Printing reprap parts/ help with delamination

Posted by eried

|

Printing reprap parts/ help with delamination January 05, 2016 10:31AM |

Registered: 10 years ago Posts: 114 |

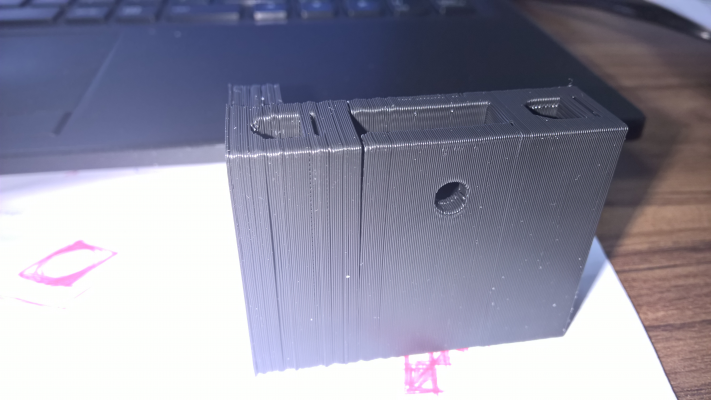

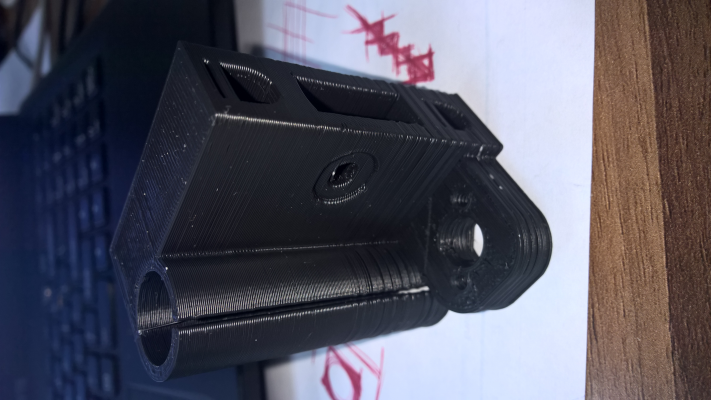

Hi, I can't figure out why my pieces are printed so delaminated at the first centimeters of height. Is this a temperature problem? My printer is an old TOM, here are some pictures:

Full size images:

[cloudup.com]

[cloudup.com]

Full size images:

[cloudup.com]

[cloudup.com]

|

Re: Printing reprap parts/ help with delamination January 05, 2016 10:44AM |

Registered: 12 years ago Posts: 2,470 |

What material? What temperature? Is the printer enclosed, if yes what internal temperatur?

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Printing reprap parts/ help with delamination January 05, 2016 12:56PM |

Registered: 10 years ago Posts: 114 |

|

Re: Printing reprap parts/ help with delamination January 05, 2016 01:33PM |

Registered: 10 years ago Posts: 14,672 |

You need to enclose your printer in order to print ABS prints more than a few mm high, to increase the temperature of the air around the print and protect it from draughts. You don't necessarily need active heating of the chamber, the heat from the bed may be enough. I have a delta printer, and putting two plastic bags over it was enough for me to get good ABS prints.

Keep the electronics out of the warm chamber. Also make sure that the hot end fan is cooling only the hot end heatsink and not blowing air on the print. Check for backwash from the fan too and fit a fan inlet duct if necessary.

Alternatively, print in a less critical material such as PLA or PETG.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Keep the electronics out of the warm chamber. Also make sure that the hot end fan is cooling only the hot end heatsink and not blowing air on the print. Check for backwash from the fan too and fit a fan inlet duct if necessary.

Alternatively, print in a less critical material such as PLA or PETG.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Printing reprap parts/ help with delamination January 05, 2016 02:12PM |

Registered: 10 years ago Posts: 580 |

What DC42 said, and also:

What nozzle diameter, perimeter width, layer height, print speed?

These parameters, including what Shrek asked, together make a big difference in layer adhesion.

Make sure your extrusion width is > nozzle diameter x 1.05, (and less than 1.7x nozzle diameter). The wider you make the extrusion width the more it must squish onto the previous layer, making a better bond. 1.5 x nozzle diameter will be bonded much better than 1x. Printing at a lower speed will melt it into the previous layer more.

However much this might help, it won't fix the problem if you don't have some heat contained.

Don't be afraid to try a bit higher temperature, you may get more even extrusion.

There is also some perimeter offsetting from the start. You may need to lower acceleration or print speeds, tighten belts, etc. This may help.

Edited 1 time(s). Last edit at 01/05/2016 02:14PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

What nozzle diameter, perimeter width, layer height, print speed?

These parameters, including what Shrek asked, together make a big difference in layer adhesion.

Make sure your extrusion width is > nozzle diameter x 1.05, (and less than 1.7x nozzle diameter). The wider you make the extrusion width the more it must squish onto the previous layer, making a better bond. 1.5 x nozzle diameter will be bonded much better than 1x. Printing at a lower speed will melt it into the previous layer more.

However much this might help, it won't fix the problem if you don't have some heat contained.

Don't be afraid to try a bit higher temperature, you may get more even extrusion.

There is also some perimeter offsetting from the start. You may need to lower acceleration or print speeds, tighten belts, etc. This may help.

Edited 1 time(s). Last edit at 01/05/2016 02:14PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Printing reprap parts/ help with delamination January 05, 2016 02:31PM |

Registered: 10 years ago Posts: 114 |

Quote

dc42

You need to enclose your printer in order to print ABS prints more than a few mm high, to increase the temperature of the air around the print and protect it from draughts. You don't necessarily need active heating of the chamber, the heat from the bed may be enough. I have a delta printer, and putting two plastic bags over it was enough for me to get good ABS prints.

Keep the electronics out of the warm chamber. Also make sure that the hot end fan is cooling only the hot end heatsink and not blowing air on the print. Check for backwash from the fan too and fit a fan inlet duct if necessary.

Alternatively, print in a less critical material such as PLA or PETG.

Thanks for the suggestions, but the strange thing is that the delamination is happening in the lower part of the print, not on the top so I am not sure if is a heat related issue

|

Re: Printing reprap parts/ help with delamination January 05, 2016 02:36PM |

Registered: 10 years ago Posts: 114 |

Quote

Paul Wanamaker

What DC42 said, and also:

What nozzle diameter, perimeter width, layer height, print speed?

These parameters, including what Shrek asked, together make a big difference in layer adhesion.

Make sure your extrusion width is > nozzle diameter x 1.05, (and less than 1.7x nozzle diameter). The wider you make the extrusion width the more it must squish onto the previous layer, making a better bond. 1.5 x nozzle diameter will be bonded much better than 1x. Printing at a lower speed will melt it into the previous layer more.

However much this might help, it won't fix the problem if you don't have some heat contained.

Don't be afraid to try a bit higher temperature, you may get more even extrusion.

There is also some perimeter offsetting from the start. You may need to lower acceleration or print speeds, tighten belts, etc. This may help.

Hey, thanks for the tip, which temperature should I try? I increased it from bed 120, nozzle 225 to 120/235 (to get more flow) but issue still continues in the initial layers (aprox 2 first centimeters). I have tighten all the belts, even added spring tighteners

Nozzle: 0.4mm, perimeter width not sure but I am using 1 shell, 0.3 layer height. 30 mm/s print speed. It is a 5 year old printer and I am using an old version of skeinforge (the last supported properly, probably 0035)

|

Re: Printing reprap parts/ help with delamination January 05, 2016 04:22PM |

Registered: 10 years ago Posts: 580 |

Temp is OK, you are in the range (about 135 to 160 depending on the filament). Speed is fine.

Lets concentrate on the layer adhesion issue.

Note that you are printing at just about the max sane layer height for that nozzle diameter.

.40 * .80 = .32. This is going to limit adhesion unless a wide perimeter is used.

Have you tried a lower layer height, say .20? That will also take a big load off your extruder.

Other than that, I'm not sure how Skeinforge sets perimeter width. I use Slic3r and can set the width for each kind of feature...

Have you tried printing with plastic bags over the printer? If it's cold you could even warm it up inside a bit with a hair dryer, not too hot if electronics are enclosed...

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Lets concentrate on the layer adhesion issue.

Note that you are printing at just about the max sane layer height for that nozzle diameter.

.40 * .80 = .32. This is going to limit adhesion unless a wide perimeter is used.

Have you tried a lower layer height, say .20? That will also take a big load off your extruder.

Other than that, I'm not sure how Skeinforge sets perimeter width. I use Slic3r and can set the width for each kind of feature...

Have you tried printing with plastic bags over the printer? If it's cold you could even warm it up inside a bit with a hair dryer, not too hot if electronics are enclosed...

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Printing reprap parts/ help with delamination January 05, 2016 11:07PM |

Registered: 10 years ago Posts: 239 |

|

Re: Printing reprap parts/ help with delamination January 06, 2016 09:05AM |

Registered: 10 years ago Posts: 114 |

Quote

Bill Clark

I have printed ABS as high as 280c resulting in a significant increase in layer bonding and no noticeable ill effects. Not recommending you bandaid the problem with high temps rather don't be afraid to pour some heat to it. There are a lot of other variables at play here as stated above

Hey Bill, have you tested the pieces empirically or it is just a perception about they increase layer bonding? I am not sure if my extruder can reach that temperature without breaking, is a MK6 without a fan

|

Re: Printing reprap parts/ help with delamination January 06, 2016 09:06AM |

Registered: 10 years ago Posts: 114 |

Quote

Paul Wanamaker

Temp is OK, you are in the range (about 135 to 160 depending on the filament). Speed is fine.

Lets concentrate on the layer adhesion issue.

Note that you are printing at just about the max sane layer height for that nozzle diameter.

.40 * .80 = .32. This is going to limit adhesion unless a wide perimeter is used.

Have you tried a lower layer height, say .20? That will also take a big load off your extruder.

Other than that, I'm not sure how Skeinforge sets perimeter width. I use Slic3r and can set the width for each kind of feature...

Have you tried printing with plastic bags over the printer? If it's cold you could even warm it up inside a bit with a hair dryer, not too hot if electronics are enclosed...

I think the .32 layer height helped a lot, plus some extra calibration of the platform. I am going to test again tonight. Great tip! thanks

Edited 1 time(s). Last edit at 01/06/2016 09:06AM by eried.

|

Re: Printing reprap parts/ help with delamination January 06, 2016 12:27PM |

Registered: 10 years ago Posts: 580 |

|

Re: Printing reprap parts/ help with delamination January 06, 2016 02:01PM |

Registered: 10 years ago Posts: 114 |

Quote

Paul Wanamaker

eried,

I wasn't recommending going to .32, was recommending smaller, like .20 and wider extrusion width.

But by all means do test!

haha yeah I extrapolated the recommendation with the multiplication you wrote. I was using a not optimal .3, and .32 / .28 seems to be better for my 8 mm per turn rod, in terms of inter lineal precision

|

Re: Printing reprap parts/ help with delamination January 06, 2016 08:14PM |

Registered: 10 years ago Posts: 239 |

yes, back to back tests on a part and a single extrusion width wall test piece changing only temps. These particular test pieces looked identical. I have and normally do get excellent layer adhesion at 245 on my printer though.Quote

eried

Quote

Bill Clark

I have printed ABS as high as 280c resulting in a significant increase in layer bonding and no noticeable ill effects. Not recommending you bandaid the problem with high temps rather don't be afraid to pour some heat to it. There are a lot of other variables at play here as stated above

Hey Bill, have you tested the pieces empirically or it is just a perception about they increase layer bonding? I am not sure if my extruder can reach that temperature without breaking, is a MK6 without a fan

|

Re: Printing reprap parts/ help with delamination January 07, 2016 03:01AM |

Registered: 8 years ago Posts: 916 |

+1 on Bill's idea of going hotter.

I was getting layer adhesion issues on lego-style pieces when I was at 235 degrees, now I print at 245 degrees and no more issues (no other changes). This was confirmed in multiple tests, when I was at 235 I could separate layers with my fingernail and the parts would delaminate when separating the lego pieces, but at 245 they are stuck well and truly.

Note that in my case, 245 is only really helpful when at 0.1mm layer height. When using 0.3mm layer heights I need to back off the temps to 240 or lower to avoid zits.

That said it looks like you've got some mechanical issues there, possibly Z-wobble or similar. I'd carefully check all the pieces that go into moving the extruder / bed up and down in the Z direction.

Edited 2 time(s). Last edit at 01/07/2016 03:04AM by nebbian.

I was getting layer adhesion issues on lego-style pieces when I was at 235 degrees, now I print at 245 degrees and no more issues (no other changes). This was confirmed in multiple tests, when I was at 235 I could separate layers with my fingernail and the parts would delaminate when separating the lego pieces, but at 245 they are stuck well and truly.

Note that in my case, 245 is only really helpful when at 0.1mm layer height. When using 0.3mm layer heights I need to back off the temps to 240 or lower to avoid zits.

That said it looks like you've got some mechanical issues there, possibly Z-wobble or similar. I'd carefully check all the pieces that go into moving the extruder / bed up and down in the Z direction.

Edited 2 time(s). Last edit at 01/07/2016 03:04AM by nebbian.

|

Re: Printing reprap parts/ help with delamination January 09, 2016 10:06AM |

Registered: 10 years ago Posts: 114 |

245C was really helpful for adhesion. I am printing at 0.24m now, there is a little strange layers at first but it is totally usable for my new prusa

thanks

[cloudup.com] <- more images

thanks

[cloudup.com] <- more images

Sorry, only registered users may post in this forum.