Using FSR at hotend level for an unoptrusive bed probing via the nozzle

Posted by realthor

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 02, 2016 04:54PM |

Registered: 9 years ago Posts: 487 |

I don't think a video will demonstrate how it works, the movement is tiny, which is the point, I'll try to explain.

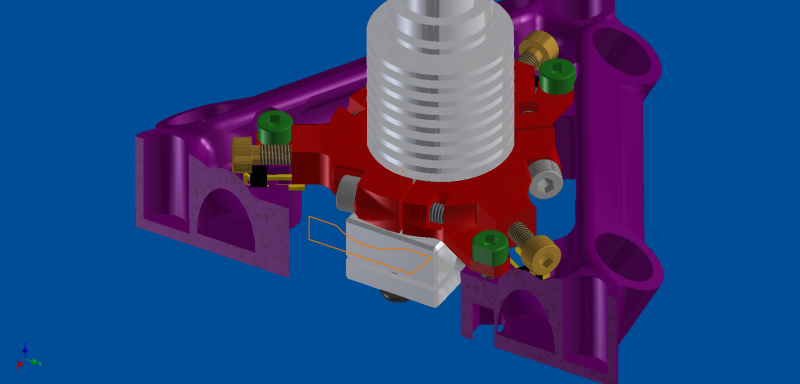

The red part I call the heatsink clamp, it's a printed ABS part that clamps to the bottom of the heatsink and moves with the hot end when the nozzle is pressed against the print bed (movement is <0.1mm)

The red part also has three arms designed to be springy that are bolted (green bolts) to the effector frame (purple) so that without any force on the nozzle the red part is pressed down.

Pressing down the red part forces the brass bolts onto the gold pins. Think of this like a switch, when the brass bolt is in contact with both the gold pins the switch is closed but when the red part lifts the brass bolt nolonger contacts both gold pins and the circuit is broken creating the z-probe event. When the force on the nozzle is removed and the red part springs back down the brass bolt again bridges the two pins and the probe is reset.

I'll try to get some photos of the actual thing but my printer is in the middle of an 11h print at the moment.

Moriquendi

Apologies, you posted while I was typing my reply.

I think that the round on round contact might work better, however, space is at a premium in a delta effector. Every millimetre larger is a millimetre of lost print diameter. I've already made the effector larger to accommodate wider rod spacing (better rigidity) and heatsink mounting (shorter joint-nozzle distance). This was the quickest way of testing my idea and it worked well enough that further development got postponed.

I'll try to knock up a diagram and perhaps some instructions for the comparator circuit and how I used them.

Edited 1 time(s). Last edit at 02/02/2016 05:05PM by Moriquendi.

The red part I call the heatsink clamp, it's a printed ABS part that clamps to the bottom of the heatsink and moves with the hot end when the nozzle is pressed against the print bed (movement is <0.1mm)

The red part also has three arms designed to be springy that are bolted (green bolts) to the effector frame (purple) so that without any force on the nozzle the red part is pressed down.

Pressing down the red part forces the brass bolts onto the gold pins. Think of this like a switch, when the brass bolt is in contact with both the gold pins the switch is closed but when the red part lifts the brass bolt nolonger contacts both gold pins and the circuit is broken creating the z-probe event. When the force on the nozzle is removed and the red part springs back down the brass bolt again bridges the two pins and the probe is reset.

I'll try to get some photos of the actual thing but my printer is in the middle of an 11h print at the moment.

Moriquendi

Apologies, you posted while I was typing my reply.

I think that the round on round contact might work better, however, space is at a premium in a delta effector. Every millimetre larger is a millimetre of lost print diameter. I've already made the effector larger to accommodate wider rod spacing (better rigidity) and heatsink mounting (shorter joint-nozzle distance). This was the quickest way of testing my idea and it worked well enough that further development got postponed.

I'll try to knock up a diagram and perhaps some instructions for the comparator circuit and how I used them.

Edited 1 time(s). Last edit at 02/02/2016 05:05PM by Moriquendi.

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 02, 2016 05:04PM |

Registered: 9 years ago Posts: 1,035 |

Thanks for your detailed explanation... I felt pretty stupid while reading it because as I've re-read your post 10mins ago I got it ...well... another explanation never hurts.

I am curious as why did you choose the pins instead of the usual bearing steel balls (more difficult to wire or to fix to the support?). I wonder if the contact disruption would be faster (with an even <0.1mm movement) with round on round contact, which is theoretically a point.

How about the wiring? I have no prior electronics exp so a "for Dummies" instructional would be necessary I suppose this in series link meas a wire from one pin to the next and so on until you make the full circle. You would then have 2x3=6 points where any disruption would break the circuit. That means you get two wires out of this, one goes to the 5V on Arduino/Ramps and the other one goes to Ground? Is this wired just as a normal endstop? (although those might have 3 wires)

I suppose this in series link meas a wire from one pin to the next and so on until you make the full circle. You would then have 2x3=6 points where any disruption would break the circuit. That means you get two wires out of this, one goes to the 5V on Arduino/Ramps and the other one goes to Ground? Is this wired just as a normal endstop? (although those might have 3 wires)

Edited 1 time(s). Last edit at 02/02/2016 05:05PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I am curious as why did you choose the pins instead of the usual bearing steel balls (more difficult to wire or to fix to the support?). I wonder if the contact disruption would be faster (with an even <0.1mm movement) with round on round contact, which is theoretically a point.

How about the wiring? I have no prior electronics exp so a "for Dummies" instructional would be necessary

I suppose this in series link meas a wire from one pin to the next and so on until you make the full circle. You would then have 2x3=6 points where any disruption would break the circuit. That means you get two wires out of this, one goes to the 5V on Arduino/Ramps and the other one goes to Ground? Is this wired just as a normal endstop? (although those might have 3 wires)

I suppose this in series link meas a wire from one pin to the next and so on until you make the full circle. You would then have 2x3=6 points where any disruption would break the circuit. That means you get two wires out of this, one goes to the 5V on Arduino/Ramps and the other one goes to Ground? Is this wired just as a normal endstop? (although those might have 3 wires)Edited 1 time(s). Last edit at 02/02/2016 05:05PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 02, 2016 05:20PM |

Registered: 9 years ago Posts: 487 |

I've edited my previous post,

You've got it. Wiring it up could be as simple as you suggest, one side to 5v (or 3.3v if that's what you need) the other side to the endstop input (adding a resistor between this side and ground wouldn't hurt, 5-10k or so.

I have reused my op-amp circuit again here though for a couple of reasons. For one I wanted an LED to activate when the probe is triggered, very helpful for tuning. Also, I found that the switching action was not as clean as it should be, rather than going from on to off there was a resistive bit inbetween, using the op-amp gave a definate, clear, switch without any dithering.

Moriquendi

You've got it. Wiring it up could be as simple as you suggest, one side to 5v (or 3.3v if that's what you need) the other side to the endstop input (adding a resistor between this side and ground wouldn't hurt, 5-10k or so.

I have reused my op-amp circuit again here though for a couple of reasons. For one I wanted an LED to activate when the probe is triggered, very helpful for tuning. Also, I found that the switching action was not as clean as it should be, rather than going from on to off there was a resistive bit inbetween, using the op-amp gave a definate, clear, switch without any dithering.

Moriquendi

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 02, 2016 05:38PM |

Registered: 9 years ago Posts: 1,035 |

I've just realized that with this, if the wiring would not be in series, you could have a precisely machined piece of glass/granite that you can edge detect to calibrate the printer every time to exact values. Say it goes on the inside of a square 10x10, it measures what it thinks those values are, then you tell it that those were 10x10 and it calibrates itself. For a delta it would need some more maybe

Ok, I was drifting. What is the simplest op-amp circuit a noob can build?

Then, if you want to debug/tune, wouldn't you activate some verbose reading from the controller board where you would see these events anyway? I don't exactly know what an om-amp is supposed to do but I believe it would be needed when you want to send a different (filtered?) signal to the printer board, or at a different time. Is this what you were referring to?

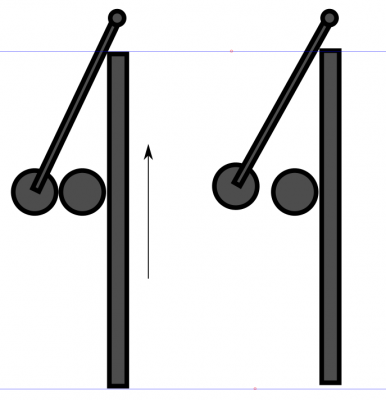

Edit: For increased response time there could be a lever-type action involved in such a way that a very small movement at the center would translate to a larger move at the end and thus the breaking of the circuit can be done at even smaller values than the 0.1mm.

I was quite shocked watching videos when people were triggering the DIY Renishaw probes, they would move a lot. Maybe that doesn't happen in realtime but I would really aim for a zero movement circuit break

Edit2: this guy uses gold-plated piercings for its probe. Quite innovative although I don't know how round those really are.

Edit3: I would like to see a picture of the ABS part that clamps the hotend so low. Isn't that affected by the heat? Plastics expand much more than metals with change in temperature ...so I was thinking that such an imp part should be as stable as possible.

Edited 3 time(s). Last edit at 02/02/2016 05:51PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Ok, I was drifting. What is the simplest op-amp circuit a noob can build?

Then, if you want to debug/tune, wouldn't you activate some verbose reading from the controller board where you would see these events anyway? I don't exactly know what an om-amp is supposed to do but I believe it would be needed when you want to send a different (filtered?) signal to the printer board, or at a different time. Is this what you were referring to?

Edit: For increased response time there could be a lever-type action involved in such a way that a very small movement at the center would translate to a larger move at the end and thus the breaking of the circuit can be done at even smaller values than the 0.1mm.

I was quite shocked watching videos when people were triggering the DIY Renishaw probes, they would move a lot. Maybe that doesn't happen in realtime but I would really aim for a zero movement circuit break

Edit2: this guy uses gold-plated piercings for its probe. Quite innovative although I don't know how round those really are.

Edit3: I would like to see a picture of the ABS part that clamps the hotend so low. Isn't that affected by the heat? Plastics expand much more than metals with change in temperature ...so I was thinking that such an imp part should be as stable as possible.

Edited 3 time(s). Last edit at 02/02/2016 05:51PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 02, 2016 05:54PM |

Registered: 9 years ago Posts: 487 |

Op-amps are very useful, one of the building blocks of analogue electronics, wikipedia will give you a basic run down of what they are and how they work.

One of the uses of an op-amp is as a comparator, at it's most basic a comparator compares two voltages, when voltage 1 is higher than voltage 2 the output is high, when 2 is higher than 1 the output is low (you can safely ignore what happens when they're the same). In this case we're comparing a reference voltage (set using a potentiometer) to the signal from the sensor (FSR, dirty switch, any analogue signal) the instant the voltage of the signal goes above the reference voltage the output of the comparator changes.

When I talk about tuning I'm talking about tuning the probe, ensuring that it triggers when it touches the bed but doesn't trigger from vibration etc. For me this is a combination of setting the reference voltage of my comparator and getting the springiness of the hot end mounting right (adjusting the green bolts)

Moriquendi

One of the uses of an op-amp is as a comparator, at it's most basic a comparator compares two voltages, when voltage 1 is higher than voltage 2 the output is high, when 2 is higher than 1 the output is low (you can safely ignore what happens when they're the same). In this case we're comparing a reference voltage (set using a potentiometer) to the signal from the sensor (FSR, dirty switch, any analogue signal) the instant the voltage of the signal goes above the reference voltage the output of the comparator changes.

When I talk about tuning I'm talking about tuning the probe, ensuring that it triggers when it touches the bed but doesn't trigger from vibration etc. For me this is a combination of setting the reference voltage of my comparator and getting the springiness of the hot end mounting right (adjusting the green bolts)

Moriquendi

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 02, 2016 08:51PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 01:48AM |

Registered: 9 years ago Posts: 1,035 |

Quote

JamesK

Very nice! These have been a very thought provoking pair of threads.

But we can do more, I hope we don't settle for what has been already done. We need to improve, incrementally advance the designs

. I get it that ultimately lasers and other optic sensors will triumph but mechanical sensors still can give them a run for their money.

. I get it that ultimately lasers and other optic sensors will triumph but mechanical sensors still can give them a run for their money.I know FSRs are not very reliable for precision measurements but we will soon be able to print them. They are plastic with conductive ink traces. The technology is almost there. But first ...

-----------------------------------

Let's design a Renishaw-style probe for cartesian printers.

Let's design a Renishaw-style probe with greater lever amplification (an even less minute movement will break contact)

Question: does the size of the ball matter in releasing contact timing?

-----------------------------------

Let's design a zero probe plate that the printer head can take and drag across the bed while probing

-----------------------------------

Edited 1 time(s). Last edit at 02/03/2016 03:23AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 04:29AM |

Registered: 9 years ago Posts: 487 |

I think we'll be able to print a reliable renishaw probe long before we can print FSRs

I tried lever amplification using switches under the print bed and I found that it wasn't helpful, the flex and slop in the lever system far outweighed the advantages.

With a cartesian printer the probe can be much more simple, the nozzle is constrained in the same way (orientation) regardless of where on the print bed it is. With a delta, due to the flexibility of the belts and joints etc there are significant differences depending on whether you're in the centre of the bed, in line with a tower or between towers. I think that a cartesian printer would work well with a single ball/contact set.

The renishaw probe is designed to detect contact in three axis (except above) so that it activates regardless of which direction the contact comes from. For a z-probe this is unnecessary so the probe can be simpler.

I don't know how ball size affects things. I do know that the contact materials are important, my probe wouldn't work with steel bolts in place of the brass ones and even the brass ones need cleaning periodically. I think when I rebuild it I will use gold plated contacts, gold doesn't tarnish, is low resistance and easy to solder to. Stainless steel is not easy to solder.

Moriquendi

Ps. I don't mean to dismiss anyone's ideas, I'm all for trying things out for yourself. One of the beauties of having a 3d printer is that you can test new ideas quickly and cheaply. I'm just sharing my experience and thought's, your mileage may vary.

I tried lever amplification using switches under the print bed and I found that it wasn't helpful, the flex and slop in the lever system far outweighed the advantages.

With a cartesian printer the probe can be much more simple, the nozzle is constrained in the same way (orientation) regardless of where on the print bed it is. With a delta, due to the flexibility of the belts and joints etc there are significant differences depending on whether you're in the centre of the bed, in line with a tower or between towers. I think that a cartesian printer would work well with a single ball/contact set.

The renishaw probe is designed to detect contact in three axis (except above) so that it activates regardless of which direction the contact comes from. For a z-probe this is unnecessary so the probe can be simpler.

I don't know how ball size affects things. I do know that the contact materials are important, my probe wouldn't work with steel bolts in place of the brass ones and even the brass ones need cleaning periodically. I think when I rebuild it I will use gold plated contacts, gold doesn't tarnish, is low resistance and easy to solder to. Stainless steel is not easy to solder.

Moriquendi

Ps. I don't mean to dismiss anyone's ideas, I'm all for trying things out for yourself. One of the beauties of having a 3d printer is that you can test new ideas quickly and cheaply. I'm just sharing my experience and thought's, your mileage may vary.

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 05:01AM |

Registered: 12 years ago Posts: 1,450 |

Hi Moriquendi, just a quick note re. soldering stainless steel. If you use something called Phosphoric acid as a flux you will find that stainless steel is about the easiest and most satisfying material to solder.The amount used is tiny - I use one end of a matchstick to dab a bit on the stainless steel then bring a normal temperature soldering iron and normal (60/40) solder to the bit to be tinned at the same time - the solder will flow easily across the surface. Phosphoric acid itself is fairly innocuous, even having a 'E' food number - E338. Having said that, avoid breathing the fumes when soldering as doing this too much will cause your jaw to fall off (see phossy jaw)

Mike

Mike

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 05:07AM |

Registered: 9 years ago Posts: 1,035 |

Quote

Moriquendi

I think we'll be able to print a reliable renishaw probe long before we can print FSRs

Agree

.

.Quote

Moriquendi

I tried lever amplification using switches under the print bed and I found that it wasn't helpful, the flex and slop in the lever system far outweighed the advantages.

I just guess we're talking about the same thing. I am referring to the renishaw-style pin-to-balls contact being introduced into a lever amplification system for breaking contact.

Let me draw a quick sketch (this is just from the top of my head, it might be viable it might be completely off track):

Yes I think the piercing gold-plated idea from the link above has some potential.Quote

Moriquendi

I think when I rebuild it I will use gold plated contacts, gold doesn't tarnish, is low resistance and easy to solder to. Stainless steel is not easy to solder.

Quote

Moriquendi

Ps. I don't mean to dismiss anyone's ideas, I'm all for trying things out for yourself. One of the beauties of having a 3d printer is that you can test new ideas quickly and cheaply. I'm just sharing my experience and thought's, your mileage may vary.

Don't worry, I am all ears. -eyes in this context

-. And I'm for crowdsourcing the group experience/brainpower fo faster/better results.

-. And I'm for crowdsourcing the group experience/brainpower fo faster/better results.Edited 2 time(s). Last edit at 02/03/2016 05:23AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 05:26AM |

Registered: 9 years ago Posts: 487 |

Quote

leadinglights

Hi Moriquendi, just a quick note re. soldering stainless steel. If you use something called Phosphoric acid as a flux you will find that stainless steel is about the easiest and most satisfying material to solder.The amount used is tiny - I use one end of a matchstick to dab a bit on the stainless steel then bring a normal temperature soldering iron and normal (60/40) solder to the bit to be tinned at the same time - the solder will flow easily across the surface. Phosphoric acid itself is fairly innocuous, even having a 'E' food number - E338. Having said that, avoid breathing the fumes when soldering as doing this too much will cause your jaw to fall off (see phossy jaw)

Mike

Interesting, does it work for chrome plating as well I wonder?

Moriquendi

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 06:15AM |

Registered: 9 years ago Posts: 58 |

I'm sorry to intrude in the topic ....

i'm having another "probeless" that I would like to investigate ...and not sure if it will be a viable solution.

I have seen some people doing it and a lot a people that don't like it

The idea will be to detect when the hotend tip touch the build plate (I'm currently having an aluminium bed).

I think that idea is pretty nice and going down slowly might not damage the bed :

The "not so good ideas" are :

- melted pla could isulate the tip. But according to someone in thingiverse (http://www.thingiverse.com/thing:7008) it isn't so bad as the soft pla squished when pressing down

- If one the wire comes out of the bed ...it could crash in the bed ...well ...I think it true for most system ! The problem is that welding on the bed isn't reaaly easy

- putting directly a circuit loop on the hotend and the bed can have some bad effect on your electronics (in case of short circuit with other elements)

I totaly agree with the later one and I think, if tried, it should be done using an isolated circuit for the hotend-bed in order to avoid shortcircuit !

What do you think ?

I'm planning to add a aluminium plate coated with PEI ....I don't known if it will be condutctive enough and if the hotend will not damage the PEI coating ...

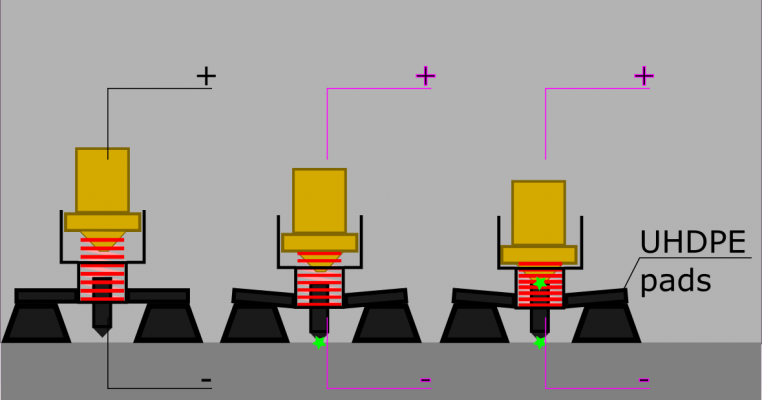

PS : attached is the schematic I plan

Edited 1 time(s). Last edit at 02/03/2016 06:30AM by lyscanthrope.

i'm having another "probeless" that I would like to investigate ...and not sure if it will be a viable solution.

I have seen some people doing it and a lot a people that don't like it

The idea will be to detect when the hotend tip touch the build plate (I'm currently having an aluminium bed).

I think that idea is pretty nice and going down slowly might not damage the bed :

The "not so good ideas" are :

- melted pla could isulate the tip. But according to someone in thingiverse (http://www.thingiverse.com/thing:7008) it isn't so bad as the soft pla squished when pressing down

- If one the wire comes out of the bed ...it could crash in the bed ...well ...I think it true for most system ! The problem is that welding on the bed isn't reaaly easy

- putting directly a circuit loop on the hotend and the bed can have some bad effect on your electronics (in case of short circuit with other elements)

I totaly agree with the later one and I think, if tried, it should be done using an isolated circuit for the hotend-bed in order to avoid shortcircuit !

What do you think ?

I'm planning to add a aluminium plate coated with PEI ....I don't known if it will be condutctive enough and if the hotend will not damage the PEI coating ...

PS : attached is the schematic I plan

Edited 1 time(s). Last edit at 02/03/2016 06:30AM by lyscanthrope.

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 06:36AM |

Registered: 9 years ago Posts: 1,035 |

Quote

lyscanthrope

I'm sorry to intrude in the topic ....

i'm having another "probeless" that I would like to investigate ...and not sure if it will be a viable solution.

I have seen some people doing it and a lot a people that don't like it

The idea will be to detect when the hotend tip touch the build plate (I'm currently having an aluminium bed).

I think that idea is pretty nice and going down slowly might not damage the bed :

The "not so good ideas" are :

- melted pla could isulate the tip. But according to someone in thingiverse it isn't so bad as the soft pla squished when pressing down

- If one the wire comes out of the bed ...it could crash in the bed ...well ...I think it true for most system ! The problem is that welding on the bed isn't reaaly easy

- putting directly a circuit loop on the hotend and the bed can have some bad effect on your electronics (in case of short circuit with other elements)

I totaly agree with the later one and I think, if tried, it should be done using an isolated circuit for the hotend-bed in order to avoid shortcircuit !

What do you think ?

I'm planning to add a aluminium plate coated with PEI ....I don't known if it will be condutctive enough and if the hotend will not damage the PEI coating ...

PS : attached is the schematic I plan

Personally I like the idea more than many others. BUT the big nono for me is that I don't want to depend on a metal bed. I am also having some mixed feelings about the possibility that repeated touching with such a sensitive surface as the brass nozzle might damage it in time, deforming the flat surface that is used to evenly distribute the melted plastic. Frankly I would (and still am thinging of) trying a small metal piece like the CNC zeroing plate that the nozzle would grab and drag around, pressing into a cylindrical piece that would rest on the nozzle's flat of the hexagonal body.

Thinking of wires breaking loose on this kind of probing is just like assuming something will break in any other method of probing. The only way to avoid that is to have a backup system. In your case it would mean an inductive probe. Or if you have a Delta you might have a switch on one of the towers, with the lever removed or the roller-end kind so that you can adapt the carriage that travels up and down that tower to activate it when the effector is closing to the bed. Then you would have a circuit that would only activate that electrically if the other circuit is broken. When both circuits are ok then it shouldn't get triggered. I am sure this is simple electronics stuff. I believe something similar would can be done for cartesian printers too. Mechanical switches are pennies so the ease of mind alone might make it worth it.

I am not sure but I doubt that the PEI coating will provide conductivity. But the Inductive probe will most likely work.

I have no idea about the short circuit thing. Others have already implemented this ... search for their experience if posted somewhere.

Edited 4 time(s). Last edit at 02/03/2016 06:44AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 06:50AM |

Registered: 9 years ago Posts: 58 |

I totaly agree that the hitting of the nozzle with the bed may be troublesome, but isn't it the same problem with the FSR or Renishaw approach ?

5btw a Renishaw for cartseian seems a good idea to me)

Regarding what you spoke about, I have see this method a few month ago :

[www.youtube.com]

The detach by a magnet is pretty neat ^^

5btw a Renishaw for cartseian seems a good idea to me)

Regarding what you spoke about, I have see this method a few month ago :

[www.youtube.com]

The detach by a magnet is pretty neat ^^

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 06:56AM |

Registered: 9 years ago Posts: 1,873 |

Yes, electrical probing with the hotend is somewhat appealing, mostly for the simplicity. I'd be worried about plastic on the nozzle preventing the contact, but if people say it works when hot then it's worth a go. One thing to consider is that the nozzle is electrically connected to the can of the heating element. Isolating that connection would likely be a bad thing from a thermal viewpoint, so you'd probably want to make sure the heater can was connected to ground, and connect the bed side to a pull-up input that would go to ground when the nozzle touched. The real problem is non-conductive beds. You could use a set of touch points just outside the bed area, but then you're not probing the bed itself, and you are limiting the set of points you can sample. Having a physical Z-min stop as a back-up if any probing system fails seems like a good idea, but you'd need it to not trigger during normal probing. That would likely mean relying on the bed springs to absorb some travel after the probe contacts until the z-min triggers.

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 07:36AM |

Registered: 9 years ago Posts: 1,035 |

Guys, I have made a rough sketch of my zeroing probe idea.

My scenario goes like this:

1) startup script sais to the printer go to these coordinates and descend this much.

2) the nozzle goes and slighlty dips into the spring of the zeroing probe

3) the probe can slide onto the non-conductive bed (glass) or maybe roll on rougher material (PEI/etc) so the nozzle drags it around probing the pre-determined points on the bed.

Probing goes like this:

a) nozzle is in touch with an outer surface of the probe and its spring, being able to exert lateral force and drag it around

b) nozzle descends compressing the spring which in turns deforms the body of the probe such that the pointy metallic pin touches the bed

c) nozzle descends even more, completely compressing the spring and touches the bottom of the pin (which is of known dimensions and being set as the offset in the firmware)

I am after 3.5h of sleep so i'll throw that as an excuse if the idea has some elementary flaw (I haven't gotten any response above with the renishaw-style probe lever amplification system so I might be on a stupid spree today). You should appreciate that I am trying .

.

Anyways here we go:

Edit: The pin needs not to be very pointy because that would only matter if we would probe so many points that the footprints of the pin would overlap. As long as we are doint 10-20 probes max, the approximation is that of circles or squares much larger than the footprint of the pin.

Also the body needs to deform symmetrically so that the pin goes vertically down. This can be done with a disc-shape of the deformable body of the probe.

Edited 2 time(s). Last edit at 02/03/2016 07:44AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

My scenario goes like this:

1) startup script sais to the printer go to these coordinates and descend this much.

2) the nozzle goes and slighlty dips into the spring of the zeroing probe

3) the probe can slide onto the non-conductive bed (glass) or maybe roll on rougher material (PEI/etc) so the nozzle drags it around probing the pre-determined points on the bed.

Probing goes like this:

a) nozzle is in touch with an outer surface of the probe and its spring, being able to exert lateral force and drag it around

b) nozzle descends compressing the spring which in turns deforms the body of the probe such that the pointy metallic pin touches the bed

c) nozzle descends even more, completely compressing the spring and touches the bottom of the pin (which is of known dimensions and being set as the offset in the firmware)

I am after 3.5h of sleep so i'll throw that as an excuse if the idea has some elementary flaw (I haven't gotten any response above with the renishaw-style probe lever amplification system so I might be on a stupid spree today). You should appreciate that I am trying

.

.Anyways here we go:

Edit: The pin needs not to be very pointy because that would only matter if we would probe so many points that the footprints of the pin would overlap. As long as we are doint 10-20 probes max, the approximation is that of circles or squares much larger than the footprint of the pin.

Also the body needs to deform symmetrically so that the pin goes vertically down. This can be done with a disc-shape of the deformable body of the probe.

Edited 2 time(s). Last edit at 02/03/2016 07:44AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 07:44AM |

Registered: 9 years ago Posts: 1,873 |

Looks good, except I'd lose the pointy tip and go round to minimize any bed damage. It would be nice if we could do without any extra stuff that would have to be positioned on the bed if possible though. I know touching the nozzle to the bed feels like a bad idea, but I think for the contact forces and durations we're talking about, both the tip and the bed are probably more than robust enough to cope.

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 07:50AM |

Registered: 9 years ago Posts: 1,035 |

Quote

JamesK

Looks good, except I'd lose the pointy tip and go round to minimize any bed damage. It would be nice if we could do without any extra stuff that would have to be positioned on the bed if possible though. I know touching the nozzle to the bed feels like a bad idea, but I think for the contact forces and durations we're talking about, both the tip and the bed are probably more than robust enough to cope.

The above works for glass beds too

. That is my main goal there. If I'd have a metal bed I'd go inductive or nozzle-contact.

. That is my main goal there. If I'd have a metal bed I'd go inductive or nozzle-contact.Also the contacts can be done in such a way that one is on the pin and the other on the spring ... then circuit will be temporarily made via the nozzle, with no other modification to the printerhead itself. So it will not be a permanent charge on the hotend (not sure about this but even if the circuit is always open after probing the current that goes either into the bed or hotend will heat the whole thing).

Edited 2 time(s). Last edit at 02/03/2016 07:55AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 07:55AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 08:06AM |

Registered: 9 years ago Posts: 1,035 |

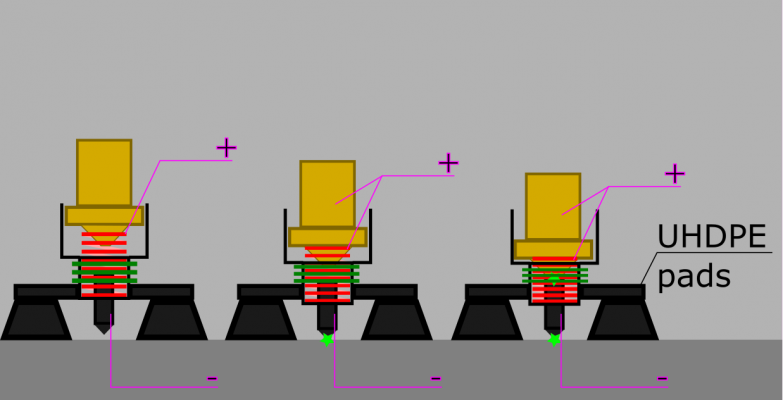

Iteration2 for the Thor Probe

This doesn't rely on the shape-shifting of the flexible material (although if that is a disc with certain cuts it will always deform vertically):

I think that besides the springs all can be 3D printed ... minus the UHDPE pads, if that's what one will end up using.

Edited 1 time(s). Last edit at 02/03/2016 08:07AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

This doesn't rely on the shape-shifting of the flexible material (although if that is a disc with certain cuts it will always deform vertically):

I think that besides the springs all can be 3D printed ... minus the UHDPE pads, if that's what one will end up using.

Edited 1 time(s). Last edit at 02/03/2016 08:07AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 08:08AM |

Registered: 12 years ago Posts: 1,450 |

I have also been throwing ideas about in my head and came up with the following.:-

Firstly, move to a position directly over (or very close to) one of the mounting points of the bed. I am assuming that the bed is mounted with a three point sprung method with adjusting screws. Directly between the adjusting nut and the structure that the bed is mounted on is a FSR or strain gauge or zero movement mechanical switch - like a Renishaw probe. Note that this transducer/ switch etc need only be under the mounting that is used to set the zero.

Move the nozzle down so that the contact is sensed, using this to set the zero position.

Use something like DC42s differential sensor to survey a number of points across the bed and set the level from that data, keeping the zero from the value obtained in the first part.

I have never liked the idea of using contact probing with the nozzle throughout the bed.

Mike

Firstly, move to a position directly over (or very close to) one of the mounting points of the bed. I am assuming that the bed is mounted with a three point sprung method with adjusting screws. Directly between the adjusting nut and the structure that the bed is mounted on is a FSR or strain gauge or zero movement mechanical switch - like a Renishaw probe. Note that this transducer/ switch etc need only be under the mounting that is used to set the zero.

Move the nozzle down so that the contact is sensed, using this to set the zero position.

Use something like DC42s differential sensor to survey a number of points across the bed and set the level from that data, keeping the zero from the value obtained in the first part.

I have never liked the idea of using contact probing with the nozzle throughout the bed.

Mike

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 08:17AM |

Registered: 9 years ago Posts: 1,035 |

Depends on your budget: now you have both FSR and DC42's IR probe. You'd better have a high end machine and have a business around it otherwise you're looking at $50-$100 right there.

I am going after pennies with the above probe but if I'd have a business around the 3d printing I would definitely consider more high end parts.

Edited 1 time(s). Last edit at 02/03/2016 08:18AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I am going after pennies with the above probe but if I'd have a business around the 3d printing I would definitely consider more high end parts.

Edited 1 time(s). Last edit at 02/03/2016 08:18AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 08:20AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 08:27AM |

Registered: 9 years ago Posts: 1,035 |

Unless there is somebody pointing a flaw in my above sketch I think I am going to pursue this and open a new thread around it (I like to keep content searchable and this thread was initially about FSR then we drifted now we drifted again )

)

I am actually more and more enthused by the possibility of making no modifications to an existing printer while still having the option to do this automatically.

Edited 2 time(s). Last edit at 02/03/2016 08:30AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

)

)I am actually more and more enthused by the possibility of making no modifications to an existing printer while still having the option to do this automatically.

Edited 2 time(s). Last edit at 02/03/2016 08:30AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 08:40AM |

Registered: 9 years ago Posts: 487 |

I love the simplicity of probing the bed electrically with the nozzle but I just don't think it's feasible. I don't know anyone using a bare metal print bed and I know that my nozzles get mucky pretty quickly even if there isn't any ooze.

One way of tackling it might be to remote sense a coil (the bed heater perhaps) using the nozzle as a pickup in the same way that live wire detectors work. I don't know how high a voltage you would need nor how accurate it would be but you could relatively easily inject a signal into the bed heater and look for it using the nozzle even through glass.

If your probe works in an active-when-the-circuits-open manner then losing a wire won't crash the bed. All that happens is that as soon as the firmware looks at the probe it thinks it's triggered and records that as the probe point, you don't get a reading bu there's no damage.

Moriquendi

One way of tackling it might be to remote sense a coil (the bed heater perhaps) using the nozzle as a pickup in the same way that live wire detectors work. I don't know how high a voltage you would need nor how accurate it would be but you could relatively easily inject a signal into the bed heater and look for it using the nozzle even through glass.

If your probe works in an active-when-the-circuits-open manner then losing a wire won't crash the bed. All that happens is that as soon as the firmware looks at the probe it thinks it's triggered and records that as the probe point, you don't get a reading bu there's no damage.

Moriquendi

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 08:42AM |

Registered: 9 years ago Posts: 58 |

Just wondering why you need the pad and cannot use a longer green spring ?

In fact, i would perhaps even use only one spring and put the metal part in the middle of it (so you have a bit of spring on top and on bottom).

One main issue I see on the PLA spring is that ...you cannot probe with the bed warm ...and not with the hotend hot. Having the hotend hot would be interrsteing to squeeze filament residue ...else thet contact may be troublesome.

or am I wrong ?

In fact, i would perhaps even use only one spring and put the metal part in the middle of it (so you have a bit of spring on top and on bottom).

One main issue I see on the PLA spring is that ...you cannot probe with the bed warm ...and not with the hotend hot. Having the hotend hot would be interrsteing to squeeze filament residue ...else thet contact may be troublesome.

or am I wrong ?

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 08:45AM |

Registered: 9 years ago Posts: 1,035 |

Quote

Moriquendi

I love the simplicity of probing the bed electrically with the nozzle but I just don't think it's feasible. I don't know anyone using a bare metal print bed and I know that my nozzles get mucky pretty quickly even if there isn't any ooze.

One way of tackling it might be to remote sense a coil (the bed heater perhaps) using the nozzle as a pickup in the same way that live wire detectors work. I don't know how high a voltage you would need nor how accurate it would be but you could relatively easily inject a signal into the bed heater and look for it using the nozzle even through glass.

If your probe works in an active-when-the-circuits-open manner then losing a wire won't crash the bed. All that happens is that as soon as the firmware looks at the probe it thinks it's triggered and records that as the probe point, you don't get a reading bu there's no damage.

Moriquendi

The probing would be done with the heated nozzle so that any goo would become soft and can be scraped of by taking the nozzle over some toothbrush or felt. With the nozzle clean you could then probe the bed in the manner I've explained without any issue I believe. For the cost of it it is something that is worth trying

The pads are there to keep the probe dragged around by the nozzle. It is not magnetic so there is no way the nozzle is able to grasp it.

For the springs I have to think harder about what you are saying, it's not clicking to me where you are going. The inner spring is charged, as well as the pin, so they can't touch unless they are bridged by the nozzle.

Edited 1 time(s). Last edit at 02/03/2016 08:48AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 08:56AM |

Registered: 9 years ago Posts: 487 |

Sorry, a lot got posted while I was typing my last post, I'm still digesting what you're suggesting realthor, I was talking about direct electrical probing of a conductive bed with the nozzle.

I don't know about dragging a probe around the bed with the nozzle. Once I've got abs juice from a couple of prints on the bed it's too rough to drag a probe around on.

I think Lyscanthrope is thinking that the springs would be printed PLA.

Moriquendi

I don't know about dragging a probe around the bed with the nozzle. Once I've got abs juice from a couple of prints on the bed it's too rough to drag a probe around on.

I think Lyscanthrope is thinking that the springs would be printed PLA.

Moriquendi

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 09:01AM |

Registered: 9 years ago Posts: 58 |

Oh sorry,

I misunderstood the "dragged", I was thinking you will attach it (by any mean) to the hotend and then lift and go.

I understand now why you need that pads ....because it will just slide along the hotend.

I was wrong about the springs, I misundertood it too

You are right that it would be worth going in another thread ! (just be sure to reference it here ! ==> [forums.reprap.org])

Edited 1 time(s). Last edit at 02/03/2016 09:37AM by lyscanthrope.

I misunderstood the "dragged", I was thinking you will attach it (by any mean) to the hotend and then lift and go.

I understand now why you need that pads ....because it will just slide along the hotend.

I was wrong about the springs, I misundertood it too

You are right that it would be worth going in another thread ! (just be sure to reference it here ! ==> [forums.reprap.org])

Edited 1 time(s). Last edit at 02/03/2016 09:37AM by lyscanthrope.

|

Re: Using FSR at hotend level for an unoptrusive bed probing via the nozzle February 03, 2016 09:32AM |

Registered: 9 years ago Posts: 1,035 |

Quote

Moriquendi

Sorry, a lot got posted while I was typing my last post, I'm still digesting what you're suggesting realthor, I was talking about direct electrical probing of a conductive bed with the nozzle.

I don't know about dragging a probe around the bed with the nozzle. Once I've got abs juice from a couple of prints on the bed it's too rough to drag a probe around on.

I think Lyscanthrope is thinking that the springs would be printed PLA.

Moriquendi

The pads would be there for clean surfaces but even wheels can be employed for rougher (but constant roughness like PEI) ones. All it matters that the central pin has a horizontal base so it can go up and down vertically without deviation and that it's lower surface can cover the roughness of the bed so that it wouldn't dive into a hole and register that as a zero. If you have hills and valleys on the bed then other probing methods (except Inductive -which reads the metallic bed not the hills and valleys) would be fooled and will take wrong readings, creating a deviated plane for the print.

At the end of the day a giroscope base is a print away. Justkidding, from my pov, whatever you have on the bed, should be uniform.

Edited 2 time(s). Last edit at 02/03/2016 09:41AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.