Building a concrete 3D printer - need help with movement

Posted by mekastudios

|

Re: Building a concrete 3D printer - need help with movement December 22, 2015 03:11AM |

Registered: 10 years ago Posts: 14,672 |

What are your Z steps/mm, and the maximum speed, jerk speed and acceleration configured for the Z axis in firmware?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Building a concrete 3D printer - need help with movement December 22, 2015 03:51AM |

Registered: 10 years ago Posts: 71 |

|

Re: Building a concrete 3D printer - need help with movement December 22, 2015 04:29AM |

Registered: 10 years ago Posts: 14,672 |

I think the problem is that your Z steps/mm is very low for a printer with a relatively heavy extruder. But you can try setting a much lower Z jerk speed, for example 1mm/sec or even less, and a lower Z acceleration such as 10mm/sec^2.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Building a concrete 3D printer - need help with movement December 22, 2015 05:27PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Building a concrete 3D printer - need help with movement December 22, 2015 07:33PM |

Registered: 10 years ago Posts: 71 |

I'm not sure I get what you mean with the pulley and counter weights.

We're having such a hard time with the z-axis, the movement is really unreliable.

i'm jut about to just change it to a lead screw system. What do you think?

I'm not very sure about the connection between the jerk settings, acceleration and speed. When does it all come into play?

This build is part of a project we're completing with a university in Singapore, they are interested in some building technologies.

From what i hear, this is just a first prototype. So this will be extruding concrete.

I'll actually be interested in printing chairs with these. nice concrete industrial looking chairs.

Read our blog at www.everyoneacreator.com

We're having such a hard time with the z-axis, the movement is really unreliable.

i'm jut about to just change it to a lead screw system. What do you think?

I'm not very sure about the connection between the jerk settings, acceleration and speed. When does it all come into play?

This build is part of a project we're completing with a university in Singapore, they are interested in some building technologies.

From what i hear, this is just a first prototype. So this will be extruding concrete.

I'll actually be interested in printing chairs with these. nice concrete industrial looking chairs.

Read our blog at www.everyoneacreator.com

|

Re: Building a concrete 3D printer - need help with movement December 23, 2015 01:34AM |

Registered: 10 years ago Posts: 71 |

|

Re: Building a concrete 3D printer - need help with movement December 23, 2015 08:47AM |

Registered: 12 years ago Posts: 153 |

|

Re: Building a concrete 3D printer - need help with movement December 23, 2015 10:38PM |

Registered: 11 years ago Posts: 1,049 |

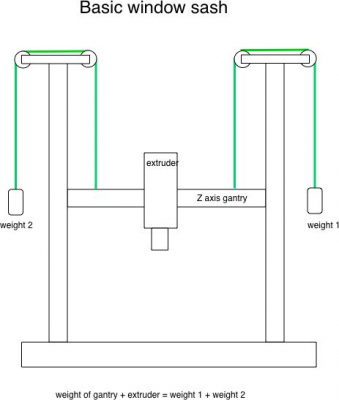

Basic window sash mechanism -- makes your Z-axis gantry weightless

you should have the gantry a little heavy so it goes down?

University art majors? get some mechanical engineer students???

you should have the gantry a little heavy so it goes down?

University art majors? get some mechanical engineer students???

Quote

mekastudios

I'm not sure I get what you mean with the pulley and counter weights.

---project we're completing with a university in Singapore

|

Re: Building a concrete 3D printer - need help with movement December 24, 2015 02:34AM |

Registered: 10 years ago Posts: 14,672 |

Did you try reducing the Z acceleration and jerk to the lower values that I suggested? If that doesn't work and you are already running your Z motor current as high as you can without the drivers or motors overheating, then I think changing to a leadscrew would be a good solution.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Building a concrete 3D printer - need help with movement December 24, 2015 02:43AM |

Registered: 10 years ago Posts: 71 |

|

Re: Building a concrete 3D printer - need help with movement December 24, 2015 07:08AM |

Registered: 8 years ago Posts: 475 |

Your motors are high torque Nema 23 motors.

Their inductance is 17mH which is 5~10 times the average printer motor.

They need fairly high voltage to run properly, and you may consider 36V as a minimum.

3D printer stepper driver are not designed for such motors.

Your machine size and design is more like a CNC router than a printer, so you shall use CNC stuff instead of 3D printer.

You need to set external drivers usually used for CNC router/mill.

Full step basically don't work, even for heavy machines. 1/2 step is an absolute minimum, and 1/4 to 1/8 work much better.

for drivers, if you got some money, I advise the Gecko (the G202), else driver based upon Toshiba TB6600HG circuit (or THB6064AH), do NOT use driver based upon TB6560, they burn too easily.

For the Z axis, as it is moving slowly, I advise counterweight. I used to have a CNC machine installed vertically and I got all sort of troubles till I installed counterweights. The problem is that you shall carry the weight while moving in other axis, so acceleration shall be reduced. Tradeoffs...

[otocoup.com] Thats quite obsolete, especially on the driver side (12 years old...), but you may find some stuff in this site

Edited 1 time(s). Last edit at 12/24/2015 07:29AM by PRZ.

Their inductance is 17mH which is 5~10 times the average printer motor.

They need fairly high voltage to run properly, and you may consider 36V as a minimum.

3D printer stepper driver are not designed for such motors.

Your machine size and design is more like a CNC router than a printer, so you shall use CNC stuff instead of 3D printer.

You need to set external drivers usually used for CNC router/mill.

Full step basically don't work, even for heavy machines. 1/2 step is an absolute minimum, and 1/4 to 1/8 work much better.

for drivers, if you got some money, I advise the Gecko (the G202), else driver based upon Toshiba TB6600HG circuit (or THB6064AH), do NOT use driver based upon TB6560, they burn too easily.

For the Z axis, as it is moving slowly, I advise counterweight. I used to have a CNC machine installed vertically and I got all sort of troubles till I installed counterweights. The problem is that you shall carry the weight while moving in other axis, so acceleration shall be reduced. Tradeoffs...

[otocoup.com] Thats quite obsolete, especially on the driver side (12 years old...), but you may find some stuff in this site

Edited 1 time(s). Last edit at 12/24/2015 07:29AM by PRZ.

|

Re: Building a concrete 3D printer - need help with movement December 24, 2015 07:19AM |

Registered: 10 years ago Posts: 14,672 |

Quote

PRZ

Your motors are high torque Nema 23 motors.

Their inductance is 17mH which is 5~10 times the average printer motor.

They need fairly high voltage to run properly, and you may consider 36V as a minimum.

3D printer stepper driver are not designed for such motors.

Your machine size and design is more like a CNC router than a printer, so you shall use CNC stuff instead of 3D printer.

You need to set external drivers usually used for CNC router/mill.

I respectfully disagree. The motors are rated at 1.8A (see the first post in this thread) and the drivers are DRV8825 with heatsink correctly mounted on the opposite side of the PCB to the chip. So he should be able to run the motors at 1.5A or 1.6A, which is about right for a 1.8A motor. The phase resistance is 2.75 ohms so the voltage drop at 1.5A is only 4.1V. So even with two motors in series, a 12V supply would just about be OK at low speeds (we are talking about the Z axis here), but in any case he is using a 24V supply. It's only for high speed movement that more than 24V would be needed.

Edited 2 time(s). Last edit at 12/24/2015 07:28AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Building a concrete 3D printer - need help with movement December 24, 2015 07:28AM |

Registered: 10 years ago Posts: 14,672 |

@mekastudios, does your Z axis need to support the weight of the concrete print? If not, how much weight does it need to support?

Also, what is the radius (or tooth count and tooth pitch) of the belt you are using to drive the Z axis? A close up photo of the Z driving mechanism would help.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Also, what is the radius (or tooth count and tooth pitch) of the belt you are using to drive the Z axis? A close up photo of the Z driving mechanism would help.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Building a concrete 3D printer - need help with movement December 24, 2015 07:49AM |

Registered: 8 years ago Posts: 475 |

Quote

dc42

Quote

PRZ

Your motors are high torque Nema 23 motors.

Their inductance is 17mH which is 5~10 times the average printer motor.

They need fairly high voltage to run properly, and you may consider 36V as a minimum.

3D printer stepper driver are not designed for such motors.

Your machine size and design is more like a CNC router than a printer, so you shall use CNC stuff instead of 3D printer.

You need to set external drivers usually used for CNC router/mill.

I respectfully disagree. The motors are rated at 1.8A (see the first post in this thread) and the drivers are DRV8825 with heatsink correctly mounted on the opposite side of the PCB to the chip. So he should be able to run the motors at 1.5A or 1.6A, which is about right for a 1.8A motor. The phase resistance is 2.75 ohms so the voltage drop at 1.5A is only 4.1V. So even with two motors in series, a 12V supply would just about be OK at low speeds (we are talking about the Z axis here), but in any case he is using a 24V supply. It's only for high speed movement that more than 24V would be needed.

It seems he use the same motor on all axis. However, due to the size of the pinion, the motor will have a relatively low rpm, so 24V may work if they move slowly. I don't know what is the intended speed for a concrete printer ?

|

Re: Building a concrete 3D printer - need help with movement December 25, 2015 03:03AM |

Registered: 10 years ago Posts: 71 |

@dc42,

The Z-axis does not need to support the concrete print, we've made the bed stationary.

The bed will be a trolley that we can pull out once the print is done.

@PRZ

I would imagine concrete 3D printer needs to print very slowly.

At the moment, we move at about 20mm/min. Which i suspect may be too slow.

@cozmicray

We tried a very quick iteration of the Pulley system and although it worked, the movement was still very unreliable.

The sprockets are 15-teeth and we use a chain to drive the axis.

Already placed an order for the lead screws and other necessary stuff, just a matter of waiting now and testing those.

You can view some photos here.

[drive.google.com]

Read our blog at www.everyoneacreator.com

The Z-axis does not need to support the concrete print, we've made the bed stationary.

The bed will be a trolley that we can pull out once the print is done.

@PRZ

I would imagine concrete 3D printer needs to print very slowly.

At the moment, we move at about 20mm/min. Which i suspect may be too slow.

@cozmicray

We tried a very quick iteration of the Pulley system and although it worked, the movement was still very unreliable.

The sprockets are 15-teeth and we use a chain to drive the axis.

Already placed an order for the lead screws and other necessary stuff, just a matter of waiting now and testing those.

You can view some photos here.

[drive.google.com]

Read our blog at www.everyoneacreator.com

|

Re: Building a concrete 3D printer - need help with movement December 25, 2015 11:32PM |

Registered: 11 years ago Posts: 1,049 |

Wondering why you selected a chain drive?

Did you think timing belt was not strong enough?

timing belts have rayon or kevlar belts inside.

Did you "engineer" your Z-Axis?

Did you think timing belt was not strong enough?

timing belts have rayon or kevlar belts inside.

Did you "engineer" your Z-Axis?

Quote

mekastudios

@cozmicray

We tried a very quick iteration of the Pulley system and although it worked, the movement was still very unreliable.

The sprockets are 15-teeth and we use a chain to drive the axis.

Already placed an order for the lead screws and other necessary stuff, just a matter of waiting now and testing those.

|

Re: Building a concrete 3D printer - need help with movement December 26, 2015 12:50AM |

Registered: 10 years ago Posts: 71 |

I figured the axes would be too heavy for a belt drive to work reliably.

Hence we chose a chain drive.

Belt drives may be able to work too actually.

And we were inspired by some of the other concrete 3D printers we saw.

It all seems like a guessing game right now, we're running out of time on this project, so at the moment, it's really about just getting the lead screws to work well.

Shafiq

Read our blog at www.everyoneacreator.com

Hence we chose a chain drive.

Belt drives may be able to work too actually.

And we were inspired by some of the other concrete 3D printers we saw.

It all seems like a guessing game right now, we're running out of time on this project, so at the moment, it's really about just getting the lead screws to work well.

Shafiq

Read our blog at www.everyoneacreator.com

|

Re: Building a concrete 3D printer - need help with movement December 28, 2015 02:53AM |

Registered: 10 years ago Posts: 71 |

I was looking through configuration_adv.h and I found this.

// Microstep setting (Only functional when stepper driver microstep pins are connected to MCU.

#define MICROSTEP_MODES {16,16,16,16,16} // [1,2,4,8,16]

// Motor Current setting (Only functional when motor driver current ref pins are connected to a digital trimpot on supported boards)

#define DIGIPOT_MOTOR_CURRENT {135,135,135,135,135} // Values 0-255 (RAMBO 135 = ~0.75A, 185 = ~1A)

Do these make a difference to the current and microstepping modes? Or will it follow the settings that I have already done on the RUMBA Board and Motor drivers.

Shafiq

Read our blog at www.everyoneacreator.com

// Microstep setting (Only functional when stepper driver microstep pins are connected to MCU.

#define MICROSTEP_MODES {16,16,16,16,16} // [1,2,4,8,16]

// Motor Current setting (Only functional when motor driver current ref pins are connected to a digital trimpot on supported boards)

#define DIGIPOT_MOTOR_CURRENT {135,135,135,135,135} // Values 0-255 (RAMBO 135 = ~0.75A, 185 = ~1A)

Do these make a difference to the current and microstepping modes? Or will it follow the settings that I have already done on the RUMBA Board and Motor drivers.

Shafiq

Read our blog at www.everyoneacreator.com

|

Re: Building a concrete 3D printer - need help with movement December 29, 2015 09:53PM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: Building a concrete 3D printer - need help with movement December 29, 2015 10:37PM |

Registered: 10 years ago Posts: 71 |

|

Re: Building a concrete 3D printer - need help with movement January 06, 2016 11:12AM |

Registered: 10 years ago Posts: 71 |

I have a question.

I've wired my motors for the Y axis and Z axis in series.

How does that affect the current limits?

I guess what I am asking is, can i now tune my pots to double the VREF for the Y and Z axis?

Wiring in series, does it half the torque? How does wiring in series affect anything? plenty of people I work with are confused about this.

is it possible to actually wire up 4 motors on a single axis/stepper motor driver?

Shafiq

Read our blog at www.everyoneacreator.com

I've wired my motors for the Y axis and Z axis in series.

How does that affect the current limits?

I guess what I am asking is, can i now tune my pots to double the VREF for the Y and Z axis?

Wiring in series, does it half the torque? How does wiring in series affect anything? plenty of people I work with are confused about this.

is it possible to actually wire up 4 motors on a single axis/stepper motor driver?

Shafiq

Read our blog at www.everyoneacreator.com

|

Re: Building a concrete 3D printer - need help with movement January 06, 2016 05:00PM |

Registered: 10 years ago Posts: 14,672 |

If your Z motors are wired in series and are the same type as the X and Y motors, use the same Vref for Z as you do for X and Y. Connecting motors in series doesn't affect the torque at low speeds unless you are using low current/high voltage motors, but reduces the speed at which the torque starts to decrease. Higher speeds can be maintained by using a higher supply voltage, if your electronics allows that.

With 4 motors, depending on the motor type and the supply voltage, either 4 in series or 2 parallel chains of 2 in series might be best.

Be aware that when multiple motors are used to drive the Z axis, they tend to get out of sync. In particular, when you power the printer down and up again, each motor jumps to one of the nearest full-step positions, and different motors may jump in different directions. A single motor driving 3 leadscrews via a belt avoids this problem.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

With 4 motors, depending on the motor type and the supply voltage, either 4 in series or 2 parallel chains of 2 in series might be best.

Be aware that when multiple motors are used to drive the Z axis, they tend to get out of sync. In particular, when you power the printer down and up again, each motor jumps to one of the nearest full-step positions, and different motors may jump in different directions. A single motor driving 3 leadscrews via a belt avoids this problem.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Building a concrete 3D printer - need help with movement February 13, 2016 02:45AM |

Registered: 10 years ago Posts: 71 |

Hello,

Just an update! We've got all the movements working!

Had to change the z-axis to lead screws! and even had to readjust the x and y axis! but it's all working fine now.

The issue now is with the extruder, I can't get it to constantly stay turning. There is a lot of high speed turning then stop, turn then stop.

This doesn't really work well for extruding concrete.

Is there a way for me to just turn on the motor on the extruder, turn off during layer change and then turn on again.

And when turned on, it has to be at a constant speed.

Shafiq

Read our blog at www.everyoneacreator.com

Just an update! We've got all the movements working!

Had to change the z-axis to lead screws! and even had to readjust the x and y axis! but it's all working fine now.

The issue now is with the extruder, I can't get it to constantly stay turning. There is a lot of high speed turning then stop, turn then stop.

This doesn't really work well for extruding concrete.

Is there a way for me to just turn on the motor on the extruder, turn off during layer change and then turn on again.

And when turned on, it has to be at a constant speed.

Shafiq

Read our blog at www.everyoneacreator.com

Sorry, only registered users may post in this forum.