This engineer claims 100 grams direct extruder. I want one

Posted by realthor

Re: This engineer claims 100 grams direct extruder. I want one March 20, 2016 11:01AM |

Admin Registered: 16 years ago Posts: 13,886 |

... this "super-high-resolution-manufacturing" was mostly needed for micro-sensors - here the part sizes are mostly from some centi- to millimeters, but the needed accuracies form microns to some ten nanoemters ... but here the costs of some ten- to hundred-thousands of Euros for the development of the process and needed tools were in the common /acceptes ranges too ... and sometimes I've even got it 3x to 10x cheaper than expected

For me (and my 'homebrew'-tinkering) interesting is the transfer from this sizes/precisions to bigger/coarser parts or combination of FDM/SLA/SLS with micro-manufacturing.

So an "additive laserhead" with changeable filament diameters from 0.5mm to 0.01mm can be used for either high precision (but slow buildup times), or for coarser parts with faster fabbing by will

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

For me (and my 'homebrew'-tinkering) interesting is the transfer from this sizes/precisions to bigger/coarser parts or combination of FDM/SLA/SLS with micro-manufacturing.

So an "additive laserhead" with changeable filament diameters from 0.5mm to 0.01mm can be used for either high precision (but slow buildup times), or for coarser parts with faster fabbing by will

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: This engineer claims 100 grams direct extruder. I want one March 20, 2016 12:26PM |

Registered: 8 years ago Posts: 1,671 |

Considering the accuracy that inkjet printers can resolve, and blu-ray lasers without super expensive linear guides, I wonder how many years before these things are as cheap as when blu ray's came out. Though cleaning out the system could be a little trickier than an inkjet...and we all know what a PIA that can be.

Re: This engineer claims 100 grams direct extruder. I want one March 20, 2016 01:32PM |

Registered: 10 years ago Posts: 580 |

Realthor,

I've been thinking about what you want to achieve - in a reductionist sense, really just 2 things:

- Light hot end assembly

- Accurate extrusion

The referenced design used three components:

- a DC motor

- an encoder

- a controller with a servo loop.

Of the three components, the function of the encoder (right at the output end) and the controller must be as-is, the extruder motor could be entirely different. The encoder/controller allow you to accurately control any other method of feeding the filament, so a bowden extruder could be used to achieve a light hot end assembly.

The solution I am proposing would work with any Reprap electronics and firmware as-is, and would work even better with some integration.

No special DC motors or DC motor controllers would be needed, making it easier to source parts.

Call it a "Smart Extrusion Controller" perhaps - (c) 2016 Reprap.org

Here are the components:

- A standard bowden extruder

- A wheel-driven encoder measuring the actual filament fed into the hot end (right at that point) - with a high-level output (SPI or equivalent).

The Smart Extrusion Controller consisting of:

- A micro-controller breakout board of your choice

- With a stepper driver like a Polulu DRV8825

The following would be wired to the Smart Extrusion Controller:

- The extruder step/direction, enable outputs from the Reprap controller

- The SPI output from the encoder

Outputs from the microcontroller breakout:

- to the Stepper Driver for: step, direction, enable.

- from the stepper driver to the extruder's stepper motor

Operation:

1 - your standard reprap controller would feed it's extruder digital step/direction pulses to the Smart Extrusion Controller.

2 - the Smart Extrusion Controller would keep track of the position of the filament entering the extruder

3 - the Smart Extrusion Controller would then use a simplified servo-like feedback loop to move the filament as needed

4 - the Smart Extrusion Controller could sense many things in the process - filament out, extruder stall, load (based on input steps vs output), etc.

This would overcome several problems:

- Hysteresis due to: lash, springiness of the filament, friction in the bowden tube, melt-rate.

- Increased feed required due to deformation of the filament from the drive gear at higher pressures/feed rates.

- No extra load on the main Reprap controller.

- Easier to source parts

I think this method could be used with some existing controllers, if they have a spare SPI input, and enough spare cycles for the servo loop, and the servo loop programmed...

What do you think?

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I've been thinking about what you want to achieve - in a reductionist sense, really just 2 things:

- Light hot end assembly

- Accurate extrusion

The referenced design used three components:

- a DC motor

- an encoder

- a controller with a servo loop.

Of the three components, the function of the encoder (right at the output end) and the controller must be as-is, the extruder motor could be entirely different. The encoder/controller allow you to accurately control any other method of feeding the filament, so a bowden extruder could be used to achieve a light hot end assembly.

The solution I am proposing would work with any Reprap electronics and firmware as-is, and would work even better with some integration.

No special DC motors or DC motor controllers would be needed, making it easier to source parts.

Call it a "Smart Extrusion Controller" perhaps - (c) 2016 Reprap.org

Here are the components:

- A standard bowden extruder

- A wheel-driven encoder measuring the actual filament fed into the hot end (right at that point) - with a high-level output (SPI or equivalent).

The Smart Extrusion Controller consisting of:

- A micro-controller breakout board of your choice

- With a stepper driver like a Polulu DRV8825

The following would be wired to the Smart Extrusion Controller:

- The extruder step/direction, enable outputs from the Reprap controller

- The SPI output from the encoder

Outputs from the microcontroller breakout:

- to the Stepper Driver for: step, direction, enable.

- from the stepper driver to the extruder's stepper motor

Operation:

1 - your standard reprap controller would feed it's extruder digital step/direction pulses to the Smart Extrusion Controller.

2 - the Smart Extrusion Controller would keep track of the position of the filament entering the extruder

3 - the Smart Extrusion Controller would then use a simplified servo-like feedback loop to move the filament as needed

4 - the Smart Extrusion Controller could sense many things in the process - filament out, extruder stall, load (based on input steps vs output), etc.

This would overcome several problems:

- Hysteresis due to: lash, springiness of the filament, friction in the bowden tube, melt-rate.

- Increased feed required due to deformation of the filament from the drive gear at higher pressures/feed rates.

- No extra load on the main Reprap controller.

- Easier to source parts

I think this method could be used with some existing controllers, if they have a spare SPI input, and enough spare cycles for the servo loop, and the servo loop programmed...

What do you think?

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Re: This engineer claims 100 grams direct extruder. I want one March 20, 2016 02:25PM |

Registered: 8 years ago Posts: 1,671 |

Re: This engineer claims 100 grams direct extruder. I want one March 20, 2016 02:42PM |

Admin Registered: 16 years ago Posts: 13,886 |

... there were some ideas for measuring the real filament extrusion from the beginning of the RepRap project on - mostly based on optical mice sensors or small wheels with encoders.

Some of the prototypes were successfull - but didn't get enough 'momentum' to get widely accepted ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Some of the prototypes were successfull - but didn't get enough 'momentum' to get widely accepted ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: This engineer claims 100 grams direct extruder. I want one March 20, 2016 03:21PM |

Registered: 8 years ago Posts: 1,671 |

Yes I've seen the mouse wheel stuff, and the other threads on filament sensors, but havent seen the killer combo yet, or maybe I have and it's much simpler, maybe striped filament is the answer?

on the subject of the small hotend decided not to get the nema11 because there isnt a suitable mount, unless I made one, so have gone with a lighter nema17, but in the search for a decent small mount, something smaller than the steel ones, I come up with an idea to use a part from the Mk8 feeder to mount my 17...its perfect for my needs, strong, small, black...though I'll be using it for the X arm, not the extruder.

Edited 2 time(s). Last edit at 03/21/2016 06:59AM by MechaBits.

on the subject of the small hotend decided not to get the nema11 because there isnt a suitable mount, unless I made one, so have gone with a lighter nema17, but in the search for a decent small mount, something smaller than the steel ones, I come up with an idea to use a part from the Mk8 feeder to mount my 17...its perfect for my needs, strong, small, black...though I'll be using it for the X arm, not the extruder.

Edited 2 time(s). Last edit at 03/21/2016 06:59AM by MechaBits.

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 04:30AM |

Registered: 9 years ago Posts: 1,035 |

Measuring the filament entering the hotend entrance on a bowden setup sounds intriguing. It is definitely something that is worth pursuing. I have no electronics experience but can totally see the value in this. How would that board look like from a schematic pov? Would it be easy enough to do on a breadboard with a soldering iron on the kitchen table?

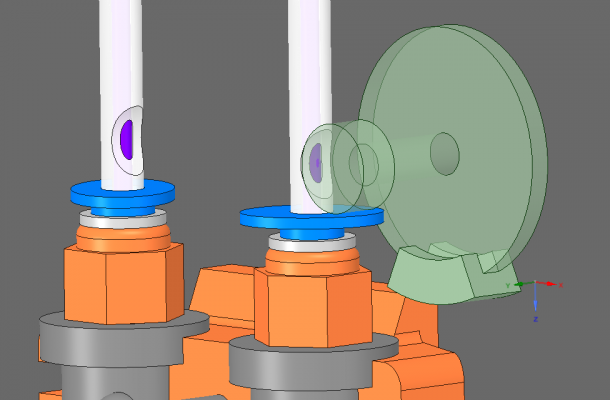

The wheel-driven encoder should be something that doesn't slip on the filament which means some pressure right on the filament or some rubbery rim on a 3d printed wheel of sorts. Also the bowden at the entrance of the hotend should be half stripped to allow direct contact from the wheel to the plastic filament. This can be optical or magnetic. Which one would be more suitable for this purpose? I believe it should be quite sensitive to very little movement, maybe we can have a small wheel that is turned by the filament which has a larger diameter wheel on its axis and have that one be "read" by the sensor to increase resolution. Something like this maybe?

Edited 1 time(s). Last edit at 03/21/2016 04:30AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

The wheel-driven encoder should be something that doesn't slip on the filament which means some pressure right on the filament or some rubbery rim on a 3d printed wheel of sorts. Also the bowden at the entrance of the hotend should be half stripped to allow direct contact from the wheel to the plastic filament. This can be optical or magnetic. Which one would be more suitable for this purpose? I believe it should be quite sensitive to very little movement, maybe we can have a small wheel that is turned by the filament which has a larger diameter wheel on its axis and have that one be "read" by the sensor to increase resolution. Something like this maybe?

Edited 1 time(s). Last edit at 03/21/2016 04:30AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 07:08AM |

Admin Registered: 16 years ago Posts: 13,886 |

... this would only be precise enough, if you get 'perfect' filament - with common (real world) filament the diameter and circular/oval cross section shape is often some 5 to 10 percents off

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 07:41AM |

Registered: 9 years ago Posts: 1,035 |

Quote

VDX

... this would only be precise enough, if you get 'perfect' filament - with common (real world) filament the diameter and circular/oval cross section shape is often some 5 to 10 percents off

Well the wheel could be pressed against the filament at all times. I can imagine a clip-on thing on the bowden. Do you have any advise/solution to this bowden-sensor?

If this could be done we could use a geared DC motor as extruder.

Edited 1 time(s). Last edit at 03/21/2016 07:43AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 09:23AM |

Admin Registered: 16 years ago Posts: 13,886 |

... no, the length/travel measuring can be super perfect - but the volume per mm value, what's needed to calculate the extrusion amount, will be some ten percents off.

So regardless, how good your feed-sensor is, the extruded volume is related to the inserted volume {= length * (varying) cross-section}, not the length alone!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

So regardless, how good your feed-sensor is, the extruded volume is related to the inserted volume {= length * (varying) cross-section}, not the length alone!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 09:33AM |

Registered: 9 years ago Posts: 1,035 |

Quote

VDX

... no, the length/travel measuring can be super perfect - but the volume per mm value, what's needed to calculate the extrusion amount, will be some ten percents off.

So regardless, how good your feed-sensor is, the extruded volume is related to the inserted volume {= length * (varying) cross-section}, not the length alone!

Ohh I see now. But isn't that the same situation with direct extruders? They are all based on length not volume... how can one measure volume without complicated electronics? If all extruders out there have this issue it means those 10% lost in the sensor described above would be nothing other types of extrusion don't already loose and would still be getting the bowden up to the same level with direct extrusion, still achieving the lighter weight of the printhead.

I believe that in this area we are at the mercy of the filament makers and getting those filaments to better tolerances.

Edited 2 time(s). Last edit at 03/21/2016 09:54AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 11:07AM |

Admin Registered: 16 years ago Posts: 13,886 |

Quote

realthor

.. But isn't that the same situation with direct extruders?

... exactly the same situation -- so most "measuring" projects were cancelled, as they didn't give you a better way to control the extruding ...

Quote

realthor

I believe that in this area we are at the mercy of the filament makers and getting those filaments to better tolerances.

... yes, of course

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 11:21AM |

Registered: 9 years ago Posts: 1,035 |

Quote

realthor

[...] would still be getting the bowden up to the same level with direct extrusion, still achieving the lighter weight of the printhead.

So this technique would actually benefit the bowden right? I twill bring it up to par with direct extruders at a much lighter printheads. Then why dismiss this length-sensor-feedback-loop as an alternative for a lighter printhead?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 11:42AM |

Registered: 8 years ago Posts: 1,671 |

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 12:05PM |

Registered: 10 years ago Posts: 580 |

Sure it would benefit bowden setups, and all others too. They all have the same problems to a greater or lesser extent as I noted above. Measuring the input filament length eliminates one huge variable in the equation (regardless of motor or extruder type).

Filament quality is a separate topic!

Your design for the sensor interface is similar to what I had in mind.

Use a Dremel to cut a slit for it to go into, and a thin sharp metal gear to ride on the filament. There would be a spring mechanism to apply pressure.

The electronics could be easily bread-boarded - that's really the easiest part.

The difficult parts are (regardless of the motor type) :

- The rotary encoder selection

- The firmware to:

- read the incoming pulses from the main controller

- read the current filament position from the rotary encoder

- pulse the extruder stepper appropriately.

There may be open source software to do most of this (servo loop), so the wheel may not need to be entirely reinvented. I know how it would be done but I have too many other projects.

This could easily be a standalone board, but it would be easy enough to include in the firmware of a 32-bit controller.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Filament quality is a separate topic!

Your design for the sensor interface is similar to what I had in mind.

Use a Dremel to cut a slit for it to go into, and a thin sharp metal gear to ride on the filament. There would be a spring mechanism to apply pressure.

The electronics could be easily bread-boarded - that's really the easiest part.

The difficult parts are (regardless of the motor type) :

- The rotary encoder selection

- The firmware to:

- read the incoming pulses from the main controller

- read the current filament position from the rotary encoder

- pulse the extruder stepper appropriately.

There may be open source software to do most of this (servo loop), so the wheel may not need to be entirely reinvented. I know how it would be done but I have too many other projects.

This could easily be a standalone board, but it would be easy enough to include in the firmware of a 32-bit controller.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 12:10PM |

Registered: 13 years ago Posts: 268 |

So what do you intend to do with the sensed position of the filament with this wheel? Is your intention to modulate the XY feed to keep up with the extruder? Or are you intending to modify the feed at the other end of the Bowden based on data from this encoder? Both of those have drawbacks, some significant.

History in this project used a DC motor with encoder for filament extrusion. Nobody uses this approach anymore, perhaps this is trodden territory?

History in this project used a DC motor with encoder for filament extrusion. Nobody uses this approach anymore, perhaps this is trodden territory?

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 12:16PM |

Registered: 9 years ago Posts: 1,035 |

Quote

Paul Wanamaker

This could easily be a standalone board, but it would be easy enough to include in the firmware of a 32-bit controller.

Besides my previous sketch I am useless... I can't do electronics nor coding so I can only hope it's time that modern firmwares would include encoders/DC motors code. :-/

From my pov this would really reduce the weight on the printhead. imagine several hotends and no motor on-site and no bowden downsides. Sounds like a perfect match to me.

What kind of encoder would be the easiest to build? Maybe there is already code for one specific type of encoder and then we will take it up from there...

I believe this should be thought as both a stand alone board for the plethora of Mega/Ramps-es out there as well as something that can be included in the 32 bit boards...

@Koko76: you posted while I was writing...so yeah, if what you say is true this might have already been proven a dead end; I would imagine we must try to feed the extruder data fom the hotend-entry so that we avoid all the inconsistencies related to the bowden.

Edited 1 time(s). Last edit at 03/21/2016 12:19PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 01:22PM |

Registered: 10 years ago Posts: 580 |

Quote

Koko76

So what do you intend to do with the sensed position of the filament with this wheel? Is your intention to modulate the XY feed to keep up with the extruder? Or are you intending to modify the feed at the other end of the Bowden based on data from this encoder? Both of those have drawbacks, some significant.

The intention is to have the input into the hot end match what is commanded. Yes, that means increasing or decreasing the feed of the extruder on the other end of the bowden (closed loop). What drawback do you see for that?

Quote

Koko76

History in this project used a DC motor with encoder for filament extrusion.

I'm not advocating using a DC motor, just closing the loop. This is motor-agnostic, but really, there is no reason to use a DC motor on a bowden. I prefer a Nema 23 direct-drive myself.

Quote

Koko76

Nobody uses this approach anymore, perhaps this is trodden territory?

Don't get me started... oh, too late:

1 - There are a lot of things that commercial machines do for good reason - that repraps do not, and should!

2 - This is partially due to the brain dead way that 8-bit controllers have been adhered to - there is already too much complexity in the firmware to allow for further innovation.

3 - The only reason the engineer was able to do what he claims to have done - an extruder that light - is because he used a small motor with closed-loop control. Note that his project is partially failing because he picked his favorite but not powerful enough micro-controller! He can not turn all the features on at once - that's probably why he did not show it printing.

4 - Open loop stepper control was much easier to implement, and it mostly served the purpose - but not for extrusion. I can list the ways it fails, I mostly already have.

5 - There have been very few reprapers who have attempted closed loop control of the extrusion - that does not mean it was unsuccessful - just few innovators willing to try with the limitations at the time, and with steppers already as a (mostly) working alternative.

6 - The proposed solution could be done inexpensively as a breakout - and added back into firmware when it proves itself, or used separately for brain-dead controllers. It's mostly just software and a sensor.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 02:09PM |

Admin Registered: 16 years ago Posts: 13,886 |

... encoders aren't new for RepRap either - the old Gen3-motor-drivers were built with a chip capable of driving either stepper-, or DC-motors ... and on the driver was a plug for a quadrature-encoder.

But as nearly all people went the "stepper-way", this option was skipped in the next versions ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

But as nearly all people went the "stepper-way", this option was skipped in the next versions ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 02:24PM |

Registered: 13 years ago Posts: 268 |

Good luck Paul, I believe that you will find "closing the loop" to be more difficult than you think. Modern machine tools still keep servo encoders on the motor shaft instead of the moving table for very good reason, the same one which makes it difficult to close the loop here. Personally I think this is a dead end and I am working to make a lightweight direct solution. I think I can get pretty close to the proposed magic number.

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 03:39PM |

Registered: 10 years ago Posts: 580 |

Koko76,

Thank you for your advice.

I'm sure you are right - it will be a challenge.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Thank you for your advice.

I'm sure you are right - it will be a challenge.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Re: This engineer claims 100 grams direct extruder. I want one March 21, 2016 04:34PM |

Registered: 8 years ago Posts: 1,671 |

pity that molten material couldnt be pumped into a reservoir with known dimensions, maybe a device just for measuring filament average prior to print feeding back into feedrate numbers, and then used from there (but I guess pla/abs doesnt like too stay molten for long, step in UV or laser cure material), but would have to evacuate fully after each layer, maybe use up spare material on perimeter or spare part.

Re: This engineer claims 100 grams direct extruder. I want one March 22, 2016 01:24AM |

Registered: 8 years ago Posts: 7 |

Perhaps I'm missing something, but is there any practical reason that a digital dial indicator couldn't be mounted in line with the bowden tube right after or before the extruder. Most of said indicators output a signal that could be sent the controller to get a reasonably accurate idea of what the diameter is. After that input the length of the bowden tube and distance from indicator to extruder. Coupled with the proposed position sensor, we'd have a good idea of volume and position of the filament at all times.

It seems like the hardest part would be firmware implementation.

It seems like the hardest part would be firmware implementation.

Re: This engineer claims 100 grams direct extruder. I want one March 22, 2016 05:08AM |

Registered: 12 years ago Posts: 2,470 |

Such a sensor can not differentiate between oval filament or general over- / undersize. You would need to measure from several directions (at least two at 90°) to get a useable result.Quote

The Mechanic

Perhaps I'm missing something, but is there any practical reason that a digital dial indicator couldn't be mounted in line with the bowden tube right after or before the extruder. Most of said indicators output a signal that could be sent the controller to get a reasonably accurate idea of what the diameter is. After that input the length of the bowden tube and distance from indicator to extruder. Coupled with the proposed position sensor, we'd have a good idea of volume and position of the filament at all times.

It seems like the hardest part would be firmware implementation.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Re: This engineer claims 100 grams direct extruder. I want one March 22, 2016 05:33AM |

Registered: 10 years ago Posts: 179 |

What do filament manufacturers use to track freshly extruded filament's diameter? I think I was watching a video of extrudr.eu manufacturing process where they had a live graph of filament diameter measurement as it was being extruded. Whatever they are using must be working and it should be possible to implement unless hardware is massive.

Edited 1 time(s). Last edit at 03/22/2016 05:34AM by Edvardas.

Edited 1 time(s). Last edit at 03/22/2016 05:34AM by Edvardas.

Re: This engineer claims 100 grams direct extruder. I want one March 22, 2016 06:22AM |

Registered: 8 years ago Posts: 1,671 |

Maybe its time to start using cylindrical heater/nozzle blocks, I bet these things get hot quick.

[www.ebay.co.uk]

[www.ebay.co.uk]

[www.ebay.co.uk]

Edited 3 time(s). Last edit at 03/22/2016 06:27AM by MechaBits.

[www.ebay.co.uk]

[www.ebay.co.uk]

[www.ebay.co.uk]

Edited 3 time(s). Last edit at 03/22/2016 06:27AM by MechaBits.

Re: This engineer claims 100 grams direct extruder. I want one March 22, 2016 02:36PM |

Registered: 12 years ago Posts: 33 |

Quote

Koko76

Good luck Paul, I believe that you will find "closing the loop" to be more difficult than you think. Modern machine tools still keep servo encoders on the motor shaft instead of the moving table for very good reason, the same one which makes it difficult to close the loop here. Personally I think this is a dead end and I am working to make a lightweight direct solution. I think I can get pretty close to the proposed magic number.

Actually why do we care what speed the extruder motor is moving? What we really are interested in is the quantity of filament extruded (or retracted).

Thus:

Why not use a small motor such as the one linked above: similar to stratasys geared maxon motor and instead of an encoder on the motor, just use the mouse sensor to determine filament movement?

Lots of torque, easy to control, and very lightweight.

Re: This engineer claims 100 grams direct extruder. I want one March 22, 2016 04:44PM |

Registered: 13 years ago Posts: 268 |

Because moving the encoder further away in the chain from the source of motion makes it far harder to control. As I said in the post you quoted, modern machine tools still put the servo encoder on the motor shaft, not post gearbox, and not on the moving table. A simplified version of what will happen is that the motor will hunt back and forth through the lash present in the system to get to the commanded position. It becomes harder to damp, and the max velocity and acceleration go way down.Quote

jonnycowboy

Quote

Koko76

Good luck Paul, I believe that you will find "closing the loop" to be more difficult than you think. Modern machine tools still keep servo encoders on the motor shaft instead of the moving table for very good reason, the same one which makes it difficult to close the loop here. Personally I think this is a dead end and I am working to make a lightweight direct solution. I think I can get pretty close to the proposed magic number.

Actually why do we care what speed the extruder motor is moving? What we really are interested in is the quantity of filament extruded (or retracted).

Thus:

Why not use a small motor such as the one linked above: similar to stratasys geared maxon motor and instead of an encoder on the motor, just use the mouse sensor to determine filament movement?

Lots of torque, easy to control, and very lightweight.

Servo systems are wonderful things, they can be very accurate and powerful when sized and above all tuned correctly. But getting them to that point is certainly more complicated than dropping in a stepper motor, especially with the power levels we are talking about. A DC servo system will be marginally cheaper but nowhere near as simple or adaptable to different builds, loading and other factors. It's not a worthless endeavor, but I fail to see exactly what problems this solves.

Re: This engineer claims 100 grams direct extruder. I want one March 22, 2016 05:37PM |

Registered: 10 years ago Posts: 48 |

@MechaBits

You might want to check this out

http://deltaprintr.com/shop/parts-and-accessories/hardware/mini-hotend/

You might want to check this out

http://deltaprintr.com/shop/parts-and-accessories/hardware/mini-hotend/

Re: This engineer claims 100 grams direct extruder. I want one March 22, 2016 08:19PM |

Registered: 8 years ago Posts: 1,671 |

Sorry, only registered users may post in this forum.