Cable management bad magnetic field or induction??? Or anything?

Posted by Bobyni

Cable management bad magnetic field or induction??? Or anything? November 14, 2015 05:27PM |

Registered: 9 years ago Posts: 221 |

Just wanted to know, what are the impacts (if any) when we bundle up all the cables that a 3 d printer has.....

Does it cause signals to be noisy?

Dies it cause print imperfection?

Does it cause anything at all?

I hope if you know something could share it with me/ us/ the community...

Thanks in advance!

Edited 2 time(s). Last edit at 11/14/2015 05:28PM by Bobyni.

Does it cause signals to be noisy?

Dies it cause print imperfection?

Does it cause anything at all?

I hope if you know something could share it with me/ us/ the community...

Thanks in advance!

Edited 2 time(s). Last edit at 11/14/2015 05:28PM by Bobyni.

Re: Cable management bad magnetic field or induction??? Or anything? November 14, 2015 07:46PM |

Registered: 10 years ago Posts: 580 |

I had to deal with this in my printer early on. It was a pain to find.

The printer would do random resets, particularly when a retract happened.

As I was exploring all possible causes, I shielded all my stepper cables as recommended here, all except the extruder's wires...

It turned out I had one particular particular wire running perpendicular to those extruder wires. That one wire was going to a reset button I had installed. It would decide to get a reset signal from that extruder at some random time during a 12 hour print...

Stepper motor wires are NOISY, because of the high inductive loads.

It is recommended to keep the stepper output cables as far away from any signal cable as possible - for instance: thermistor wiring, reset switch wires...

The heated bed wiring is also a potential issue, as heavy currents are being switched rapidly.

Having a wire running perpendicular to another wire is the best case for keeping them isolated, but you still do not want them close if one is noisy.

The other wires can be bundled.

Hope that helps!

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

The printer would do random resets, particularly when a retract happened.

As I was exploring all possible causes, I shielded all my stepper cables as recommended here, all except the extruder's wires...

It turned out I had one particular particular wire running perpendicular to those extruder wires. That one wire was going to a reset button I had installed. It would decide to get a reset signal from that extruder at some random time during a 12 hour print...

Stepper motor wires are NOISY, because of the high inductive loads.

It is recommended to keep the stepper output cables as far away from any signal cable as possible - for instance: thermistor wiring, reset switch wires...

The heated bed wiring is also a potential issue, as heavy currents are being switched rapidly.

Having a wire running perpendicular to another wire is the best case for keeping them isolated, but you still do not want them close if one is noisy.

The other wires can be bundled.

Hope that helps!

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Re: Cable management bad magnetic field or induction??? Or anything? November 15, 2015 10:23AM |

Registered: 9 years ago Posts: 221 |

Re: Cable management bad magnetic field or induction??? Or anything? November 15, 2015 10:33AM |

Registered: 10 years ago Posts: 580 |

Re: Cable management bad magnetic field or induction??? Or anything? November 15, 2015 11:00AM |

Registered: 11 years ago Posts: 5,780 |

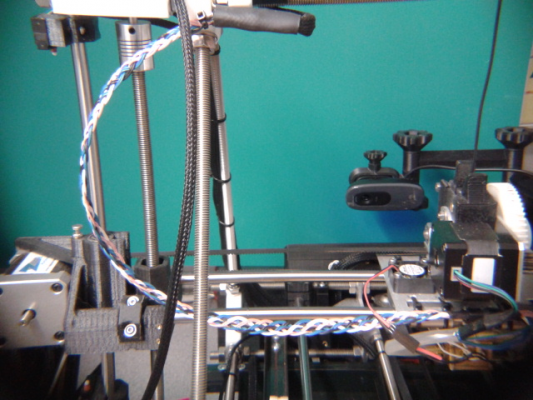

It's a good idea to twist current carrying wires into pairs. The twist helps organize the wires and helps control stray magnetic fields created by the current running in the wire. You can easily twist wires into pairs by clamping one end of a pair in a vise and putting the other end in the chuck of an electric drill. Pull the wires taut then run the drill while keeping some tension on the wires. You'll end up with beautifully twisted wires in a jiffy.

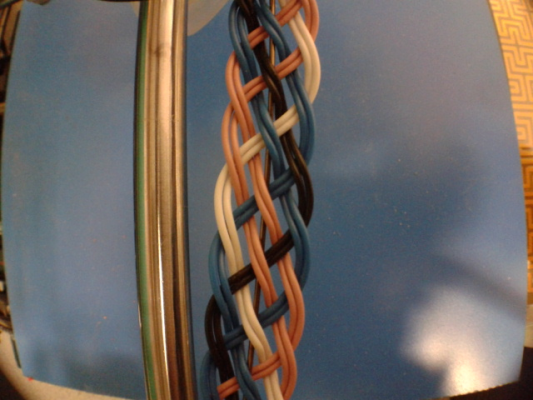

I like to braid the twisted pairs and single wires to help keep them organized, too. If you braid them you won't need external jacketing or loom. Of course, if you braid them, making changes later can be a little troublesome, but no more so than if you used loom or a jacket. It only takes a few minutes to braid them- clamp one in in a vise and manually do the braiding. There are a lot of web sites/videos that demonatrate how to braid any number of wires/cords.

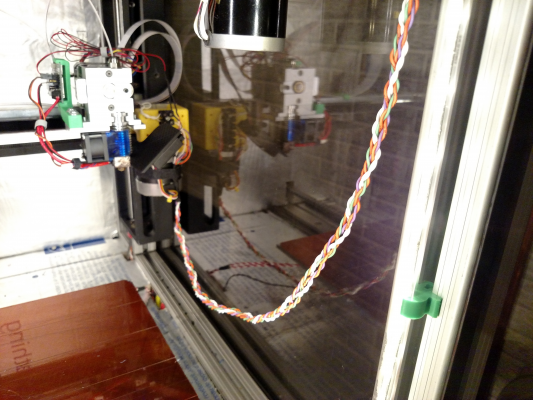

Here's the X axis cabling in my printer- the colored wires are for the motor coils and the white wires are for the X minimum limit switch. Each coil has its own twisted pair.

Edited 2 time(s). Last edit at 11/15/2015 11:04AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I like to braid the twisted pairs and single wires to help keep them organized, too. If you braid them you won't need external jacketing or loom. Of course, if you braid them, making changes later can be a little troublesome, but no more so than if you used loom or a jacket. It only takes a few minutes to braid them- clamp one in in a vise and manually do the braiding. There are a lot of web sites/videos that demonatrate how to braid any number of wires/cords.

Here's the X axis cabling in my printer- the colored wires are for the motor coils and the white wires are for the X minimum limit switch. Each coil has its own twisted pair.

Edited 2 time(s). Last edit at 11/15/2015 11:04AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: Cable management bad magnetic field or induction??? Or anything? November 15, 2015 01:36PM |

Registered: 9 years ago Posts: 221 |

Re: Cable management bad magnetic field or induction??? Or anything? November 16, 2015 06:18AM |

Registered: 12 years ago Posts: 1,450 |

The method of braiding the cables together used by the_digital_dentist has some additional advantages:

Nitinol wire is visible in the bunch or wires

Mike

Edited 1 time(s). Last edit at 11/16/2015 06:23AM by leadinglights.

- As there is a twisting component on the wires a braided bunch is more flexible than putting them in a sleeve or tying them together with cable ties or string.

- The noise performance is as good as twisted pair cable. Wires intended for picking up very low level signals (e.g. electrocardiograph) are frequently braided together for this reason

Nitinol wire is visible in the bunch or wires

Mike

Edited 1 time(s). Last edit at 11/16/2015 06:23AM by leadinglights.

Re: Cable management bad magnetic field or induction??? Or anything? November 16, 2015 06:45AM |

Registered: 10 years ago Posts: 14,672 |

There are two sorts of crosstalk you can get between electrical wires:

1. Magnetic induction. A cable carrying a current that varies rapidly (even if only occasionally) generates a magnetic field, which can be coupled to another cable. For example, a stepper motor or bed heater cable could induce a voltage in an endstop switch cable. Minimise this be making sure that the outgoing and return conductors carrying the current are as close together as possible (i.e. in the same multicore cable), and preferably twisting them together. Similarly for the signal and ground connections of the endstop switch circuit.

2. Capacitive coupling. A cable carrying a varying voltage runs close to a signal cable with a high impedance input, and the capacitance between the cables gives rise to a voltage on the signal cable. Minimise this by shielding one or both cables (independently), or keeping them away from each other, or avoiding high impedance signal inputs.

The problem the OP had was almost certainly caused by capacitive coupling.

These types of coupling have a bearing on whether you use NO or NC endstop switches. If you use NO switches and printer electronics with a high impedance input (e.g. RAMPS or RADDS), then you are at the mercy of capacitive coupling and you had better use shielded cable for the endstop switch cables. OTOH if you use NC switches then capacitive coupling is unlikely to be a problem. Inductive coupling could still be a problem; so use one multicore cable for the stepper motor and a separate twin core cable (or twisted pair) for the endstop switch.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Magnetic induction. A cable carrying a current that varies rapidly (even if only occasionally) generates a magnetic field, which can be coupled to another cable. For example, a stepper motor or bed heater cable could induce a voltage in an endstop switch cable. Minimise this be making sure that the outgoing and return conductors carrying the current are as close together as possible (i.e. in the same multicore cable), and preferably twisting them together. Similarly for the signal and ground connections of the endstop switch circuit.

2. Capacitive coupling. A cable carrying a varying voltage runs close to a signal cable with a high impedance input, and the capacitance between the cables gives rise to a voltage on the signal cable. Minimise this by shielding one or both cables (independently), or keeping them away from each other, or avoiding high impedance signal inputs.

The problem the OP had was almost certainly caused by capacitive coupling.

These types of coupling have a bearing on whether you use NO or NC endstop switches. If you use NO switches and printer electronics with a high impedance input (e.g. RAMPS or RADDS), then you are at the mercy of capacitive coupling and you had better use shielded cable for the endstop switch cables. OTOH if you use NC switches then capacitive coupling is unlikely to be a problem. Inductive coupling could still be a problem; so use one multicore cable for the stepper motor and a separate twin core cable (or twisted pair) for the endstop switch.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Cable management bad magnetic field or induction??? Or anything? November 17, 2015 12:02AM |

Registered: 9 years ago Posts: 221 |

Re: Cable management bad magnetic field or induction??? Or anything? November 17, 2015 02:27PM |

Registered: 11 years ago Posts: 805 |

Re: Cable management bad magnetic field or induction??? Or anything? November 17, 2015 04:48PM |

Registered: 10 years ago Posts: 14,672 |

Quote

sungod3k

are there any rules how to choose the paires to twist eg only the A coil and only the B coil or one wire from A with one wire from B

If you are going to twist them, use a separate twisted pair for each coil.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Re: Cable management bad magnetic field or induction??? Or anything? November 17, 2015 06:56PM |

Registered: 11 years ago Posts: 5,780 |

Quote

dc42

Quote

sungod3k

are there any rules how to choose the paires to twist eg only the A coil and only the B coil or one wire from A with one wire from B

If you are going to twist them, use a separate twisted pair for each coil.

To elaborate on this a little, think about what is happening when you twist the wires connected to one motor coil around each other. By twisting, you turned the wires into coils. Think about the current in one of the wires. A current in a coil produces a magnetic field that remains largely within the confines of the coil, until it escapes at the ends. With two wires twisted around each other, the currents move in opposite directions, so the magnet fields created are equal and opposite, thereby canceling each other out and greatly reducing the tendency for the twisted pair to induce noise in adjacent wires. Of course, it isn't perfect and there will always be leakage of the magnetic flux, especially at bends in the cable, but it works well enough.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: Cable management bad magnetic field or induction??? Or anything? November 17, 2015 10:19PM |

Registered: 11 years ago Posts: 805 |

Re: Cable management bad magnetic field or induction??? Or anything? November 17, 2015 10:30PM |

Registered: 11 years ago Posts: 5,780 |

Shielding prevents capacitive coupling but does nothing to prevent inductive coupling.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: Cable management bad magnetic field or induction??? Or anything? December 06, 2015 09:04PM |

Registered: 9 years ago Posts: 189 |

Thanks.

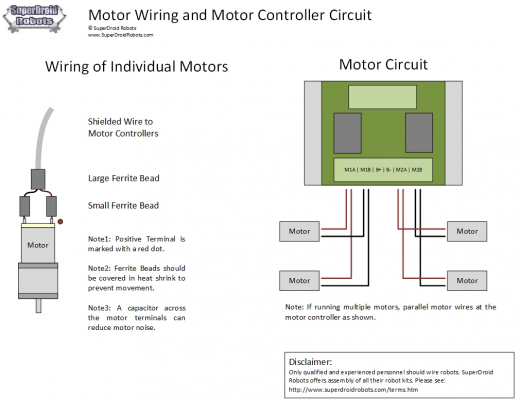

Ferrite core

Ferrite beads

Ferrite core

Ferrite beads

Re: Cable management bad magnetic field or induction??? Or anything? December 07, 2015 12:57AM |

Registered: 9 years ago Posts: 221 |

Sorry, only registered users may post in this forum.