This engineer claims 100 grams direct extruder. I want one

Posted by realthor

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 08:36AM |

Registered: 9 years ago Posts: 1,035 |

Quote

Mutley3D

realthor - in part i agree, in part i differ in view.

flying extruders on a delta are going to start introducing lots of harmonics to deal with when talking two or more motors, and realistically flying extruders are not cmpatible with other machine styles.

Yes, not quite compatible, unless we make them to be. Next option is FlexyDrive for 3+ hotends. But I don't like the cost of that

, which might make sense after all when I see how expensive steppers some use.

, which might make sense after all when I see how expensive steppers some use.Motors being thrown all over at high speeds just doesn't make much sense to me.

Quote

Mutley3D

The inspiring video at the beginning of this thread - the over-riding thing i noticed was that it was not shown printing unless i missed something. I also seem to recall noticing the belt drive/motor mount setup looked a little suspect (cantilvered and suspended?)

I said inspiring not illuminating

These being said, the most we can do atm is to make one extruder setup that is light enough, and then attach 2-3 of them to the printhead, depending on your needs. Then dimension the rods/rails as fit and setup a proper speed for what we have.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 08:40AM |

Registered: 13 years ago Posts: 268 |

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 08:45AM |

Registered: 9 years ago Posts: 1,035 |

Haven't found that info on a quick search it seems to be in the 150g ballpark (source: some thread on soliforum)

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 08:47AM |

Registered: 9 years ago Posts: 1,873 |

Quote

These being said, the most we can do atm is to make one extruder setup that is light enough, and then attach 2-3 of them to the printhead, depending on your needs. Then dimension the rods/rails as fit and setup a proper speed for what we have.

I may have lost track of everywhere this thread has been, but the quote above sounds like you don't consider bowden setups to be an option, and I was wondering why that was? If the objective is as little weight as possible on the carriage then bowden sounds like the answer. Personally I'm going with direct drive because I want to print flex filaments and I'm willing to trade speed for function, but if speed is the issue then restricting the scope to non-flex filaments seems like a reasonable trade. I doubt if there is a one-size fits all approach to 3d printing.

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 08:58AM |

Registered: 9 years ago Posts: 425 |

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 09:03AM |

Registered: 13 years ago Posts: 268 |

There are several alternate ways to increase the ammount of filaments extruded which don't mean mounting more extruder motors to the moving portion of the head. Perhaps some "out of the box thinking" can be applied. After I get the weight down on the single extruder I'll tackle some of these.

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 09:05AM |

Registered: 13 years ago Posts: 268 |

Quote

Mutley3D

Flex shaft weight is negligable since it is quite literally suspended/floating due to the arc taken by the ptfe tube within which it is housed.

inspiring/illuminating....slip of the toungue

But what is the number? If you don't want to share that's one thing, but I'm capable of determining what is "negligible" all by my self.

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 09:09AM |

Registered: 9 years ago Posts: 425 |

Quote

Koko76

Quote

Mutley3D

Flex shaft weight is negligable since it is quite literally suspended/floating due to the arc taken by the ptfe tube within which it is housed.

inspiring/illuminating....slip of the toungue

But what is the number? If you don't want to share that's one thing, but I'm capable of determining what is "negligible" all by my self.

LOL when i say negligible I really do mean negligible. Im sure i said "suspended/floating" in other words, zero negligible nada. i didnt mean to insult your intelligence or capability

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 09:13AM |

Registered: 9 years ago Posts: 1,873 |

Quote

Mutley3D

LOL when i say negligible I really do mean negligible. Im sure i said "suspended/floating" in other words, zero negligible nada. i didnt mean to insult your intelligence or capability

That's a little misleading. Even if the net downward force on the carriage is negative, the mass of the flexdrive still has to be accelerated in an arc as the carriage moves. Figuring out what the required force for that is would be a pain, but you still can't wish it away.

Edited 2 time(s). Last edit at 03/15/2016 09:14AM by JamesK.

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 09:15AM |

Registered: 13 years ago Posts: 268 |

The shaft doesn't weigh zero, stop the semantics nonsense. I don't care how you suspend it, I want to know the mass of the shaft and its housing. Again, if you don't want to share that's fine, but it isn't zero. So again, not what you think the net effect is, mass of the component please?Quote

Mutley3D

Quote

Koko76

Quote

Mutley3D

Flex shaft weight is negligable since it is quite literally suspended/floating due to the arc taken by the ptfe tube within which it is housed.

inspiring/illuminating....slip of the toungue

But what is the number? If you don't want to share that's one thing, but I'm capable of determining what is "negligible" all by my self.

LOL when i say negligible I really do mean negligible. Im sure i said "suspended/floating" in other words, zero negligible nada. i didnt mean to insult your intelligence or capability

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 09:35AM |

Registered: 9 years ago Posts: 425 |

JamesK - Im not wishing anything away. You will be better off assessing the PTFE tube for lateral inertial mass as that is stiffer than the drivershaft.

Koko - I am not giving semantics or nonsense as you so kinldy put it, I was simply responding to your question. If you wanted more clarification, just ask. No need to go all high and mighty. And again as per the line above, for sake of calculations you may want to consider the ptfe tubing and its stiffness for its lateral mass effect. As for its downward mass effect it doesnt have any on the extruder as it is like i said, floating and supported by the natural curve of the ptfe tube.

If you want the mass/weight of the driveshaft as an individual on some scales, this would be dependant on its length. You want semantics, ill give you semantics!

Koko - I am not giving semantics or nonsense as you so kinldy put it, I was simply responding to your question. If you wanted more clarification, just ask. No need to go all high and mighty. And again as per the line above, for sake of calculations you may want to consider the ptfe tubing and its stiffness for its lateral mass effect. As for its downward mass effect it doesnt have any on the extruder as it is like i said, floating and supported by the natural curve of the ptfe tube.

If you want the mass/weight of the driveshaft as an individual on some scales, this would be dependant on its length. You want semantics, ill give you semantics!

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 09:36AM |

Registered: 9 years ago Posts: 425 |

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 09:46AM |

Registered: 13 years ago Posts: 268 |

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 10:13AM |

Registered: 8 years ago Posts: 260 |

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 10:27AM |

Registered: 9 years ago Posts: 425 |

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 10:35AM |

Registered: 9 years ago Posts: 1,035 |

Would it be totally insanely out-of-the-box to think of two extruders working in tandem?

One big and mighty off-site and one small and puny on the printhead, one whose sole purpose is to match the speed of the mighty one and feed the filament into the hotend? These two can result in some sort of semi-flexi-drive for a fraction of the cost. I think that the puny one can leave without gearing altogether as its job would be to keep the length of the filament between the mighty extruder and it's own hobbed gear the same at all times.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

One big and mighty off-site and one small and puny on the printhead, one whose sole purpose is to match the speed of the mighty one and feed the filament into the hotend? These two can result in some sort of semi-flexi-drive for a fraction of the cost. I think that the puny one can leave without gearing altogether as its job would be to keep the length of the filament between the mighty extruder and it's own hobbed gear the same at all times.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 10:46AM |

Registered: 9 years ago Posts: 425 |

Quote

realthor

Would it be totally insanely out-of-the-box to think of two extruders working in tandem?

One big and mighty off-site and one small and puny on the printhead, one whose sole purpose is to match the speed of the mighty one and feed the filament into the hotend? These two can result in some sort of semi-flexi-drive for a fraction of the cost. I think that the puny one can leave without gearing altogether as its job would be to keep the length of the filament between the mighty extruder and it's own hobbed gear the same at all times.

You might be making a suggestion that inadvertently leads onto another, the clue being in the word "tandem" - if your machine is wide enough, and the carriages light enough, you could run two carriages seperated by a rigid link, thereby doubling the output of your machine. ie two extruders printing the same thing at the same time on the same axis. So a 300x300 bed would in fact become two 150x300 beds. If you could connect/disconnect/clip/unclip the secondary carriage, you could choose your mode of operation depending on whether your doing production work or one off larger prints.

Getting back to your original idea, a "pre-feeder" might be another way to describe it. If there is no synchronisation issue then it could work, if I understand you correctly. Also bear in mind that slight differences in tension arm tension can alter your effective esteps, over relatively short distances of say 1mtr of filament, you may end up with tension or buckling of the filament between the two hobbs? Just something to consider. But prefeeder might not be such a barmy idea.

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 11:37AM |

Registered: 9 years ago Posts: 1,035 |

Yes, the only challenge is synchronization the way I see it. But this approach will, for sub $30/pair I would guess, allow for a very light printhead.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 06:31PM |

Registered: 8 years ago Posts: 1,671 |

So last night I was thinking, how can I keep the weight off my extruder, do away with the heat, and the direct drive, and the bowden, and the filament and get the most out of the XYZ machine...

So I thought if UV resin was pumped through tube(big syringe) and droplets are cured as released... curing fast.

print speeds higher with resin, because its a layer at a time...but why not Drop Deposit Mod'

I know capillary action, resin viscosity would be an issue, but it sounds do-able...UV reacitve sugar water...whatever...

So I thought if UV resin was pumped through tube(big syringe) and droplets are cured as released... curing fast.

print speeds higher with resin, because its a layer at a time...but why not Drop Deposit Mod'

I know capillary action, resin viscosity would be an issue, but it sounds do-able...UV reacitve sugar water...whatever...

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 06:51PM |

Admin Registered: 16 years ago Posts: 13,886 |

.. I'm actually building/developing paste-dispenser applications with UV-curable pastes too - the head is an piezo-driven ink-jet-dispenser with comparable or even higher weights to an FDM head ... but jes, it's doable

But some years ago we discussed a FDM process, where the heat is generated by a laser-beam, fed by small mirors, and so (without heaters and coolers) only the filament feeder is adding weight, what can be a pretty small DC-motor, pushing 0.1mm to 0.3mm thick filament through a tube into the laser spot ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

But some years ago we discussed a FDM process, where the heat is generated by a laser-beam, fed by small mirors, and so (without heaters and coolers) only the filament feeder is adding weight, what can be a pretty small DC-motor, pushing 0.1mm to 0.3mm thick filament through a tube into the laser spot ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 06:59PM |

Registered: 8 years ago Posts: 1,671 |

Wow Cool! but piezo sounds fine, very fine...I was thinking a little larger blob, maybe with the consistency of wet sand, around a mm square, maybe half...but droplet bricks rather than a vat of resin, but however it's done it could be a winner, especially if a powder or solution could be mixed at home.

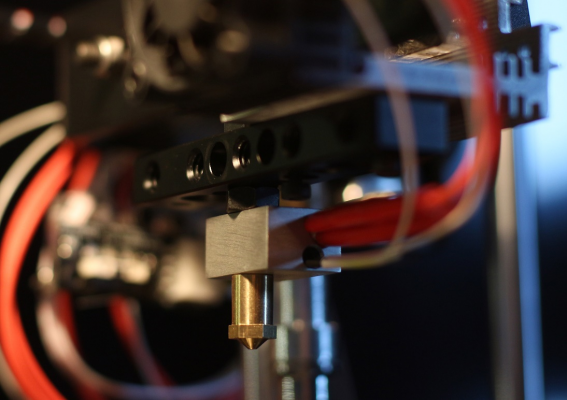

My small nozzle takes shape.

Edited 1 time(s). Last edit at 03/15/2016 07:10PM by MechaBits.

My small nozzle takes shape.

Edited 1 time(s). Last edit at 03/15/2016 07:10PM by MechaBits.

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 07:09PM |

Admin Registered: 16 years ago Posts: 13,886 |

... with low viscous fluids the droplets can be as small as 0.03mm in diameter - but here is a test with tooth-paste, showing thicker dots/droplets and lines too:

[vimeo.com]

- here a presentation with coloured hand creme - [vimeo.com]

With UV-resins this is similar - have one with high viscosity of around 100-200 MPas ... but found some with 1300 MPas, others with 47000 MPas!

Edited 2 time(s). Last edit at 03/15/2016 07:10PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[vimeo.com]

- here a presentation with coloured hand creme - [vimeo.com]

With UV-resins this is similar - have one with high viscosity of around 100-200 MPas ... but found some with 1300 MPas, others with 47000 MPas!

Edited 2 time(s). Last edit at 03/15/2016 07:10PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 07:14PM |

Registered: 8 years ago Posts: 1,671 |

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 08:16PM |

Admin Registered: 16 years ago Posts: 13,886 |

... I have watercooled 405nm-LED's with 9Watts optical output and want to fix one beside the nozzle for 'instant' curing ... the other option is first to deposit a complete layer and cure it then ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 08:41PM |

Registered: 9 years ago Posts: 1,873 |

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 09:18PM |

Registered: 8 years ago Posts: 1,671 |

Testing an idea, didnt say it would work  maybe I need block other way up, well spotted, but still might not be enough, but the hope is the brass bit gets hot from the alu and keeps more heat than steel throat, also want to try the brass throats, but both go deep inside nozzle, maybe with a little chamber...maybe just steel throat/nozzle, who knows where it will lead.

maybe I need block other way up, well spotted, but still might not be enough, but the hope is the brass bit gets hot from the alu and keeps more heat than steel throat, also want to try the brass throats, but both go deep inside nozzle, maybe with a little chamber...maybe just steel throat/nozzle, who knows where it will lead.

Edited 1 time(s). Last edit at 03/15/2016 09:20PM by MechaBits.

maybe I need block other way up, well spotted, but still might not be enough, but the hope is the brass bit gets hot from the alu and keeps more heat than steel throat, also want to try the brass throats, but both go deep inside nozzle, maybe with a little chamber...maybe just steel throat/nozzle, who knows where it will lead.

maybe I need block other way up, well spotted, but still might not be enough, but the hope is the brass bit gets hot from the alu and keeps more heat than steel throat, also want to try the brass throats, but both go deep inside nozzle, maybe with a little chamber...maybe just steel throat/nozzle, who knows where it will lead.Edited 1 time(s). Last edit at 03/15/2016 09:20PM by MechaBits.

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 09:34PM |

Registered: 9 years ago Posts: 1,873 |

Re: This engineer claims 100 grams direct extruder. I want one March 15, 2016 10:25PM |

Registered: 8 years ago Posts: 1,671 |

I think you have a few more tools than me there James, I'm just at the crying out for tools stage.

@vdx .. Interesting possibilities, be great if your laser could do some other tricks while printing, a bit of etching(you're already there), or the paste as a glue layer in other composites... How long from commercial reality? or affordability?

I assume that strange noise was the piezo?

Edited 2 time(s). Last edit at 03/15/2016 10:28PM by MechaBits.

@vdx .. Interesting possibilities, be great if your laser could do some other tricks while printing, a bit of etching(you're already there), or the paste as a glue layer in other composites... How long from commercial reality? or affordability?

I assume that strange noise was the piezo?

Edited 2 time(s). Last edit at 03/15/2016 10:28PM by MechaBits.

Re: This engineer claims 100 grams direct extruder. I want one March 16, 2016 04:21AM |

Admin Registered: 16 years ago Posts: 13,886 |

Quote

I assume that strange noise was the piezo?

yes, the piezo is 'hammering' while opening and closing the nozzle at high speed

We'll present this paste-dispensers (and a laser-machine) in sample/demo applications on an exhibition in April in Nürnberg, Germany -- from then on they are available in Germany.

I'm developing this system (machine and Pronterface+converters) together with my wife since October 2015 (she in part-time-job since summer) - the "presentation" video was made for an exhibition in November with the first prototype ... now we have 4 machines running and building a "0-series" of up to ten sets ...

***

For the lasers - I'm doing a lot with lasers ... etching/marking, cutting, sintering, melting/remelting,

Have different lasers - from diodes (UV, blue, red, IR) with up to 25Watts CW to fiberlasers with 120Watts ... and some other types too.

Were testing and developing around all sorts of laser-applications at home and in the job since some +25 years now ... and around 3D-printing-applications since +20 years

Edited 1 time(s). Last edit at 03/16/2016 04:23AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: This engineer claims 100 grams direct extruder. I want one March 16, 2016 05:34AM |

Registered: 8 years ago Posts: 1,671 |

Vintage Veteran Viktor Von FrazzleStien

The Mind Boggles as to whats stored in that brain of yours.

Edited 1 time(s). Last edit at 03/16/2016 07:47AM by MechaBits.

The Mind Boggles as to whats stored in that brain of yours.

Edited 1 time(s). Last edit at 03/16/2016 07:47AM by MechaBits.

Sorry, only registered users may post in this forum.