Independent Touch Probe for Z Leveling in 3D printers with any bed surface

Posted by realthor

|

Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 03, 2016 08:53AM |

Registered: 9 years ago Posts: 1,035 |

Hi,

I am spawning off a section from another thread where I have explored this idea and now, that it seems doable, I prefer to open a thread only about it (design/build/suggestions/etc).

I was looking into a very cheap auto-level and went from FSR to Strain Gauges to Direct-Nozzle-Touch to Renishaw Probe and after a while it feels more and more appealing that I have a probe that can be used in auto-leveling but one that is independent of the printer so that no modifications are done to existing printers and no additional overhead is required around the hotends..

Also I like the idea of actually probing at the nozzle axis instead of centimeters away.

I also want this to be suitable for any bed material.

And I also want things simple and cheap.

Hopefully I'll reach my goals in great proportion.

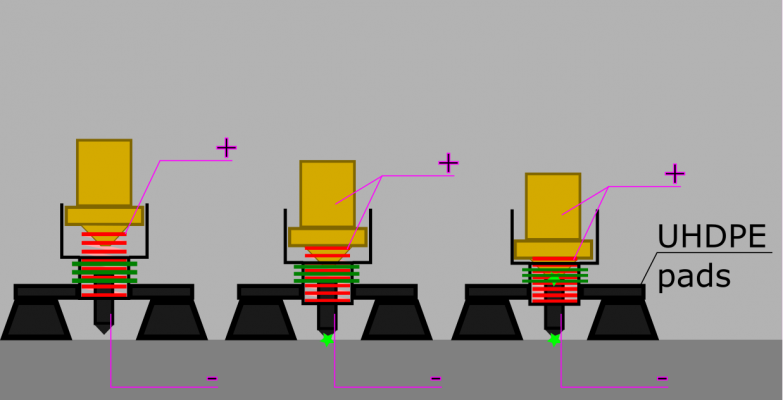

So here is a sketch of what I am intending to pursue:

My working principle would be something along these lines:

1) startup script sais to the printer go to these coordinates and descend this much.

2) the nozzle goes and slighlty dips into the spring of the zeroing probe

3) the probe can slide onto the non-conductive bed (glass) or maybe roll on rougher material (PEI/etc) so the nozzle drags it around probing the pre-determined points on the bed.

Probing goes like this:

a) nozzle is in touch with an outer surface of the probe and its spring, being able to exert lateral force and drag it around

b) nozzle descends compressing the spring which in turns compresses another, outer spring in such a way that the metallic pin touches the bed before the nozzle touches the pin. At this time the nozzle is in direct contact with the charged spring, becoming itself one side of a switch

c) nozzle descends even more, completely compressing the inner spring and touches the bottom of the pin (which is of known dimensions and being set as the offset in the firmware)

Portions of this design can be printed others have to be sourced (springs, pin, collar for the hot nozzle). It needs some combing and maybe make it better through suggestions from you guys.

I am not much of a maker so there is a great chance somebody else will make it before I do (my printer is on the shelf, broken, waiting for parts from the manufacturer)

Please let me know your thoughts.

Edited 5 time(s). Last edit at 02/03/2016 06:33PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I am spawning off a section from another thread where I have explored this idea and now, that it seems doable, I prefer to open a thread only about it (design/build/suggestions/etc).

I was looking into a very cheap auto-level and went from FSR to Strain Gauges to Direct-Nozzle-Touch to Renishaw Probe and after a while it feels more and more appealing that I have a probe that can be used in auto-leveling but one that is independent of the printer so that no modifications are done to existing printers and no additional overhead is required around the hotends..

Also I like the idea of actually probing at the nozzle axis instead of centimeters away.

I also want this to be suitable for any bed material.

And I also want things simple and cheap.

Hopefully I'll reach my goals in great proportion.

So here is a sketch of what I am intending to pursue:

My working principle would be something along these lines:

1) startup script sais to the printer go to these coordinates and descend this much.

2) the nozzle goes and slighlty dips into the spring of the zeroing probe

3) the probe can slide onto the non-conductive bed (glass) or maybe roll on rougher material (PEI/etc) so the nozzle drags it around probing the pre-determined points on the bed.

Probing goes like this:

a) nozzle is in touch with an outer surface of the probe and its spring, being able to exert lateral force and drag it around

b) nozzle descends compressing the spring which in turns compresses another, outer spring in such a way that the metallic pin touches the bed before the nozzle touches the pin. At this time the nozzle is in direct contact with the charged spring, becoming itself one side of a switch

c) nozzle descends even more, completely compressing the inner spring and touches the bottom of the pin (which is of known dimensions and being set as the offset in the firmware)

Portions of this design can be printed others have to be sourced (springs, pin, collar for the hot nozzle). It needs some combing and maybe make it better through suggestions from you guys.

I am not much of a maker so there is a great chance somebody else will make it before I do (my printer is on the shelf, broken, waiting for parts from the manufacturer)

Please let me know your thoughts.

Edited 5 time(s). Last edit at 02/03/2016 06:33PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 03, 2016 09:08AM |

Registered: 8 years ago Posts: 312 |

Biggest issue I can see with this way of levelling is that the tip of the nozzle might not be completely clean, or have some solidified plastic on it.

This can cause two errors.

1) you will not make electric contact

2) you will have different heights measured depending on how much plastic is stuck to the nozzle.

Hope you have a solution for that.

Lykle

This can cause two errors.

1) you will not make electric contact

2) you will have different heights measured depending on how much plastic is stuck to the nozzle.

Hope you have a solution for that.

Lykle

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 03, 2016 09:25AM |

Registered: 9 years ago Posts: 1,035 |

Quote

Lykle

Biggest issue I can see with this way of levelling is that the tip of the nozzle might not be completely clean, or have some solidified plastic on it.

This can cause two errors.

1) you will not make electric contact

2) you will have different heights measured depending on how much plastic is stuck to the nozzle.

Hope you have a solution for that.

Lykle

The pre-extruding and priming procedures are independent of the device and should be done at every print on all printers out there. Ultimaker does that at the begining of the print, after nozzle has reached temp.

Some HP printers have a small wire brush located at the back of the build plate and you can program the nozzle to be dragged through the wire brush before the start of a print and also at any time during the print from the software settings.

On top of that the probing would be done with hot nozzle that has been wiped off a hairy pad/ felt/et..

There are already printers doing that (example).

Thanks for chiming in.

Edited 1 time(s). Last edit at 02/03/2016 10:08AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 03, 2016 06:26PM |

Registered: 9 years ago Posts: 1,035 |

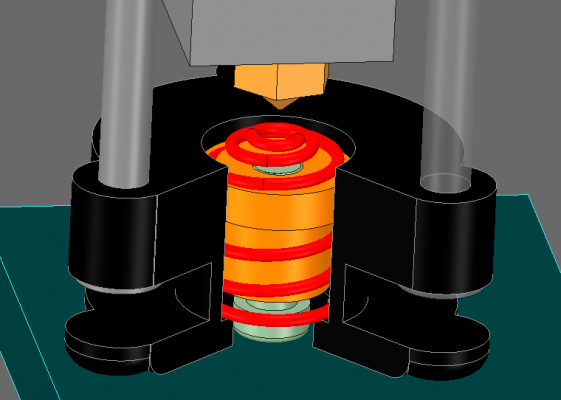

Ok, I have to admit I have a problem with this system if a heated nozzle is to be probed. I would have to have materials that can withstand the nozzle temperature and also be dielectric (the only metal parts should be the pin and the interior spring. The rest must not conduct current (the exterior spring can be metal too because it will not be in direct contact to any of the the two mentioned parts).

I need your expert opinion guys. Is it imperative that the calibration temp is the target temp the next print will be done with? And if so, what do you suggest for the dielectric materials in the following sketch? Basically both the black and the orange parts should be either plastic if the cold hotend would be probed or some sort of ceramic? otherwise.

The additional problem is that those two have to be pretty smooth so they can slide past one another.

Visually this is for a moving bed printer but it is the same for moving the printerhead up and down.

At contact the bed would back up a few millimeters and the carriage would move to the next probing point, dragging the probe with it. I haven't yet included the HDPE/UHMWPE sliding pads that would allow dragging without friction almost (for a clean glass that is) or the wheels? for rougher terrain (PEI) because I want to solve the issues one by one as they arise.

I am thinking about magnetic z probe but not just yet. I have to run out of options for the current iteration.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I need your expert opinion guys. Is it imperative that the calibration temp is the target temp the next print will be done with? And if so, what do you suggest for the dielectric materials in the following sketch? Basically both the black and the orange parts should be either plastic if the cold hotend would be probed or some sort of ceramic? otherwise.

The additional problem is that those two have to be pretty smooth so they can slide past one another.

Visually this is for a moving bed printer but it is the same for moving the printerhead up and down.

At contact the bed would back up a few millimeters and the carriage would move to the next probing point, dragging the probe with it. I haven't yet included the HDPE/UHMWPE sliding pads that would allow dragging without friction almost (for a clean glass that is) or the wheels? for rougher terrain (PEI) because I want to solve the issues one by one as they arise.

I am thinking about magnetic z probe but not just yet. I have to run out of options for the current iteration.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 03:26AM |

Registered: 9 years ago Posts: 487 |

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 04:15AM |

Registered: 9 years ago Posts: 1,035 |

Repeatability mainly. Secondary are the other flaws that make us create threads like microswitch vs opto, microswitch vs hal, microswitch vs inductive probe... . Also I want to probe spot on under the nozzle instead of ofsetting.

Of course I can install a microswitch in the probe, one of the push button type Josef Prusa used in his auto-leveling video and have the nozzle just press on it. Or a FSR (repeatability issues again). Or a Piezo disc (same). But all of them have a small space in which you'd have to guess where it did trigger.

But the direct contact between the nozzle and the pin has no room for error (at least that's the way i understand it - unless there's a micro-arch of electricity that closes the gap before the two actually touch), the spring doesn't matter much as long as the pin reaches first the bed and then the nozzle reaches the pin the contact is always the same, repetable and rigid, just like the CNC auto-zero tool-to-plate contact. All it needs is the inner spring be stronger and overcome the outer string's force and the friction between the two barrels so that the pin touches first the bed and nozzle touches second the pin, registering the zero.

Now I can do cold probing and offset in software pin length+nozzle dilatation value learned from Printrbot-like inductive probe calibration, but that would take away from it some of the "naked truth" appeal.

I also like the rep-rappiness of it, the fact that anybody could make one instead of buying, isn't this one of the reasons rep-raps have been created in the first place? And it's interesting to have the internal spring and the pin connected to the negative and positive and have the nozzle close the circuit when in contact with both the spring and the pin.

Edit: what I do really is take a CNC specific auto-zero plate and make it "draggable" around the bed by the nozzle, for multi-point probing.

Edited 5 time(s). Last edit at 02/04/2016 05:17AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Of course I can install a microswitch in the probe, one of the push button type Josef Prusa used in his auto-leveling video and have the nozzle just press on it. Or a FSR (repeatability issues again). Or a Piezo disc (same). But all of them have a small space in which you'd have to guess where it did trigger.

But the direct contact between the nozzle and the pin has no room for error (at least that's the way i understand it - unless there's a micro-arch of electricity that closes the gap before the two actually touch), the spring doesn't matter much as long as the pin reaches first the bed and then the nozzle reaches the pin the contact is always the same, repetable and rigid, just like the CNC auto-zero tool-to-plate contact. All it needs is the inner spring be stronger and overcome the outer string's force and the friction between the two barrels so that the pin touches first the bed and nozzle touches second the pin, registering the zero.

Now I can do cold probing and offset in software pin length+nozzle dilatation value learned from Printrbot-like inductive probe calibration, but that would take away from it some of the "naked truth" appeal.

I also like the rep-rappiness of it, the fact that anybody could make one instead of buying, isn't this one of the reasons rep-raps have been created in the first place? And it's interesting to have the internal spring and the pin connected to the negative and positive and have the nozzle close the circuit when in contact with both the spring and the pin.

Edit: what I do really is take a CNC specific auto-zero plate and make it "draggable" around the bed by the nozzle, for multi-point probing.

Edited 5 time(s). Last edit at 02/04/2016 05:17AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 08:22AM |

Registered: 8 years ago Posts: 1,671 |

What are the downsides of having a simple short for the switch(accuracy/repeatability, arcing), instead of a micro switch, eg a normally open signal circuit, which closes either when hotend touches level screw, or metal clip attached to bed, or a bearing touches end of rail, obviously not the bearing hitting the bumpers, but hitting a wire near the end...obviously this could bend and move and mess things up, tricky to isolate parts of the signal path, but not impossible.

Edited 1 time(s). Last edit at 02/04/2016 08:23AM by MechaBits.

Edited 1 time(s). Last edit at 02/04/2016 08:23AM by MechaBits.

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 09:33AM |

Registered: 9 years ago Posts: 1,035 |

I'm sorry I think my english doesn't help me completely understand what you are saying.

I am basing my attempt of a probe on a tried one, the zero probe plate used in most CNC machines. It's just that for that one you have to use crocodile clamps on the tool bit and the plate itself to connect it to a voltage source and that there has to be an operator moving it around at pre-determined spots (for a general calibration), or place it on a working piece otherwise.

I just want something that is easy to move around by the hotend itself, probes at nozzle axis, is independent of bed material and is cheap.

I find the "on-contact" probes better than the break-contact ones in terms of repeatability and accuracy in general.

Edited 1 time(s). Last edit at 02/04/2016 09:43AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I am basing my attempt of a probe on a tried one, the zero probe plate used in most CNC machines. It's just that for that one you have to use crocodile clamps on the tool bit and the plate itself to connect it to a voltage source and that there has to be an operator moving it around at pre-determined spots (for a general calibration), or place it on a working piece otherwise.

I just want something that is easy to move around by the hotend itself, probes at nozzle axis, is independent of bed material and is cheap.

I find the "on-contact" probes better than the break-contact ones in terms of repeatability and accuracy in general.

Edited 1 time(s). Last edit at 02/04/2016 09:43AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 10:33AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 10:44AM |

Registered: 9 years ago Posts: 1,035 |

It will be done one day but it's not on the cheaper side.

What I find difficult to incorporate in my design, besides a way to probe it with the heated nozzle, is a way for the printer head to "snatch" the probe without magnets. That's why my solution reliez on a smooth surface where HDPE pads would slide easily. But if you don't swap glasses, like every other print a new clean glass, and the goo from ABS slurry or hairspray adds up, sliding will not be possible anymore.

So wheels of sorts or finally even the magnetic snatching will be a better solution.

Right now I am thinking to use a feeler gauge strip instead of the pin... this design still has a lot of room to evolve, even if it's such a simple low-tech solution.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

What I find difficult to incorporate in my design, besides a way to probe it with the heated nozzle, is a way for the printer head to "snatch" the probe without magnets. That's why my solution reliez on a smooth surface where HDPE pads would slide easily. But if you don't swap glasses, like every other print a new clean glass, and the goo from ABS slurry or hairspray adds up, sliding will not be possible anymore.

So wheels of sorts or finally even the magnetic snatching will be a better solution.

Right now I am thinking to use a feeler gauge strip instead of the pin... this design still has a lot of room to evolve, even if it's such a simple low-tech solution.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 11:11AM |

Registered: 8 years ago Posts: 3,525 |

I like the idea and was always fairly happy printing onto aluminium, until I got printbite, so no more hairspray which is a nice feature. But to have accurate nozzle based probing I'd go back to aluminium and save the printbite for my other printer.

Why not mount a little wire brush somewhere, heat the nozzle to sub-ooze temperatures (I use 160 for ABS and 130 for PLA) go to the wipe coordinates and wipe itself, then with a heated bed probe electrically, then resume heating to printing temperatures and print. I'd expect a small amount of closure of the nozzle to bed gap once fully heated (probably can be calculated by some keen physicist reading this) and just build that offset into the slicer or use baby stepping during brim printing to adjust the z height to get a nice first layer then m500 to save.

Why not mount a little wire brush somewhere, heat the nozzle to sub-ooze temperatures (I use 160 for ABS and 130 for PLA) go to the wipe coordinates and wipe itself, then with a heated bed probe electrically, then resume heating to printing temperatures and print. I'd expect a small amount of closure of the nozzle to bed gap once fully heated (probably can be calculated by some keen physicist reading this) and just build that offset into the slicer or use baby stepping during brim printing to adjust the z height to get a nice first layer then m500 to save.

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 02:10PM |

Registered: 9 years ago Posts: 1,035 |

Yes for such a device used as a probe a software solution of brushing the nozzle after pre-heating to sub-ooze temperatures should be mandatory to ensure a clean contact metal to metal.

Such solutions already exist and there are several videos online showing different approaches.

I am brainstorming different approaches to allow the nozzle heat to printing temperatures and still be able to get close/touch the probe while dragging it. I am thinking ceramic but can't find a proper hardware-store item to adapt to my design. Yet

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Such solutions already exist and there are several videos online showing different approaches.

I am brainstorming different approaches to allow the nozzle heat to printing temperatures and still be able to get close/touch the probe while dragging it. I am thinking ceramic but can't find a proper hardware-store item to adapt to my design. Yet

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 03:00PM |

Registered: 9 years ago Posts: 1,035 |

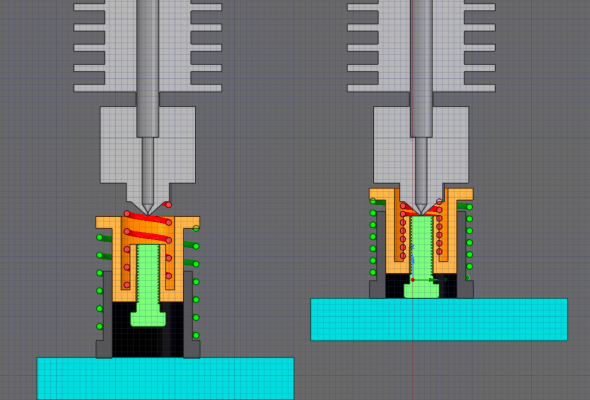

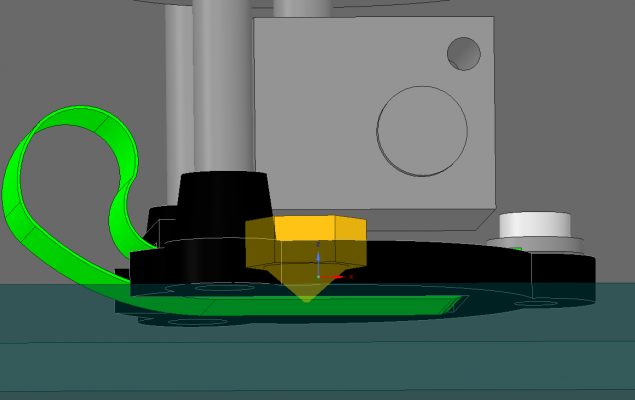

I simplified the core design even more (core because I am not thinking yet too hard about the "dragging around" method).

Here's the design, the white thing being a ceramic collar of some sorts, maybe I can find such a thing in electrical department somewhere around. Maybe you electrical engineers know a common source of ceramic stuff that I can use in that area where the nozzle will press into and will use to drag the probe around:

I may be able to glue that to the orange plastic piece but no idea other than that yet. Have to solve the temperature issue now.

I would really like to make this the simplest way to probe the bed with direct contact nozzle to bed (well, using an intermediary piece here but still solid contact, no springy unreliable contact) while the nozzle is at printing temp, fully expanded. And worry not about damaging the bed, be it PEI, glass or whatever.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Here's the design, the white thing being a ceramic collar of some sorts, maybe I can find such a thing in electrical department somewhere around. Maybe you electrical engineers know a common source of ceramic stuff that I can use in that area where the nozzle will press into and will use to drag the probe around:

I may be able to glue that to the orange plastic piece but no idea other than that yet. Have to solve the temperature issue now.

I would really like to make this the simplest way to probe the bed with direct contact nozzle to bed (well, using an intermediary piece here but still solid contact, no springy unreliable contact) while the nozzle is at printing temp, fully expanded. And worry not about damaging the bed, be it PEI, glass or whatever.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 03:07PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 03:23PM |

Registered: 9 years ago Posts: 1,035 |

If you are talking about the Renishaw-style probe that has been discussed in my other thread (the FSR one), then all I can say is that it is a very elegant solution that copies the original very close and that I believe is one of the best approaches besides optical. BUT: 1) you have to create a new printer head; 2) I haven't seen it yet on a cartesian printer ; 3) adds some complexity and weight to the X carriage; 4) if you have PEI/Buildtalk/etc a hot nozzle can damage it; 5) I don't really like the whole printer head to be prone to involuntary movement (vibrations/etc) that would trigger such a sensitive "switch"; I can probably find more.

I am trying to isolate the hot probing from both the printer and the bed. This is a niche that can satisfy many users if it will ever become a real thing. And it's not even that complicated, can be done in a day.

And I believe that modularity is key tu future 3d printers, which will be able to change tool-heads on the fly and the "calibration tool" will be one of them.

Edited 2 time(s). Last edit at 02/04/2016 03:45PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I am trying to isolate the hot probing from both the printer and the bed. This is a niche that can satisfy many users if it will ever become a real thing. And it's not even that complicated, can be done in a day.

And I believe that modularity is key tu future 3d printers, which will be able to change tool-heads on the fly and the "calibration tool" will be one of them.

Edited 2 time(s). Last edit at 02/04/2016 03:45PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 08:43PM |

Registered: 9 years ago Posts: 1,035 |

Ok, I'm having another dilemma: if there was a pin of known exact dimensions, with super flat surfaces top and bottom, what would that be? Is there anything industrially made that we can use as a pin of very precise dimension?

I am looking at an alternative to use a filler gauge strip but that is more difficult to incorporate. Anyways, this video is a nice instructional how to do a manual bed leveling with a multimeter and a filler gauge. This would be enough for people that want a level bed but don't want their machine to go up and down during print.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I am looking at an alternative to use a filler gauge strip but that is more difficult to incorporate. Anyways, this video is a nice instructional how to do a manual bed leveling with a multimeter and a filler gauge. This would be enough for people that want a level bed but don't want their machine to go up and down during print.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 08:51PM |

Registered: 12 years ago Posts: 548 |

What you need is a pin gage. For example: [lmscnc.com]

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 04, 2016 09:00PM |

Registered: 9 years ago Posts: 1,035 |

Uhh, that's much more expensive than a strip filler gauge -and I mean the whole pack of them- ... even for the individual ones i've looked online. But I need a small piece, max 15mm, that is of known dimensions (to tolerances), and that has super flat faces. There has to be some other option, that is less costly (excuse my cheapness but at $6 a piece -one that i found on aliexpress-, the inductive probe gives it a run for the money).

I believe I mostly need something super flat on its ends not necessarily at tolerances in length, those don't matter quite as much.

Edited 1 time(s). Last edit at 02/04/2016 09:01PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 05, 2016 02:03AM |

Registered: 9 years ago Posts: 58 |

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 05, 2016 04:33AM |

Registered: 9 years ago Posts: 1,035 |

Quote

lyscanthrope

Well.. I was thinking at a typical m3/m4 screw with a flat head. I'm not sure that you need precision length as you will measure it when assembling the probe.

Not length but flatness .. I sketched a screw in my pictures but I figure the threaded end is not machined/cut to precision and the nozzle might not sit every time on the same spot, at lest not in the free-floating (sliding) variant.

I am maybe complicating the mechanism (and hate to add vitamins) but I am actually designing a clamping solution so the probe could be attached to the hotend during probing as the dragging around is quite a stretch. It would also center the nozzle onto the screw/pin.

Here's what I am thinking:

The probe has 3 studs going up, being the diam of the round fins or going into vertical holes accommodated into the fans shroud or whatever plastic covers the hotend (they can literally be nails). These studs get pressed into those holes / onto the fins so that the probe remains there for the duration of the probing (they can also be magnetically attached). There is no force exerting itself on these studs during probing at all.

I have moved the spring from above the interior barrel to below and this time it only function as a pulling string, keeping the central pin pressed into the bed.

The current is connected to the central pin, like before, and to the lamelar angled spring screwed into the upper surface of the probe. When the gap between the probe and the nozzle closes in, that lamelar spring touches the heater block so that the nozzle is again used as a bridge to close the circuit.

I haven't given up the sliding probe and I will try to make this one work without the pins too, but now there is no upper string to always push into the hot nozzle transferring heat down into the plastic.

Edited 6 time(s). Last edit at 02/05/2016 05:21AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 05, 2016 05:40AM |

Registered: 9 years ago Posts: 58 |

Hmmm just a stupid question ... I think I may be mistaken again but ...do you need the spring ?

Wouldn't it be possible to use a thin aluminium foil on (attached on the stubs so it get dragged around) connected to the netagive side, then when the probe goes to the ground it stops when touching the foil (contact detected) ?

Wouldn't it be possible to use a thin aluminium foil on (attached on the stubs so it get dragged around) connected to the netagive side, then when the probe goes to the ground it stops when touching the foil (contact detected) ?

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 05, 2016 07:06AM |

Registered: 9 years ago Posts: 1,035 |

Quote

lyscanthrope

Hmmm just a stupid question ... I think I may be mistaken again but ...do you need the spring ?

Wouldn't it be possible to use a thin aluminium foil on (attached on the stubs so it get dragged around) connected to the netagive side, then when the probe goes to the ground it stops when touching the foil (contact detected) ?

You are right, the spring is legacy from the previous design

... gravity should do the trick in my current design (of keeping the pin on the bed), the spring is there to ensure strong contact between pin and bed.

... gravity should do the trick in my current design (of keeping the pin on the bed), the spring is there to ensure strong contact between pin and bed.BUT I am actually not happy with my above design and will make the spring go through the orange plastic and be able to be touched by the nozzle and current will be provided again via the spring.

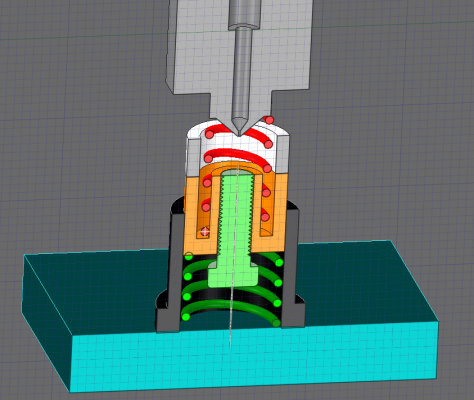

Smth like this:

Your solution totally works and I am too thinking of using a filler gauge (for which the exact width is known) but in your case you will at all times keep a wire on the hotend, which I am trying to avoid (don't know though if for the right reasons, my whole premise of the design is that the probe should be independent wire-wise). Using the pin instead of the filler gauge could be cheaper if a pin with sufficiently flat surfaces would be available in the hardware store. But both solutions are sufficiently cheap compared to the alternatives.

There is a situation where I'd put the negative (ground?) permanently on the hotend somewhere and that is if there is another such wire going from the heater maybe to the controlboard. That way i can piggy-back and let the current an already existing way to escape when I touch the + coming from the pin or foil in your case.

I do not know too much electronics but is there a difference between always having one of the two contacts on the hotend and having brief contacts like i do in my design?

Edited 2 time(s). Last edit at 02/05/2016 07:30AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 07, 2016 01:57PM |

Registered: 9 years ago Posts: 1,035 |

Ok, my design for the pin-based probe is not going to suffer much of a change. It's pretty basic and i believe it will work as is. My main hurdle remaining is the precision of the pin's end surfaces... they should be pretty darn straight if any quality is to be expected of the probe.

Note: I've foudn this cideo on youtube of a similar approach to what I am trying to achieve (nozzle-to-bed-close-current-loop-probing) and thought of posting it here cause it doesn't use any useful keywords in the title or description to be easy to find: https://www.youtube.com/watch?v=hrQYFOIPBEo. Please post if you know of other such attempts.

Meanwhile I kind of have a first iteration of the thin-strip-based probe, which seems even simpler in the current design. Before I post it here I wanted to ask around two things:

1) I am thinking at a filler gauge strip for a very precise intermediary between the nozzle and the bed. This time I am considering the ground directly on the hotend and the 5V on the strip. I can always add another element to provide the ground in the probe. i have seen filler gauge strips as wide as 14mm and wanted to ask you if there is any standard or they can be found in even wider varieties?

2) What other thin strip of something metal is precision-made so that I can use it instead of the filler gauge? Wild idea would be a beer can aluminum strip. Can those be trusted to any tolerances across a very small area where the nozzle will meet the strip? Is the low-grade beer can aluminum too weak to take the constant beating of the brass nozzle? I am guessing the filler gauges are stainless steel or something similar, so much stronger than the low-grade aluminum of the beer cans.

Edit: I've just learned that many filler gauges are brass too, so at least brass on brass will be a neutral contact.

Edited 3 time(s). Last edit at 02/09/2016 06:04AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Note: I've foudn this cideo on youtube of a similar approach to what I am trying to achieve (nozzle-to-bed-close-current-loop-probing) and thought of posting it here cause it doesn't use any useful keywords in the title or description to be easy to find: https://www.youtube.com/watch?v=hrQYFOIPBEo. Please post if you know of other such attempts.

Meanwhile I kind of have a first iteration of the thin-strip-based probe, which seems even simpler in the current design. Before I post it here I wanted to ask around two things:

1) I am thinking at a filler gauge strip for a very precise intermediary between the nozzle and the bed. This time I am considering the ground directly on the hotend and the 5V on the strip. I can always add another element to provide the ground in the probe. i have seen filler gauge strips as wide as 14mm and wanted to ask you if there is any standard or they can be found in even wider varieties?

2) What other thin strip of something metal is precision-made so that I can use it instead of the filler gauge? Wild idea would be a beer can aluminum strip. Can those be trusted to any tolerances across a very small area where the nozzle will meet the strip? Is the low-grade beer can aluminum too weak to take the constant beating of the brass nozzle? I am guessing the filler gauges are stainless steel or something similar, so much stronger than the low-grade aluminum of the beer cans.

Edit: I've just learned that many filler gauges are brass too, so at least brass on brass will be a neutral contact.

Edited 3 time(s). Last edit at 02/09/2016 06:04AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 08, 2016 02:53AM |

Registered: 9 years ago Posts: 58 |

There is this one too :

[www.thingiverse.com]

I think the aluminum can (or even a kitchen foil) could be usefull. The only think I'll be carefull is that for can, the paint could be non-conductive. As a first try, I would better suggest to go for aluminium foil (from the kitchen)

[www.thingiverse.com]

I think the aluminum can (or even a kitchen foil) could be usefull. The only think I'll be carefull is that for can, the paint could be non-conductive. As a first try, I would better suggest to go for aluminium foil (from the kitchen)

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 08, 2016 04:15AM |

Registered: 9 years ago Posts: 1,035 |

Quote

lyscanthrope

There is this one too :

[www.thingiverse.com]

I think the aluminum can (or even a kitchen foil) could be usefull. The only think I'll be carefull is that for can, the paint could be non-conductive. As a first try, I would better suggest to go for aluminium foil (from the kitchen)

The beer can coating on the inside should be buffed off as it's a plastic (BPA maybe) that protects the can material. It could be useful because, as a product of a large industrial process, it should be quite precise in thinckness uniformity. The pressure inside the can keeps it "wrinkle-free". Other products that can offer this are spray cans.

Regarding the "clamping" mechanism to the hotend, I might think of something else than the three-stud system because the heater block can be in the way and there are many hotends that do not abide to the round 24mm diameter fins hotend. A more universal mechanism would be to use the same mount that the hotend is mounted to or some plastic part that is adjacent to it, maybe even the fan shroud if it is screwed to the X carriage (and not floating freely on the hotend).

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 09, 2016 05:54AM |

Registered: 9 years ago Posts: 1,035 |

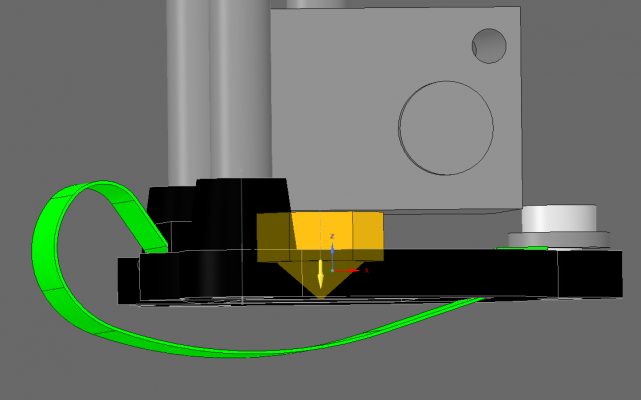

After quite a few sketches I think i have the one design that is the most minimal that I could think of. This is for the strip/leaf based probe and it looks way easier to do than the pin-based one before, although that one looks more industrial while this looks more DIY-ish:

I had to find a way to ensure that the foil/strip doesn't have any chance to touch the nozzle while the hotend is traveling to the next probing position. So after nozzle completes the electric circuit by making contact with the foil, the instant the bed comes down the contact should be broken. I have explored some torsion spring based designs but ultimately -at least for me- the simplicity of this one won. It takes advantage of the elasticity of a metallic strip so when relaxed it will conform to the shape that has the largest radius possible, thus keeping away from the nozzle.

This will only have one current lead to the screw that also clamps down the strip on one end (on the right in the pictures), while the other wire will be soldered/fastened to the hotend itself. Of course there can be a leaf spring of sorts that provides that function on the probe itself when the nozzle approaches by touching it. It can be attached to the probe on the very screw that clamps the metallic strip. In this case one must ensure that the two leads are insulated from one another to avoid a short circuit that would trigger the Z_min signal.

Edited 2 time(s). Last edit at 02/09/2016 06:02AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I had to find a way to ensure that the foil/strip doesn't have any chance to touch the nozzle while the hotend is traveling to the next probing position. So after nozzle completes the electric circuit by making contact with the foil, the instant the bed comes down the contact should be broken. I have explored some torsion spring based designs but ultimately -at least for me- the simplicity of this one won. It takes advantage of the elasticity of a metallic strip so when relaxed it will conform to the shape that has the largest radius possible, thus keeping away from the nozzle.

This will only have one current lead to the screw that also clamps down the strip on one end (on the right in the pictures), while the other wire will be soldered/fastened to the hotend itself. Of course there can be a leaf spring of sorts that provides that function on the probe itself when the nozzle approaches by touching it. It can be attached to the probe on the very screw that clamps the metallic strip. In this case one must ensure that the two leads are insulated from one another to avoid a short circuit that would trigger the Z_min signal.

Edited 2 time(s). Last edit at 02/09/2016 06:02AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 09, 2016 08:14PM |

Registered: 9 years ago Posts: 1,035 |

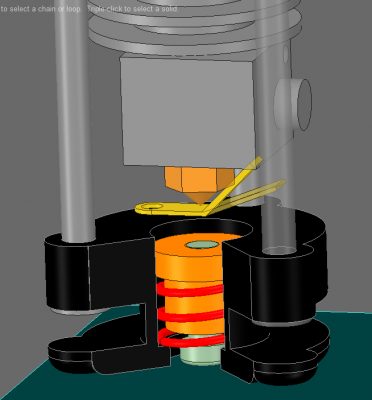

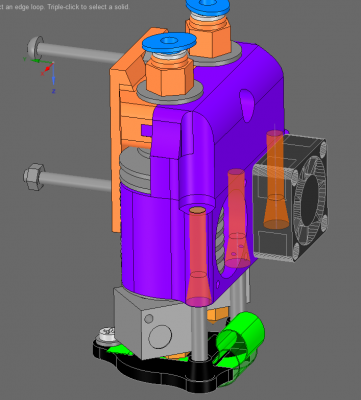

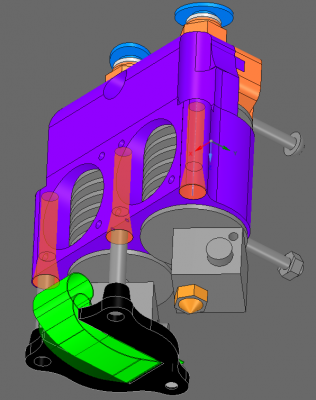

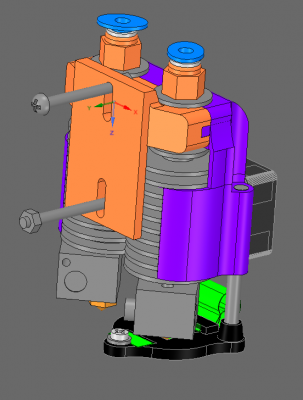

And possible "attaching the probe to the print head" arrangement:

This is how the probe would look like on my current dual hotend mount. I have re-designed the half clamp that holds the hotends in place so that it includes the fans shroud because the Probe would attach to the shroud via tube holes that receive the Probe's pins. Right now I am betting on friction alone but magnets can be fitted at the top where the pins end.

The probe can be attached to either hotend. If both hotends would be probed via a special g-code script, the difference in nozzle height can be detected and maintenance can be requested so that both nozzles are at the same height.

This is still WIP. I haven't thought through all the details the idea is that the probe sits somewhere where the print head can reach, at the edge of the bed, a known position. then the print head goes to those coordinates and descends over it (or the bed rises pushing the pins in the "auto-centering" holes) until the nozzle touches the bed -the metal strip actually- completing the current circuit as the probe is wired, basically sending a Z_min to the controller for that position. Then, with the Probe on the printhead, the classic auto-leveling procedure can be performed. At the end the print head goes to the same coordinates where it somehow detaches the probe (haven't figured it out yet).

Edited 2 time(s). Last edit at 02/09/2016 08:22PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

This is how the probe would look like on my current dual hotend mount. I have re-designed the half clamp that holds the hotends in place so that it includes the fans shroud because the Probe would attach to the shroud via tube holes that receive the Probe's pins. Right now I am betting on friction alone but magnets can be fitted at the top where the pins end.

The probe can be attached to either hotend. If both hotends would be probed via a special g-code script, the difference in nozzle height can be detected and maintenance can be requested so that both nozzles are at the same height.

This is still WIP. I haven't thought through all the details the idea is that the probe sits somewhere where the print head can reach, at the edge of the bed, a known position. then the print head goes to those coordinates and descends over it (or the bed rises pushing the pins in the "auto-centering" holes) until the nozzle touches the bed -the metal strip actually- completing the current circuit as the probe is wired, basically sending a Z_min to the controller for that position. Then, with the Probe on the printhead, the classic auto-leveling procedure can be performed. At the end the print head goes to the same coordinates where it somehow detaches the probe (haven't figured it out yet).

Edited 2 time(s). Last edit at 02/09/2016 08:22PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 11, 2016 09:09AM |

Registered: 9 years ago Posts: 1,035 |

What I think it's cool about this technique is that if the probe's pins would slip a bit it wouldn't matter, because the bed moving up will push it again until the metal strip is the only thing between it and the nozzle. This calls for various "less than exact" clamping mechanisms like a reversible snap-fit pin.

Comparing this with the calibration that needs to be done for all other probes and endstops, plus the fact that it can be done with the hot nozzle without fear of damaging the bed if it is plastic-based. Then it's so cheap you can basically DIY for less than a mechanical end switch. Then it's very easy to source parts if one breaks because it has so few of them.

Now I am thinking of applying this technique for X and Y to try to replace the endstops there too. And I believe it is possible to create some sort of contact trigger that works on both ends, without having to install X_Min and X_Max, Y_Min and Y_Max ...

I am quite surprised to see rather thin interest in this. Maybe i'm overseeing some major flaw though

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Comparing this with the calibration that needs to be done for all other probes and endstops, plus the fact that it can be done with the hot nozzle without fear of damaging the bed if it is plastic-based. Then it's so cheap you can basically DIY for less than a mechanical end switch. Then it's very easy to source parts if one breaks because it has so few of them.

Now I am thinking of applying this technique for X and Y to try to replace the endstops there too. And I believe it is possible to create some sort of contact trigger that works on both ends, without having to install X_Min and X_Max, Y_Min and Y_Max ...

I am quite surprised to see rather thin interest in this. Maybe i'm overseeing some major flaw though

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 11, 2016 10:04AM |

Registered: 9 years ago Posts: 58 |

I really like the design for the hotend. I'm not sure that It'll be really usefull for the Xmin/Ymin but ...why not. I guess people d'ont really like having circuit open in their printer

Wouldn't it be possible to have a second thin strip running parallel to the bottom of the printed part ? Positionned so that the tip is touching it. The idea would be that when the hotend approach the bed, it closes the gap between the hanging strip and the parralel one. The circuit will be conectd to the two strips (removing the need to attach a wire to the hotend.

I totaly think the magnet to hold the pole are a good idea !

Wouldn't it be possible to have a second thin strip running parallel to the bottom of the printed part ? Positionned so that the tip is touching it. The idea would be that when the hotend approach the bed, it closes the gap between the hanging strip and the parralel one. The circuit will be conectd to the two strips (removing the need to attach a wire to the hotend.

I totaly think the magnet to hold the pole are a good idea !

|

Re: Independent Touch Probe for Z Leveling in 3D printers with any bed surface February 11, 2016 10:21AM |

Registered: 9 years ago Posts: 1,035 |

Quote

lyscanthrope

I really like the design for the hotend. I'm not sure that It'll be really usefull for the Xmin/Ymin but ...why not. I guess people d'ont really like having circuit open in their printer

Wouldn't it be possible to have a second thin strip running parallel to the bottom of the printed part ? Positionned so that the tip is touching it. The idea would be that when the hotend approach the bed, it closes the gap between the hanging strip and the parralel one. The circuit will be conectd to the two strips (removing the need to attach a wire to the hotend.

I totaly think the magnet to hold the pole are a good idea !

The current will still flow through the hotend because it's metal on metal contact. The same could be applied to the Probe as it is now but adding a leaf spring that is wired instead of the hotend and when the nozzle approaches it touches the nozzle, then comes down with it until the nozzle touches the metal strip. Now tou don't wire the hotend but the Probe itself with both leads. Yet the current will still flow through the hotend on contact.

And a strip fixed on the bed is not that useful because you would only be able to probe on that area , so why not a metal bed then?

THis hotend is a part of a broader design I am making for a corexy printer (called CoofeeCore as it's being built around a metal frame coffeetable

). The design is in the CoreXY category.

). The design is in the CoreXY category.RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.