TriloByte Extruder

Posted by MechaBits

|

TriloByte Extruder November 02, 2015 09:17PM |

Registered: 8 years ago Posts: 1,671 |

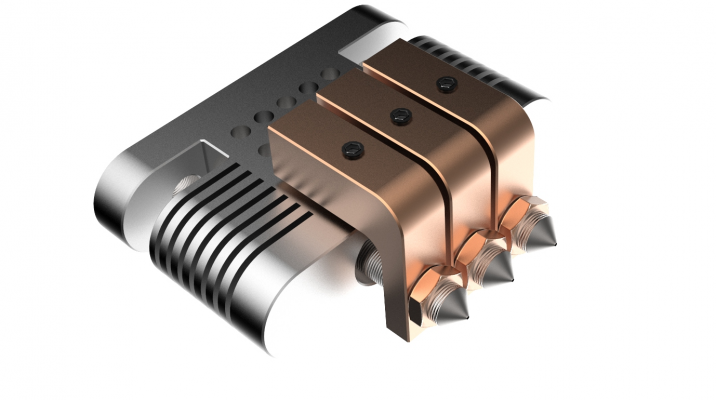

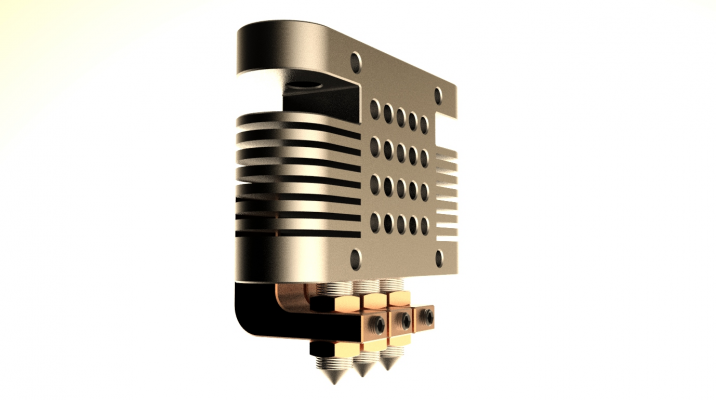

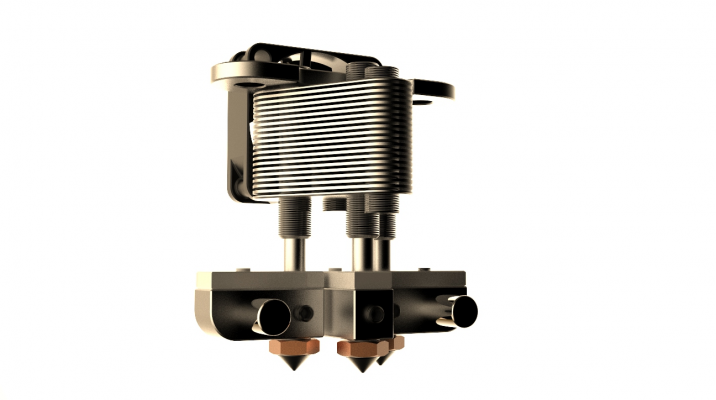

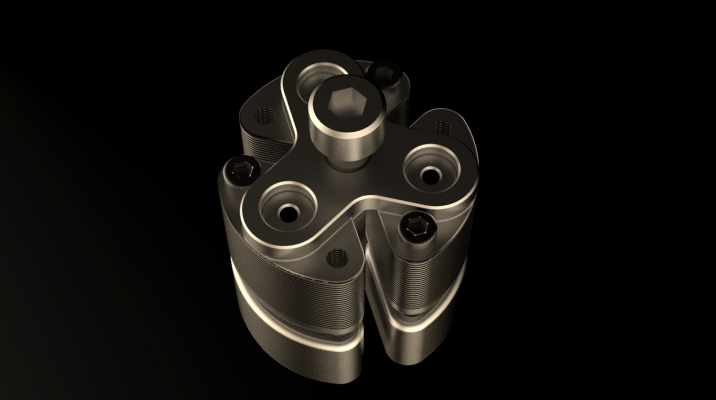

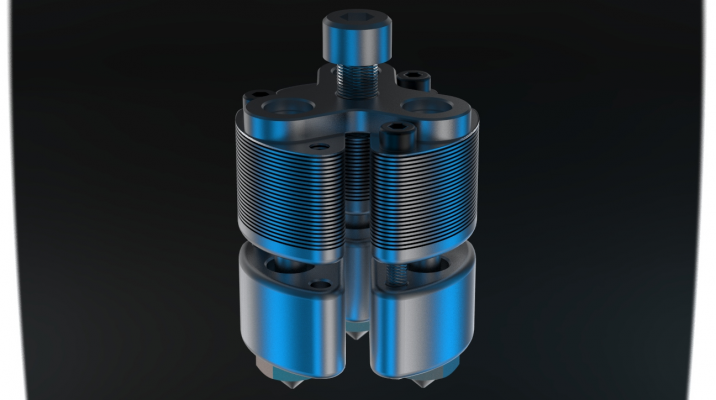

Well the devil makes work for idle hands, so while waiting for some more parts to arrive I thought I try would design a triple extruder,

not that I need it at the moment, but who knows maybe in the future. The overall shape & size is what i need to fit with my X carriage, the throats need to be 9mm apart, everything else can change, fin thickness, materials etc.

I thought PEEK might be the way to go, but then you read a little more and find that all that could be done away with. if you want high temps multi material all metal hotend.

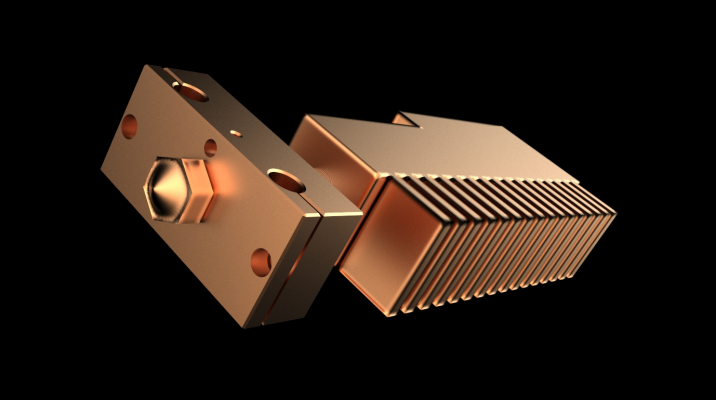

Copper heat block the ideal, but maybe too pricey?

I have many old CPU heatsinks I could chop into slices, I even have a nice copper one, but its pretty heavy, definatly need to slice it into 10mm strips.

Ideally I would like the option for different temps at each nozzle, I would like the heating elements vertical, but it may transfer too much heat over to the Heatsink unless a thermal barrier can be found. There is a little room to rearrange the heatblocks, and if 3 temps is too ambitious, I could settle for one overall temp, at this point 1 filament feed is fine, so I could reduce size further, 40x40x15 somewhere in that range.

Some CPU heatsinks already have the copper heatpipes in the design to take heat way, but these heatsinks are far to big, a smaller version would need designing.

Ideally throats & nozzles of ebay, without ptfe liners, the way the nozzles and throats on ebay screw into 6mm holes on heater block, I wonder if you could arrange the 6mm throat into 6mm female nozzle which has larger male thread to go into heater block, or held in by another heatblocking nut, obviously a combined throat & nozzle might be a better solution.

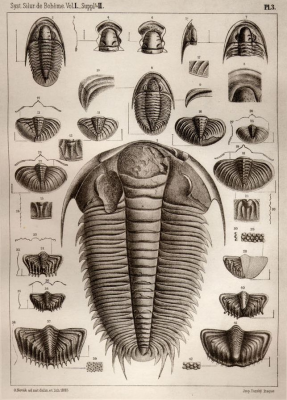

Thoughts & ideas welcome. If I can make it look more like a trilobyte that would be cool

Edited 1 time(s). Last edit at 11/02/2015 09:18PM by MechaBits.

|

Re: TriloByte Extruder November 02, 2015 09:29PM |

Registered: 10 years ago Posts: 14,672 |

Looks nice! You definitely need independent temperature control of each nozzle, because the way you prevent the non printing nozzles from oozing is to reduce their temperatures. I suggest you use much smaller heating blocks, otherwise heating and cooling times will be too long and the PID constants will be harder to get right.

Edited 1 time(s). Last edit at 11/02/2015 09:32PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 11/02/2015 09:32PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: TriloByte Extruder November 02, 2015 09:36PM |

Registered: 8 years ago Posts: 1,671 |

I could separate the 2 outer ones by rotating 90 degrees but realize its a little tight, might have to take a leaf out of the ultimakers arrangement, steel spring and some isolation/barrier material, could ceramic be used?

Smaller heaters needed note taken, I wonder can someone make a heater nut/nozzle.

You Ooze you loose, the working title was the triple dribbler, or trible trouble for the trekkies.

Edited 4 time(s). Last edit at 11/02/2015 11:50PM by MechaBits.

Smaller heaters needed note taken, I wonder can someone make a heater nut/nozzle.

You Ooze you loose, the working title was the triple dribbler, or trible trouble for the trekkies.

Edited 4 time(s). Last edit at 11/02/2015 11:50PM by MechaBits.

|

Re: TriloByte Extruder November 03, 2015 08:19AM |

Registered: 8 years ago Posts: 1,671 |

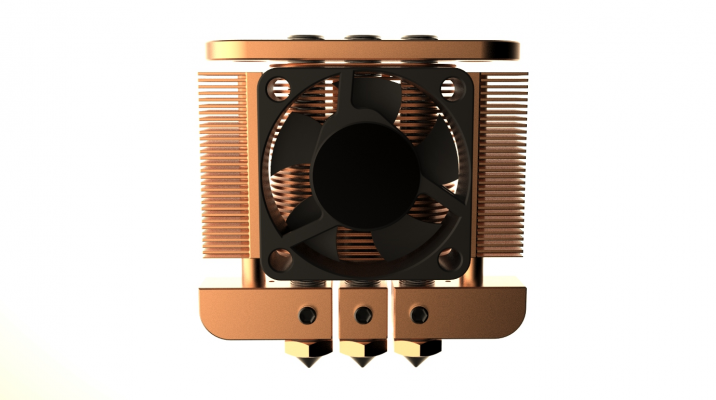

TriloByte Evolution

Looking a little more like a copper critter cambrian crustacean.

Edited 3 time(s). Last edit at 11/03/2015 08:30AM by MechaBits.

Looking a little more like a copper critter cambrian crustacean.

Edited 3 time(s). Last edit at 11/03/2015 08:30AM by MechaBits.

|

Re: TriloByte Extruder November 04, 2015 04:02AM |

Registered: 8 years ago Posts: 1,671 |

Someone beat me to it

[www.thingiverse.com]

[www.thingiverse.com]

Edited 1 time(s). Last edit at 11/04/2015 04:12AM by MechaBits.

[www.thingiverse.com]

[www.thingiverse.com]

Edited 1 time(s). Last edit at 11/04/2015 04:12AM by MechaBits.

|

Re: TriloByte Extruder November 07, 2015 06:19PM |

Registered: 8 years ago Posts: 1,671 |

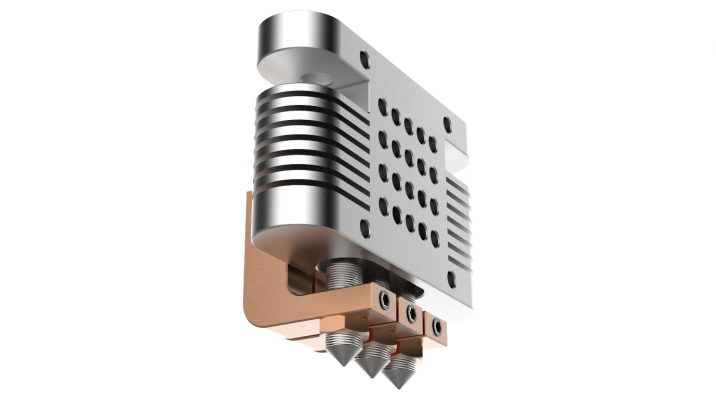

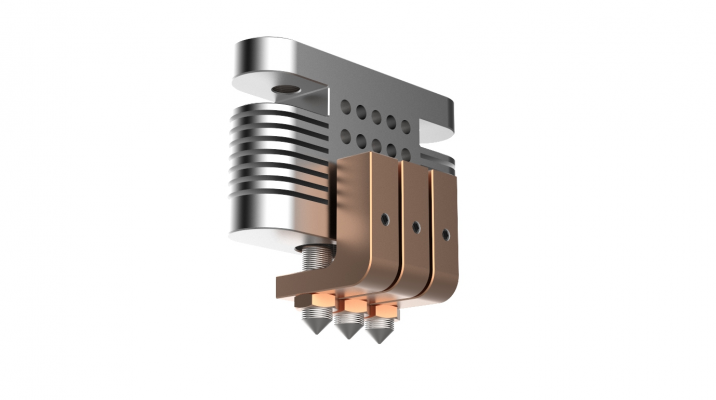

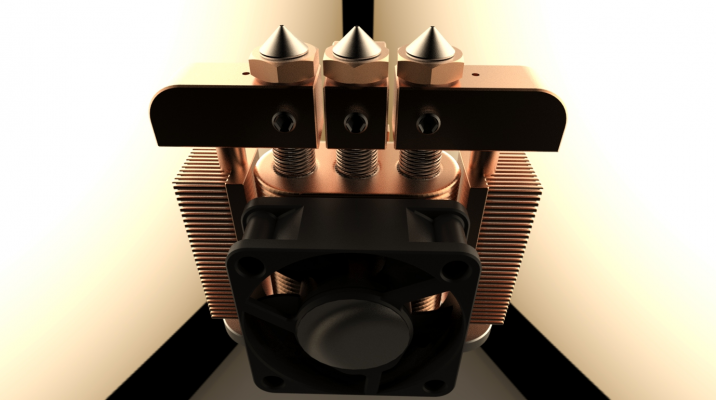

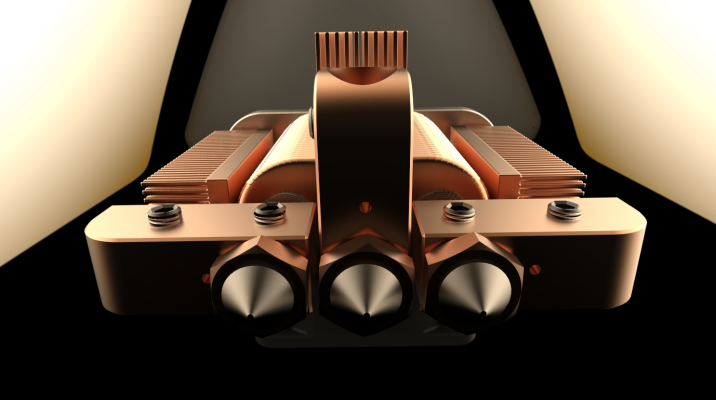

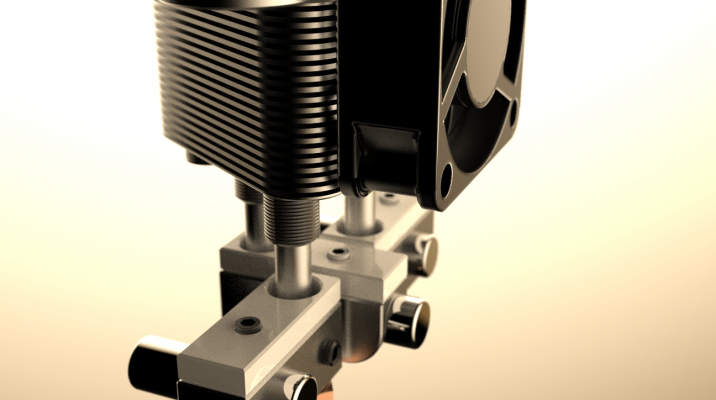

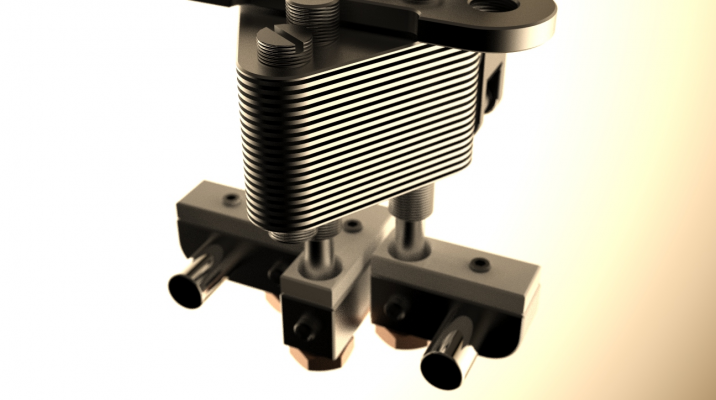

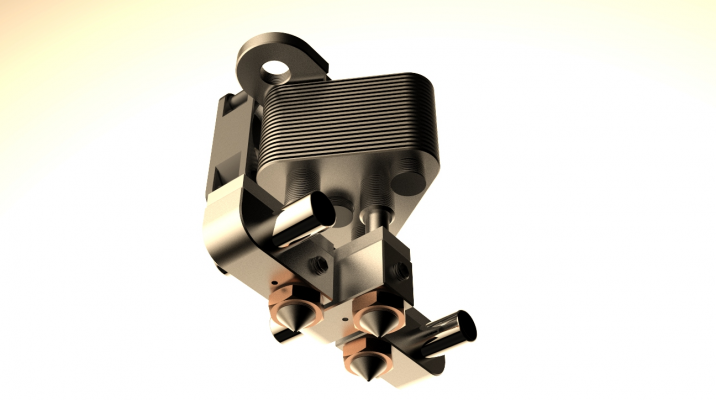

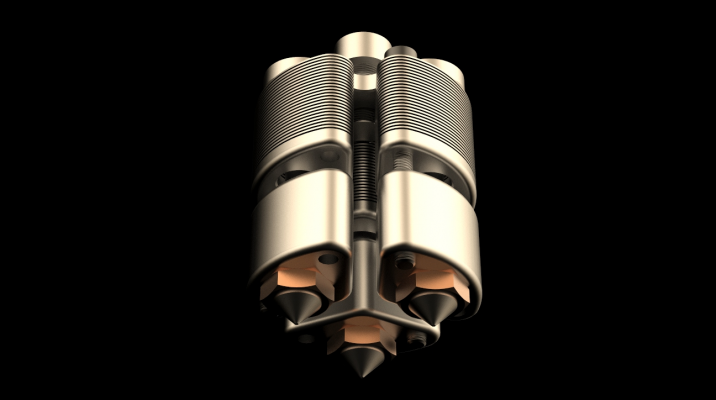

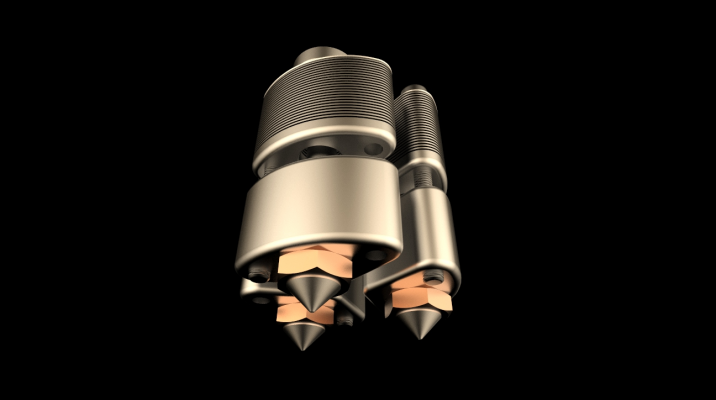

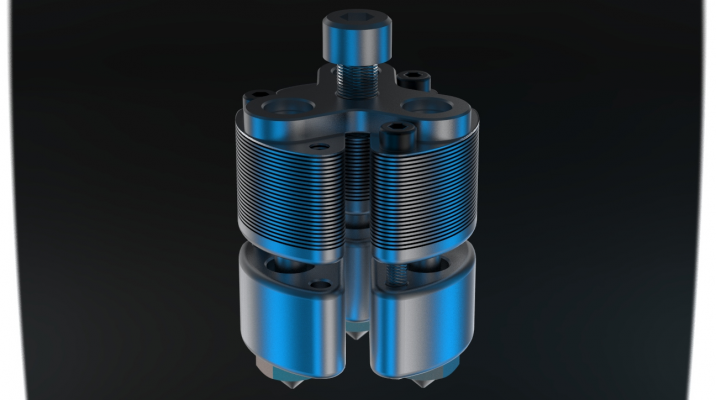

A few more images of the latest revision.

|

Re: TriloByte Extruder November 10, 2015 05:08PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: TriloByte Extruder November 11, 2015 01:46PM |

Registered: 8 years ago Posts: 1,671 |

If you noticed the last picture was a little bit of a joke, then top marks to you.

Overall the shape would fit my setup, when the X axis rods are above each other, rather than as they are now.

Back on the trail of the Tripple dribbler, I've altered things for V3, though space for the heaters is limited, if the standard cartridge is ever reduced to 3mm diameter then this arrangement might be more achievable.

Though I recognize manufacturing could be a little tricky or expensive...so unless the Chinese can figure it out,

just another design folly.

Thing is, my carriage is aluminium, and there is a possibility it could be used to dissipate some of the heat,

so not sure how small I could make things on the hotend, or how a little heat transferring to the bearings & rods would effect things.

Edited 2 time(s). Last edit at 11/11/2015 01:55PM by MechaBits.

|

Re: TriloByte Extruder November 23, 2015 12:48AM |

Registered: 8 years ago Posts: 1,671 |

Wondering if Aerogels/fabrics could be the ideal material to help create a new extruder or modify existing ones, is this the fabric currently used to wrap hotends? Certainly help to save a reprap from melting.

[www.buyaerogel.com]

Edited 1 time(s). Last edit at 11/23/2015 12:49AM by MechaBits.

[www.buyaerogel.com]

Edited 1 time(s). Last edit at 11/23/2015 12:49AM by MechaBits.

|

Re: TriloByte Extruder November 23, 2015 04:35AM |

Registered: 9 years ago Posts: 722 |

Hi guys,

The 3D pictures are awsome, and the ideas are interesting.

On the last attempt, I can't imagine the price of that extruder if it were machined !

Just something you did not thought about.

The more closer are the nozzles, the worst oozing you'll get.

3 Separate nozzles are not interesting.

When you mix colours, you'd rather have several filaments getting out by the same nozzle. Like on the E3D cyclops.

It's the only way to get rid of oozing. You can build an ooze shield, but then you can't cool your part properly.

You don't want that expecialy on parts with holes or cavities.

A separate nozzle is just wanted if you need to use a soluble filament as support material.

So you don't care about oozing.

To me a perfect configuration would be 2/3 colours in one (like cyclops) + 1 nozzle for support material that can be disable if you don't use it.

On special print with limited oozing risks, that +1 nozzle can also be used for colour.

++JM

The 3D pictures are awsome, and the ideas are interesting.

On the last attempt, I can't imagine the price of that extruder if it were machined !

Just something you did not thought about.

The more closer are the nozzles, the worst oozing you'll get.

3 Separate nozzles are not interesting.

When you mix colours, you'd rather have several filaments getting out by the same nozzle. Like on the E3D cyclops.

It's the only way to get rid of oozing. You can build an ooze shield, but then you can't cool your part properly.

You don't want that expecialy on parts with holes or cavities.

A separate nozzle is just wanted if you need to use a soluble filament as support material.

So you don't care about oozing.

To me a perfect configuration would be 2/3 colours in one (like cyclops) + 1 nozzle for support material that can be disable if you don't use it.

On special print with limited oozing risks, that +1 nozzle can also be used for colour.

++JM

|

Re: TriloByte Extruder November 23, 2015 07:26AM |

Registered: 10 years ago Posts: 14,672 |

Quote

J-Max

The more closer are the nozzles, the worst oozing you'll get.

3 Separate nozzles are not interesting.

When you mix colours, you'd rather have several filaments getting out by the same nozzle. Like on the E3D cyclops.

It's the only way to get rid of oozing. You can build an ooze shield, but then you can't cool your part properly.

I print PLA with 2 nozzles and I never have a problem with oozing. The key is when switching tools, retract filament a little in the nozzle you have just finished printing with, and reduce the temperature of that nozzle to standby temperature (e.g. 150C for PLA). Meanwhile, heat the new active nozzle up from standby to active temperature. You don't need to wait for the inactive nozzle to cool right down to the standby temperature before resuming the print, but you obviously need to wait for the new active nozzle to reach printing temperature. RepRapFirmware makes all of this very easy to do because you define tool change files containing the gcodes you want to execute. However, most slicers also have a way of inserting extra gcodes when changing tools.

In my experience, the real problem with 2-nozzle printing is that if the standby nozzle crosses filament that has just been laid down by the printing nozzle, it leaves a mark. Ideally, the non-printing nozzle would be lifted half a mm or so. Failing that, it helps to increase the separation between the nozzles (so that the standby nozzle is less likely to cross filament that has just been laid down by the active nozzle), and to have a print cooling fan.

The single nozzle/multiple filaments idea is certainly interesting and would avoid this problem, however I have heard reports that when printing with one filament, the molten filament tends to creep up the other filament feeds and jam them.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: TriloByte Extruder November 23, 2015 09:43PM |

Registered: 8 years ago Posts: 1,671 |

Thanks for the input guys,

Sounds like trouble which ever way you go, but one nozzle with switching feeds sounds like the goal, dont have the worry of the other heads getting in the way, (I wondered how the positions of those would be mapped out in the code to avoid things?), maybe another nozzle dedicated to support material, one keeps things smaller & maybe cheaper, but agreed not with all the machining above.

I had thought about the temps in the different nozzles, and what happens to the materials while they are waiting to be used, full retractions needed, keeping the filament paths straight is a limit to designs, but so is drilling a bent hole...that diamond triple nozzle is starting to appear on ebay, but I dont really want 3 heatsinks all at weird angles, great for the delta's, but I need(sometime way down the line) something else smaller neater... The microscope idea was something that could be followed up on, perhaps just as a way to change the feed, not nozzle.

In a future version i'll explore that avenue, but in a linear fashion, would be nice if the change could be accomplished with some solenoids or servo's or combination of both, and great if it could also help out with retractions, without adding too much weight.

Sounds like trouble which ever way you go, but one nozzle with switching feeds sounds like the goal, dont have the worry of the other heads getting in the way, (I wondered how the positions of those would be mapped out in the code to avoid things?), maybe another nozzle dedicated to support material, one keeps things smaller & maybe cheaper, but agreed not with all the machining above.

I had thought about the temps in the different nozzles, and what happens to the materials while they are waiting to be used, full retractions needed, keeping the filament paths straight is a limit to designs, but so is drilling a bent hole...that diamond triple nozzle is starting to appear on ebay, but I dont really want 3 heatsinks all at weird angles, great for the delta's, but I need(sometime way down the line) something else smaller neater... The microscope idea was something that could be followed up on, perhaps just as a way to change the feed, not nozzle.

In a future version i'll explore that avenue, but in a linear fashion, would be nice if the change could be accomplished with some solenoids or servo's or combination of both, and great if it could also help out with retractions, without adding too much weight.

|

Re: TriloByte Extruder November 24, 2015 05:05AM |

Registered: 9 years ago Posts: 722 |

Hi guys

The Cyclops configuration is the only way I found to get rid of that issue.

No Jam encountered within a month of regular use...

I just noticed sometimes a small amount of contamination between the two materials.

When I worked with 2xE3D V6, my retract settings were 13mm, and I did not tryed any M190 gcode i must confess.

Multiple extrusion increases drasticaly time printing anyways.

Wipe and prime tower is a must to preserve continuous filament flow.

I guess changing temperature may increase printing time even more.

Anyways, if there is some fun about it, I consider dual material printing as a gadget for now.

Only an anecdotic percentage of the parts I print realy needs 2 colours or a soluble support material.

I will only keep a single printer with this feature, and If the firmware was the same,

I would probably mount the dual nozzle on a magnetic support to use it only if I need it, and that's not often !

++JM

Thanks for the input. That's exactly what I call oozing (English is not my main language, as you probably allready guess).Quote

dc42

In my experience, the real problem with 2-nozzle printing is that if the standby nozzle crosses filament that has just been laid down by the printing nozzle, it leaves a mark.

The Cyclops configuration is the only way I found to get rid of that issue.

No Jam encountered within a month of regular use...

I just noticed sometimes a small amount of contamination between the two materials.

When I worked with 2xE3D V6, my retract settings were 13mm, and I did not tryed any M190 gcode i must confess.

Multiple extrusion increases drasticaly time printing anyways.

Wipe and prime tower is a must to preserve continuous filament flow.

I guess changing temperature may increase printing time even more.

Anyways, if there is some fun about it, I consider dual material printing as a gadget for now.

Only an anecdotic percentage of the parts I print realy needs 2 colours or a soluble support material.

I will only keep a single printer with this feature, and If the firmware was the same,

I would probably mount the dual nozzle on a magnetic support to use it only if I need it, and that's not often !

++JM

|

Re: TriloByte Extruder November 24, 2015 06:22AM |

Registered: 10 years ago Posts: 14,672 |

I haven't found a wipe and prime tower necessary. On my dual extruder Ormerod, I use 10mm tool change retraction, which is the slic3r default and seems to work, and 150C standby temperature when printing PLA. Tool changes to take a little longer because of having to heat the new active tool up from the standby temperature. They took even longer before I implemented the firmware option to not wait for the other nozzle to cool down to standby temperature.

Here's an example of 1 2-colour print I did this way.

Edited 1 time(s). Last edit at 11/24/2015 06:24AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Here's an example of 1 2-colour print I did this way.

Edited 1 time(s). Last edit at 11/24/2015 06:24AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: TriloByte Extruder November 24, 2015 02:09PM |

Registered: 9 years ago Posts: 722 |

|

Re: TriloByte Extruder November 24, 2015 03:37PM |

Registered: 10 years ago Posts: 14,672 |

Quote

J-Max

Hi guys,

Yep, I know this pic.

I will try to play with tool change gcodes for Chimera mode extrusion.

Is there some trustable sources/examples for these gcodes ?

++JM

You can find the ones I used at [miscsolutions.wordpress.com] in the section on tool changes files.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: TriloByte Extruder November 24, 2015 03:47PM |

Registered: 8 years ago Posts: 1,671 |

I've only been playing with this design out of boredom, I know other solutions will appear long before I ever decide to build a multi extruder, cant see me wanting multi colour anytime soon, but this looks like an interesting development, [www.mosaicmanufacturing.com]

a little large & price might be a shocker though.

But a simpler colour wheel gate could be used to feed a bowden tube, i wouldnt mind some nice greyscale prints.

Edited 2 time(s). Last edit at 11/24/2015 04:05PM by MechaBits.

a little large & price might be a shocker though.

But a simpler colour wheel gate could be used to feed a bowden tube, i wouldnt mind some nice greyscale prints.

Edited 2 time(s). Last edit at 11/24/2015 04:05PM by MechaBits.

|

Re: TriloByte Extruder November 25, 2015 07:14PM |

Registered: 8 years ago Posts: 1,671 |

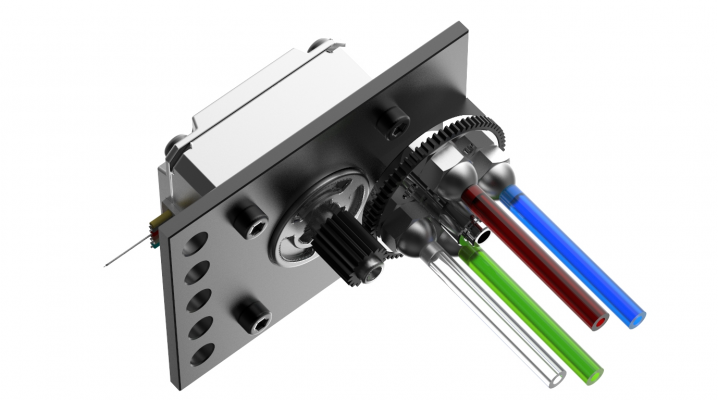

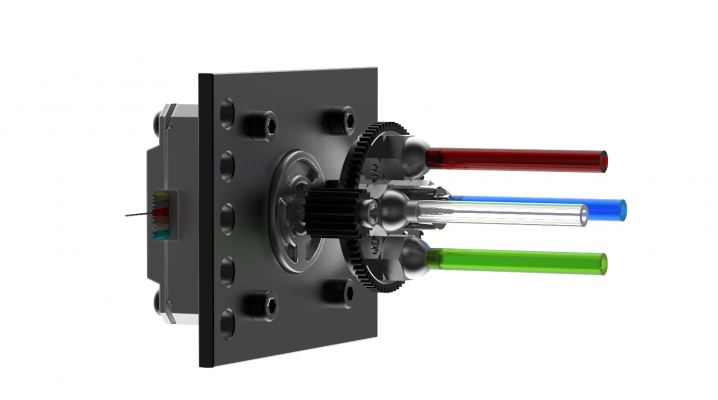

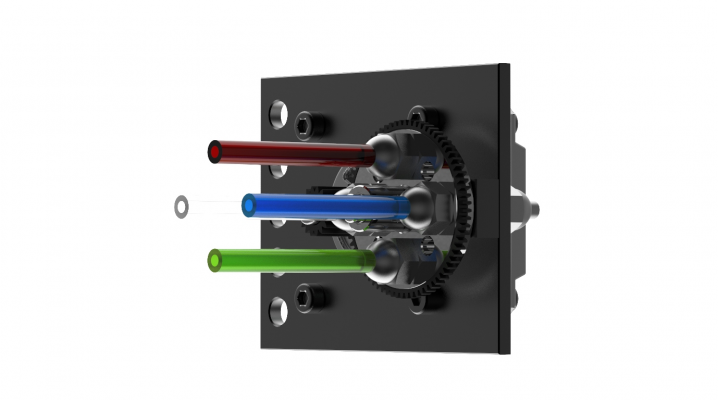

2 trains of thought at the moment, one rotational the other linear, the linear one only needs to move 0,9,18mm(though doesn't matter too much if its remote), just a simple dovetail block.

The other rotational one, could be belt or direct, so i tried direct first.

Wondering if I need to add a blade, or if retraction would be enough,

also with a tendency to make things more difficult than need be, initial thought where to add a rising motion to the turns, so it could disengage any recessed fitting, but maybe that's not needed either.

RGB for illustration purposes only, I know it needs cmyk, and there's probably already something like it?

Also doubles up as a multi-flavored colonic irrigation machine.

Edited 3 time(s). Last edit at 11/25/2015 10:39PM by MechaBits.

The other rotational one, could be belt or direct, so i tried direct first.

Wondering if I need to add a blade, or if retraction would be enough,

also with a tendency to make things more difficult than need be, initial thought where to add a rising motion to the turns, so it could disengage any recessed fitting, but maybe that's not needed either.

RGB for illustration purposes only, I know it needs cmyk, and there's probably already something like it?

Also doubles up as a multi-flavored colonic irrigation machine.

Edited 3 time(s). Last edit at 11/25/2015 10:39PM by MechaBits.

|

Re: TriloByte Extruder January 10, 2016 11:29PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: TriloByte Extruder June 01, 2016 04:39AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: TriloByte Extruder July 22, 2016 07:08AM |

Registered: 9 years ago Posts: 245 |

If you use the M4 heater cartridge the ultimaker 2 uses, you can make it smaller

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

|

Re: TriloByte Extruder July 22, 2016 09:17AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: TriloByte Extruder July 24, 2016 02:58AM |

Registered: 9 years ago Posts: 245 |

Also recommend you use a m3 hole for PT100 sensor or similar Thermocoupler. Same as E3Ds PT100 and UM2.

You can get thermocoupler with same measurements - I use these with E3Ds pt100 alu-blocks with smoothieware board which doesn't support pt100 sensors in firmware.

I really hate the standard thermistors... they can fail in a lot of ways and doesn't last very long if you change stuff a lot.

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

You can get thermocoupler with same measurements - I use these with E3Ds pt100 alu-blocks with smoothieware board which doesn't support pt100 sensors in firmware.

I really hate the standard thermistors... they can fail in a lot of ways and doesn't last very long if you change stuff a lot.

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

|

Re: TriloByte Extruder September 09, 2016 05:52PM |

Registered: 8 years ago Posts: 1,671 |

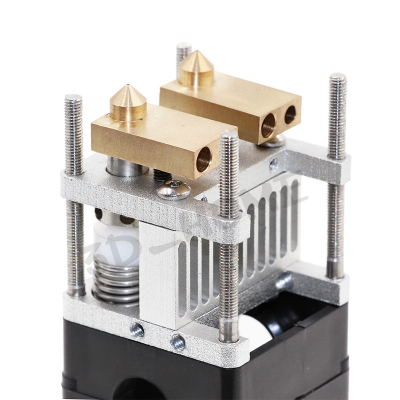

hmm the trilobite extruder lives, well sort of perhaps a little more thought went into what could be made...

[www.aliexpress.com]

I always wondered what the extra holes on the ultimakers print head plates would/could be used for other heads..

but this approach has done away with all of those extra parts....not sure I would trust this to work well but ya never know.

[www.aliexpress.com]

this one probably better, could do with one of those olsen blocks or similar.. will probably find it in

aliexpress, its like candyland, lots of new developments appearing, from injection molded bulldogs for a few dollars, titan clones, so much more choice than ebay.

Edited 4 time(s). Last edit at 09/09/2016 07:23PM by MechaBits.

[www.aliexpress.com]

I always wondered what the extra holes on the ultimakers print head plates would/could be used for other heads..

but this approach has done away with all of those extra parts....not sure I would trust this to work well but ya never know.

[www.aliexpress.com]

this one probably better, could do with one of those olsen blocks or similar.. will probably find it in

aliexpress, its like candyland, lots of new developments appearing, from injection molded bulldogs for a few dollars, titan clones, so much more choice than ebay.

Edited 4 time(s). Last edit at 09/09/2016 07:23PM by MechaBits.

|

Re: TriloByte Extruder September 09, 2016 08:05PM |

Registered: 8 years ago Posts: 318 |

damn mechabits, that is some sexy looking metal. How did you generate those renders?

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

|

Re: TriloByte Extruder September 09, 2016 08:24PM |

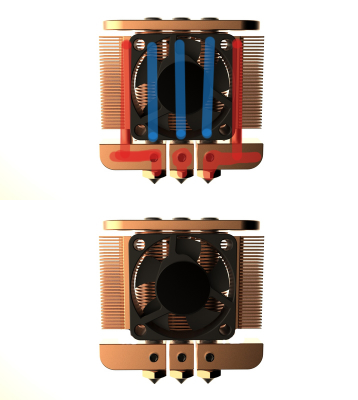

Registered: 8 years ago Posts: 318 |

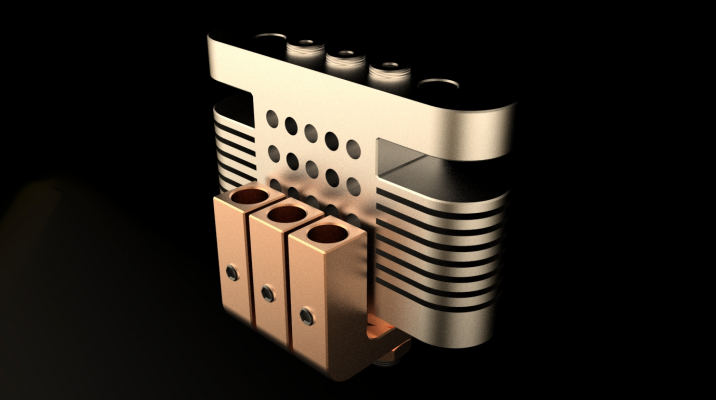

Uh, in this picture, arent two of those heat sinks cooling what should be the hot end instead of cooling the cold end? Tried to demonstrate what I mean, and how I think it should be with the picture

keep the hot side hot and the cold side cold

Edited 1 time(s). Last edit at 09/09/2016 08:25PM by DaGameFace.

keep the hot side hot and the cold side cold

Edited 1 time(s). Last edit at 09/09/2016 08:25PM by DaGameFace.

|

Re: TriloByte Extruder September 09, 2016 09:29PM |

Registered: 8 years ago Posts: 1,671 |

Well spotted...but what if you needed different temps(cut power to cartridge duh)...obviously then you'd need to change the fan part and split the fins, anyway these where just experiments, way to bulky...though obviously someone else didnt think so and carried on with the thought train...also it made the thing look more trilobite like, they where meant to be just heatpipes for the fins, here's another with glaringly obvious design flaw, good to add a red herring here n there...I, well at least I thought so, for copy detection, but people design around it, go the extra mile and then bobs your uncle new product hits the streets.

couldn't really mount a fan on this without the heater blocks being effected..though I am also starting to see more throats with integrated nozzles

renders done the easy way(a little too clinical), there was a time I used to enjoy tweeking with the render engines settings in 3DS Max...so much control...add some dirt n grime, roughened edges, ambient occlusion, but too much control is a real time eater, hours of toil, but things have moved on and great results are easy for anyone within easy reach of keyshot formerly bunkspeed hypershot,

Edited 3 time(s). Last edit at 09/10/2016 12:00AM by MechaBits.

couldn't really mount a fan on this without the heater blocks being effected..though I am also starting to see more throats with integrated nozzles

renders done the easy way(a little too clinical), there was a time I used to enjoy tweeking with the render engines settings in 3DS Max...so much control...add some dirt n grime, roughened edges, ambient occlusion, but too much control is a real time eater, hours of toil, but things have moved on and great results are easy for anyone within easy reach of keyshot formerly bunkspeed hypershot,

Edited 3 time(s). Last edit at 09/10/2016 12:00AM by MechaBits.

|

Re: TriloByte Extruder September 11, 2016 09:47AM |

Registered: 8 years ago Posts: 318 |

Cool! Will definitely look into it or some other render software, I didn't know i needed it until I saw those.

You said that people have copied these designs? Must say I'm kinda supprised

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

You said that people have copied these designs? Must say I'm kinda supprised

If you need some help, or don't understand what I just said, feel free to send me a PM anytime

Printer: Prusa i3, 2 E3D v6 Hotends, Arduino + RAMPS 1.4 with a Bypassed 5V Regulator, 400w Insignia ATX PSU, Custom Designed Bowden Extruders

|

Re: TriloByte Extruder September 11, 2016 03:14PM |

Registered: 8 years ago Posts: 1,671 |

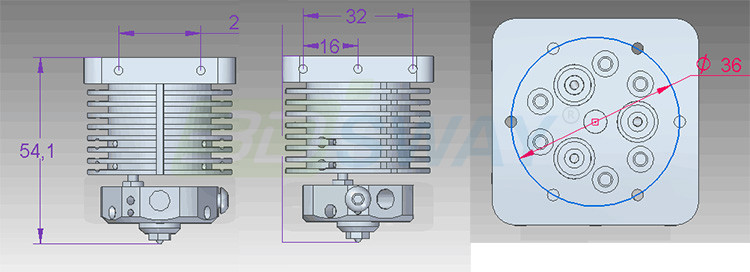

Copied...Derived, inspired? who knows....all I know is I hadnt seen this shape used before in a hotend

cylinder cut into 3 zones....then the other day I saw this

Have you ever seen this model of hotend before? I hadn't,

See in this Pic

the heatsinks where 3 distinct units, so obviously I needed to attach each one to each heater block, which is why you could see those 2 extra throats

what they are made of and how they would be machined is a different story.

Edited 1 time(s). Last edit at 09/11/2016 03:17PM by MechaBits.

cylinder cut into 3 zones....then the other day I saw this

Have you ever seen this model of hotend before? I hadn't,

See in this Pic

the heatsinks where 3 distinct units, so obviously I needed to attach each one to each heater block, which is why you could see those 2 extra throats

what they are made of and how they would be machined is a different story.

Edited 1 time(s). Last edit at 09/11/2016 03:17PM by MechaBits.

|

Re: TriloByte Extruder September 11, 2016 09:07PM |

Registered: 8 years ago Posts: 1,671 |

Quote

DaGameFace

You said that people have copied these designs? Must say I'm kinda supprised

All I can say on this is looking at the posts view count tells me someone's been looking/ interested...probably just because of the catchy name

and the promise of what it could be with a little collaborative development....

but I'm more interested in something simpler & smaller....3 nozzle throats, 3 heater blocks, cooler and not much else

and thats really why these designs where posted...to be continued.

Sorry, only registered users may post in this forum.