This engineer claims 100 grams direct extruder. I want one

Posted by realthor

Re: This engineer claims 100 grams direct extruder. I want one February 16, 2016 10:00AM |

Registered: 9 years ago Posts: 49 |

Those nema 14's are a good find! that 14HR05-0504S is BINGO for me. Thanks for sharing. I'll try to see if i can score one. That earlier mentioned cheap steppermotor with build in reduction is lacking bearings IMO, perhaps it's possible to modify it.

That pencil principle might work, nice, a retro Rotring. Lovely pencils. But it would require quite a complex mechanism; retracting wouldn't be the biggest concern, i think a smooth movement is important, so most likely two of these 'pushclamps' in series to get a smooth movement.

Another possible issue with the pencil-pusher is that it wouldn be challanging to create a design that can cope with flexible filaments.

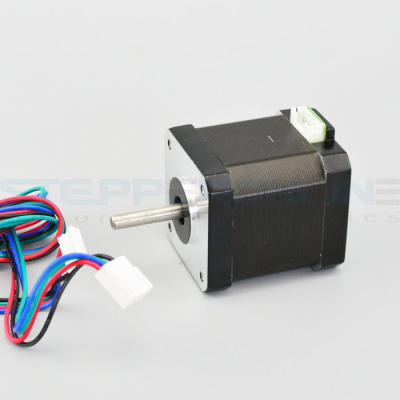

this is the stepper as used in the coreXY printer that's in this thread too. It's available in the US through Ebay for a relative fair price, but shipping to Europe is killer

That pencil principle might work, nice, a retro Rotring. Lovely pencils. But it would require quite a complex mechanism; retracting wouldn't be the biggest concern, i think a smooth movement is important, so most likely two of these 'pushclamps' in series to get a smooth movement.

Another possible issue with the pencil-pusher is that it wouldn be challanging to create a design that can cope with flexible filaments.

this is the stepper as used in the coreXY printer that's in this thread too. It's available in the US through Ebay for a relative fair price, but shipping to Europe is killer

Re: This engineer claims 100 grams direct extruder. I want one February 22, 2016 12:46PM |

Registered: 8 years ago Posts: 1,671 |

This looks very similar to the stratasys motor..

[www.ebay.co.uk]

and a small 46g Black one,

[www.ebay.co.uk]

Rather expensive, and maybe not the ideal solution, the encoder might make things tricky, probably underpowered too,

my nema 17 pancake arrived to play with, but I think I got the wrong one, silver n black 1.8 deg, the other all black is 0.9 deg,

I would rather have got that one, another version of the 17 has just shown up, all black with the quick disconnect

[www.ebay.co.uk]

[www.ebay.co.uk]

and a small 46g Black one,

[www.ebay.co.uk]

Rather expensive, and maybe not the ideal solution, the encoder might make things tricky, probably underpowered too,

my nema 17 pancake arrived to play with, but I think I got the wrong one, silver n black 1.8 deg, the other all black is 0.9 deg,

I would rather have got that one, another version of the 17 has just shown up, all black with the quick disconnect

[www.ebay.co.uk]

Re: This engineer claims 100 grams direct extruder. I want one February 24, 2016 04:06AM |

Registered: 9 years ago Posts: 49 |

I just recceived the 14HR05-0504S, That thing is tiny. (oo,) some 48p gears are on the way, an 18t and a 76t/90t spur, which should give me ~ 30/35 N/cm of (holding) torque. With the used mk7 hobbed gear (larger diameter, means more grip on the filament) this translates into ~5 - 6kg of pushing capability. Don't know how it behaves at (higher) RPM though. torque will be significantly lower. If it doesn't work i'll buy the bigger version of that motor.

I'm currently working on 2 printers. One is a delta, which I need to machine some parts for (made a neat design for the pushrods, no magnets, but a lightweight delrin cup with a 10mm ball on 8mm lightweight rods). All the other structual/electronic parts are here, so I can't wait to begin Also planning on building a corexy, got some parts for that as well, just need to order extrusion and machine the structural needed parts. One of the goals was to use as little machining as possible.

Also planning on building a corexy, got some parts for that as well, just need to order extrusion and machine the structural needed parts. One of the goals was to use as little machining as possible.

This lightweight extruder is handy for printing flexible filament on the delta, and the corexy should benifit from it as well.

I'll get a working proto as soon as the gears and all have arrived.

I'm currently working on 2 printers. One is a delta, which I need to machine some parts for (made a neat design for the pushrods, no magnets, but a lightweight delrin cup with a 10mm ball on 8mm lightweight rods). All the other structual/electronic parts are here, so I can't wait to begin

Also planning on building a corexy, got some parts for that as well, just need to order extrusion and machine the structural needed parts. One of the goals was to use as little machining as possible.

Also planning on building a corexy, got some parts for that as well, just need to order extrusion and machine the structural needed parts. One of the goals was to use as little machining as possible.This lightweight extruder is handy for printing flexible filament on the delta, and the corexy should benifit from it as well.

I'll get a working proto as soon as the gears and all have arrived.

Re: This engineer claims 100 grams direct extruder. I want one February 24, 2016 05:14AM |

Registered: 12 years ago Posts: 799 |

Sounds interesting with this stepper.

I`m more looking for a ST3518M1004 Nema 8 at the moment, 60g, with only 1.7Ncm not so strong but also not so tall, as i need a tiny extruder.

I`m thinking about a 4:10 reductions but using a 8mm Bolt/MK8 pulley as i never had grip problems with 8mm bolts (i even printed with 6mm bolts) and you gain some extra torque.

That 14HR05-0504S even is 10g less heavy, but seems to me more bulky ?

I think i also have to draw some extruders to see which one would be better when it comes to the overall size.

Is there also a 1.8° version of it available ?

Which gear module do you use?, it`s not easy to find gears that fullfill every spec i need to ...

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

I`m more looking for a ST3518M1004 Nema 8 at the moment, 60g, with only 1.7Ncm not so strong but also not so tall, as i need a tiny extruder.

I`m thinking about a 4:10 reductions but using a 8mm Bolt/MK8 pulley as i never had grip problems with 8mm bolts (i even printed with 6mm bolts) and you gain some extra torque.

That 14HR05-0504S even is 10g less heavy, but seems to me more bulky ?

I think i also have to draw some extruders to see which one would be better when it comes to the overall size.

Is there also a 1.8° version of it available ?

Which gear module do you use?, it`s not easy to find gears that fullfill every spec i need to ...

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Re: This engineer claims 100 grams direct extruder. I want one February 25, 2016 03:55PM |

Registered: 9 years ago Posts: 49 |

This nema 14 is only available in .9 degree, so that tames down the torque somewhat. I'm having doubts that this 7Ncm can provide enough power, leave alone a 1.6Ncm. It's very compact compared to a nema 17. I'll shoot a picture of it in contrast to a nema 17/nema 23 stepper.

I'm using 48p gears. In an 18t pinion a 5 mm hole should fit fine. Just make sure not to buy the hardened traxxas pinions, they might be a pita to drill the hole.

Bought this and these on alie. Readily available type of gears. My first proto will use a sliding slot for te stepper in order to get the gearmesh right for testing different spurs/pinions.

Perhaps a smaller diameter hobbed drivepulley is something to test as well. Should make a flexible design.

Edited 1 time(s). Last edit at 02/25/2016 03:56PM by to3dornottobe.

I'm using 48p gears. In an 18t pinion a 5 mm hole should fit fine. Just make sure not to buy the hardened traxxas pinions, they might be a pita to drill the hole.

Bought this and these on alie. Readily available type of gears. My first proto will use a sliding slot for te stepper in order to get the gearmesh right for testing different spurs/pinions.

Perhaps a smaller diameter hobbed drivepulley is something to test as well. Should make a flexible design.

Edited 1 time(s). Last edit at 02/25/2016 03:56PM by to3dornottobe.

Re: This engineer claims 100 grams direct extruder. I want one February 25, 2016 04:25PM |

Registered: 9 years ago Posts: 1,035 |

Since starting this thread I see there are already a few solutions that are either "working" solutions, already implemented in somebody's setup or very promising concepts that will at some point -hopefully soon, become "working" solutions.

But could we have a section in the reprap wiki or on instructables or even on github -if suitable- where these solutions could have a home so we all could pick one and order the parts and replicate it and report back and the process of improvement would go on? I hope this is not a foolish idea and you are agreeing with me that we could use such a thing.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

But could we have a section in the reprap wiki or on instructables or even on github -if suitable- where these solutions could have a home so we all could pick one and order the parts and replicate it and report back and the process of improvement would go on? I hope this is not a foolish idea and you are agreeing with me that we could use such a thing.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one February 25, 2016 05:47PM |

Registered: 8 years ago Posts: 1,671 |

Just found out about Maxon motors(was it mentioned earlier), look very nice swiss made, lots of small ones with planetary gearboxes, but I have no idea the right combo of rpm, ratio's & newton meters, etc

There's even a nice one that can do 12000rpm, wonder if i could use it as a mini etcher, only going to cost a fiver to find out.

One thing I do know is this one's probably not going to cut it, but I'm still trying to figure out a use for it, just love tiny tech toys.

[www.youtube.com]

Edited 4 time(s). Last edit at 02/25/2016 07:45PM by MechaBits.

There's even a nice one that can do 12000rpm, wonder if i could use it as a mini etcher, only going to cost a fiver to find out.

One thing I do know is this one's probably not going to cut it, but I'm still trying to figure out a use for it, just love tiny tech toys.

[www.youtube.com]

Edited 4 time(s). Last edit at 02/25/2016 07:45PM by MechaBits.

Re: This engineer claims 100 grams direct extruder. I want one February 26, 2016 04:17AM |

Registered: 9 years ago Posts: 49 |

If maxon only was chinese, sold it for 20usd and used a steppermotor, they would have been king in this topic

About the maxon motors, I must admit, i'm a sucker for that type of stuff as well.

Just going through their page, it includes prices as well. Byebye Maxon.. you mean 120000 rpm btw!

you mean 120000 rpm btw!

I think a brushless inrunner from RC is more cost efficient.

About the maxon motors, I must admit, i'm a sucker for that type of stuff as well.

Just going through their page, it includes prices as well. Byebye Maxon..

you mean 120000 rpm btw!

you mean 120000 rpm btw! I think a brushless inrunner from RC is more cost efficient.

Re: This engineer claims 100 grams direct extruder. I want one February 26, 2016 06:35AM |

Registered: 8 years ago Posts: 1,671 |

I bought the 12000 rpm for £7 its only 13mm dia' got to be handy for something, The Crazy thing is while looking for some Linear Actuators I found these Maxon's and these other motors called Ondrives, they have some nice machined add ons, wormgears & planetary...but they also have the name Micron(registered)

So its a registered name owned by Thomsonlinear....which as far as I know is not the same Micron who make the extruder above,

and the design of the Micron extruder appears to be the same as some other printed ones i've seen, so I'm kinda wondering who's copied who.

So its a registered name owned by Thomsonlinear....which as far as I know is not the same Micron who make the extruder above,

and the design of the Micron extruder appears to be the same as some other printed ones i've seen, so I'm kinda wondering who's copied who.

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 05:08AM |

Registered: 8 years ago Posts: 153 |

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 06:30AM |

Registered: 9 years ago Posts: 1,873 |

Quote

n8bot

I got my cold end down to 310g. Nema11 with 5:1 planetary gb mated to an ezstruder. Works great, even with .25mm nozzle.

[imgur.com]

That looks nice, but I'm surprised it's still over 300g. I guess the gearbox is pretty heavy, and it looks like the nema11 is one of the bigger ones, probably weighing in at about 180 to 190g. That's the same weight as a nem14 with more power, so I guess the main benefit of the 11 is a more convenient shape to fit in the delta effector? I just ordered a pair of 14s to play with, but since I'm building for a Cartesian I have a lot more space to play with. I can't get the idea of a delta with a diamond triple feed mixing nozzle out of my head. Darn this addictive hobby

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 01:18PM |

Registered: 9 years ago Posts: 49 |

For my project i kind of rejected the planetary reduction. Too long and way too heavy for my likings and needs. The current motor and reduction I'm planning on using should weigh about 70-80 grams. The nema 14 Motor weights 48g with long wires. Haven't decided whether I'm going to machine it from aluminium or make a version that's printable. perhaps both, so the community could benefit from it as well. Next up. Prototyping, to see if the motor is able to push hard and fast enough or if i need to upgrade to a beefier motor or use different gearing. It should be compact for the core xy.

I recognize the magnet balls/ tefflon sheets on that design! Are you the creator of that setup or a customer of the person who made them?

Edited 2 time(s). Last edit at 02/28/2016 01:25PM by to3dornottobe.

I recognize the magnet balls/ tefflon sheets on that design! Are you the creator of that setup or a customer of the person who made them?

Edited 2 time(s). Last edit at 02/28/2016 01:25PM by to3dornottobe.

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 01:29PM |

Registered: 9 years ago Posts: 1,873 |

48g for the nema 14 is very impressive - I went cheap on the ones I ordered, but it's still a fair weight saving over my current nema 17s, and the torque is still quite respectable.

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 02:18PM |

Registered: 9 years ago Posts: 49 |

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 02:27PM |

Registered: 9 years ago Posts: 1,873 |

Yes, 190g, Heavy but still a saving of 100g per extruder vs my current nema 17 motors. I'm currently using roughly 1:5 reduction with the nema 17 and I'm hoping that will be enough with the 14, but they haven't arrived yet so I haven't been able to test. I'd also like to try some belt driven designs, but I haven't got as far as seeing how big the pulleys get for different ratios. I'm hoping they are more compact than the gears and I might be able to get a bigger gearing ratio that way.

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 04:13PM |

Registered: 9 years ago Posts: 1,035 |

Could cycloidal printed gears be used for a lightweight gearing system for the Nema14 you mention? It would be a nice combo that surely beats herringbone gears on size and backlash (maybe). I haven't seen much buzz on cycloidal gears lately but they are maybe the best shot besides the harmonic drive. Here's one example with a large reduction ratio but that can be altered in the design easily: [www.thingiverse.com]

Edit: a professional version would look like this, and weights around 70gr but i can't tell any price for this one.

Edited 1 time(s). Last edit at 02/28/2016 04:31PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Edit: a professional version would look like this, and weights around 70gr but i can't tell any price for this one.

Edited 1 time(s). Last edit at 02/28/2016 04:31PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 04:33PM |

Registered: 8 years ago Posts: 153 |

I do have a shorter nema11, also with a 5:1, but the gearbox had a rough spot in it and the motor would stall at that point, even at full current. It likely would work marginally well, but probably not since it hiccupped on the rough spot on the gearbox with a .4mm nozzle. with a .25mm nozzle it might not be great, as this longer one is borderline for .25mm nozzle.

The main reason for nema11 was form factor, yes. I don't think I could fit a larger form factor between the magnets.

The main reason for nema11 was form factor, yes. I don't think I could fit a larger form factor between the magnets.

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 04:35PM |

Registered: 9 years ago Posts: 1,873 |

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 05:22PM |

Registered: 13 years ago Posts: 268 |

Quote

n8bot

I do have a shorter nema11, also with a 5:1, but the gearbox had a rough spot in it and the motor would stall at that point, even at full current. It likely would work marginally well, but probably not since it hiccupped on the rough spot on the gearbox with a .4mm nozzle. with a .25mm nozzle it might not be great, as this longer one is borderline for .25mm nozzle.

The main reason for nema11 was form factor, yes. I don't think I could fit a larger form factor between the magnets.

I have one like this (the short 5:1) and it does work with a .3 nozzle. It is on the edge though, and although I'm not happy with the ratio I'm swapping the short motor and 27:1 gearbox next. Once I've worked through a few things a cycloid is going to be built and integrated into the block I'm currently using as a heatsink and extruder. Cycloid will be in the 9-15 to 1 range I think.

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 05:40PM |

Registered: 9 years ago Posts: 1,035 |

Quote

Koko76

Once I've worked through a few things a cycloid is going to be built and integrated into the block I'm currently using as a heatsink and extruder. Cycloid will be in the 9-15 to 1 range I think.

Will you be printing the cycloid or do you have the means to machine it. It shouldn't be complicated to machine the real challenge is to get access to a machine and somebody with knowledge to do it. I don't exaclty know if a cycloid would wear and which parts are more prone to wearing maybe (if any) only a few parts need to be machined.

I am thinking at some point at 3d printed parts (cycloidal gears) 1-2mm smaller than a 3d printed mold, then pour some tough resin to fill the gap for the contact surfaces to be as strong as possible. The cycloidal gears have almost zero backlash which is always a nice thing.

Edited 1 time(s). Last edit at 02/28/2016 05:41PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 06:26PM |

Registered: 13 years ago Posts: 268 |

Quote

realthor

Quote

Koko76

Once I've worked through a few things a cycloid is going to be built and integrated into the block I'm currently using as a heatsink and extruder. Cycloid will be in the 9-15 to 1 range I think.

Will you be printing the cycloid or do you have the means to machine it. It shouldn't be complicated to machine the real challenge is to get access to a machine and somebody with knowledge to do it. I don't exaclty know if a cycloid would wear and which parts are more prone to wearing maybe (if any) only a few parts need to be machined.

I am thinking at some point at 3d printed parts (cycloidal gears) 1-2mm smaller than a 3d printed mold, then pour some tough resin to fill the gap for the contact surfaces to be as strong as possible. The cycloidal gears have almost zero backlash which is always a nice thing.

I have "the means" to machine it. Those parts are unsuitable to be made with general 3d printers available today in order to have the claimed "zero backlash".

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 06:39PM |

Registered: 8 years ago Posts: 210 |

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 06:52PM |

Registered: 9 years ago Posts: 1,035 |

Quote

Koko76

I have "the means" to machine it. Those parts are unsuitable to be made with general 3d printers available today in order to have the claimed "zero backlash".

That is indeed lucky of you. I will be following with great interest your project should you be documenting it online. I might have the "luxury" to get the parts machined in my home country for a beer but here in Finland I wouldn't dare ask a quote from somebody for such a job. Do you have anything started yet for the cycloid drive? Will you be using some openscad libraries or will it be a personal project that you will calculate/design yourself?

Quote

thefrog

Don't know if this got linked already ...

My extruder is down to 160g with steel gears and the Sanyo Denki Nema 17 Motor

I linked the youtube video on the first page, but this discussion on ultimaker forums is an interesting addition. Thanks. BTW, is this yours?

Edited 2 time(s). Last edit at 02/28/2016 06:53PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 06:55PM |

Registered: 10 years ago Posts: 580 |

Quote

Realthor

But could we have a section in the reprap wiki or on instructables or even on github -if suitable- where these solutions could have a home so we all could pick one and order the parts and replicate it and report back and the process of improvement would go on?

The answer is a qualified "Yes". It's just up to whoever develops the solution to document it, and make a page.

To put a page on the Wiki, just register/login separately in the Wiki, and then (more than one way to do this)

- Search for the exact name you want the page to be. Consider this carefully.

- It will ask if you want to make the page, click Yes.

- Bingo you have a new html page.

- Here is a simplified cheat sheet, so you don't have to do all HTML.

- There is an Upload file link on the left side of the Wiki so you can upload your images.

- There is a messy example page that shows some examples, and you can also edit another page and copy the format...

- Adding one or more Categories will help to make the page more accessible within the Wiki.

Edited 1 time(s). Last edit at 02/28/2016 07:29PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 07:01PM |

Registered: 13 years ago Posts: 268 |

Luck has little to do with it, years of hard work and research. Not planning on spending a lot of time documenting it, possibly some pics of the completed assembly. Don't use OpenSCAD, I have better tools available, several designs completed just have to finish some numbers and get some free time.Quote

realthor

Quote

Koko76

I have "the means" to machine it. Those parts are unsuitable to be made with general 3d printers available today in order to have the claimed "zero backlash".

That is indeed lucky of you. I will be following with great interest your project should you be documenting it online. I might have the "luxury" to get the parts machined in my home country for a beer but here in Finland I wouldn't dare ask a quote from somebody for such a job. Do you have anything started yet for the cycloid drive? Will you be using some openscad libraries or will it be a personal project that you will calculate/design yourself?

Quote

thefrog

Don't know if this got linked already ...

My extruder is down to 160g with steel gears and the Sanyo Denki Nema 17 Motor

I linked the youtube video on the first page, but this discussion on ultimaker forums is an interesting addition. Thanks. BTW, is this yours?

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 07:10PM |

Registered: 8 years ago Posts: 210 |

Quote

realthor

Quote

Koko76

I have "the means" to machine it. Those parts are unsuitable to be made with general 3d printers available today in order to have the claimed "zero backlash".

That is indeed lucky of you. I will be following with great interest your project should you be documenting it online. I might have the "luxury" to get the parts machined in my home country for a beer but here in Finland I wouldn't dare ask a quote from somebody for such a job. Do you have anything started yet for the cycloid drive? Will you be using some openscad libraries or will it be a personal project that you will calculate/design yourself?

Quote

thefrog

Don't know if this got linked already ...

My extruder is down to 160g with steel gears and the Sanyo Denki Nema 17 Motor

I linked the youtube video on the first page, but this discussion on ultimaker forums is an interesting addition. Thanks. BTW, is this yours?

Yep thats mine

Re: This engineer claims 100 grams direct extruder. I want one February 28, 2016 07:53PM |

Registered: 9 years ago Posts: 1,035 |

Impressive sir.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 12:16AM |

Registered: 8 years ago Posts: 153 |

Quote

thefrog

Don't know if this got linked already ...

My extruder is down to 160g with steel gears and the Sanyo Denki Nema 17 Motor

That pancake extruder is amazing. I bet that would fit on my delta effector. Does it have enough force to push filament through a .25mm nozzle? Where did you source the motor/what are the specs?

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 01:37AM |

Registered: 9 years ago Posts: 49 |

this is the used motor.

A cyclodial gearing might look easy, but it's rather complex/expensive? in terms of bearings/sliderpins. If anyone needs some machined, i have access to a neat little homegrown machineshop. I do think that traditional 48p gears might cut it, and they cost only about 5usd a set when bought in small quantities.

@thefrog; is 160gram the total weight of your carriage? Extruder itself should be lighter? And it seems that you are using 64p gears?

A cyclodial gearing might look easy, but it's rather complex/expensive? in terms of bearings/sliderpins. If anyone needs some machined, i have access to a neat little homegrown machineshop. I do think that traditional 48p gears might cut it, and they cost only about 5usd a set when bought in small quantities.

@thefrog; is 160gram the total weight of your carriage? Extruder itself should be lighter? And it seems that you are using 64p gears?

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 02:27AM |

Registered: 9 years ago Posts: 1,035 |

Just to add one more option to the discussion: has anyone considered this old idea of a remote-extruder (not bowden, not flex-shaft)? I've been contemplating at it for quite some time before finding -like anything else these days, no idea is truly new.

It's basically a square tube of sorts that has a sliding pinion and that drives the filament with the motor sitting at a more convenient position inertia-wise. It is a very good solution from my pov fo a certain type of cartesian printers but. The price for carbon square tubes that would be very slippery for a plastic pinion or plastic bushing for a metal pinion can be bought for less than Eur5 for a 10x10mm square tube. For example this, at HK is EU4.46 for a 750mm tube and I am sure it can be found cheaper elsewhere.

The one in the example is more than one year old but I still don't know why wouldn't people consider it more often, it's quite innovative and very cheap too. Here's a video of the thing: [www.youtube.com]

Edited 3 time(s). Last edit at 02/29/2016 02:36AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

It's basically a square tube of sorts that has a sliding pinion and that drives the filament with the motor sitting at a more convenient position inertia-wise. It is a very good solution from my pov fo a certain type of cartesian printers but. The price for carbon square tubes that would be very slippery for a plastic pinion or plastic bushing for a metal pinion can be bought for less than Eur5 for a 10x10mm square tube. For example this, at HK is EU4.46 for a 750mm tube and I am sure it can be found cheaper elsewhere.

The one in the example is more than one year old but I still don't know why wouldn't people consider it more often, it's quite innovative and very cheap too. Here's a video of the thing: [www.youtube.com]

Edited 3 time(s). Last edit at 02/29/2016 02:36AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.