This engineer claims 100 grams direct extruder. I want one

Posted by realthor

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 02:41AM |

Registered: 8 years ago Posts: 5,232 |

My gut-feeling tells me, that a pancake motor has a lot of "dead" weight on it like front and back-covers, huge bearings.

How do they compare against a smaller but longer motor of same weight, torque-wise?

@JamesK

A belt driven system would be heavier IMHO, because the body of the extruder would need to be stiffer for proper belt tension.

How do they compare against a smaller but longer motor of same weight, torque-wise?

@JamesK

A belt driven system would be heavier IMHO, because the body of the extruder would need to be stiffer for proper belt tension.

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 03:24AM |

Registered: 12 years ago Posts: 799 |

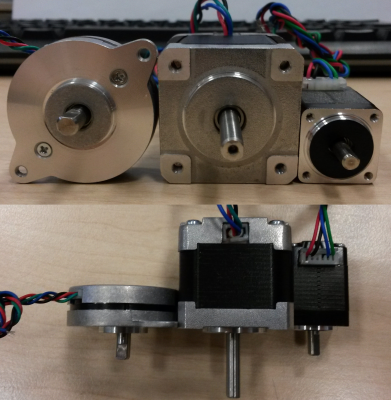

Got my Nema 8 and 14 this weekend, man they are just so tiny compared to my normally used "large" Nema 14`s

left: Nema14 slim 14HR05-0504S 7Ncm/50g

middle: Nema14: SM35HT34-02 176Ncm/175g

right: Nema 8 8HS11-0204S 1.6Ncm/50g

I think the Nema 8 will be too weak.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

left: Nema14 slim 14HR05-0504S 7Ncm/50g

middle: Nema14: SM35HT34-02 176Ncm/175g

right: Nema 8 8HS11-0204S 1.6Ncm/50g

I think the Nema 8 will be too weak.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 04:01AM |

Registered: 9 years ago Posts: 49 |

@realthor; Yes, i've thought about that as well. The sliding gear is the challange, this is why. The torque-rod part is too thin, it will bend badly when the carriage is far away from the E motor.

What would work if you use an endless belt and a gear (driven on 1 side) and a stationary E motor , cancel out the X motion in the firmware and use the difference compared to the E motion. Needless to say, acceleration and jerk should be taken into account as well. or you'll end up with unwanted extrusion behaviour It could work for CoreXY too, but i don't know if the computing power is available for these calculations?

It could work for CoreXY too, but i don't know if the computing power is available for these calculations?

Status of the lightweight NEMA 14 extruder; I'm currently putting down the concept on the back of a napkin, prior to the CAD work.. I'll shoot a picture to share the general idea. Cooling the nema 14 is mandatory, i think.

@Chri; i received mine as well, it's tiny, right? And light.. Mine weighs 48.21 grams. I too think the NEMA8 is too weak. I'm going to make my design so that it also could fit the larger version of the NEMA14 you suggested.

About the 'dead weight' with a stepper it's not the aluminium that weighs the most; it's the copper, metal and magnets that make it heavy.

The superslim pancape nema17 of sanyo denki weights 70g.

Weight to power ratio of the pancakes is way better than the 'standard' nema 8 and 14 motors.

Look at the info Chris shared, nema 8 50 grams, 1.25Ncm holding torque. Nema 14 pancake 50 gram and 7Ncm of holding torque

Edited 4 time(s). Last edit at 02/29/2016 04:08AM by to3dornottobe.

What would work if you use an endless belt and a gear (driven on 1 side) and a stationary E motor , cancel out the X motion in the firmware and use the difference compared to the E motion. Needless to say, acceleration and jerk should be taken into account as well. or you'll end up with unwanted extrusion behaviour

It could work for CoreXY too, but i don't know if the computing power is available for these calculations?

It could work for CoreXY too, but i don't know if the computing power is available for these calculations? Status of the lightweight NEMA 14 extruder; I'm currently putting down the concept on the back of a napkin, prior to the CAD work.. I'll shoot a picture to share the general idea. Cooling the nema 14 is mandatory, i think.

@Chri; i received mine as well, it's tiny, right? And light.. Mine weighs 48.21 grams. I too think the NEMA8 is too weak. I'm going to make my design so that it also could fit the larger version of the NEMA14 you suggested.

About the 'dead weight' with a stepper it's not the aluminium that weighs the most; it's the copper, metal and magnets that make it heavy.

The superslim pancape nema17 of sanyo denki weights 70g.

Weight to power ratio of the pancakes is way better than the 'standard' nema 8 and 14 motors.

Look at the info Chris shared, nema 8 50 grams, 1.25Ncm holding torque. Nema 14 pancake 50 gram and 7Ncm of holding torque

Edited 4 time(s). Last edit at 02/29/2016 04:08AM by to3dornottobe.

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 04:25AM |

Registered: 12 years ago Posts: 799 |

Quote

to3dornottobe

@Chri; i received mine as well, it's tiny, right? And light.. Mine weighs 48.21 grams. I too think the NEMA8 is too weak. I'm going to make my design so that it also could fit the larger version of the NEMA14 you suggested.

Look at the info Chris shared, nema 8 50 grams, 1.25Ncm holding torque. Nema 14 pancake 50 gram and 7Ncm of holding torque

It`s Chri, not Chris

for the "normal" Nema14, we are using our Miniwade design since a couple of years, its very reliable

I think i had some sort of calculation error when i going through the Nema8 gearratio stuff

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 04:32AM |

Registered: 9 years ago Posts: 1,035 |

Quote

to3dornottobe

@realthor; Yes, i've thought about that as well. The sliding gear is the challange, this is why. The torque-rod part is too thin, it will bend badly when the carriage is far away from the E motor.

Interesting, I never new about this phenomenon...

Quote

to3dornottobe

What would work if you use an endless belt and a gear (driven on 1 side) and a stationary E motor , cancel out the X motion in the firmware and use the difference compared to the E motion. Needless to say, acceleration and jerk should be taken into account as well. or you'll end up with unwanted extrusion behaviourIt could work for CoreXY too, but i don't know if the computing power is available for these calculations?

It doesn't sound very good. On a corexy you'd have to add extra weight on the Y carriage, which is kind of the same as if you put it on X, so not much gained there. At least when the weight is on X, it is supported by both Y rails/rods, while if you put it on Y it will always be on one side only. Unless you have dual extrusion and you would put one extruder on one Y and the other on the other Y.

Quote

to3dornottobe

Status of the lightweight NEMA 14 extruder; I'm currently putting down the concept on the back of a napkin, prior to the CAD work.. I'll shoot a picture to share the general idea. Cooling the nema 14 is mandatory, i think.

@Chri; i received mine as well, it's tiny, right? And light.. Mine weighs 48.21 grams. I too think the NEMA8 is too weak. I'm going to make my design so that it also could fit the larger version of the NEMA14 you suggested.

About the 'dead weight' with a stepper it's not the aluminium that weighs the most; it's the copper, metal and magnets that make it heavy.

The superslim pancape nema17 of sanyo denki weights 70g.

Weight to power ratio of the pancakes is way better than the 'standard' nema 8 and 14 motors.

Look at the info Chris shared, nema 8 50 grams, 1.25Ncm holding torque. Nema 14 pancake 50 gram and 7Ncm of holding torque

I am really interested in where this is going, the Nema14 looks very promising for a good solution. Can't wait to see the CAD.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 04:43AM |

Registered: 9 years ago Posts: 49 |

Quote

It`s Chri, not Chris

You got to give me some credit Chri! I at least typed a few times right

No, that's not what I meant. You could use the motor stationary as well and have the X/Y motion cancelled out and interpreted in the XY motion when extrusion movement is needed. But at high speeds that design it's pretty worthless, and high speeds is the main reason for lowering the weight of the moving x/y partQuote

It doesn't sound very good. On a corexy you'd have to add extra weight on the Y carriage,

because you need a VERY fast E motor.. (And another downside is you need to have a serious reduction, otherwise you will have a torque-twist going on in your X/Y motion when the extruder kicks in

because you need a VERY fast E motor.. (And another downside is you need to have a serious reduction, otherwise you will have a torque-twist going on in your X/Y motion when the extruder kicks in  this could be overcome with the use of a differential on the moving part though, but that requires 2 stationary (non moving) motors for E and 4 for a double extruder.. Then they only need to move when extruder needs action..

this could be overcome with the use of a differential on the moving part though, but that requires 2 stationary (non moving) motors for E and 4 for a double extruder.. Then they only need to move when extruder needs action..Edited 2 time(s). Last edit at 02/29/2016 04:57AM by to3dornottobe.

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 05:01AM |

Registered: 9 years ago Posts: 1,035 |

Quote

to3dornottobe

You could use the motor stationary as well and have the X/Y motion cancelled out and interpreted in the XY motion when extrusion movement is needed. But at high speeds that design it's pretty worthless, and high speeds is the main reason for lowering the weight of the moving x/y partbecause you need a VERY fast E motor.. (And another downside is you need to have a serious reduction, otherwise you will have a torque-twist going on in your X/Y motion when the extruder kicks in

this could be overcome with the use of a differential on the moving part though, but that requires 2 stationary (non moving) motors for E and 4 for a double extruder.. Then they only need to move when extruder needs action..

That is sounding even worse

)) ... i got it, not worth it. And I agree but just wanted to mention it here for the perspective.

)) ... i got it, not worth it. And I agree but just wanted to mention it here for the perspective.RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 05:26AM |

Registered: 12 years ago Posts: 799 |

Quote

I am really interested in where this is going, the Nema14 looks very promising for a good solution. Can't wait to see the CAD.

for me it may take a while because i`m very busy with other projects at the moment

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 06:44AM |

Registered: 9 years ago Posts: 49 |

I've just finished putting the lightweight nema14 in cad (rough drawing, haven't taken it apart for exact bearing sizes etc) it's size accurate to suit my needs. Began on drawing the motor plate, for now with adjustable gear mesh enabling a large variety of spurs/pinions, Thinking about making a generic solution for using different makes/brands of spur gears (an adjustable holder using M3 screws). I do have got the e3d v6 drawing from another project i can use. Have got a plan for the extruders tension. (a U shape that covers the bearing and with pressure at the centre of the bearing)I'm using 5x11x4 bearings to hold the spur in place along with the drive-gear, the bearing that's used for pressure is the standard 625zz or a variant with 6mm hole instead of 5). I think disk springs might be excellent for this task. Small movement, low profile. Only need a clever quick release, without adding too much parts. Some progress has been made.

Edited 1 time(s). Last edit at 02/29/2016 06:46AM by to3dornottobe.

Edited 1 time(s). Last edit at 02/29/2016 06:46AM by to3dornottobe.

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 06:58AM |

Registered: 12 years ago Posts: 799 |

Quote

to3dornottobe

I've just finished putting the lightweight nema14 in cad (rough drawing, haven't taken it apart for exact bearing sizes etc) it's size accurate to suit my needs. Began on drawing the motor plate, for now with adjustable gear mesh enabling a large variety of spurs/pinions, Thinking about making a generic solution for using different makes/brands of spur gears (an adjustable holder using M3 screws). I do have got the e3d v6 drawing from another project i can use. Have got a plan for the extruders tension. (a U shape that covers the bearing and with pressure at the centre of the bearing)I'm using 5x11x4 bearings to hold the spur in place along with the drive-gear, the bearing that's used for pressure is the standard 625zz or a variant with 6mm hole instead of 5). I think disk springs might be excellent for this task. Small movement, low profile. Only need a clever quick release, without adding too much parts. Some progress has been made.

I recommend you to use some smaller bearings like MR85, saves alot of space and some weight

Chri.

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 08:59AM |

Registered: 9 years ago Posts: 49 |

LOL! i thought I was being cheeky with the 5x11x4's. These MR85's are tiny! the two 5x11x4's weight 2.93 grams per 2 btw.. The MK7 hobbed should weigh a fair bit too, (i guess around 6g, perhaps the MK8 is better since the goal is to make a lightweight extruder) i'll get some MK8 hobbed gears as well.. And I'll order some MR85's to do some testing with. Just a thought; it would be rather simple to make the NEMA14 and the gearing with a NEMA17 faceplate, so it can replace any nema 17 on an existing extruder.. . The 76T is about 42 mm od, (same size as the NEMA17 faceplate in square).

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 10:04AM |

Registered: 9 years ago Posts: 49 |

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 02:16PM |

Registered: 8 years ago Posts: 210 |

Quote

n8bot

Quote

thefrog

Don't know if this got linked already ...

My extruder is down to 160g with steel gears and the Sanyo Denki Nema 17 Motor

That pancake extruder is amazing. I bet that would fit on my delta effector. Does it have enough force to push filament through a .25mm nozzle? Where did you source the motor/what are the specs?

It has 0,383 N with the 13/60 gearing. That should be sufficient.

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 02:41PM |

Registered: 8 years ago Posts: 210 |

Quote

to3dornottobe

this is the used motor.

A cyclodial gearing might look easy, but it's rather complex/expensive? in terms of bearings/sliderpins. If anyone needs some machined, i have access to a neat little homegrown machineshop. I do think that traditional 48p gears might cut it, and they cost only about 5usd a set when bought in small quantities.

@thefrog; is 160gram the total weight of your carriage? Extruder itself should be lighter? And it seems that you are using 64p gears?

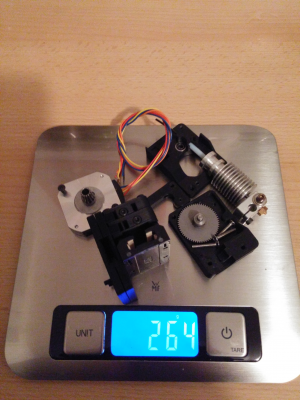

No whole carriage with belt tensioners and magnetic coupling is 264g

Edited 1 time(s). Last edit at 02/29/2016 02:47PM by thefrog.

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 03:09PM |

Registered: 12 years ago Posts: 799 |

Hmm, 264g sounds heavy to me, can you list the weight of the single parts ?

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 03:36PM |

Registered: 8 years ago Posts: 210 |

Well the big normal Nema 17 Motor most Extruders use weigh almost the same as my whole carriage ...

E3D v6 with PTFE = 37g

Lever with bearing and screw = 4g

Extruder gear and 60t steel gear combo on axle with bearing = 23g

Spring and Drive side plate with bearing = 9g

Side plate = 8g

Nema 17 pancake and 13t gear = 79g

GT2 tensioner, magnetic coupling and linear carriage = 107g

E3D v6 with PTFE = 37g

Lever with bearing and screw = 4g

Extruder gear and 60t steel gear combo on axle with bearing = 23g

Spring and Drive side plate with bearing = 9g

Side plate = 8g

Nema 17 pancake and 13t gear = 79g

GT2 tensioner, magnetic coupling and linear carriage = 107g

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 04:01PM |

Registered: 9 years ago Posts: 49 |

Thanks for sharing thefrog!

Is that an Igus slider? You are currently using a fan on your setup as well, right? (with heatsink or not? I forgot)

I'm going to use an MGN12 slider on my coreXY, that weights a fair bit. The metal gears are also heavy. 48p gears, btw?

The weight of the e3d you mentioned, that's without fan/ fan shroud, correct?

Edited 2 time(s). Last edit at 02/29/2016 04:10PM by to3dornottobe.

Is that an Igus slider? You are currently using a fan on your setup as well, right? (with heatsink or not? I forgot)

I'm going to use an MGN12 slider on my coreXY, that weights a fair bit. The metal gears are also heavy. 48p gears, btw?

The weight of the e3d you mentioned, that's without fan/ fan shroud, correct?

Edited 2 time(s). Last edit at 02/29/2016 04:10PM by to3dornottobe.

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 04:24PM |

Registered: 8 years ago Posts: 210 |

Yes its a Drylin TWE sldier from IGUS.

check out the ultimaker forum post for more information and files ...

thats without the fan because I only have 40 mm fans at the moment. (and the fan is not something you can't lose weight with anyway, so...)

A 40 mm fan is about 15g.

I want to redesign the E3D to a radial fan and smaller heatsink anyway though.

Edited 1 time(s). Last edit at 02/29/2016 04:24PM by thefrog.

check out the ultimaker forum post for more information and files ...

thats without the fan because I only have 40 mm fans at the moment. (and the fan is not something you can't lose weight with anyway, so...)

A 40 mm fan is about 15g.

I want to redesign the E3D to a radial fan and smaller heatsink anyway though.

Edited 1 time(s). Last edit at 02/29/2016 04:24PM by thefrog.

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 04:44PM |

Registered: 13 years ago Posts: 268 |

Quote

I want to redesign the E3D to a radial fan and smaller heatsink anyway though.

I got down to 15mm tall for that part (enough to fit the throat) by making it a water block, which is also part of the extruder assembly. After getting everything prototyped I'll split the block so that only the lower part is aluminum and seal with a delrin block which becomes the cycloid gearbox. I had initially planned to use a radial fan here and an air based heat sink but couldn't get a geometry I liked as far as where that fan wound up. I'm also gonna switch to a dual setup soon s the water works well for that too.

Re: This engineer claims 100 grams direct extruder. I want one February 29, 2016 05:38PM |

Registered: 8 years ago Posts: 153 |

Re: This engineer claims 100 grams direct extruder. I want one March 03, 2016 10:47PM |

Registered: 11 years ago Posts: 31 |

This is exact thread I was looking for.

I am also working on design light direct drive extruder for my H-bot printer.

I got 14HR05-0504S pancake stepper in my hand already.

The trouble I have now is decide gear ratio and find appropriate gears.

I'm not sure how much reduction is needed for 0.7 Kgf.cm stepper to drive 1.75 filament through 0.35 nozzle.

I'll share the progress of my extruder here, if you interest.

Thanks.

I am also working on design light direct drive extruder for my H-bot printer.

I got 14HR05-0504S pancake stepper in my hand already.

The trouble I have now is decide gear ratio and find appropriate gears.

I'm not sure how much reduction is needed for 0.7 Kgf.cm stepper to drive 1.75 filament through 0.35 nozzle.

I'll share the progress of my extruder here, if you interest.

Thanks.

Re: This engineer claims 100 grams direct extruder. I want one March 03, 2016 10:52PM |

Registered: 11 years ago Posts: 31 |

Quote

thefrog

Quote

n8bot

Quote

thefrog

Don't know if this got linked already ...

My extruder is down to 160g with steel gears and the Sanyo Denki Nema 17 Motor

That pancake extruder is amazing. I bet that would fit on my delta effector. Does it have enough force to push filament through a .25mm nozzle? Where did you source the motor/what are the specs?

It has 0,383 N with the 13/60 gearing. That should be sufficient.

@theFlog I think the torque of stepper you're using is 0.083Nm (0.846Kgfcm), right?. if so, 13/60 ratio is still correct for your configuration? (Your configuration gives 3.9 Kgf.cm torque)

Re: This engineer claims 100 grams direct extruder. I want one March 04, 2016 04:34AM |

Registered: 9 years ago Posts: 1,035 |

What solution would you choose to loose weight on the cooling part if fans are considered? I have in my design 2 blower fans for cooling each nozzle for a 2-hotend setup and 2 small axial fans for the hotend cooling. I know that one can't save much weight on fans, as stated before, but the option between maybe one larger fan for both hotends or even one single blower for both nozzles would be something to consider?

There can be some weight gain from using 3 bearings instead of 4 and maybe 3 bushings for that matter. I would prefer the graphite inlaid bushings.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

There can be some weight gain from using 3 bearings instead of 4 and maybe 3 bushings for that matter. I would prefer the graphite inlaid bushings.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 05, 2016 03:01AM |

Registered: 8 years ago Posts: 5,232 |

Re: This engineer claims 100 grams direct extruder. I want one March 06, 2016 09:01AM |

Registered: 9 years ago Posts: 49 |

The numbers don't give you the specified torque, those numbers are holding torque, a static number. You need a graph of the actual torque in relation to RPM to determine the torque we need.

I'm using an 18/76 gearing, with the opion to go to 15/90 (4.22:1 vs 6:1).

i'm looking into the cooling part too, perhaps a single fan, with an adjustable ratio between workpiece/hotend. I was looking at a tiny radial fan.

I'm using an 18/76 gearing, with the opion to go to 15/90 (4.22:1 vs 6:1).

i'm looking into the cooling part too, perhaps a single fan, with an adjustable ratio between workpiece/hotend. I was looking at a tiny radial fan.

Re: This engineer claims 100 grams direct extruder. I want one March 06, 2016 10:10AM |

Registered: 11 years ago Posts: 5,780 |

You can minimize moving mass by using an air pump and a small hose to deliver air to cool the print.

I bought a 12V pump (http://www.ebay.com/itm/181589976209?_trksid=p2060353.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT) to try out first. I selected this one because it uses a brushless motor which I expected would have a longer lifetime than similar pumps that use brush type motors and it could operate directly from the fan speed control output from a controller board. I was afraid the output (claimed 1.4 l/m) would be insufficient and it does seem pretty low. I'll have to test it on the printer to see how it does.

Then I found this on the hack rack at the makerspace:

It is line powered and produces 4 l/min which seems to be enough air, but I'm not sure how to use the PWM output from the controller board to achieve variable output. Maybe I have to live with just switching it on and off. This thing hums when it's operating (can't remember the words?), but my machine is already pretty noisy, so what's a little more noise? You can find similar pumps all over ebay, but most of the cheaper pumps don't specify the capacity, so unless you're willing to spend $30 or 40 you'll be gambling.

Edit: here's one that claims about 5 l/m for $9: [www.ebay.com]

I also got some 4mm silicone tubing (http://www.ebay.com/itm/231830507938?_trksid=p2060353.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT) that is very flexible and heat resistant. I'll be testing both of these pumps on my printer in the immediate future, after I put the machine back together from some recent Y axis modifications.

One of the nice things about delivering air via a tube is that you can direct it with a small nozzle and know that it's going exactly where you intend.

Edited 2 time(s). Last edit at 03/06/2016 10:53AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I bought a 12V pump (http://www.ebay.com/itm/181589976209?_trksid=p2060353.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT) to try out first. I selected this one because it uses a brushless motor which I expected would have a longer lifetime than similar pumps that use brush type motors and it could operate directly from the fan speed control output from a controller board. I was afraid the output (claimed 1.4 l/m) would be insufficient and it does seem pretty low. I'll have to test it on the printer to see how it does.

Then I found this on the hack rack at the makerspace:

It is line powered and produces 4 l/min which seems to be enough air, but I'm not sure how to use the PWM output from the controller board to achieve variable output. Maybe I have to live with just switching it on and off. This thing hums when it's operating (can't remember the words?), but my machine is already pretty noisy, so what's a little more noise? You can find similar pumps all over ebay, but most of the cheaper pumps don't specify the capacity, so unless you're willing to spend $30 or 40 you'll be gambling.

Edit: here's one that claims about 5 l/m for $9: [www.ebay.com]

I also got some 4mm silicone tubing (http://www.ebay.com/itm/231830507938?_trksid=p2060353.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT) that is very flexible and heat resistant. I'll be testing both of these pumps on my printer in the immediate future, after I put the machine back together from some recent Y axis modifications.

One of the nice things about delivering air via a tube is that you can direct it with a small nozzle and know that it's going exactly where you intend.

Edited 2 time(s). Last edit at 03/06/2016 10:53AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Re: This engineer claims 100 grams direct extruder. I want one March 10, 2016 08:41AM |

Registered: 9 years ago Posts: 1,035 |

Hi guys, is nema14+gearing the general consensus for an optimal weight/cost for a lightweight extruder?

I've found this 4-lead, bi-polar Nema14 of 20oz (1,4kg) torque at 180g weight, which is not very flattering for our purpose but at 16Eur can't be overlooked.

The 7N pancake just a tad more expensive (found it at ~$20) but are those 7N enough to get it with a not-so-high gearing ratio to operational parameters for extruding (say 1.75mm, 0.3. nozzle).

Where do you guys look for gearing and how do you calculate the gearing ratio necessary?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I've found this 4-lead, bi-polar Nema14 of 20oz (1,4kg) torque at 180g weight, which is not very flattering for our purpose but at 16Eur can't be overlooked.

The 7N pancake just a tad more expensive (found it at ~$20) but are those 7N enough to get it with a not-so-high gearing ratio to operational parameters for extruding (say 1.75mm, 0.3. nozzle).

Where do you guys look for gearing and how do you calculate the gearing ratio necessary?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 10, 2016 09:27AM |

Registered: 8 years ago Posts: 260 |

you have the round nema 14 also in a 12 Nm version 100 grams, still 40 grams lighter then the one below and 80 grams lighter then the one you came with

One remark : these are not a drop in replacement fr normal NEMA 14's )

and if you want the normal Nema 14 then this is better

[eu.stepperonline.com]

40 grams lighter , same torque and cheaper and they ship also from Germany

Edited 1 time(s). Last edit at 03/10/2016 10:44AM by amigob.

One remark : these are not a drop in replacement fr normal NEMA 14's )

and if you want the normal Nema 14 then this is better

[eu.stepperonline.com]

40 grams lighter , same torque and cheaper and they ship also from Germany

Edited 1 time(s). Last edit at 03/10/2016 10:44AM by amigob.

Re: This engineer claims 100 grams direct extruder. I want one March 10, 2016 10:16AM |

Registered: 9 years ago Posts: 1,035 |

Quote

amigob

you have the round nema 14 also in a 12 Nm version 100 grams, still 40 grams lighter then the one below and 80 grams lighter then the one you came with

One remark : these are not a drop in replacement fr normal NEMA 14's )

and if you want the normal Nema 14 then this is better

[eu.stepperonline.com]

40 grams lighter , same torque and cheaper and they chip also from Germany

Nice find. "not a drop in replacement" in what sense? The need for a gearing system I guess is implied.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 10, 2016 10:44AM |

Registered: 8 years ago Posts: 260 |

Sorry, only registered users may post in this forum.