Charcoal filter

Posted by DjDemonD

|

Re: Charcoal filter January 20, 2016 04:38PM |

Registered: 8 years ago Posts: 3,525 |

News so far, it turns out that a travel hair dryer will move air through a handheld vacuum hepa filter filled with activated charcoal beads and a foam prefilter. The filter is connected to the hairdryer inlet. However I'm waiting on some ducting before I can see how well the heater/filter/recirculator actually works. Hoping to have the ducting by friday.

|

Re: Charcoal filter January 20, 2016 04:40PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Charcoal filter January 20, 2016 11:51PM |

Registered: 8 years ago Posts: 916 |

Has anyone considered using a 'normal' carbon face mask? Ie one with just a layer of paper, some carbon, then another layer of paper in the shape of a face.

I bought a couple of these, as well as a 90mm fan not too long ago with the aim of seeing if this would reduce the ABS fumes a bit. I think that airflow might be better with this setup. Yet to try it though.

I bought a couple of these, as well as a 90mm fan not too long ago with the aim of seeing if this would reduce the ABS fumes a bit. I think that airflow might be better with this setup. Yet to try it though.

|

Re: Charcoal filter January 21, 2016 01:31AM |

Registered: 11 years ago Posts: 1,171 |

Quote

nebbian

Has anyone considered using a 'normal' carbon face mask? Ie one with just a layer of paper, some carbon, then another layer of paper in the shape of a face.

I bought a couple of these, as well as a 90mm fan not too long ago with the aim of seeing if this would reduce the ABS fumes a bit. I think that airflow might be better with this setup. Yet to try it though.

It may help the smell but it's not going to stop the harmful micro particles that can get into your lungs, only true Hepa filter can do that.

My new fan (suppose to be actual high pressure) is due to arrive tomorrow so hopefully I will have a working unit soon.

|

Re: Charcoal filter January 21, 2016 05:47PM |

Registered: 11 years ago Posts: 1,171 |

I got my new fan in today. Hooked it up and I do get airflow through my Hepa filter now.

This new fan sounds like a hair dryer or high end vacuum cleaner (they warned me it was noisy at around 68db)

I held a tissue in front of the filter and it was drawn onto the filter, not with a lot of pressure but the filter is 14cm diameter so there is a lot of surface area.

Not crazy about the noise it makes but it is moving massive air. The thing is rated at 2.5amps though it actually draws 2.1amps. My other fan that I thought would work was only 0.1amp.

If anybody is interested it's a Mechatronics MD1238X12B DC 12v (not PWM).

This new fan sounds like a hair dryer or high end vacuum cleaner (they warned me it was noisy at around 68db)

I held a tissue in front of the filter and it was drawn onto the filter, not with a lot of pressure but the filter is 14cm diameter so there is a lot of surface area.

Not crazy about the noise it makes but it is moving massive air. The thing is rated at 2.5amps though it actually draws 2.1amps. My other fan that I thought would work was only 0.1amp.

If anybody is interested it's a Mechatronics MD1238X12B DC 12v (not PWM).

|

Re: Charcoal filter January 21, 2016 06:42PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Charcoal filter January 22, 2016 03:13AM |

Registered: 11 years ago Posts: 1,171 |

|

Re: Charcoal filter January 22, 2016 07:11AM |

Registered: 9 years ago Posts: 1,873 |

If you're recirculating, I suspect that almost any detectable airflow at the outlet side will be enough (providing the inlet side doesn't leak, so all the out air is coming through the filter). Over the sort of times that a print takes, even relatively low flow rates will pull the entire volume through the filter many times over. Agreed though, it sure would be nice to be able to measure the flow and know what the cycle time is. I have an end-of-print cooldown phase where the head moves around the bed a few times with the part fans running at max, which takes about 5 minutes. If I could cycle the chamber volume through the filter in about that time I'm guessing I'd be good, but it is just a guess at this point. I can't remember, but I think I decided the volume was about 3 cubic feet, so something in the 1 cubic foot per minute range sounds good.

|

Re: Charcoal filter January 22, 2016 08:51AM |

Registered: 11 years ago Posts: 5,780 |

While you're all getting your HEPA filters and fans running, has anyone considered electrostatic precipitation? All that's needed is a HV power supply and a couple metal screens/plates. One of these ought to work for the power supply: [www.goldmine-elec-products.com]

I use one of these to mitigate cat box odor (at its lowest setting, it produces a little ozone which is a great deodorizer) and as you can see, it picks up quite a bit of dust from the air, too. I got this thing at a secondhand store for $5. There are no fans in this device, only a HV supply, a grid of needles for the negative electrode and the plates for the positive side. The electric field causes the air to move without a fan. In a 3D printer with a grounded metal frame, the negative side could be just a ball of steel wool and the positive side grounded to the frame. The dust would then just stick to the frame of the machine and would require periodic wiping with a rag.

Yes, I'm aware of the hazards of ozone, and of this particular model device.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I use one of these to mitigate cat box odor (at its lowest setting, it produces a little ozone which is a great deodorizer) and as you can see, it picks up quite a bit of dust from the air, too. I got this thing at a secondhand store for $5. There are no fans in this device, only a HV supply, a grid of needles for the negative electrode and the plates for the positive side. The electric field causes the air to move without a fan. In a 3D printer with a grounded metal frame, the negative side could be just a ball of steel wool and the positive side grounded to the frame. The dust would then just stick to the frame of the machine and would require periodic wiping with a rag.

Yes, I'm aware of the hazards of ozone, and of this particular model device.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Charcoal filter January 22, 2016 08:55AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Charcoal filter January 22, 2016 02:04PM |

Registered: 8 years ago Posts: 3,525 |

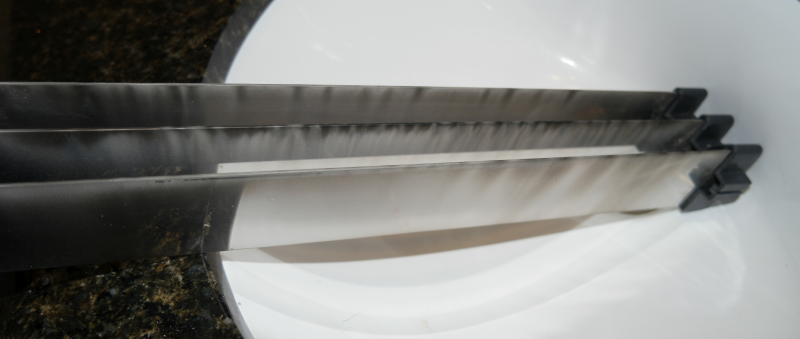

I've built my hair dryer based recirculator. Photos attached. The only issue in preliminary testing is the thermal cutout trips on the hairdryer. It does move air through the hepa filter and carbon granules. Wondering if I can reduce the heater power of the hairdryer as I do not need it to heat up very quickly.I am currently using slow PWM mode using e1 thermistor and heater channel via an ssr, I might try normal PWM it might run it a bit slower once I'm near to my set chamber temperature 50 deg C if I turn on my heatbed first to pre heat the chamber. I weighed the filter and charcoal beads but I had to remove the prefilter as it restricted airflow too much so most of any gain in mass will be dust. In terms of noise it quieter than when the hairdryer was in use before as it is now enclosed at both ends.

Edited 2 time(s). Last edit at 01/22/2016 02:15PM by DjDemonD.

Edited 2 time(s). Last edit at 01/22/2016 02:15PM by DjDemonD.

|

Re: Charcoal filter January 22, 2016 08:04PM |

Registered: 8 years ago Posts: 3,525 |

Well it seems regular PWM works, the hair dryer runs very slowly once the chamber is hot and manages to stay just below the thermal cut out temperature, it also does not make much noise once its maintaining the chamber temperature and the SSR is not heating up at all.

I have printed a small calibration object with the chamber heated to 45 Deg C, recirculating air from the top, back to the bottom via the filter and hair dryer. The air in the chamber smelt clean afterwards, there was no detectable "ABS smell". So whether it is effectively removing all the fumes and particulates it certainly seems to show some promise.

Next thing to investigate is how to circumvent the problem of the hair dryer's thermal cut out, as I'm still not confident it won't activate during printing triggering a thermal runaway condition. I need to have a little more current to the fan and a little less to the heater in the hair dryer. This would keep the chamber warm but given the relatively greater airflow versus heating, it should not come close to overheating the hair dryer.

Any ideas on how to do this? Resistors will not be up to the job its around 600w with the heater being given full power. I would split the input and run the heater off the SSR via the ramps board e1 output and have the fan just wired to be on all the time, this would make filtration perform better, but the fan then runs at full speed all the time and is noisy even when maintaining the temperature, and I cannot remotely shut it off via the PC, and it won't turn itself off at the end of a print. Suggestions welcome.

I have printed a small calibration object with the chamber heated to 45 Deg C, recirculating air from the top, back to the bottom via the filter and hair dryer. The air in the chamber smelt clean afterwards, there was no detectable "ABS smell". So whether it is effectively removing all the fumes and particulates it certainly seems to show some promise.

Next thing to investigate is how to circumvent the problem of the hair dryer's thermal cut out, as I'm still not confident it won't activate during printing triggering a thermal runaway condition. I need to have a little more current to the fan and a little less to the heater in the hair dryer. This would keep the chamber warm but given the relatively greater airflow versus heating, it should not come close to overheating the hair dryer.

Any ideas on how to do this? Resistors will not be up to the job its around 600w with the heater being given full power. I would split the input and run the heater off the SSR via the ramps board e1 output and have the fan just wired to be on all the time, this would make filtration perform better, but the fan then runs at full speed all the time and is noisy even when maintaining the temperature, and I cannot remotely shut it off via the PC, and it won't turn itself off at the end of a print. Suggestions welcome.

|

Re: Charcoal filter January 22, 2016 08:23PM |

Registered: 11 years ago Posts: 5,780 |

American Science and Surplus sells blowers from CPAP machines (you can probably find them on ebay or at garage sales, too) that run quietly and can produce pressure. They typically have brushless DC motors that can be driven by an ESC for a model airplane ($8 from Hobby King), with a servo tester ($5 from Hobby King) to provide the drive signals for the ESC. I tested one blowing air into a foam cooler and had to pile weights on top to keep it from blowing the top off the cooler.

Here's a max speed test of one small, $8 blower which goes far beyond the quiet operation point: CPAP blower

This thing is like a miniature leaf blower when you crank up the drive.

In a CPAP machine, these things run very quietly yet produce enough pressure to feel like it is inflating your lungs for you (I know, I use a CPAP).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Here's a max speed test of one small, $8 blower which goes far beyond the quiet operation point: CPAP blower

This thing is like a miniature leaf blower when you crank up the drive.

In a CPAP machine, these things run very quietly yet produce enough pressure to feel like it is inflating your lungs for you (I know, I use a CPAP).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Charcoal filter January 23, 2016 02:54AM |

Registered: 10 years ago Posts: 580 |

Quote

DD

American Science and Surplus sells blowers from CPAP machines

That's a great find. Do you by any chance have the link? My searches everywhere came up empty.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Charcoal filter January 23, 2016 07:20AM |

Registered: 11 years ago Posts: 5,780 |

I bought it at the local shop, in Milwaukee. I don't see any listed on their web site.

I found this on ebay- it looks identical to the one I have, but the price is crazy: [www.ebay.com]

Edited 1 time(s). Last edit at 01/23/2016 07:40AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I found this on ebay- it looks identical to the one I have, but the price is crazy: [www.ebay.com]

Edited 1 time(s). Last edit at 01/23/2016 07:40AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Charcoal filter January 23, 2016 01:09PM |

Registered: 8 years ago Posts: 3,525 |

I came across a suggestion that I could place a diode in series with the heater coil of the hair dryer which would reduce its power output by essentially preventing the AC current flowing in one direction so dropping the heater power by 50%. This would work nicely but I am concerned that the diode will melt. Does anyone have any experience of using this method and how large a diode would I need to reduce a 600w heater element to 300w?

|

Re: Charcoal filter January 23, 2016 02:25PM |

Registered: 11 years ago Posts: 5,780 |

A 600W heater pulls about 600/117=5.1 A from the power line. A diode, when conducting, drops about 1 V, so it will dissipate about 5W during forward conduction and about 0W when it's reverse biased, so it will actually dissipate about 2.5-3W because it is forward biased only about 1/2 of the time. Any diode rated for 10-20A at 350V or more should be OK.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Charcoal filter January 23, 2016 03:02PM |

Registered: 8 years ago Posts: 3,525 |

|

Re: Charcoal filter January 23, 2016 03:44PM |

Registered: 11 years ago Posts: 5,780 |

In that case I'd look for a 500V 10A diode.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Charcoal filter January 24, 2016 02:05PM |

Registered: 10 years ago Posts: 580 |

I've found one source for the blowers:

High pressure low noise mini 24v DC Brushless Blower Fan Electric air blower small centrifugal fan Air purifier dehumidifier fan

These will do quite high pressure.

The one shown there shows the 3 phase controller they use (not included). I'm not familiar with powering or controlling this kind of motor.

Mark (D.D.) can you use the the same method as you showed above?

I tried looking at Craigslist - lots of cpap machines, but cheapest was the same price as the above, and used for 2 years...

I'm looking at this also as a possibly quieter and more efficient blower for my remote hot-end cooling system. It could be quieted even more by mounting it inside a silencer box.

Edit: I've done some further looking into ESCs (electronic speed control) , based on Mark's info, on wikipedia: [en.wikipedia.org]. The ESC is controlled by PWM, provided by the servo tester. Looks straightforward.

Edited 1 time(s). Last edit at 01/24/2016 02:58PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

High pressure low noise mini 24v DC Brushless Blower Fan Electric air blower small centrifugal fan Air purifier dehumidifier fan

These will do quite high pressure.

The one shown there shows the 3 phase controller they use (not included). I'm not familiar with powering or controlling this kind of motor.

Mark (D.D.) can you use the the same method as you showed above?

I tried looking at Craigslist - lots of cpap machines, but cheapest was the same price as the above, and used for 2 years...

I'm looking at this also as a possibly quieter and more efficient blower for my remote hot-end cooling system. It could be quieted even more by mounting it inside a silencer box.

Edit: I've done some further looking into ESCs (electronic speed control) , based on Mark's info, on wikipedia: [en.wikipedia.org]. The ESC is controlled by PWM, provided by the servo tester. Looks straightforward.

Edited 1 time(s). Last edit at 01/24/2016 02:58PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Charcoal filter January 24, 2016 06:18PM |

Registered: 11 years ago Posts: 5,780 |

You might want to see how much their driver is - ESCs require some smarts and special input as a safety measure when used in airplanes and helicopters. They require that the input starts at zero then ramps up- they won't just turn on when you apply power, which might make it tricky to interface to a 3D printer controller board. They also monitor battery voltage and will shut down if the voltage drops to the lower limit of the battery type it is programmed for.

Since these motors have no brushes and usually ball bearings, they last a loooong time. I wouldn't worry about a 2 year old machine's motor giving out.

Edited 1 time(s). Last edit at 01/24/2016 06:19PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Since these motors have no brushes and usually ball bearings, they last a loooong time. I wouldn't worry about a 2 year old machine's motor giving out.

Edited 1 time(s). Last edit at 01/24/2016 06:19PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Charcoal filter January 24, 2016 11:32PM |

Registered: 10 years ago Posts: 580 |

Their drivers are around $41. I've seen several models.

So a bit under $100 for a new motor and controller. That's a little bit of ouch, but it may well be worth it if it's quieter and more powerful.

[www.aliexpress.com]

[EDIT]

I found a good article about Brushless DC Motor Control on Digikey. Interesting how the hall sensors are used. Perhaps that could make the fan run quieter or more efficiently? Looks like it.

Edited 3 time(s). Last edit at 01/25/2016 05:50PM by Paul Wanamaker.

So a bit under $100 for a new motor and controller. That's a little bit of ouch, but it may well be worth it if it's quieter and more powerful.

[www.aliexpress.com]

[EDIT]

I found a good article about Brushless DC Motor Control on Digikey. Interesting how the hall sensors are used. Perhaps that could make the fan run quieter or more efficiently? Looks like it.

Edited 3 time(s). Last edit at 01/25/2016 05:50PM by Paul Wanamaker.

|

Re: Charcoal filter January 25, 2016 07:20AM |

Registered: 11 years ago Posts: 5,780 |

A Hall sensor isn't actually needed to get the motor running. I think they are mainly used when you need to control the RPM very accurately. The blower in my video had a Hall sensor and I just ignored the leads for it. The ESC doesn't have an input for a Hall sensor, either. When you connect the wires for a 3 phase motor to an ESC and try to run the motor for the first time, if the motor doesn't start you just swap two of the wires and it will start and run every time after that.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Charcoal filter January 25, 2016 07:26AM |

Registered: 11 years ago Posts: 5,780 |

Someone provided a link in another thread on a similar topic to a $25 (?) kit that uses a small air pump instead of a blower. It might be worth investigating, though I don't know how much air an aquarium pump can move. The CPAP type blower definitely moves more than enough air but the cost may be a bit steep for the application (you're trying to replace a $3 fan or two).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Charcoal filter February 02, 2016 10:51AM |

Registered: 8 years ago Posts: 16 |

I have been doing research into various ways to go about building filtration. I came across this while looking around and wanted to see what you all thought.

Amazon has a GermGuardian FLT5250PT True HEPA Filter that is approx 4.8"x19.25" or 122x489mm. This is about the same dimensions as a 1x4 stack of 120mm fans (120x480mm). There are also Carbon Pre-Filters, one of which is included on the HEPA filter already. I don't know if that would be enough to absorb the majority of the sytrene. I am not knowledgeable enough to say. One could always add some charcoal pellets after the HEPA filtration as well. I have one of those air filtration units and the filters have a foam frame to make a good seal, so that is a plus.

Edited 2 time(s). Last edit at 02/02/2016 10:52AM by ihaveworms.

Amazon has a GermGuardian FLT5250PT True HEPA Filter that is approx 4.8"x19.25" or 122x489mm. This is about the same dimensions as a 1x4 stack of 120mm fans (120x480mm). There are also Carbon Pre-Filters, one of which is included on the HEPA filter already. I don't know if that would be enough to absorb the majority of the sytrene. I am not knowledgeable enough to say. One could always add some charcoal pellets after the HEPA filtration as well. I have one of those air filtration units and the filters have a foam frame to make a good seal, so that is a plus.

Edited 2 time(s). Last edit at 02/02/2016 10:52AM by ihaveworms.

|

Re: Charcoal filter February 02, 2016 11:00AM |

Registered: 8 years ago Posts: 3,525 |

Whether it works scientifically to a standard that is acceptable i.e. reduces harmful particles and fumes to below the recommended levels, I do not know but my preliminary testing with a handheld vacuum hepa filter and activated carbon granules produces no discernible odour in the enclosure after a long print. My only issue is I am trying to use this as a combined heater/re-circulator and filter and my chosen heater a hair dryer keeps overheating. A plan is afoot to half the heater coil's output using a diode, but I only just got the tri-wing style screwdriver I need to get the damn thing open.

|

Re: Charcoal filter February 02, 2016 11:11AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Charcoal filter February 02, 2016 11:26AM |

Registered: 11 years ago Posts: 5,780 |

I recently did some digging into nano particle filtration by different techniques and found these papers, one on removal using filters only and the other using a combo of soft x-rays and electrostatic precipitation. The second scheme can be used to remove even virii from the air in hospital clean rooms.

Removal of UFPs by filtration

X-ray enhanced electrostatic precipitation

It is actually pretty easy to make a soft x-ray source using an old vacuum tube and a small, low current, HV supply. Electrostatic precipitators are also quite simple requiring only another small, low current HV supply...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Removal of UFPs by filtration

X-ray enhanced electrostatic precipitation

It is actually pretty easy to make a soft x-ray source using an old vacuum tube and a small, low current, HV supply. Electrostatic precipitators are also quite simple requiring only another small, low current HV supply...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Charcoal filter February 02, 2016 03:03PM |

Registered: 8 years ago Posts: 16 |

Going from the filter link I posted earlier, I also found that there is a smaller model. With this unit containing the fan already as well as the filter media, maybe you can just cut a hole in the side of the enclosure and mount this in it. I would probably want to put some more carbon filtering in addition to that single carbon foam piece thingy.

GermGuardian AC4100 3-in-1 HEPA Air Purifier System

Edited 1 time(s). Last edit at 02/02/2016 03:04PM by ihaveworms.

GermGuardian AC4100 3-in-1 HEPA Air Purifier System

Edited 1 time(s). Last edit at 02/02/2016 03:04PM by ihaveworms.

|

Re: Charcoal filter February 03, 2016 04:59PM |

Registered: 8 years ago Posts: 3,525 |

Okay seems to be working, printing now and the enclosure is at 45 deg C. Air is being successfully re-circulated from the top of the enclosure to the bottom via the hepa filter and charcoal beads, by the hair dryer which is now operating at half its original "low setting" heater power by addition of a diode in series with that heater.

The noise level is very low once its warm, my 20 month-old-son is sleeping in another room about 5 meters away, as I am running it using standard PWM via an SSR (which is stone cold) and it is barely running to maintain the chamber temperature, air is moving though and can be felt at the pipe which returns the warm clean air to the chamber. 30 minute print initially as I am still concerned the hairdryer or ssr will overheat, no sign of it yet though.

Now to see if the air in the chamber at least smells clean, I cannot detect any ABS fumes in the room, so it looks good.

The noise level is very low once its warm, my 20 month-old-son is sleeping in another room about 5 meters away, as I am running it using standard PWM via an SSR (which is stone cold) and it is barely running to maintain the chamber temperature, air is moving though and can be felt at the pipe which returns the warm clean air to the chamber. 30 minute print initially as I am still concerned the hairdryer or ssr will overheat, no sign of it yet though.

Now to see if the air in the chamber at least smells clean, I cannot detect any ABS fumes in the room, so it looks good.

Sorry, only registered users may post in this forum.