This engineer claims 100 grams direct extruder. I want one

Posted by realthor

Re: This engineer claims 100 grams direct extruder. I want one April 19, 2016 03:58AM |

Registered: 8 years ago Posts: 260 |

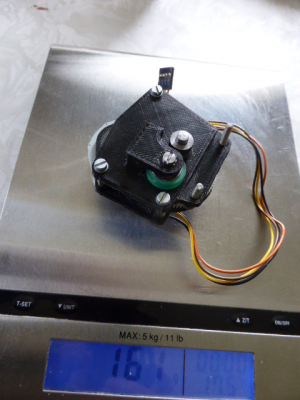

Have them both , measured weight including about 20cm of cable.

14HR05-0504S = 50g 7Ncm

14HR08-0654S = 90g 12 Ncm

With a ~1:4.3 and hobbit bolt ( ~ 5-6mm diameter ) ( I use no enclosure yet ) I have the same forced cooling for both steppers.

the 7 Ncm works, but I see a lot of steps skipped( I see it even reverse ) more at low speed then at high speed. It also gets reasonably hot ~ 50 degrees I use 400mA

the 12 7Ncm doesn't skip, doesn't get hot (< 30 degrees), and it is running on 500mA.

I will ditch the 7Ncm and put a 12Ncm in the second extruder in my dual extruder setup. Total weight about 300 grams (14HR08-0654S) per extruder ( including E3D v6 and cooling )

My dual extrude setup now weighs the same as my first single extruder setup.

If I really want, I can reduce the weight easily by 50 grams per extruder.

But my opinion is that the limiting factor now is the filament for high speed extruding not the P3steel that I have now. So I will improve my P3Steel on other areas, By the way if you make sure that the

weight of the complete extruder is ballanced around the mounting point of the driving belt you will not have problems with fast acceleration/deceleration of the extruders.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

14HR05-0504S = 50g 7Ncm

14HR08-0654S = 90g 12 Ncm

With a ~1:4.3 and hobbit bolt ( ~ 5-6mm diameter ) ( I use no enclosure yet ) I have the same forced cooling for both steppers.

the 7 Ncm works, but I see a lot of steps skipped( I see it even reverse ) more at low speed then at high speed. It also gets reasonably hot ~ 50 degrees I use 400mA

the 12 7Ncm doesn't skip, doesn't get hot (< 30 degrees), and it is running on 500mA.

I will ditch the 7Ncm and put a 12Ncm in the second extruder in my dual extruder setup. Total weight about 300 grams (14HR08-0654S) per extruder ( including E3D v6 and cooling )

My dual extrude setup now weighs the same as my first single extruder setup.

If I really want, I can reduce the weight easily by 50 grams per extruder.

But my opinion is that the limiting factor now is the filament for high speed extruding not the P3steel that I have now. So I will improve my P3Steel on other areas, By the way if you make sure that the

weight of the complete extruder is ballanced around the mounting point of the driving belt you will not have problems with fast acceleration/deceleration of the extruders.

P3steel DXL, with Due/RADDS/Raps128 dual Wade's extruder

Re: This engineer claims 100 grams direct extruder. I want one April 19, 2016 04:35AM |

Registered: 8 years ago Posts: 5,232 |

@powdermetal is running a 80gr/4Ncm NEMA8 stepper with 2.85mm filament...

how much better would it work with a NEMA14 pancake ( 50gr/4Ncm or 90gr/12Ncm) and 1.75mm filament?

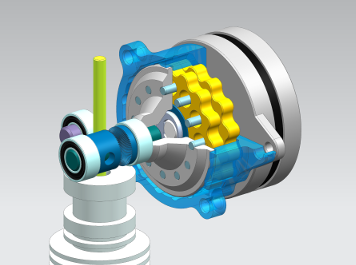

Compared to harmonic drives, a cycloidal drive seems to be easier to print.

BTW: Have you seen this page?

It talks about magnetic cycloidal drives ( which I read as: stepper&cycloidal drive can be one ) but a bit down the page it talks about hypocycloidal drives which are even easier to print

Edited 2 time(s). Last edit at 04/19/2016 05:23AM by o_lampe.

how much better would it work with a NEMA14 pancake ( 50gr/4Ncm or 90gr/12Ncm) and 1.75mm filament?

Compared to harmonic drives, a cycloidal drive seems to be easier to print.

BTW: Have you seen this page?

It talks about magnetic cycloidal drives ( which I read as: stepper&cycloidal drive can be one ) but a bit down the page it talks about hypocycloidal drives which are even easier to print

Edited 2 time(s). Last edit at 04/19/2016 05:23AM by o_lampe.

Re: This engineer claims 100 grams direct extruder. I want one April 19, 2016 11:19AM |

Registered: 8 years ago Posts: 5,232 |

Re: This engineer claims 100 grams direct extruder. I want one April 20, 2016 03:03PM |

Registered: 9 years ago Posts: 425 |

Quote

o_lampe

I wonder if the flex3drive would benefit from a cycloidal drive? The worm gears it uses now will sure have a lower efficiency?!

Very unlikely.

An injection moulded worm gear, using a high end (very expensive) engineering polymer, moulded in hardened steel tools, with a sliding contact patch of approx 1mm^2 and very shallow lead angle, is going to be far more efficient and accurate than a 3d printed cycloidal system, and cheaper than a machined or off-the-shelf cycloidal. Realistically speaking probably cheaper than solutions so far mentioned in this thread.

Quote

o_lampe

...think of multifeed flex3drive extruders...

Stacking more than two cycloidal extruders is difficult because input and output shaft are inline.

Would you be able to pack the necessary components for a single drive cycloidal, into the footprint of a dual drive Flex3Drive or achieve sub 100 grammes for a dual drive? Based on this thread it seems quite a struggle to achieve sub 100g for a single direct drive.

It would be easy not to appreciate what is actually behind the Flex3Drive, but I shall continue forwards for more upcoming awesomeness

J

Re: This engineer claims 100 grams direct extruder. I want one April 22, 2016 06:54PM |

Registered: 8 years ago Posts: 62 |

Quote

powdermetal

Quote

jonnycowboy

Powermetal, are your files available?

I'd like to rework it for the NEMA14 two-bolt stepper (50g only - 14HR08-0654S). With your solution we could bring the complete cold/hot end down to 100g combined with the new DeltaMini hot end.

I am planning to put the files to a wiki page here - just in case you want to play with them. This will include parts in STEP-format and simplified parts (no blends/chamfers/...) for easier modification.

The 14HR08-0654S as proposed by Chri and others seems to be a nice lightweight and effective motor solution for such kind of application - maybe another gearbox with a modified ratio (something like 15:1) with this stepper will make it's way...

Regarding precision: Is there anybody, who has access to a precise lasercutter or watercutter, who could cut properly toleranced gears from plastics to see, whether this concept is viable at all?

1. Some docs: Cycloidal Extruder Drive

2. Have indulgence - it's my first wiki...

Re: This engineer claims 100 grams direct extruder. I want one April 22, 2016 07:01PM |

Registered: 9 years ago Posts: 1,873 |

Many thanks! My nema14 extruder with 5:1 ratio is right on the ragged edge for 3mm pla, so I'm looking for alternatives in the 10:1 ballpark. I may end up trying this

Re: This engineer claims 100 grams direct extruder. I want one April 23, 2016 06:51AM |

Registered: 8 years ago Posts: 5,232 |

Great wiki page!

I would like to add this hypocycloidal cam generator, which is copyrighted by Dan Boyer and based on Alex Lait's python script. ( zincland ). I doesn't work very well, but it's a good base to start your own software.

I would like to add this hypocycloidal cam generator, which is copyrighted by Dan Boyer and based on Alex Lait's python script. ( zincland ). I doesn't work very well, but it's a good base to start your own software.

Re: This engineer claims 100 grams direct extruder. I want one April 23, 2016 03:47PM |

Registered: 9 years ago Posts: 1,035 |

Here's some work on filament sensing: [plus.google.com]

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: This engineer claims 100 grams direct extruder. I want one April 24, 2016 01:37PM |

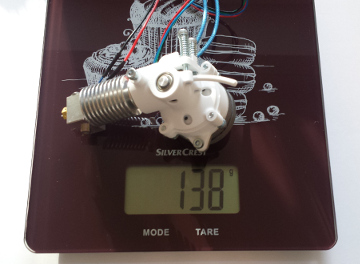

As I had a few steppers and gears from old printers, I decided to give it a try.

I couldn't find the data (brand Sankyo) so I did some measurements. The lightest one was 110g, PM type 48 steps/t about 7 ohm, 12 mH.

Looked OK to me, so I connected it to one of driver set to 1 A. The holding torque was about 12 N.cm.

Not bad as for the direct drive, I made using the NEMA 17 from plus in house 8.5 mm hobbed gear and idler (will not give up below 40N pull) I measured the required torque to be about 8 - 12 N.cm.to extrude PLA 200°C, 0.35mm nozzle, 1.75 filament;

But obviously, this motor was beyond its limit, as it became really hot (60°).

Fact is, I didn't need a high gear ratio. Besides, a high ratio means high step/turn and this could lead to stalling while retracting the filament.

Among the gears I had, I tried a few and selected an 82 t, the motor was fitted with a 17 t.

Put the parts together using printed parts, a few screws, ball bearings (from old hard drive) etc..

160g, OK I will have to add the hot end, but first, I will have to make a totally new better one.

I had already gained close to 100g compared to the MK8 with my previous one.

Fact is, I feel the next step to really gain weight is to use DC servo motors with an encoder on the idler as it sticks to the filament.

I just did a few print tests pushing the speed to 3 times the default 60mm/s. Looks OK. I can't say for bigger one. What about ABS and other. Will see.

Edited 2 time(s). Last edit at 04/24/2016 03:10PM by MKSA.

I couldn't find the data (brand Sankyo) so I did some measurements. The lightest one was 110g, PM type 48 steps/t about 7 ohm, 12 mH.

Looked OK to me, so I connected it to one of driver set to 1 A. The holding torque was about 12 N.cm.

Not bad as for the direct drive, I made using the NEMA 17 from plus in house 8.5 mm hobbed gear and idler (will not give up below 40N pull) I measured the required torque to be about 8 - 12 N.cm.to extrude PLA 200°C, 0.35mm nozzle, 1.75 filament;

But obviously, this motor was beyond its limit, as it became really hot (60°).

Fact is, I didn't need a high gear ratio. Besides, a high ratio means high step/turn and this could lead to stalling while retracting the filament.

Among the gears I had, I tried a few and selected an 82 t, the motor was fitted with a 17 t.

Put the parts together using printed parts, a few screws, ball bearings (from old hard drive) etc..

160g, OK I will have to add the hot end, but first, I will have to make a totally new better one.

I had already gained close to 100g compared to the MK8 with my previous one.

Fact is, I feel the next step to really gain weight is to use DC servo motors with an encoder on the idler as it sticks to the filament.

I just did a few print tests pushing the speed to 3 times the default 60mm/s. Looks OK. I can't say for bigger one. What about ABS and other. Will see.

Edited 2 time(s). Last edit at 04/24/2016 03:10PM by MKSA.

Re: This engineer claims 100 grams direct extruder. I want one April 24, 2016 05:05PM |

Registered: 9 years ago Posts: 425 |

|

Anonymous User

Re: This engineer claims 100 grams direct extruder. I want one April 25, 2016 01:10AM |

Quote

Mutley3D

Quote

MKSA

a high ratio means high step/turn and this could lead to stalling while retracting the filament.

Complete rubbish! - (OK Perhaps a bit harsh I admit - apologies!) - So, the following may cause some consternation. This is not my objective. I wish to generate thought and debate toward a definitive resolution and understanding for wider community and dispell some myths being purported as fact! There are some over looked fundamentals that need to be revisited! I am possibly deviating from the topic somewhat, but it is directly related to the objective in this thread. Perhaps another thread should take this subject matter further.

....

Too bad but looks like my stepper didn't know it

because it stalled while retracting the filament (which has to be a lot faster than the normal feed) but was fine feeding it with a tremendous torque (about 70Ncm) with a 12.4 reduction !

because it stalled while retracting the filament (which has to be a lot faster than the normal feed) but was fine feeding it with a tremendous torque (about 70Ncm) with a 12.4 reduction ! As the torque at the hobbed gear far exceed what is required, I changed gears and went to a 4.82 ratio.

Note I am using the gears I have on hand and can't come up with even figures

An other thing, less gears, less backlash as I am using regular ones.

My extruder with the stepper driver set to deliver 0.4A pulls about 20N (measured with a piece of filament engaged) far more than what is needed and far above the bulky, heavy MK8.

No issue to get the filament from the spool, either the filament comes or the entire spool !

If I get a smaller, lighter stepper, less torque, high pps, I will try higher reduction with more sophisticated gear box.

But is it worth it compared to a DC plus servo ? The later seems to be the way to go.

BTW: I told my stepper what you said but he doesn't seem to care, it keeps purring while feeding, the filament

I guess you misunderstood what I wrote. I agree with what you wrote, just the torque versus pps is missing.

Edited 5 time(s). Last edit at 04/25/2016 02:45PM by MKSA.

Re: This engineer claims 100 grams direct extruder. I want one April 25, 2016 03:32PM |

Registered: 8 years ago Posts: 62 |

Quote

thefrog

Don't know if this got linked already ...

My extruder is down to 160g with steel gears and the Sanyo Denki Nema 17 Motor

There seem to be more designs using the Sanyo Denki Nema 17 Motor: Ultimaker 2 pancake stepper direct drive

Just a very small direct driven knurled shaft...

Re: This engineer claims 100 grams direct extruder. I want one April 25, 2016 05:44PM |

Registered: 9 years ago Posts: 1,035 |

Quote

powdermetal

There seem to be more designs using the Sanyo Denki Nema 17 Motor: Ultimaker 2 pancake stepper direct drive

Just a very small direct driven knurled shaft...

Nice find. I also like the spring-less idler arm.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: This engineer claims 100 grams direct extruder. I want one April 26, 2016 02:04AM |

Quote

powdermetal

Quote

thefrog

Don't know if this got linked already ...

My extruder is down to 160g with steel gears and the Sanyo Denki Nema 17 Motor

There seem to be more designs using the Sanyo Denki Nema 17 Motor: Ultimaker 2 pancake stepper direct drive

Just a very small direct driven knurled shaft...

The hobbed gear is really small, not well designed.

It is just a scaled down normal direct drive.

OK, a good point it is simplified by removing the spring, and relying on the lever flexibility. I suppose the notches allow some pressure adjustment ?.

I would like to know its performance. Must be inferior to the regular MK8.

The challenge is to gain weight while not loosing in performance and even better them.

Edited 2 time(s). Last edit at 04/26/2016 02:18AM by MKSA.

Re: This engineer claims 100 grams direct extruder. I want one April 26, 2016 03:39AM |

Registered: 8 years ago Posts: 5,232 |

Quote

MKSA

The hobbed gear is really small, not well designed.

I agree, the pattern is very rough compared to the size.

I wonder, if a diamond powdered grinder tool ( dremel size ) would be a good micro-hobbed bolt? (still thinking about smaller diameter filament, like 0.8-1mm )

Edited 1 time(s). Last edit at 04/26/2016 03:40AM by o_lampe.

Re: This engineer claims 100 grams direct extruder. I want one April 26, 2016 06:47AM |

Registered: 9 years ago Posts: 1,035 |

The Titan from E3D is about 195g ... looks pretty neat what do you say?

[youtu.be]

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

[youtu.be]

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Anonymous User

Re: This engineer claims 100 grams direct extruder. I want one April 26, 2016 11:13AM |

Indeed, it is a good one.

They did the right thing, correct hobbed gear, moderate reduction tuned to the motor, giving torque AND retraction speed.

They know their business.

Yet I prefer mine

I took the same approach, just used parts I had on hand which are similar BTW, yet my idler is simpler.

I took the same approach, just used parts I had on hand which are similar BTW, yet my idler is simpler.As I wrote above, a smaller stepper with higher reduction could allow further gain provided its torque/pps allows fast filament retraction.

What we gain in motor weight has not to be lost in increased gear box weight. Backlash has to be considered too.

Yet, Servo DC is the way to go if we want more.

While browsing for motors, I noticed that the leaders seem to concentrate on these more sophisticated products, leaving the market of cheap steppers,PM, Hybrid to the Chinese.

Re: This engineer claims 100 grams direct extruder. I want one April 29, 2016 03:08PM |

Registered: 9 years ago Posts: 1,035 |

Another good one, don't know if you've seen this one:

Nscrypt FDM extruder

... from [nscrypt.com]

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Nscrypt FDM extruder

... from [nscrypt.com]

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one April 29, 2016 11:52PM |

Registered: 8 years ago Posts: 72 |

Is there a drop-in translation electronics to use heavy geared dc motor instead of a stepper? I have a couple of small and light DC motors with planetary gearbox strapped to them. Would gladly try them out as a candidate for "less weight more speed".

If I remember correct, DC motors have a decent torque at low speed. This makes them a perfect candidate for use in an extruder motor. Also, I believe Stratasys uses rather small DC motors in their extruders. The reason RepRaps use steppers instead of DC is the complexity of the control electronics. In fact, first reprap extruders were DC, but had trouble with control and calibration. I wish we could go back and reverse that change towards steppers: maybe at the time it was reasonable – after all there were no accessible fast microcontrollers to do the closed-loop control, but now there are plenty of them.

So ,from time to time I read some news about the DC motor based closed-loop control, but there is no code or it is very specific to the application. I wish there would be a board with a tiny 8-bit controller, an H-bridge and a rotary encoder sensor that would basically accept the step signals and translate it to DC motor language.

If I remember correct, DC motors have a decent torque at low speed. This makes them a perfect candidate for use in an extruder motor. Also, I believe Stratasys uses rather small DC motors in their extruders. The reason RepRaps use steppers instead of DC is the complexity of the control electronics. In fact, first reprap extruders were DC, but had trouble with control and calibration. I wish we could go back and reverse that change towards steppers: maybe at the time it was reasonable – after all there were no accessible fast microcontrollers to do the closed-loop control, but now there are plenty of them.

So ,from time to time I read some news about the DC motor based closed-loop control, but there is no code or it is very specific to the application. I wish there would be a board with a tiny 8-bit controller, an H-bridge and a rotary encoder sensor that would basically accept the step signals and translate it to DC motor language.

Re: This engineer claims 100 grams direct extruder. I want one April 30, 2016 03:07AM |

Registered: 9 years ago Posts: 1,035 |

Quote

toxuin

Is there a drop-in translation electronics to use heavy geared dc motor instead of a stepper? I have a couple of small and light DC motors with planetary gearbox strapped to them. Would gladly try them out as a candidate for "less weight more speed".

If I remember correct, DC motors have a decent torque at low speed. This makes them a perfect candidate for use in an extruder motor. Also, I believe Stratasys uses rather small DC motors in their extruders. The reason RepRaps use steppers instead of DC is the complexity of the control electronics. In fact, first reprap extruders were DC, but had trouble with control and calibration. I wish we could go back and reverse that change towards steppers: maybe at the time it was reasonable – after all there were no accessible fast microcontrollers to do the closed-loop control, but now there are plenty of them.

So ,from time to time I read some news about the DC motor based closed-loop control, but there is no code or it is very specific to the application. I wish there would be a board with a tiny 8-bit controller, an H-bridge and a rotary encoder sensor that would basically accept the step signals and translate it to DC motor language.

+1

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one April 30, 2016 03:21AM |

Registered: 8 years ago Posts: 5,232 |

Wouldn't it be easier to use 3-phase brushless DC motors without encoders?

They are used in "brushless camera gimbals" with a L6234D 3-phase stepper controller chip ( 5A max current!)

The motors are available in many sizes and have more torque/weight than classic steppers because they are outrunners and have an inbuilt magnetic 7:1 gear reduction by design.

They are used in "brushless camera gimbals" with a L6234D 3-phase stepper controller chip ( 5A max current!)

The motors are available in many sizes and have more torque/weight than classic steppers because they are outrunners and have an inbuilt magnetic 7:1 gear reduction by design.

Re: This engineer claims 100 grams direct extruder. I want one April 30, 2016 04:08AM |

Registered: 9 years ago Posts: 1,035 |

Quote

o_lampe

Wouldn't it be easier to use 3-phase brushless DC motors without encoders?

They are used in "brushless camera gimbals" with a L6234D 3-phase stepper controller chip ( 5A max current!)

The motors are available in many sizes and have more torque/weight than classic steppers because they are outrunners and have an inbuilt magnetic 7:1 gear reduction by design.

Very interesting, I never knew about it. Good info, reading more about it now.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one April 30, 2016 07:18AM |

Registered: 9 years ago Posts: 1,873 |

Quote

toxuin

I wish there would be a board with a tiny 8-bit controller, an H-bridge and a rotary encoder sensor that would basically accept the step signals and translate it to DC motor language.

Isn't that exactly this? [forums.reprap.org]

Re: This engineer claims 100 grams direct extruder. I want one May 05, 2016 06:11AM |

Registered: 8 years ago Posts: 3,525 |

Well I can confirm an e3d titan with 20mm nema 17 motor weighs 200g and feeds 1.75mm filament like a champ. So for £50 we're certainly a bit closer. I'm currently using this setup on a kossel mini as a flying extruder, but am going to try it as a direct extruder on my corexy too. Be interesting to see if it's light enough (I'm currently using a flex3drive at 85g, so an additional 115g on the print head) to still enable a better optimum between speed and quality. Might be a smaller geared stepper that comes in at less than the ungeared pancake nema 17.

Edited 1 time(s). Last edit at 05/05/2016 08:50AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 05/05/2016 08:50AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Re: This engineer claims 100 grams direct extruder. I want one May 05, 2016 06:45PM |

Registered: 8 years ago Posts: 62 |

Quote

JamesK

Many thanks! My nema14 extruder with 5:1 ratio is right on the ragged edge for 3mm pla, so I'm looking for alternatives in the 10:1 ballpark. I may end up trying this

The Cycloidal Extruder Drive has been updated with a 16:1 ratio to engage the proposed lightweight NEMA14 pancake stepper 14HR08-0654S (7Ncm, 50g). This did work fine until the heat from the stepper made the PLA-components start to creep - will be resolved soon...

Re: This engineer claims 100 grams direct extruder. I want one May 05, 2016 06:51PM |

Registered: 9 years ago Posts: 1,035 |

Quote

powdermetal

The Cycloidal Extruder Drive has been updated with a 16:1 ratio to engage the proposed lightweight NEMA14 pancake stepper 14HR08-0654S (7Ncm, 50g). This did work fine until the heat from the stepper made the PLA-components start to creep - will be resolved soon...

That's a very well made wiki, congrats. You've gotten to a respectable weight and I am happy some actual documented project has emerged from the discussion.

Thanks.

Edited 2 time(s). Last edit at 05/05/2016 07:02PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one May 05, 2016 06:57PM |

Registered: 9 years ago Posts: 1,873 |

Quote

powdermetal

The Cycloidal Extruder Drive has been updated with a 16:1 ratio to engage the proposed lightweight NEMA14 pancake stepper 14HR08-0654S (7Ncm, 50g). This did work fine until the heat from the stepper made the PLA-components start to creep - will be resolved soon...

Fantastic! Thanks again. Yes, heat with these smaller motors is an issue. I suspect I'm going to need some active cooling once the enclosure is done.

Re: This engineer claims 100 grams direct extruder. I want one May 06, 2016 02:09AM |

Registered: 7 years ago Posts: 78 |

The Nscrypt above seems to be using a worm and DC motor. Initial Reprap design used a screw to drive the filament directly, but the filament twists while advancing in response to the rotation of the screw. More recent attempts use two counter rotating screws but I haven't seen any good results yet.

Here is another idea inspired by these two:

1) thread the shaft of a tiny stepper (1-2Ncm is probably enough, <50g) with something between an M3-M5

2) make grooves with the corresponding tap (M3-M5) into the outside of a small bearing (e.g, 623, 624)

3) use the resulting screw shaft of the stepper to drive directly the bearing as a worm gear using another similar bearing as idler on the opposite side, something along the lines of (beware ASCII art)

o|O/

where o = idler, | = filament, O = grooved bearing, / = stepper shaft.

This way, you get the reduction advantage of the worm drive without twisting filament. Bonus: groove cleaning is built-in. The stepper could have 7.5deg steps or be driven with 1/2 micro stepping to achieve higher rpms for retraction.

Here is another idea inspired by these two:

1) thread the shaft of a tiny stepper (1-2Ncm is probably enough, <50g) with something between an M3-M5

2) make grooves with the corresponding tap (M3-M5) into the outside of a small bearing (e.g, 623, 624)

3) use the resulting screw shaft of the stepper to drive directly the bearing as a worm gear using another similar bearing as idler on the opposite side, something along the lines of (beware ASCII art)

o|O/

where o = idler, | = filament, O = grooved bearing, / = stepper shaft.

This way, you get the reduction advantage of the worm drive without twisting filament. Bonus: groove cleaning is built-in. The stepper could have 7.5deg steps or be driven with 1/2 micro stepping to achieve higher rpms for retraction.

Re: This engineer claims 100 grams direct extruder. I want one May 06, 2016 03:27AM |

Registered: 9 years ago Posts: 1,035 |

Quote

ipcalit

The Nscrypt above seems to be using a worm and DC motor. Initial Reprap design used a screw to drive the filament directly, but the filament twists while advancing in response to the rotation of the screw. More recent attempts use two counter rotating screws but I haven't seen any good results yet.

Here is another idea inspired by these two:

1) thread the shaft of a tiny stepper (1-2Ncm is probably enough, <50g) with something between an M3-M5

2) make grooves with the corresponding tap (M3-M5) into the outside of a small bearing (e.g, 623, 624)

3) use the resulting screw shaft of the stepper to drive directly the bearing as a worm gear using another similar bearing as idler on the opposite side, something along the lines of (beware ASCII art)

o|O/

where o = idler, | = filament, O = grooved bearing, / = stepper shaft.

This way, you get the reduction advantage of the worm drive without twisting filament. Bonus: groove cleaning is built-in. The stepper could have 7.5deg steps or be driven with 1/2 micro stepping to achieve higher rpms for retraction.

The Nscrypt above seems to me to have a pretty complex assortment of normal gears at the exit of the motor, then a worm which then engages the hobbing gear/pinion combo (or just a pinion). The worm doesn't directly drive the filament, there is an idler arm pressing against this pinion or hobbing-gear-pinion combo and the filament runs through the apparent slot in the design.

It seems to me that it gets to huge ratios for driving maybe very thin filament (0.2mm ?). The problem with all those gears is that as the number of gears increases, so does the combined backlash ... so I'd still bet on a metal laser-cut cycloidal drive.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Re: This engineer claims 100 grams direct extruder. I want one May 06, 2016 04:05AM |

Registered: 8 years ago Posts: 3,525 |

I wonder if it would be possible to just stick a small stepper on the top of a flex3drive extruder, with its 40:1 reduction, especially for driving 1.75mm, it should need only a very small and light motor. I wonder if it would have sufficient power for a decent retract.

This motor [www.omc-stepperonline.com] can provide 7Ncm which into 40:1 (with no losses from the flexdrive itself), is only 50g making the complete extruder only 135g. Using a 13 Ncm nema 17 pancake with 3:1 gearing works extremely well on the titan so it should be powerful enough.

Edited 1 time(s). Last edit at 05/06/2016 04:23AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

This motor [www.omc-stepperonline.com] can provide 7Ncm which into 40:1 (with no losses from the flexdrive itself), is only 50g making the complete extruder only 135g. Using a 13 Ncm nema 17 pancake with 3:1 gearing works extremely well on the titan so it should be powerful enough.

Edited 1 time(s). Last edit at 05/06/2016 04:23AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.