 50s would be a nice starting point. Those were big, fine looking units with doors that revealed the picture tube...Zenith comes to mind. Strip the guts from the inside, screw in the Makerslide and you might be on to something cool.

Or a coffee table built from 4x4s, with a CoreXY printer inside...glass tabletop, of course.

The suggestions for using metal conduit are good ideas, too. It probably depends on what kind of materials you have on hand and like to work with.

Too many ideas, too little time...

|

Re: plastic (composite) frame for reprap printers? November 07, 2015 05:51PM |

Registered: 9 years ago Posts: 1,035 |

Well, this is why brainstorming is a convenient method of picking up community wisdom/experience. Keep going guys, we'll end up somwhere.

I was thinking at first at coffee tables with a corexy underneath but then I thought that for now 3d printers are cool and we all are mesmerized watching them. But in time they will become the next drill or angle grinder and we will not want them in the livingroom. Just like you keep your electric drill or angle grinder somewhere in another room you will want the 3d printer to be unobtrusive and you will just go there to pick up the print and do maintenance. That's why furniture or a minifridge-like applicance will be the right place for them.

Going further with this taught, the cheaper solution is existing cupboards where you can spare a whole shelf for an enclosed box. I like your Makerslide affixing solution but personally I think, as you might already know, that aluminum extrusion is a quite expensive solution. But depending on budget it's a good solution nevertheless.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I was thinking at first at coffee tables with a corexy underneath but then I thought that for now 3d printers are cool and we all are mesmerized watching them. But in time they will become the next drill or angle grinder and we will not want them in the livingroom. Just like you keep your electric drill or angle grinder somewhere in another room you will want the 3d printer to be unobtrusive and you will just go there to pick up the print and do maintenance. That's why furniture or a minifridge-like applicance will be the right place for them.

Going further with this taught, the cheaper solution is existing cupboards where you can spare a whole shelf for an enclosed box. I like your Makerslide affixing solution but personally I think, as you might already know, that aluminum extrusion is a quite expensive solution. But depending on budget it's a good solution nevertheless.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 08, 2015 10:19PM |

Registered: 8 years ago Posts: 310 |

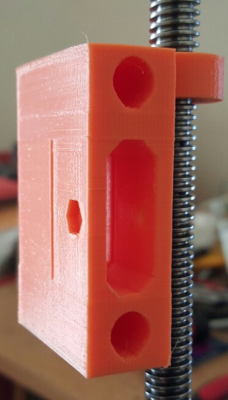

I made these

They been running 8 days solid making other parts I have designed for another printer, so far all still going very well, they are on a prusa i3 printed at 0.1mm with 10mm leads crew thread 2mm pitch as I couldn't fit the brass nut on without making lots of parts. I took a chance.

The new printer has a a lot of parts made of plastic. It's a box shape, all corners are printed, I will use pla first, but are reinforced with steel tube, basically has a full plastic skin all round with corners being bigger and thicker plastic part. Xy carriage is plastics, but I'm not printng the thread due to size of printer and weight, it seems to be holding up on the i3 with single hotend but I'm not so sure for 2 or 3 hotends couple with a diamond nozzle. I was going to do the z with mostly plastic but it really is faster and cheaper to use aluminum. I will make all the parts again in abs once I finished the pla parts, it just much faster to print at smaller layer heights, just to see what it's like for measurements. But hotends area are all abs. So apart from rods, bearings, nuts and bolts, electronic and the reinforcement the rest are printed.

Ps. I'm not so sure about acrylic, my frame is rather flexible, my y carriage is in critical condition after few months of usage, one arm is falling down the way I hold that up with a bearing, I can no longer level the bed with springs so I have spacers and different length of screws to level it to the closes possible and use autobed for the small corrections, seems even better this way than before, or maybe because the y carriage was beginning to bend soon after its first print, I always had leveling problem right from the start.

Edited 3 time(s). Last edit at 11/08/2015 10:28PM by deaconfrost.

They been running 8 days solid making other parts I have designed for another printer, so far all still going very well, they are on a prusa i3 printed at 0.1mm with 10mm leads crew thread 2mm pitch as I couldn't fit the brass nut on without making lots of parts. I took a chance.

The new printer has a a lot of parts made of plastic. It's a box shape, all corners are printed, I will use pla first, but are reinforced with steel tube, basically has a full plastic skin all round with corners being bigger and thicker plastic part. Xy carriage is plastics, but I'm not printng the thread due to size of printer and weight, it seems to be holding up on the i3 with single hotend but I'm not so sure for 2 or 3 hotends couple with a diamond nozzle. I was going to do the z with mostly plastic but it really is faster and cheaper to use aluminum. I will make all the parts again in abs once I finished the pla parts, it just much faster to print at smaller layer heights, just to see what it's like for measurements. But hotends area are all abs. So apart from rods, bearings, nuts and bolts, electronic and the reinforcement the rest are printed.

Ps. I'm not so sure about acrylic, my frame is rather flexible, my y carriage is in critical condition after few months of usage, one arm is falling down the way I hold that up with a bearing, I can no longer level the bed with springs so I have spacers and different length of screws to level it to the closes possible and use autobed for the small corrections, seems even better this way than before, or maybe because the y carriage was beginning to bend soon after its first print, I always had leveling problem right from the start.

Edited 3 time(s). Last edit at 11/08/2015 10:28PM by deaconfrost.

|

Re: plastic (composite) frame for reprap printers? November 09, 2015 03:49AM |

Registered: 9 years ago Posts: 1,035 |

@deaconfrost: a picture of the whole frame would be nice when ready or at least this one with the metal tubinf/etc attached so we can see the way it's designed to hold the other parts.

What kind of steel tube are you talking about? Is it electrical conduit? It seems a motif already in this thread.

Can your design be adapted/applied as is to any box-shaped frame?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

What kind of steel tube are you talking about? Is it electrical conduit? It seems a motif already in this thread.

Can your design be adapted/applied as is to any box-shaped frame?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 09, 2015 07:41AM |

Registered: 8 years ago Posts: 310 |

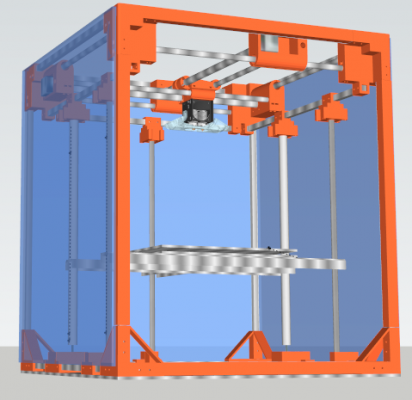

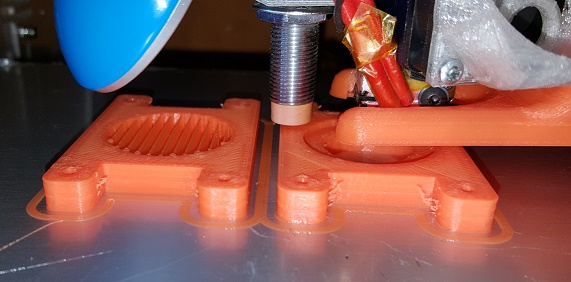

I made these so far

linear bearing block for 10mm leadscrew nuts and 12mm smooth rods, xy carriage, dual E3D v6 + inductive sensor holder, fan shrud, printing one of the Z top bearing mount for the leadscrew at the moment,

not sure if the tubes are electrical conduit, I was just going around local stores for strong steel tubing at reasonable price

haven't completely finished the drawing yet, once finished I will make an animation as well, but the rest of the frame will be skinned up like the front part, only smooth rods are not covered, I could use other metal part without having to put a plastic skin over, but I like how it looks with the plastic skin and I can add some texture design to it later,

the hotends mount can certainly be adapted to other printers, I am going to make a xy carriage for that to fit the ultimaker

Edited 1 time(s). Last edit at 11/09/2015 08:32AM by deaconfrost.

linear bearing block for 10mm leadscrew nuts and 12mm smooth rods, xy carriage, dual E3D v6 + inductive sensor holder, fan shrud, printing one of the Z top bearing mount for the leadscrew at the moment,

not sure if the tubes are electrical conduit, I was just going around local stores for strong steel tubing at reasonable price

haven't completely finished the drawing yet, once finished I will make an animation as well, but the rest of the frame will be skinned up like the front part, only smooth rods are not covered, I could use other metal part without having to put a plastic skin over, but I like how it looks with the plastic skin and I can add some texture design to it later,

the hotends mount can certainly be adapted to other printers, I am going to make a xy carriage for that to fit the ultimaker

Edited 1 time(s). Last edit at 11/09/2015 08:32AM by deaconfrost.

|

Re: plastic (composite) frame for reprap printers? November 09, 2015 08:48AM |

Registered: 9 years ago Posts: 1,035 |

Very professional looking thank you for posting the images.

Just curious what software do u use for the CAD? That is pretty strange looking to me Anyway I am eagerly waiting for the animation, I can't really tell from the image which is smooth rod and which is structural tubing.

Anyway I am eagerly waiting for the animation, I can't really tell from the image which is smooth rod and which is structural tubing.

Edited 1 time(s). Last edit at 11/09/2015 08:49AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Just curious what software do u use for the CAD? That is pretty strange looking to me

Anyway I am eagerly waiting for the animation, I can't really tell from the image which is smooth rod and which is structural tubing.

Anyway I am eagerly waiting for the animation, I can't really tell from the image which is smooth rod and which is structural tubing.Edited 1 time(s). Last edit at 11/09/2015 08:49AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: plastic (composite) frame for reprap printers? November 09, 2015 08:59AM |

Registered: 8 years ago Posts: 310 |

Thanks for the comments, I did the drawings in sketchup , all measurement's are typed in while drawing the parts so it is precise, there are 3 smooth rods and 2 z leads crews, I was going to draw the leads crew but feeling a bit lazy and it's not really needed to be drawn as I know which is which  on the front top you see a stepper in the drawing, that would be the leadscrew side

on the front top you see a stepper in the drawing, that would be the leadscrew side

Edited 1 time(s). Last edit at 11/09/2015 09:13AM by deaconfrost.

on the front top you see a stepper in the drawing, that would be the leadscrew side

on the front top you see a stepper in the drawing, that would be the leadscrew side

Edited 1 time(s). Last edit at 11/09/2015 09:13AM by deaconfrost.

Sorry, only registered users may post in this forum.