Reprapable linear drives ...

Posted by VDX

|

Reprapable linear drives ... October 28, 2007 03:07PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi all,

... on sunday i was with my youngest son in the basement at my parents house, where we 'revisited' some of my old projects from scool-time, nearly thirty years ago ...

One of them was a workaround, where i converted a Brother-HR1-typewheelprinter in a pen-plotter for my oldstyled Commodore C64-homecomputer.

It was really working after the long time - a condensator in the powersupply fumed, but didn't change anything

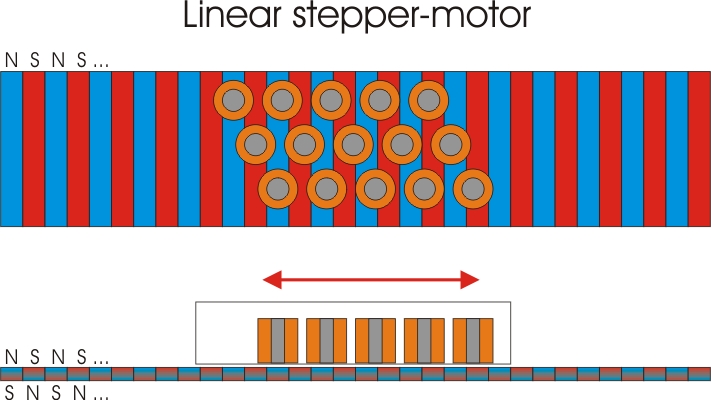

I checked, if the Printer-mechanics was worth to salvage and found, that the carriage wasn't driven by a steppermotor with a tooth-belt as usual, but was a direct-drive linear-stepper!!! - here the carriage holds several slightly displaced coils with small toothed iron-cores and a massive iron-bar as feeding, with same toothing as counterpart works as linear stepper-motor-setup, to travel the carriage by switching current in the right cores ...

Then me struck the idea, that a similar setup could easily be reprapped, when i insert magnets in the feeding and complementary coils in the mover.

So the X- and Y-axis with motors and feeding could be made completely by the reprap or from aluminium-blades and some feeding rolls ...

Here is an image, to show how the setup of a magnet<->coil linear stepper-drive could be arranged:

The magnets could be bought at [www.supermagnete.de] , the coils could be salvaged form old electromechanic switches or from telecom-relays ...

Viktor

... on sunday i was with my youngest son in the basement at my parents house, where we 'revisited' some of my old projects from scool-time, nearly thirty years ago ...

One of them was a workaround, where i converted a Brother-HR1-typewheelprinter in a pen-plotter for my oldstyled Commodore C64-homecomputer.

It was really working after the long time - a condensator in the powersupply fumed, but didn't change anything

I checked, if the Printer-mechanics was worth to salvage and found, that the carriage wasn't driven by a steppermotor with a tooth-belt as usual, but was a direct-drive linear-stepper!!! - here the carriage holds several slightly displaced coils with small toothed iron-cores and a massive iron-bar as feeding, with same toothing as counterpart works as linear stepper-motor-setup, to travel the carriage by switching current in the right cores ...

Then me struck the idea, that a similar setup could easily be reprapped, when i insert magnets in the feeding and complementary coils in the mover.

So the X- and Y-axis with motors and feeding could be made completely by the reprap or from aluminium-blades and some feeding rolls ...

Here is an image, to show how the setup of a magnet<->coil linear stepper-drive could be arranged:

The magnets could be bought at [www.supermagnete.de] , the coils could be salvaged form old electromechanic switches or from telecom-relays ...

Viktor

|

Re: Reprapable linear drives ... October 28, 2007 03:51PM |

Registered: 16 years ago Posts: 82 |

Hi Viktor,

How was the precision on the stepper? And how large were the magnets and coils? To get a decent range of movement, it would seem that you would need a _lot_ of magnets. Sounds like it could get expensive quickly, especially at >0,50 eu per magnet (>$.70). Still, it probably can't be _too_ much more expensive than the current stepper motors for Darwin, at about $60 each. If you could think of a decent pump, then I think I still like artificial muscles more. Of course, they could end up being harder to reprap.

Any ideas on how to make home-made magnets? Cheaper than manufactured? I doubt it, but it would help in making motors.

-Samuel

How was the precision on the stepper? And how large were the magnets and coils? To get a decent range of movement, it would seem that you would need a _lot_ of magnets. Sounds like it could get expensive quickly, especially at >0,50 eu per magnet (>$.70). Still, it probably can't be _too_ much more expensive than the current stepper motors for Darwin, at about $60 each. If you could think of a decent pump, then I think I still like artificial muscles more. Of course, they could end up being harder to reprap.

Any ideas on how to make home-made magnets? Cheaper than manufactured? I doubt it, but it would help in making motors.

-Samuel

|

Re: Reprapable linear drives ... October 28, 2007 04:19PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Samuel,

... 'China'-magnets can be cheap bought in big amounts for some cents each, so in bulks bought in Asia it's not so expensive ...

The coils can be wound manually with a drill, so it's best homemade ...

And the accuracy is dependant of the relation: step-width of the magnets against the amount and displacement of the coil-series - with aligned series of 8 coils in 4 rows i can make 32 full steps over the width of an magnet or 8-fold (= 256), when i use microstepping (some microstep-drivers output 1/128 steps!).

So a setup with 5mm-magnets would allow 0,02 mm per 1/8-micro-step ...

If you use thinner magnets or a finer milled toothed surface, as in the Brother-drive, then you can rise the accuracy to a higher level without using magnets.

So the question is, can i find very cheap magnets, or is it easier to mill the surface of a iron-feeding, to build a magnet-free linear drive, which only moves through induction?

To make magnets or magnetized objects at home you can use NdFeB-magnet-powder, mix it with an elastic airhardening or heatcuring resin, fill the paste in a form and apply a very strong magnet or solenoid to the form to 'teach' the polarity in the paste, until it harden - then you have a plastic-based magnet with a free defined form and field-geometry with maybe 70% to 80% the strentgh of a 'normal' NdFeB-Magnet (e.g. 0,9 Tesla max for a 'standard' mixture)

Viktor

... 'China'-magnets can be cheap bought in big amounts for some cents each, so in bulks bought in Asia it's not so expensive ...

The coils can be wound manually with a drill, so it's best homemade ...

And the accuracy is dependant of the relation: step-width of the magnets against the amount and displacement of the coil-series - with aligned series of 8 coils in 4 rows i can make 32 full steps over the width of an magnet or 8-fold (= 256), when i use microstepping (some microstep-drivers output 1/128 steps!).

So a setup with 5mm-magnets would allow 0,02 mm per 1/8-micro-step ...

If you use thinner magnets or a finer milled toothed surface, as in the Brother-drive, then you can rise the accuracy to a higher level without using magnets.

So the question is, can i find very cheap magnets, or is it easier to mill the surface of a iron-feeding, to build a magnet-free linear drive, which only moves through induction?

To make magnets or magnetized objects at home you can use NdFeB-magnet-powder, mix it with an elastic airhardening or heatcuring resin, fill the paste in a form and apply a very strong magnet or solenoid to the form to 'teach' the polarity in the paste, until it harden - then you have a plastic-based magnet with a free defined form and field-geometry with maybe 70% to 80% the strentgh of a 'normal' NdFeB-Magnet (e.g. 0,9 Tesla max for a 'standard' mixture)

Viktor

|

Re: Reprapable linear drives ... October 28, 2007 05:07PM |

Registered: 16 years ago Posts: 82 |

|

Re: Reprapable linear drives ... October 28, 2007 05:48PM |

Admin Registered: 16 years ago Posts: 13,884 |

|

Re: Reprapable linear drives ... December 06, 2007 10:18PM |

Registered: 16 years ago Posts: 2 |

|

Re: Reprapable linear drives ... December 07, 2007 01:26AM |

Registered: 16 years ago Posts: 161 |

I think this idea is fantastic!!

It has always been my feeling that There were 3 big hurdles to be overcome before RepRap could really become self-reproducing.

1: strong rigid structural members - Replacements for the metal rods in Darwin-

this is not a fundamental problem, either create a printer based on a sturdy plastic box (simple but uses lots of plastic) or find a way to use RepRap to create molds for casting and tools for finishing metal pieces (more complicated but doing these things is probably an inevitable part of the machines' development) or find a way to extrude rigid elements from other materials such as carbon fiber composites (probably farther out technologically).

2: circuitry - teaching the machine to create the electronics for itself -

the level of difficulty here runs from minimal to massive depending on your definition of "create the electronics". A printhead for circuit traces is probably going to be part of Mendel (just a guess) but that leaves a person to assemble and solder the actual components into an actual circuit. This is probably the most daunting part of the assembly for some people(me). On the other hand getting a machine to do that type of work is the cutting edge of current AI research. Some possibilities for intermediate level of self assembly include developing a fab-able circuit board based on a proto board so that pieces can be simply inserted according to a diagram printed on the board and it will work without soldering, or again, farther down the road, the technology to fab electronic components in place

3: motors - teaching the machine to create its' own mechanical actuators -

this is finally the reason this rant is posted here. How to fab motors has always been a sticking point. Decently efficient electric motors are precision instruments well beyond anything we are realistically talking about extruding and even with CAM machine tools the setup, assembly and testing would be daunting. Artificial muscles are (my opinion) at the same technological distance as fab-in-place circuitry. BUT.... if we can fab the magnetic strip, as seems likely, the rest seems fairly straight forward, winding electromagnets is easy and the framework to hold it all in place is simple and not too highly stressed. To increase the force available we just add extra rows of electromagnets in parallel over a wider magnet strip. The software is stepper software and registration marks could be printed on the strip to allow it to be used as a servo. If we can do away with the need to buy our 3 largest motors (which are also our most expensive items) we may have slain the last of our demons.

OK- real bearings are a challenge but still...

It has always been my feeling that There were 3 big hurdles to be overcome before RepRap could really become self-reproducing.

1: strong rigid structural members - Replacements for the metal rods in Darwin-

this is not a fundamental problem, either create a printer based on a sturdy plastic box (simple but uses lots of plastic) or find a way to use RepRap to create molds for casting and tools for finishing metal pieces (more complicated but doing these things is probably an inevitable part of the machines' development) or find a way to extrude rigid elements from other materials such as carbon fiber composites (probably farther out technologically).

2: circuitry - teaching the machine to create the electronics for itself -

the level of difficulty here runs from minimal to massive depending on your definition of "create the electronics". A printhead for circuit traces is probably going to be part of Mendel (just a guess) but that leaves a person to assemble and solder the actual components into an actual circuit. This is probably the most daunting part of the assembly for some people(me). On the other hand getting a machine to do that type of work is the cutting edge of current AI research. Some possibilities for intermediate level of self assembly include developing a fab-able circuit board based on a proto board so that pieces can be simply inserted according to a diagram printed on the board and it will work without soldering, or again, farther down the road, the technology to fab electronic components in place

3: motors - teaching the machine to create its' own mechanical actuators -

this is finally the reason this rant is posted here. How to fab motors has always been a sticking point. Decently efficient electric motors are precision instruments well beyond anything we are realistically talking about extruding and even with CAM machine tools the setup, assembly and testing would be daunting. Artificial muscles are (my opinion) at the same technological distance as fab-in-place circuitry. BUT.... if we can fab the magnetic strip, as seems likely, the rest seems fairly straight forward, winding electromagnets is easy and the framework to hold it all in place is simple and not too highly stressed. To increase the force available we just add extra rows of electromagnets in parallel over a wider magnet strip. The software is stepper software and registration marks could be printed on the strip to allow it to be used as a servo. If we can do away with the need to buy our 3 largest motors (which are also our most expensive items) we may have slain the last of our demons.

OK- real bearings are a challenge but still...

|

Re: Reprapable linear drives ... December 09, 2007 03:43PM |

Registered: 16 years ago Posts: 900 |

Hmmm

Like the idea of linear drive.

I think we need an stl design, motoring and circuitry for a universal winder.

Coiling automated bliss, by hand erm sperm of the devil.

I need one anyway as on my list of items to reprap is a leccy windmill.....

cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

Like the idea of linear drive.

I think we need an stl design, motoring and circuitry for a universal winder.

Coiling automated bliss, by hand erm sperm of the devil.

I need one anyway as on my list of items to reprap is a leccy windmill.....

cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: Reprapable linear drives ... December 11, 2007 01:15AM |

Registered: 16 years ago Posts: 622 |

|

Re: Reprapable linear drives ... December 11, 2007 02:24AM |

Registered: 16 years ago Posts: 900 |

I can recommend as reading anything by Hugh Piggot. He's a Scottish guy who lives on the scoraig peninsula does wind power to death.

Particularly making your own alternator/wind turbine using break drum components in the building of the alternator.

Clever guy with shed loads of kitchen table technology, including lathing molds for permag, axial alternators using a made up lathe from a washing machine motor. (My sort of guy)

He has published a very good book that was available from CAT (Centre for Alternative Technology, Macllineth Wales, [www.cat.org.uk]) Called Wind Power Workshop.

I think he also has a web site Scoraig Wind Power as well as a consulting business doing the same.

Sorry I guess this appears slightly off topic

Back to winding coils for linear motors. Hugh's designs for alternators and wind turbines do include a load of useful stuff on motors. alternators and winding your own coils. So whilst being for something other than linear motors, his stuff on three phase alternators is directly transferable.

The three phase method of overlapping coils on a suitable ferro former can of course be layed out in a straight strip. to form the linear armature.

Although I think Viktors idea above potentially cooler, 3 phase isn't that new or trendy.

For making a ferro former I think it should be possible to reprap a plug for molding the plate from resin filled with something magnetic i.e. ferrite or some such, possibly in a three step process. (although one to two would be better, Ferro component followed by encapsulant after coil insertion).

I think Viktor is probably going to be the man when it comes to suggesting a suitable filler/resin combo, I get the feeling it could even be something that he has had a crack at, at some time or other.

Additionally is it worth considering using victors method as above but standing the magnet strip up on it's side. The motor coiled bits could then be arranged like the letter C with the open part of the C sitting over the strip and the coils arranged one on each arm of the C giving a N and a S for each magnet straddled ergo twice the grip/strength. I remember reading somewhere that it is better to coil this way rather than around the middle of the C shape of the magnetic circuit as it concentrates the Magnetic flux better across the air gap. The C shape creates a better magnetic circuit too. Sorry can't remember where I read it but it makes sense if you plot lines of magnetic force and think of magnetism in terms flow, a bit like current. (Remember the iron fillings, paper and bar magnet thing at school)

Thoughts for what they are worth.

What do you guys think ??

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

Particularly making your own alternator/wind turbine using break drum components in the building of the alternator.

Clever guy with shed loads of kitchen table technology, including lathing molds for permag, axial alternators using a made up lathe from a washing machine motor. (My sort of guy)

He has published a very good book that was available from CAT (Centre for Alternative Technology, Macllineth Wales, [www.cat.org.uk]) Called Wind Power Workshop.

I think he also has a web site Scoraig Wind Power as well as a consulting business doing the same.

Sorry I guess this appears slightly off topic

Back to winding coils for linear motors. Hugh's designs for alternators and wind turbines do include a load of useful stuff on motors. alternators and winding your own coils. So whilst being for something other than linear motors, his stuff on three phase alternators is directly transferable.

The three phase method of overlapping coils on a suitable ferro former can of course be layed out in a straight strip. to form the linear armature.

Although I think Viktors idea above potentially cooler, 3 phase isn't that new or trendy.

For making a ferro former I think it should be possible to reprap a plug for molding the plate from resin filled with something magnetic i.e. ferrite or some such, possibly in a three step process. (although one to two would be better, Ferro component followed by encapsulant after coil insertion).

I think Viktor is probably going to be the man when it comes to suggesting a suitable filler/resin combo, I get the feeling it could even be something that he has had a crack at, at some time or other.

Additionally is it worth considering using victors method as above but standing the magnet strip up on it's side. The motor coiled bits could then be arranged like the letter C with the open part of the C sitting over the strip and the coils arranged one on each arm of the C giving a N and a S for each magnet straddled ergo twice the grip/strength. I remember reading somewhere that it is better to coil this way rather than around the middle of the C shape of the magnetic circuit as it concentrates the Magnetic flux better across the air gap. The C shape creates a better magnetic circuit too. Sorry can't remember where I read it but it makes sense if you plot lines of magnetic force and think of magnetism in terms flow, a bit like current. (Remember the iron fillings, paper and bar magnet thing at school)

Thoughts for what they are worth.

What do you guys think ??

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: Reprapable linear drives ... December 11, 2007 08:37AM |

Registered: 16 years ago Posts: 622 |

Andy,

Standing things on there side sounds pretty good. I can't think of any drawbacks off hand but I'm sure Viktor will have something to say on it. There still hasn't been a post as to the cost of this magnetic powder so I wouldn't go jumping the gun yet. Could be _quite_ expensive. Time will tell.

Demented

Standing things on there side sounds pretty good. I can't think of any drawbacks off hand but I'm sure Viktor will have something to say on it. There still hasn't been a post as to the cost of this magnetic powder so I wouldn't go jumping the gun yet. Could be _quite_ expensive. Time will tell.

Demented

|

Re: Reprapable linear drives ... December 11, 2007 10:04AM |

Admin Registered: 16 years ago Posts: 13,884 |

... here an update:

The guys at Supermagnete.de didn't sell powder, VAC didn't want to give their parts away, so i actually didn't find usable NdFeB-powder, but will try further ...

For a selfmade approach there could be made some hard-magnetic powder by chrunching down big magnets with a ball-mill or try to find ready NdFeB-resin-strips (should be silvery-coloured instead of brown-black as with Ferrite).

Most of the magnetic-strips are already magnetized alternating, that's what we need!

But the normal ones with Ferrite are so 'soft-magnetic', that you can easily remagnetize them with a powered coil ...

My hint is to try with toothed iron-bars - i have some linear gear-sticks from iron salvaged from old copy-printers, so they should be common in stores, that sell ACME-spindles too.

Then you didn't want to mess around with magnetic stuff, but can build pure inductive drives with coils to iron-teeth-orientation ...

Viktor

The guys at Supermagnete.de didn't sell powder, VAC didn't want to give their parts away, so i actually didn't find usable NdFeB-powder, but will try further ...

For a selfmade approach there could be made some hard-magnetic powder by chrunching down big magnets with a ball-mill or try to find ready NdFeB-resin-strips (should be silvery-coloured instead of brown-black as with Ferrite).

Most of the magnetic-strips are already magnetized alternating, that's what we need!

But the normal ones with Ferrite are so 'soft-magnetic', that you can easily remagnetize them with a powered coil ...

My hint is to try with toothed iron-bars - i have some linear gear-sticks from iron salvaged from old copy-printers, so they should be common in stores, that sell ACME-spindles too.

Then you didn't want to mess around with magnetic stuff, but can build pure inductive drives with coils to iron-teeth-orientation ...

Viktor

|

Re: Reprapable linear drives ... December 11, 2007 12:12PM |

Registered: 16 years ago Posts: 900 |

Hmmm

The ferrite or ferous material to use as filler doesnt want to retain magnetic field otherwise the linear would be severely impared.

The Resin and Ferous filler is a replacment for the soft iron laminations in a motor/generator that complete or form the magnetic circuit.

A ferrous filler that has a high hysteresis ie retains too much of the orientation of it's last magnetisation will resist the change in polarity when you switch the current in the coils the other way around (as in stepper, or motor). Bad, bad, bad.

A soft iron powder should do provided you can make sure that there the end product resin + filler does'nt readily conduct (preferably not at all for the voltage ranges likely to be induced) this is to eliminate/reduce eddy currents (The things that make transformers hum and get hot).

For filler I was thinking more of Ferrite as in ferrite rods or pot cores ground up if you cannot find a supplier of the powder that ferrite rods and pot cores are cast from.

High hystererisis = low coercivity which in magnetic circuits is bad.

Overall I think Viktors idea re magnet strip was excellent but needs standing on it's side. the coils/placment and magnetic circuit need a bit of thinking about but are probably 50% of the way to something.

Once you have an apparently viable design then it can be costed and if looking favorable trialled ...

More thoughts probably worth even less.

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

The ferrite or ferous material to use as filler doesnt want to retain magnetic field otherwise the linear would be severely impared.

The Resin and Ferous filler is a replacment for the soft iron laminations in a motor/generator that complete or form the magnetic circuit.

A ferrous filler that has a high hysteresis ie retains too much of the orientation of it's last magnetisation will resist the change in polarity when you switch the current in the coils the other way around (as in stepper, or motor). Bad, bad, bad.

A soft iron powder should do provided you can make sure that there the end product resin + filler does'nt readily conduct (preferably not at all for the voltage ranges likely to be induced) this is to eliminate/reduce eddy currents (The things that make transformers hum and get hot).

For filler I was thinking more of Ferrite as in ferrite rods or pot cores ground up if you cannot find a supplier of the powder that ferrite rods and pot cores are cast from.

High hystererisis = low coercivity which in magnetic circuits is bad.

Overall I think Viktors idea re magnet strip was excellent but needs standing on it's side. the coils/placment and magnetic circuit need a bit of thinking about but are probably 50% of the way to something.

Once you have an apparently viable design then it can be costed and if looking favorable trialled ...

More thoughts probably worth even less.

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

|

Re: Reprapable linear drives ... December 11, 2007 02:23PM |

Admin Registered: 16 years ago Posts: 13,884 |

... for induction-driving without magnets: - the common toothed rods can be found as "rack and pinion"-setups.

When using the rack-teeth instead of magnet-poles, it's the same as with non-magnetic stepper-motors - the active coils 'snap-on' at the nearest tooth, so with more slightly displaced racks and fitting coil-arrays you can build the same fine-moving linear motors as with the magnetic setup.

Only if you cut off the current, there is no holding-force as with magnets.

When i'll disassemble my Brother-typewheel-printer with the linear motor, then i would make some photos - here is the same principle without magnets working ...

Viktor

When using the rack-teeth instead of magnet-poles, it's the same as with non-magnetic stepper-motors - the active coils 'snap-on' at the nearest tooth, so with more slightly displaced racks and fitting coil-arrays you can build the same fine-moving linear motors as with the magnetic setup.

Only if you cut off the current, there is no holding-force as with magnets.

When i'll disassemble my Brother-typewheel-printer with the linear motor, then i would make some photos - here is the same principle without magnets working ...

Viktor

|

Re: Reprapable linear drives ... June 01, 2008 02:59PM |

Admin Registered: 16 years ago Posts: 13,884 |

... update ...

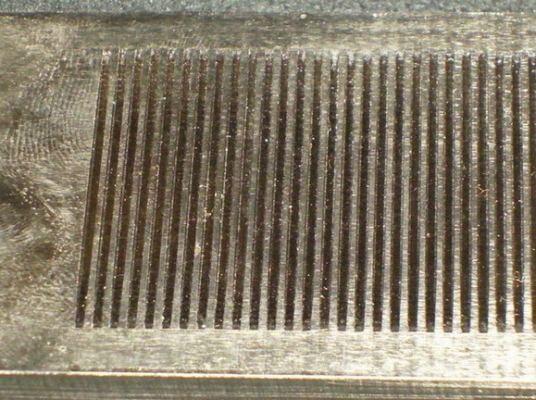

For a thread in another forum i disassembled the Brother-HR1-printer (see the first post in this thread) and made some photos of the linear drive.

The printer (the steel-barn is the toothed stator):

Toothed stator:

The coils with toothed iron-cores (4 coils in a row):

Viktor

For a thread in another forum i disassembled the Brother-HR1-printer (see the first post in this thread) and made some photos of the linear drive.

The printer (the steel-barn is the toothed stator):

Toothed stator:

The coils with toothed iron-cores (4 coils in a row):

Viktor

|

Re: Reprapable linear drives ... June 02, 2008 12:21PM |

Registered: 15 years ago Posts: 16 |

I've been thinking about this idea, and I'm glad others are thinking of it as well.

It might be possible to build an electromagnet out of simple solder and plastic. The arrangement should be simulated, I'm wondering if there are any programs out there that can simulate magnetic fields.

I think that if you made a board with grooves, then filled those grooves with solder, then covered those grooves with a layer of plastic, then you'd have the makings of a shielded cable that could be used to connect to the RepRap-ed stepper motor. This board could then also serve as the interface between the drivers for your motors. The drivers should be integrated into one unit, the Arduino unit, so that this one unit can be distributed and integrated into one place easily, which would be the electrical distribution board.

This will be the component that is un-RepRap-able, which would be a future Arduino unit. This could be manufactured in bulk and distributed, however.

The Arduino should be able to accept a USB-key (someone said this earlier), and if the key has an LCD display, the key can select existing open source STL files.

So, those are my assorted thoughts on this subject.

It might be possible to build an electromagnet out of simple solder and plastic. The arrangement should be simulated, I'm wondering if there are any programs out there that can simulate magnetic fields.

I think that if you made a board with grooves, then filled those grooves with solder, then covered those grooves with a layer of plastic, then you'd have the makings of a shielded cable that could be used to connect to the RepRap-ed stepper motor. This board could then also serve as the interface between the drivers for your motors. The drivers should be integrated into one unit, the Arduino unit, so that this one unit can be distributed and integrated into one place easily, which would be the electrical distribution board.

This will be the component that is un-RepRap-able, which would be a future Arduino unit. This could be manufactured in bulk and distributed, however.

The Arduino should be able to accept a USB-key (someone said this earlier), and if the key has an LCD display, the key can select existing open source STL files.

So, those are my assorted thoughts on this subject.

|

Re: Reprapable linear drives ... June 02, 2008 02:08PM |

Admin Registered: 16 years ago Posts: 13,884 |

... here: [femm.foster-miller.net] you can download a free finite-elements-simulator for magnetic fields (for Windows).

Viktor

Viktor

|

Re: Reprapable linear drives ... June 02, 2008 02:22PM |

Admin Registered: 17 years ago Posts: 1,915 |

I'm looking at figuring out how to Reprap these.

I'm for using a spark erosion machining head for Tommelise 2.0 to do the job. That way I don't have to worry about the tool loading that ordinary routers and grinders put on my xyz positioning system.

[en.wikipedia.org]

Edited 2 time(s). Last edit at 06/02/2008 02:46PM by Forrest Higgs.

I'm for using a spark erosion machining head for Tommelise 2.0 to do the job. That way I don't have to worry about the tool loading that ordinary routers and grinders put on my xyz positioning system.

[en.wikipedia.org]

Edited 2 time(s). Last edit at 06/02/2008 02:46PM by Forrest Higgs.

|

Re: Reprapable linear drives ... June 02, 2008 08:08PM |

Registered: 16 years ago Posts: 174 |

Why use EDM when you can use the simpler electrochemical machining: [fabathome.org]

But having a homemade ECM or EDM machine would really cool, EDM is accurate enough to make the molds for coins.

But having a homemade ECM or EDM machine would really cool, EDM is accurate enough to make the molds for coins.

|

Re: Reprapable linear drives ... June 03, 2008 03:22AM |

Registered: 16 years ago Posts: 361 |

|

Re: Reprapable linear drives ... June 03, 2008 04:05AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Ru,

i already mentioned using elastic magnetic stripes made from NdFeB-powder embedded in resin (see 3-rd post).

But for orienting the magnetized particles in the hardening resin you need much more magnetic field than usual, as you have to overcome the high forces between the already magnetized particles to rotate them in the right direction ...

Viktor

i already mentioned using elastic magnetic stripes made from NdFeB-powder embedded in resin (see 3-rd post).

But for orienting the magnetized particles in the hardening resin you need much more magnetic field than usual, as you have to overcome the high forces between the already magnetized particles to rotate them in the right direction ...

Viktor

|

Re: Reprapable linear drives ... June 03, 2008 04:12AM |

Registered: 16 years ago Posts: 361 |

|

Re: Reprapable linear drives ... June 03, 2008 07:25AM |

Registered: 15 years ago Posts: 16 |

|

Re: Reprapable linear drives ... June 03, 2008 09:35PM |

Registered: 15 years ago Posts: 251 |

Greetings all,

I'm new to this forum, so please bear with me.

This type of linear stepper motor is also known as a Sawyer motor, after the inventor. The patent citation is Sawyer, B., \Magnetic Positioning Device," U.S.

Patent 3,376,578, April 1968. Online (w/the right plugin) at: [patft.uspto.gov]

Making such actuators doesn't need large numbers of magnets, just lots of little iron (or other magnetic meaterial) teeth, usually carved into larger structures. There's a good diagram on page 21-66 of [pergatory.mit.edu]

The extension to 2-D has also been used in robotic workcells for small part assembly, by at least three companies: Automatix Inc.,

AT&T Bell Laboratories, Megamation. (I don't know if any of these are still being made, though.) I think this was also used as the basis for a high-speed plotter, but I can't recall the name of the company (except that it had XY in the name.) In the 2-D version, the two pieces are often separated by an air bearing.

These are certainly cool, but (if memory serves) usually are best in high velocity, relatively low force applications. (Much easier to gear rotary actuation, so these may not be the best match to rep-rap, but that's only a preliminary guess, not having even slept on it.)

It seems to me that for actuators, not being able to use iron/silicon steel is a serious drawback, so I'm dreaming of a reprap that can do both additive and subtractive machining.

-- Larry

I'm new to this forum, so please bear with me.

This type of linear stepper motor is also known as a Sawyer motor, after the inventor. The patent citation is Sawyer, B., \Magnetic Positioning Device," U.S.

Patent 3,376,578, April 1968. Online (w/the right plugin) at: [patft.uspto.gov]

Making such actuators doesn't need large numbers of magnets, just lots of little iron (or other magnetic meaterial) teeth, usually carved into larger structures. There's a good diagram on page 21-66 of [pergatory.mit.edu]

The extension to 2-D has also been used in robotic workcells for small part assembly, by at least three companies: Automatix Inc.,

AT&T Bell Laboratories, Megamation. (I don't know if any of these are still being made, though.) I think this was also used as the basis for a high-speed plotter, but I can't recall the name of the company (except that it had XY in the name.) In the 2-D version, the two pieces are often separated by an air bearing.

These are certainly cool, but (if memory serves) usually are best in high velocity, relatively low force applications. (Much easier to gear rotary actuation, so these may not be the best match to rep-rap, but that's only a preliminary guess, not having even slept on it.)

It seems to me that for actuators, not being able to use iron/silicon steel is a serious drawback, so I'm dreaming of a reprap that can do both additive and subtractive machining.

-- Larry

|

Re: Reprapable linear drives ... June 04, 2008 06:38PM |

Registered: 15 years ago Posts: 24 |

We have a few of these kicking about at work

[www.eclipse-magnetics.co.uk]

And a really large one on the big CNC machine (6'x4' at least) that can do 15mm cuts through plate steel with a 10mm cutter at high speed, with the magnet holding it in place easily.

Cant see an online vendor for pricing though....

Building it out of a pair of electromagents is more rappable than a perm and electro really.

J.

[www.eclipse-magnetics.co.uk]

And a really large one on the big CNC machine (6'x4' at least) that can do 15mm cuts through plate steel with a 10mm cutter at high speed, with the magnet holding it in place easily.

Cant see an online vendor for pricing though....

Building it out of a pair of electromagents is more rappable than a perm and electro really.

J.

|

Re: Reprapable linear drives ... June 04, 2008 06:45PM |

Registered: 15 years ago Posts: 24 |

Hmm pricey (more than ball screws)...

[www.chronos.ltd.uk]

Near the bottom, but the concept is still there, you could ask supermagnets to deliver a unit which is one piece and suitable that has 1mm protrusions like a H to achieve the same effect, and reprap the gaps in the H with plastic.

J.

[www.chronos.ltd.uk]

Near the bottom, but the concept is still there, you could ask supermagnets to deliver a unit which is one piece and suitable that has 1mm protrusions like a H to achieve the same effect, and reprap the gaps in the H with plastic.

J.

|

Re: Reprapable linear drives ... May 27, 2013 01:08AM |

Registered: 10 years ago Posts: 55 |

I had built a very similar design at one point. A linear drive used two coils that had C-shaped laminated cores. Both ends of the core were employed in the process when a coil was energized...

I used ready-made junk parts. My machine crawled across a 2D table. A permanent magnet held it flush to the surface of the glass. Soft iron stock cubes were used to attract electromagnets. Plastic beads were used to space those cubes evenly before the asphalt caulk solidified...

I really want to develop this idea. I live in Frederick MD, USA.

Everything else was the same, the way vernier calipers work...

I used ready-made junk parts. My machine crawled across a 2D table. A permanent magnet held it flush to the surface of the glass. Soft iron stock cubes were used to attract electromagnets. Plastic beads were used to space those cubes evenly before the asphalt caulk solidified...

I really want to develop this idea. I live in Frederick MD, USA.

Everything else was the same, the way vernier calipers work...

|

Re: Reprapable linear drives ... May 27, 2013 01:56AM |

Admin Registered: 16 years ago Posts: 13,884 |

... there were some professional developments with 2D tooth-milled steel-plates as stator grid and multiple 'planar steppers' arranged in a form so the moving part could be displaced linear with some ten microns accuracy and/or or rotated with high angular resolution.

The XY-positioning feedbach was made with PC-mouse ssensors ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The XY-positioning feedbach was made with PC-mouse ssensors ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Reprapable linear drives ... May 27, 2013 06:06AM |

Registered: 11 years ago Posts: 973 |

Demented Chihuahua Wrote:

-------------------------------------------------------

> Ah, the windmill idea! Great one that has been

> tossed around before. Don't know if the link is

> still up in the wiki but had a great bit about

> making a windmill from odds and ends. Very

> awesome. Must have one (20) myself.

>

> Demented

have you checked this out vertical axis wind turbine

-------------------------------------------------------

> Ah, the windmill idea! Great one that has been

> tossed around before. Don't know if the link is

> still up in the wiki but had a great bit about

> making a windmill from odds and ends. Very

> awesome. Must have one (20) myself.

>

> Demented

have you checked this out vertical axis wind turbine

Sorry, only registered users may post in this forum.