Keeping an e3d hot end happy?

Posted by jimmyclarke

|

Keeping an e3d hot end happy? December 18, 2015 06:25AM |

Registered: 8 years ago Posts: 22 |

Hi all,

I am having real problems running a hot end without getting it jammed, I am beginning to think it might be my filament, but before I chuck it out, are there any obvious steps I am missing?

Scenario

E3D v6 hot end, all metal 1.75mm throat, with a bowden tube and cooling fan in place. Printing with PLA

The cooling fan seems to be doing the job adequately as all the fans are cool to the touch after a long time at 200 degrees.

I have tightened everything up when it is at temperature, the last time it jammed I thought I can't have tightened it enough, but when I removed the nozzle the jam was in the throat itself about half way up, and I could not retract or pull it out.

I had various success in retracting far away from the the whole assembly in between prints, but this ultimately failed me too, maybe because it takes so long for my prusa i3 to get from z-max to z-min after the heating process of a print start.

My e-steps are correct, the extruder motor is no longer getting hot (admittedly I have not tried printing again since adjusting this) and there are no audible missed steps on the exrtuder.

Any beginner advice would be much appreciated, I have auto levelling working now, as bed level was stopping me finally having a working printer, so I am so close

Thanks

I am having real problems running a hot end without getting it jammed, I am beginning to think it might be my filament, but before I chuck it out, are there any obvious steps I am missing?

Scenario

E3D v6 hot end, all metal 1.75mm throat, with a bowden tube and cooling fan in place. Printing with PLA

The cooling fan seems to be doing the job adequately as all the fans are cool to the touch after a long time at 200 degrees.

I have tightened everything up when it is at temperature, the last time it jammed I thought I can't have tightened it enough, but when I removed the nozzle the jam was in the throat itself about half way up, and I could not retract or pull it out.

I had various success in retracting far away from the the whole assembly in between prints, but this ultimately failed me too, maybe because it takes so long for my prusa i3 to get from z-max to z-min after the heating process of a print start.

My e-steps are correct, the extruder motor is no longer getting hot (admittedly I have not tried printing again since adjusting this) and there are no audible missed steps on the exrtuder.

Any beginner advice would be much appreciated, I have auto levelling working now, as bed level was stopping me finally having a working printer, so I am so close

Thanks

|

Re: Keeping an e3d hot end happy? December 18, 2015 12:00PM |

Registered: 9 years ago Posts: 329 |

I highly suggest insulating the hot end block. This will minimize radiated heat from rising (and will prevent burning your fingers to a crisp)...

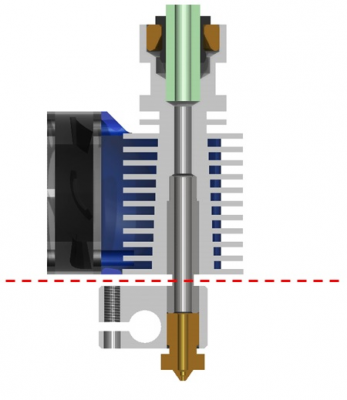

Keeping the heat below the red line is the goal. The heat sink that is build into the E3D hot end is to cool the filament tube, not the hot end. The problem you're having is due to the heat rising too far up the tube, causing the filament to melt at the inlet side of the PTFE tube, or perhaps even higher. When this happens, the filament bunches up (like a little mushroom) at the top of the PTFE causing it to stop due to the increased diameter of the filament at that point. The ONLY place that the filament should melt is inside the hot end block itself, not in the tube.

-David

Find me online at:

Thingiverse

Instructables.com

LinkedIn

Facebook

Check out my FolgerTech Prusa i3 (plexi) at MindRealm.net

Keeping the heat below the red line is the goal. The heat sink that is build into the E3D hot end is to cool the filament tube, not the hot end. The problem you're having is due to the heat rising too far up the tube, causing the filament to melt at the inlet side of the PTFE tube, or perhaps even higher. When this happens, the filament bunches up (like a little mushroom) at the top of the PTFE causing it to stop due to the increased diameter of the filament at that point. The ONLY place that the filament should melt is inside the hot end block itself, not in the tube.

-David

Find me online at:

Thingiverse

Instructables.com

Check out my FolgerTech Prusa i3 (plexi) at MindRealm.net

|

Re: Keeping an e3d hot end happy? December 20, 2015 05:16PM |

Registered: 8 years ago Posts: 44 |

I had exactly the same problem with my e3d when printing pla. You need to season it. Just Google season e3d and all will be explained.

Iv had no problems since seasoning mine.

You also need to make sure your not retracting to far as pulling the molten filament up into the heat break is a recipe for disaster! The filament will just cool and jam, and is a nightmare to get out! I'm not at my pc but I think I run 1mm retraction with no problems.

Iv had no problems since seasoning mine.

You also need to make sure your not retracting to far as pulling the molten filament up into the heat break is a recipe for disaster! The filament will just cool and jam, and is a nightmare to get out! I'm not at my pc but I think I run 1mm retraction with no problems.

|

Re: Keeping an e3d hot end happy? December 22, 2015 11:57PM |

Registered: 10 years ago Posts: 128 |

Quote

chngyian

Is there a ptfe liner for the e3d style hotend? if not then perhaps you can try printing with abs and see if the problem persists.

my experience with all metal hotends is that they don't print pla well, because the expanded bulb sticks to the walls of the hotend very well (unless you polish till mirror finish). of course, many here have printed pla with no problem and ymmv.

This is what i posted in another thread, may come handy.

[forums.reprap.org]

|

Re: Keeping an e3d hot end happy? December 23, 2015 03:45AM |

Registered: 9 years ago Posts: 893 |

Have you looked through this page?

E3D troubleshooting

This is assuming that you're using a genuine E3Dv6...

E3D troubleshooting

This is assuming that you're using a genuine E3Dv6...

|

Re: Keeping an e3d hot end happy? December 23, 2015 07:25PM |

Registered: 8 years ago Posts: 22 |

Thanks for all the responses

I think that my problem was PLA with the all metal throat yes

As fixing that meant waiting on the post I have ordered a j-head instead, and it is currently printing better than the E3D ever did, and this is on a non levelled, roughly guessed height print bed, so I think my mentality/set up is just more suited to the j-head.

I will revisit the E3D one day when I need hotter temps, but for now I am going to enjoy finally having a working printer!!

I think that my problem was PLA with the all metal throat yes

As fixing that meant waiting on the post I have ordered a j-head instead, and it is currently printing better than the E3D ever did, and this is on a non levelled, roughly guessed height print bed, so I think my mentality/set up is just more suited to the j-head.

I will revisit the E3D one day when I need hotter temps, but for now I am going to enjoy finally having a working printer!!

|

Re: Keeping an e3d hot end happy? December 23, 2015 08:11PM |

Registered: 10 years ago Posts: 17 |

Hi

I had the same problem and found the culprit to be a slightly scored Bowden tube resulting in about 70% of the force required to move the filament went into overcoming the tube friction. I proved this by lightly lubricating the filament with some rice cooking oil and the problem went away completely. The small amount of oil does not seem to cause any ill effect on the plastic. To prove it I went back to using no oil and the problem resurfaced.

For this reason I have removed the Bowden tube and now only use direct drive extruders and never get any problems.

Merry Christmas.

I had the same problem and found the culprit to be a slightly scored Bowden tube resulting in about 70% of the force required to move the filament went into overcoming the tube friction. I proved this by lightly lubricating the filament with some rice cooking oil and the problem went away completely. The small amount of oil does not seem to cause any ill effect on the plastic. To prove it I went back to using no oil and the problem resurfaced.

For this reason I have removed the Bowden tube and now only use direct drive extruders and never get any problems.

Merry Christmas.

|

Re: Keeping an e3d hot end happy? December 25, 2015 08:26AM |

Registered: 9 years ago Posts: 476 |

I'm having this problem twice already and I suspecting my filament, in fact this is the second occurrence and the heatbreak along with the nozzle were cleaned with the acetone. Can a palm oil cooking oil be used to lube it or season it?

I also put a short teflon tube to protect my filament from being chipped away due to direct drive with mk8 extruder

I also put a short teflon tube to protect my filament from being chipped away due to direct drive with mk8 extruder

|

Re: Keeping an e3d hot end happy? December 26, 2015 04:52AM |

Registered: 9 years ago Posts: 476 |

Sorry, only registered users may post in this forum.