Charcoal filter

Posted by DjDemonD

|

Re: Charcoal filter February 03, 2016 05:16PM |

Registered: 8 years ago Posts: 3,525 |

Seems to work fine - the air in the chamber only had the faintest detectable odour of abs when I opened it immediately after printing. The hairdryer did its job and the thermal cut out only tripped when I turned it off.

I think another solution instead of (or as well as) the diode, might be to control the heater in the hairdryer with the ssr leaving the fan to run at full speed, this should keep the hairdryer cool, but it will be noisier and I will not be able to turn off the hairdryer's fan via the host computer remotely, without wiring up another spare output on the ramps and a relay for the fan. I want to be able to have a level of unattended printing eventually (I have a fire safety device also).

But I think with some refinement this fulfils all the requirements I had. The 3d printed pipe elbows at either end of the setup were a bitch to print, so probably best buy them from the local store for £2 each.

I think another solution instead of (or as well as) the diode, might be to control the heater in the hairdryer with the ssr leaving the fan to run at full speed, this should keep the hairdryer cool, but it will be noisier and I will not be able to turn off the hairdryer's fan via the host computer remotely, without wiring up another spare output on the ramps and a relay for the fan. I want to be able to have a level of unattended printing eventually (I have a fire safety device also).

But I think with some refinement this fulfils all the requirements I had. The 3d printed pipe elbows at either end of the setup were a bitch to print, so probably best buy them from the local store for £2 each.

|

Re: Charcoal filter February 03, 2016 09:51PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Charcoal filter February 28, 2016 02:16PM |

Registered: 8 years ago Posts: 3,525 |

A little update on this, I was continually getting problems with the hairdryer cutting out as it was getting too hot. This is now solved with a 25mm hole in the pipe above the hairdryer which let's in a little cold (outside of the chamber) air. It will now run happily all day long. Sure it reduces the air flow through the filter but it still flows. Now to port this device over to my new smartrapcore alu. Which should be much easier (except the top) to enclose.

|

Re: Charcoal filter March 04, 2016 07:26PM |

Registered: 8 years ago Posts: 475 |

Hello, from information got from this thread and the filtration thread, completed with own experience of charcoal filter, I have added a Filtration chapter in the reprap wiki Health and Safety page [reprap.org] and also somewhat reorganised the page.

I think the filtration topic may be worth its own page, as it is a complex subject. I (or someone else) could see.

Comments are welcome and as english is not my mother language, you may want to improve the wording. Note that the wiki needs a different registration than the forum (I personally use same name and password for both). No need to be afraid of the Captcha, it doesn't bite if you type the wrong text.

I think the filtration topic may be worth its own page, as it is a complex subject. I (or someone else) could see.

Comments are welcome and as english is not my mother language, you may want to improve the wording. Note that the wiki needs a different registration than the forum (I personally use same name and password for both). No need to be afraid of the Captcha, it doesn't bite if you type the wrong text.

|

Re: Charcoal filter March 04, 2016 09:02PM |

Registered: 8 years ago Posts: 3,525 |

That looks really good, nice to see you have incorporated some of the ideas here. I think your English is very good but I would change this line

"Nothing could be done against heavy metals and filament shall be sourced at a supplier indicating compliance with US or European regulation."

To:

"There is no effective way to remove heavy metals, ensure you source filament from reputable suppliers in the US and European Union which will be covered by safety regulation."

Although I am not 100% sure that filament manufactured/sold in the US/EU necessarily is covered - anyone know more about this?

"Nothing could be done against heavy metals and filament shall be sourced at a supplier indicating compliance with US or European regulation."

To:

"There is no effective way to remove heavy metals, ensure you source filament from reputable suppliers in the US and European Union which will be covered by safety regulation."

Although I am not 100% sure that filament manufactured/sold in the US/EU necessarily is covered - anyone know more about this?

|

Re: Charcoal filter March 04, 2016 11:32PM |

Registered: 9 years ago Posts: 517 |

|

Re: Charcoal filter March 05, 2016 02:17AM |

Registered: 9 years ago Posts: 40 |

Quote

PRZ

Hello, from information got from this thread and the filtration thread, completed with own experience of charcoal filter, I have added a Filtration chapter in the reprap wiki Health and Safety page [reprap.org] and also somewhat reorganised the page.

While vacuum cleaner filters are often made from HEPA material, the folds mean that the filters may not pass a HEPA test themselves. I used one in my filter as a first stage, but noticed the careful wording saying, "made from HEPA material" rather than claiming it was a HEPA filter.

|

Re: Charcoal filter March 05, 2016 05:38AM |

Registered: 8 years ago Posts: 3,525 |

|

Re: Charcoal filter March 05, 2016 06:09AM |

Registered: 9 years ago Posts: 517 |

Quote

DjDemonD

Perhaps it should read

"There is no effective way to remove heavy metals, ensure you source filament from reputable suppliers in the US and European Union."

Or...

"There is no effective way to remove heavy metals. Ensure you source filament from reputable suppliers in the US and European Union."

|

Re: Charcoal filter March 05, 2016 06:55AM |

Registered: 8 years ago Posts: 475 |

It seems there is no regulation on emissions, but there is regulation on toxic contents of products.

In CE, this recent regulation is called 'REACH'.

Considering the health problem raised by ultra-fine particle, there may be a regulation one day. However, this is opposed by car diesel manufacturers as it is the main source of ultra-fine particle.

Regulations are not an option, but seems to be considered so by most resellers. The problem is there is no control nor penalty.

In Europe, The CE marking is compulsory and none of the spool I have (including the one made in France and Italy) do have the CE mark.

The only one which have regulation tags are the esun (China), with the ROHS tag. In principle ROHS is applicable only for electrical product, but at least it defines heavy metals maximum contents. REACH (compulsory, again) will go further with limit for some organic contents.

The only info I have is from a post in the deltabot forum from someone working in a lab here :

[groups.google.com]

Quite impressive post.

Personally, I use only transparent or white filament and I have VOC filter, but this is not the common case.

In CE, this recent regulation is called 'REACH'.

Considering the health problem raised by ultra-fine particle, there may be a regulation one day. However, this is opposed by car diesel manufacturers as it is the main source of ultra-fine particle.

Regulations are not an option, but seems to be considered so by most resellers. The problem is there is no control nor penalty.

In Europe, The CE marking is compulsory and none of the spool I have (including the one made in France and Italy) do have the CE mark.

The only one which have regulation tags are the esun (China), with the ROHS tag. In principle ROHS is applicable only for electrical product, but at least it defines heavy metals maximum contents. REACH (compulsory, again) will go further with limit for some organic contents.

The only info I have is from a post in the deltabot forum from someone working in a lab here :

[groups.google.com]

Quite impressive post.

Personally, I use only transparent or white filament and I have VOC filter, but this is not the common case.

|

Re: Charcoal filter March 05, 2016 07:10AM |

Registered: 8 years ago Posts: 68 |

And remember to stop burning candles. They generate huge amount of particles.

Back to topic... I'm planning to do circulation like this: active charcoal filter(20x50cm), fan, vacuum cleaner out HEPA filter and back to enclosure. That way I don't fill my fan with dust. Would that system suck out smell of ABS?

Back to topic... I'm planning to do circulation like this: active charcoal filter(20x50cm), fan, vacuum cleaner out HEPA filter and back to enclosure. That way I don't fill my fan with dust. Would that system suck out smell of ABS?

|

Re: Charcoal filter March 05, 2016 07:25AM |

Registered: 8 years ago Posts: 3,525 |

My experience with a recirculating system with charcoal, I am using charcoal beads designed for a cooker extractor, the smell of ABS (which is some of the VOC's were discussing) will be filtered. I haven't been running this long enough to get a feel for filter longevity. However these charcoal beads are about £6 for 500g.

|

Re: Charcoal filter March 05, 2016 07:26AM |

Registered: 8 years ago Posts: 475 |

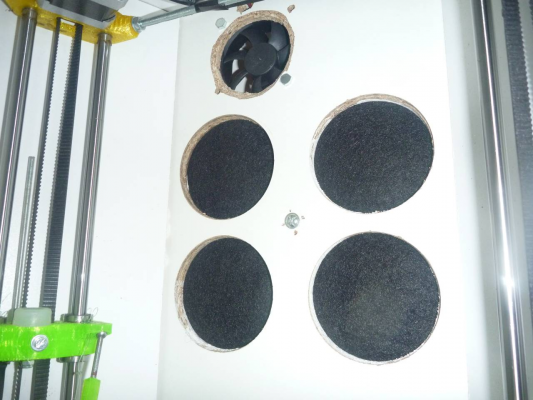

And, how are done my filters :

On the D-Box : [rouzeau.net]

and on the Lily [rouzeau.net]

I started on the D-Box.

Filtering media is kitchen activated carbon filter mattress

I started on the D-Box with only one layer and while odor was stopped (no smell after the filter), it was not easily removed from the box.

So now, my filter stack is 4 layers. Pressure drop is limited and the computer fan does not have difficulties to run flow.

However, if I had to redo it, I will go for 6 or 8 holes (diam 68) .

The Lily do have two layers with 4 holes, but its volumes is may be 1/4 of the D-Box, so the renewal is higher, even with the 60mm fan.

It shall be noted that I have very limited experience of ABS, mainly printing PETG or PLA.

Instead of what I read frequently, PETG do have an odor which is very noticeable in the boxed printers.

I was initially thinking that this setup shall only be efficient for VOC removal, however, after reading this thread and searching some info, it seems that the ultra-fine particles are stopped by adsorption. And adsorption is the principle of activated carbon (charcoal) filters. So, it may be not that bad for ultra-fine particle after all. I have no way to check.

This system have the advantage that it is simple to implement (if printer enclosed) and cost is negligible (4 euros for the filter media and 3 euros for the DC/DC converter for the fans power supply, fans being salvaged computer fans).

The media is very easy to find and install.

Edited 1 time(s). Last edit at 03/05/2016 07:52AM by PRZ.

On the D-Box : [rouzeau.net]

and on the Lily [rouzeau.net]

I started on the D-Box.

Filtering media is kitchen activated carbon filter mattress

I started on the D-Box with only one layer and while odor was stopped (no smell after the filter), it was not easily removed from the box.

So now, my filter stack is 4 layers. Pressure drop is limited and the computer fan does not have difficulties to run flow.

However, if I had to redo it, I will go for 6 or 8 holes (diam 68) .

The Lily do have two layers with 4 holes, but its volumes is may be 1/4 of the D-Box, so the renewal is higher, even with the 60mm fan.

It shall be noted that I have very limited experience of ABS, mainly printing PETG or PLA.

Instead of what I read frequently, PETG do have an odor which is very noticeable in the boxed printers.

I was initially thinking that this setup shall only be efficient for VOC removal, however, after reading this thread and searching some info, it seems that the ultra-fine particles are stopped by adsorption. And adsorption is the principle of activated carbon (charcoal) filters. So, it may be not that bad for ultra-fine particle after all. I have no way to check.

This system have the advantage that it is simple to implement (if printer enclosed) and cost is negligible (4 euros for the filter media and 3 euros for the DC/DC converter for the fans power supply, fans being salvaged computer fans).

The media is very easy to find and install.

Edited 1 time(s). Last edit at 03/05/2016 07:52AM by PRZ.

|

Re: Charcoal filter March 05, 2016 08:04AM |

Registered: 8 years ago Posts: 475 |

My filter media looks like that :

It is made by a german company, but I lost the name... bought in supermarket, bundled with grease filter (white mattress, not used).

It is made by a german company, but I lost the name... bought in supermarket, bundled with grease filter (white mattress, not used).

|

Re: Charcoal filter March 05, 2016 08:25AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Charcoal filter March 05, 2016 08:35AM |

Registered: 8 years ago Posts: 475 |

Thermistor is for D-Box heated chamber, not installed yet. My first attempt nearly set fire to the printer (...), and I was happy to have the carbon filter, as my printer was smelling burned wood for months and still is somewhat... I will then try aquarium 'lamp' heaters.

Also, I was a bit concerned by the self-combustion of carbon filters, but with the very low VOC quantity captured, that will not occured anytime soon. My experience in industry is for hundred times more VOC than what exists in a printer (filtering over oil tank), not comparable in concentration and area.

Also, I was a bit concerned by the self-combustion of carbon filters, but with the very low VOC quantity captured, that will not occured anytime soon. My experience in industry is for hundred times more VOC than what exists in a printer (filtering over oil tank), not comparable in concentration and area.

|

Re: Charcoal filter March 05, 2016 08:55AM |

Registered: 8 years ago Posts: 475 |

Also, this thermistor may help early detection of a fire, however there is no software implementation yet and this is not something I can do myself (board is Duet 0.8.5).

No thermistor on the Lily as board is Duet 0.6 and there is no spare.

I hope the future duet boards will have spare thermistor for safety (I asked for it), we'll see.

No thermistor on the Lily as board is Duet 0.6 and there is no spare.

I hope the future duet boards will have spare thermistor for safety (I asked for it), we'll see.

|

Re: Charcoal filter March 05, 2016 09:14AM |

Registered: 8 years ago Posts: 475 |

For HEPA filters, someone in a thread (the filtration one ?) suggested to use that :

[www.amazon.co.uk]

This is not a pleated filter, it is really meant for HEPA filtration (that is for a Dyson vacuum cleaner).

With its shape, that will be easy to install, but the pressure drop may be significant.

Now, we need a bit more test by people having measuring equipment.

If charcoal filter have the ability to stop ultra-fine particles by adsorption, this is the way to go as it is the simplest to install.

[www.amazon.co.uk]

This is not a pleated filter, it is really meant for HEPA filtration (that is for a Dyson vacuum cleaner).

With its shape, that will be easy to install, but the pressure drop may be significant.

Now, we need a bit more test by people having measuring equipment.

If charcoal filter have the ability to stop ultra-fine particles by adsorption, this is the way to go as it is the simplest to install.

|

Re: Charcoal filter March 05, 2016 09:48AM |

Registered: 8 years ago Posts: 3,525 |

|

Re: Charcoal filter March 05, 2016 12:43PM |

Registered: 8 years ago Posts: 3,525 |

Quote

PRZ

Also, this thermistor may help early detection of a fire, however there is no software implementation yet and this is not something I can do myself (board is Duet 0.8.5).

No thermistor on the Lily as board is Duet 0.6 and there is no spare.

I hope the future duet boards will have spare thermistor for safety (I asked for it), we'll see.

This might be useful and works even better with a recirculating filter.

[forums.reprap.org]

|

Re: Charcoal filter April 12, 2016 09:33AM |

Registered: 8 years ago Posts: 475 |

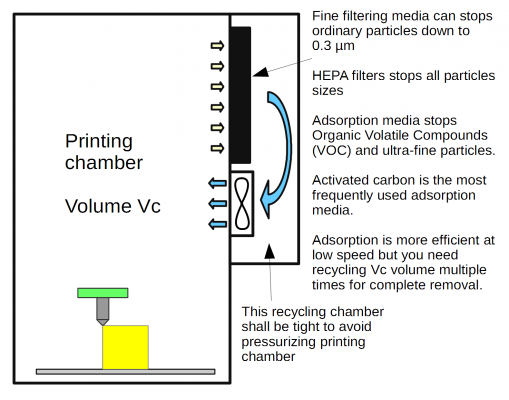

I think to add the following image on the wiki in the Health and safety page at Filtration paragraph. [reprap.org]

Any comment on the below image/text ? or on the filtration paragraph itself

Any comment on the below image/text ? or on the filtration paragraph itself

|

Re: Charcoal filter April 12, 2016 10:14AM |

Registered: 8 years ago Posts: 3,525 |

Well I'm no filtration expert but as a schematic of a recirculating hepa/carbon filter this seems fine. Might be worth saying that an alternative strategy would be an exhaust system with carbon/hepa filters, venting out of the chamber into the room air but this requires larger fans and filters. This is used on some commercial system such as the Cubicon. Or a external exhaust system venting the air (filtered or un filtered) into the outside environment.

Recirculation means lower fan speeds required, probably more complete removal of VOC's and UFP's and enables the movement of hot air from the top of the chamber back to the bottom.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Recirculation means lower fan speeds required, probably more complete removal of VOC's and UFP's and enables the movement of hot air from the top of the chamber back to the bottom.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Charcoal filter April 12, 2016 11:21AM |

Registered: 8 years ago Posts: 475 |

Ah, I was thinking the Cubicon was recirculating. What is the point to extract inside the room ?

I understand the interest to extract outside room, but extraction in the room is the worst. However, the Cubicon filter does not seems very large (from film, look here : [www.youtube.com]). I like the simplicity of their cartridge system.

I understand the interest to extract outside room, but extraction in the room is the worst. However, the Cubicon filter does not seems very large (from film, look here : [www.youtube.com]). I like the simplicity of their cartridge system.

|

Re: Charcoal filter April 12, 2016 11:44AM |

Registered: 8 years ago Posts: 3,525 |

Well I think given that many printers are open, so no filtration possible (except perhaps a large cooker-type extractor above the machine???) or enclosed and un-filtered the thinking behind the Cubicon is that any filtration is better than none. Reviews I've seen suggest qualitatively it works, there is no ABS odour when printing, so this suggests the filters are large enough and of sufficient quality to remove VOC's at least. However recirculating makes far more sense IMO, for all the reasons given in this thread.

I don't think the filters need to be very large as the quantity of VOC's and UFP's must be miniscule. I was planning to weigh my filters (I can manage 0.01g accuracy) before and after prolonged use, but much of the increase in mass is likely to be dust.

Edited 2 time(s). Last edit at 04/12/2016 12:06PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I don't think the filters need to be very large as the quantity of VOC's and UFP's must be miniscule. I was planning to weigh my filters (I can manage 0.01g accuracy) before and after prolonged use, but much of the increase in mass is likely to be dust.

Edited 2 time(s). Last edit at 04/12/2016 12:06PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Charcoal filter April 12, 2016 12:50PM |

Registered: 8 years ago Posts: 475 |

The size may not be related to the quantity extracted, but more about the capability to remove.

My experience shown that while my initial setup (~115 cm2 x 0.5 cm - 58 cm3 of mattress - which is NOT pure activated carbon, sort of a unknown compound for kitchen filter) was stopping the odor (no odor in the recycling chamber), it was not removing it from the printer. I set four layers and now I have approximately 230 cm3 of filtration media and odor is mostly removed while opening the printer (Though I am not printing ABS).

This volume is not that far from what you have in the Cubicon, knowing I don't have HEPA filter, but I am recycling. I assume granular activated carbon may have better efficiency, but you have to set-up a system to contain it with sufficient exposed area. And without any pre-filtering system, my mattress may end up polluted by dust. Multi-layer is better but if you recycle, you don't get all the dust of the room you are working in, only the small volume of your printer.

I'll try to develop the recycling viewpoint.

My experience shown that while my initial setup (~115 cm2 x 0.5 cm - 58 cm3 of mattress - which is NOT pure activated carbon, sort of a unknown compound for kitchen filter) was stopping the odor (no odor in the recycling chamber), it was not removing it from the printer. I set four layers and now I have approximately 230 cm3 of filtration media and odor is mostly removed while opening the printer (Though I am not printing ABS).

This volume is not that far from what you have in the Cubicon, knowing I don't have HEPA filter, but I am recycling. I assume granular activated carbon may have better efficiency, but you have to set-up a system to contain it with sufficient exposed area. And without any pre-filtering system, my mattress may end up polluted by dust. Multi-layer is better but if you recycle, you don't get all the dust of the room you are working in, only the small volume of your printer.

I'll try to develop the recycling viewpoint.

|

Re: Charcoal filter April 12, 2016 01:29PM |

Registered: 8 years ago Posts: 475 |

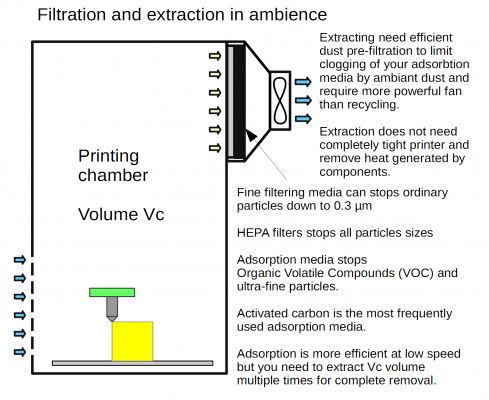

Ok, so a schematic for extraction:

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

|

Re: Charcoal filter April 13, 2016 04:46PM |

Registered: 8 years ago Posts: 475 |

I extracted (and completed) the paragraph about filtration in health and safety page on the Wiki, to make it an independant page :

Gaseous pollutant filtration [reprap.org]

I would like to have photos of your systems - please note that the license of the wiki is GFDL 1.2

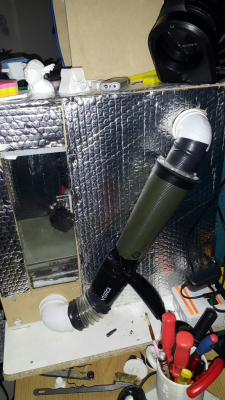

DjDemonD, you already published a photo, can I have another taken a bit more sideway, where we could see how the filter itself is installed/connected.

Gaseous pollutant filtration [reprap.org]

I would like to have photos of your systems - please note that the license of the wiki is GFDL 1.2

DjDemonD, you already published a photo, can I have another taken a bit more sideway, where we could see how the filter itself is installed/connected.

|

Re: Charcoal filter April 13, 2016 04:54PM |

Registered: 8 years ago Posts: 3,525 |

Feel free to use any photos already on here, and this other one taken from the side. This only really a proof of concept I'd plan to use much more solid tubing and less tape if I were going to move to a newer version.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.