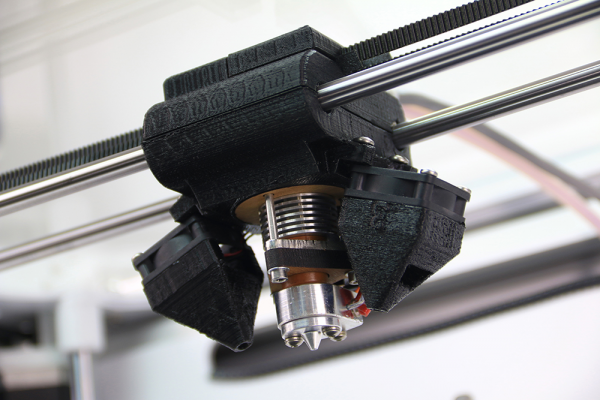

E3D to airbrush nozzle adapter

Posted by epicepee

|

E3D to airbrush nozzle adapter January 21, 2016 04:46PM |

Registered: 11 years ago Posts: 471 |

|

Re: E3D to airbrush nozzle adapter January 23, 2016 05:27PM |

Registered: 8 years ago Posts: 318 |

|

Re: E3D to airbrush nozzle adapter January 27, 2016 06:25AM |

Registered: 12 years ago Posts: 227 |

I suggested this about two years ago and my friend from Ukraine implemented it.

Project was stopped as he cannot find exact thread tap.

Project was stopped as he cannot find exact thread tap.

|

Re: E3D to airbrush nozzle adapter January 27, 2016 07:03AM |

Registered: 12 years ago Posts: 2,470 |

For the Airbrush Nozzle? Use M1.75 to get a snug fit. It works fine for the Merlin hotend for years now.Quote

karabas

I suggested this about two years ago and my friend from Ukraine implemented it.

Project was stopped as he cannot find exact thread tap.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: E3D to airbrush nozzle adapter January 27, 2016 01:03PM |

Registered: 11 years ago Posts: 471 |

|

Re: E3D to airbrush nozzle adapter January 28, 2016 06:26AM |

Registered: 12 years ago Posts: 227 |

Actually it does not matter.Quote

epicepee

karabas: Is that an entire hotend or does it attach to an E3D somehow?

It uses regular nozzle with airbrush nozzle inserted

Take a nozzle, drill, make a thread and screw airbrush nozzzle into.

Or simply buy Merlin hotend. There are many examples on his page. Highly recommended.

|

Re: E3D to airbrush nozzle adapter January 28, 2016 11:30AM |

Registered: 11 years ago Posts: 471 |

|

Re: E3D to airbrush nozzle adapter January 28, 2016 11:45AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: E3D to airbrush nozzle adapter January 28, 2016 12:22PM |

Registered: 11 years ago Posts: 471 |

|

Re: E3D to airbrush nozzle adapter January 28, 2016 12:41PM |

Registered: 12 years ago Posts: 2,470 |

Have you ever tried the Merlin?Quote

JamesK

The shape of the tip of that nozzle doesn't look very good for printing. You need a flat area around the nozzle in which to form the extruded plastic into a rectangular shape. The flat is key to nozzle performance.

Here are some examples on prints done with it

[b.bonkers.de]

[www.3ders.org]

[b.bonkers.de]

Edited 1 time(s). Last edit at 01/28/2016 12:43PM by Srek.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: E3D to airbrush nozzle adapter January 28, 2016 12:59PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: E3D to airbrush nozzle adapter January 28, 2016 01:04PM |

Registered: 12 years ago Posts: 2,470 |

you do know that the comment makes no sense at all? All prints were made by people with years of experience with a variety of printers and hotends.Quote

JamesK

Those are some pretty good looking prints! I'm surprised that such a pointy nozzle works so well. I wonder to what extent the print quality is because of the nozzle or despite it.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: E3D to airbrush nozzle adapter January 28, 2016 01:09PM |

Registered: 9 years ago Posts: 1,873 |

Not looking for a fight here Srek, you use whatever nozzle lights your candle. I remain surprised that a nozzle not designed for 3d printing and with a profile that doesn't seem to fit the way a 3d printer works is a good idea. The fact that the use of such nozzles remains very much in the minority would tend to suggest that it is not without it's disadvantages.

|

Re: E3D to airbrush nozzle adapter January 28, 2016 01:25PM |

Registered: 11 years ago Posts: 471 |

JamesK: Note that these are the best prints from this hotend. It may take a lot of work to get there. This would explain both the pictures and the relatively narrow acceptance (though it does seem to be growing).

Srek: I think he's saying that he's surprised at the Merlin's capabilities. Which makes sense, because it's a very unique design. It would be like if some company started making a five-wheeled car: it's uncommon that such a different design is good enough to compete but not good enough to simply take over.

Srek: I think he's saying that he's surprised at the Merlin's capabilities. Which makes sense, because it's a very unique design. It would be like if some company started making a five-wheeled car: it's uncommon that such a different design is good enough to compete but not good enough to simply take over.

|

Re: E3D to airbrush nozzle adapter January 28, 2016 01:33PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: E3D to airbrush nozzle adapter January 28, 2016 01:55PM |

Registered: 12 years ago Posts: 2,470 |

I spent one year of my spare time developing and testing the Merlin hotend. I tend to become a bit defensive if someone claims a print is of good quality despite the hotend beeing used, especially when that person never used it himself. The Merlin has some shortcomings, a lack of print quality is not one of them.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: E3D to airbrush nozzle adapter January 28, 2016 02:00PM |

Registered: 9 years ago Posts: 1,873 |

Quote

Srek

I spent one year of my spare time developing and testing the Merlin hotend. I tend to become a bit defensive if someone claims a print is of good quality despite the hotend beeing used, especially when that person never used it himself. The Merlin has some shortcomings, a lack of print quality is not one of them.

That's reasonable, I can see your point. I wasn't questioning the entire hot-end, just the nozzle, and specifically just the profile of the tip. During your testing, did you try machining off the tip to explore the behaviour of different ratios of exit diameter to flat? I'd be really interested to see how that affects both print quality and ease of use.

Kudos to anyone who has the vision to take a different approach to any problem domain.

|

Re: E3D to airbrush nozzle adapter January 28, 2016 02:01PM |

Registered: 11 years ago Posts: 471 |

Srek:

He's never used the Merlin, so he doesn't know how much it helps or hurts. The fact is that any hotend can get good prints, so a few pictures isn't proof of quality. All the same, people do seem to like the Merlin.

Quote

JamesK

I wonder to what extent the print quality is because of the nozzle or despite it.

He's never used the Merlin, so he doesn't know how much it helps or hurts. The fact is that any hotend can get good prints, so a few pictures isn't proof of quality. All the same, people do seem to like the Merlin.

|

Re: E3D to airbrush nozzle adapter January 28, 2016 02:27PM |

Registered: 12 years ago Posts: 2,470 |

I tried dozens of shapes of nozzles with varying angles at the tip before i ended up focusing on the airbrush solution. None of the other shapes or general solutions performed better. Some with a shallow angle did show the often cited ironing effect, but i determined that ironing only ever improves the print quality if you are extruding to much material to begin with. On the contrary, flat tips had a lot more problems with bridges and overhang that sharp tipped nozzles. The main thing you have to observe with any sharp tipped nozzle is that you have to calibrate the amount of material as good as possible and that the printing surface needs to be very planar if you want to print without a raft. If you don't observe this the tip will scrap off excess material leading to unsightly blobs, or in case of an uneven printbed or maladjusted x bridge the tip might even rip the already printed parts of the bed. But then, the real problem here is not the nozzle.

Most of the currently sold nozzles have medium steep angles and try to get the best of both worlds. They are more fogiving with incorrect adjusted extrusion, but need some serious work to print fine details as good as an airbrush nozzle.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Most of the currently sold nozzles have medium steep angles and try to get the best of both worlds. They are more fogiving with incorrect adjusted extrusion, but need some serious work to print fine details as good as an airbrush nozzle.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: E3D to airbrush nozzle adapter January 28, 2016 02:40PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: E3D to airbrush nozzle adapter January 28, 2016 03:36PM |

Registered: 11 years ago Posts: 471 |

|

Re: E3D to airbrush nozzle adapter January 28, 2016 03:39PM |

Registered: 12 years ago Posts: 2,470 |

I got a M1.75 thread cutter for a few bucks from ebay. A friend used a M1.6 with success as well. In fact i doubt either is the exact fit for the airbrush nozzle, but both work

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: E3D to airbrush nozzle adapter January 28, 2016 04:16PM |

Registered: 11 years ago Posts: 471 |

Srek:

Interesting. I'll definitely have to try this. Do you think it would work to simply buy an el-cheapo E3D nozzle, drill it to 1.5mm, and tap it with a 1.7mm tap? Do I need to take special consideration to center the hole perfectly? Do I need to buy a certain type of airbrush nozzle?

Thanks for all of your help!

Interesting. I'll definitely have to try this. Do you think it would work to simply buy an el-cheapo E3D nozzle, drill it to 1.5mm, and tap it with a 1.7mm tap? Do I need to take special consideration to center the hole perfectly? Do I need to buy a certain type of airbrush nozzle?

Thanks for all of your help!

|

Re: E3D to airbrush nozzle adapter January 28, 2016 05:00PM |

Registered: 12 years ago Posts: 2,470 |

With the merlin the thread is as long in the hotend as it is on the nozzle. I dont think it is a problem if the threaded hole is a bit longer, but shorter might be.

You will find it hard to drill the hole out without good centering.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

You will find it hard to drill the hole out without good centering.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: E3D to airbrush nozzle adapter January 30, 2016 08:23AM |

Registered: 9 years ago Posts: 1,035 |

Have you noticed the pointy nozzle of the latest Airwolf Axiom3D? Airbrush nozzle style can be onto something:

Edited 1 time(s). Last edit at 01/30/2016 08:24AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Edited 1 time(s). Last edit at 01/30/2016 08:24AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: E3D to airbrush nozzle adapter January 30, 2016 08:48AM |

Registered: 9 years ago Posts: 1,873 |

Quote

realthor

Have you noticed the pointy nozzle of the latest Airwolf Axiom3D?

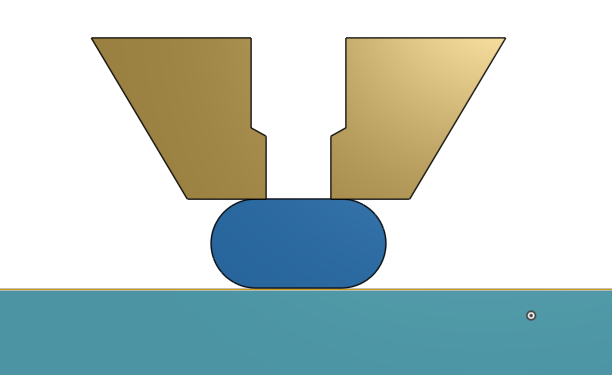

It's not as pointy as it looks in that photo. The key design feature (from my admittedly limited understanding) is the ratio of the nozzle bore to the surrounding flat. If you look at this close-up you can see that Airwolf are using a very conventional looking ratio on their nozzles:

The angle of the cone outside of the flat has only secondary effects on printing, i.e. how the head copes with print defects when things go wrong, and the temperature gradient along the length of the nozzle.

Edited 1 time(s). Last edit at 01/30/2016 08:50AM by JamesK.

|

Re: E3D to airbrush nozzle adapter January 30, 2016 09:17AM |

Registered: 9 years ago Posts: 1,035 |

Yes, I can see better on that second image. I always believed that the flat on the nozzle is to cope with the imperfections of early 3d printers, it flats out the plastic that comes out and ensures better bonding with next layers, as they don't remain rounded. This can also be solved by overextruding a bit. I wonder how a very pointy and fine nozzle like the airbrush's prints at a very high magnification level. How is the bonding between layers?

but then again I am not an expert in this so I might be very wrong

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

but then again I am not an expert in this so I might be very wrong

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: E3D to airbrush nozzle adapter January 30, 2016 10:21AM |

Registered: 9 years ago Posts: 1,873 |

Quote

realthor

I always believed that the flat on the nozzle is to cope with the imperfections of early 3d printers, it flats out the plastic that comes out and ensures better bonding with next layers, as they don't remain rounded.

Well, sort of yes and no. No to the first part, that's a common misconception, yes to the second part. It comes down to what shape are we trying to extrude and how do we get that. A round cross section extrudate would be bad, because there is minimal contact area and poor bonding

So to get better bonding we aim to extrude filament that is wider than it is high, something like

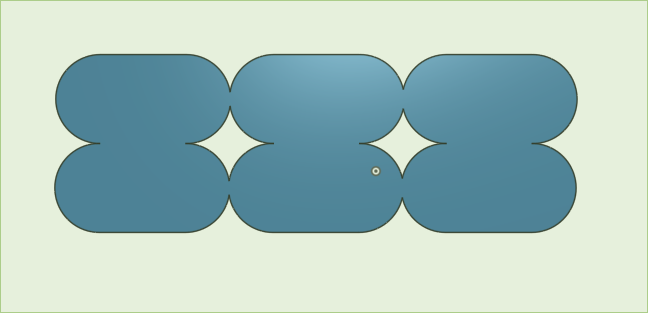

The tip of the nozzle provides a constrained space into which we can extrude the filament to get a variety of extrusion widths

The smallest width that can be extruded is limited by the bore of the nozzle - if you try and extrude less than that the system is under constrained, you can't guarantee where the filament will go and it will likely have intermittent contact the lower surface. In my simplistic view of the world, the largest width that you can extrude is determined by the diameter of the flat. If you try and extrude wider than the diameter of the flat the system is again under constrained. I'm not sure what that would look like, but given the viscosity of the plastics we use, I'm guessing it would look like this

So, my understanding (which I'm happy to have explained as to why I'm wrong) is that the nozzle bore sets the minimum extrusion width and the maximum rate of flow, while the maximum width is set by the diameter of the flat. A nozzle with a small flat looks like it should have a rather small range of usable extrusion widths, which seems like a disadvantage to me, as variable extrusion width is something that slicers can make use of to improve print quality. On the other hand, I don't yet see a disadvantage to having a large flat on the nozzle, so I'm interested in Srek's observations that the narrower tips have advantages in bridging and overhangs. I'm not disputing Srek's observations at all, just trying to understand them.

|

Re: E3D to airbrush nozzle adapter March 22, 2017 03:41PM |

Registered: 8 years ago Posts: 3,525 |

I'm quite interested in the airbrush nozzles but adapting one - 1.75mm thread, might be a challenge. I will say though whilst I mainly use e3d v6 and their nozzles, I also have a deltaprintr mini hotend and it has a very sharp nozzle but is capable of some quite good prints.

Whilst I can see many benefits of having a large flat around the nozzle orifice, I can see two possible drawbacks. One is "friction" from nozzle on the filament as its extruded, especially on first layers, and especially with PETG. The second is smudging of fine details by the flat.

Edited 3 time(s). Last edit at 03/24/2017 05:17AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Whilst I can see many benefits of having a large flat around the nozzle orifice, I can see two possible drawbacks. One is "friction" from nozzle on the filament as its extruded, especially on first layers, and especially with PETG. The second is smudging of fine details by the flat.

Edited 3 time(s). Last edit at 03/24/2017 05:17AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: E3D to airbrush nozzle adapter March 24, 2017 05:11AM |

Registered: 8 years ago Posts: 312 |

Sorry, only registered users may post in this forum.