mk 8 extruder stop printing

Posted by blro

|

mk 8 extruder stop printing February 05, 2016 04:14PM |

Registered: 8 years ago Posts: 13 |

I am new to 3d printing and have a Prusa I3. I am to the point where I can print but the extruder stops extruding filament even though the motor is still turning. I have disassembled/assembled many times (no obstruction), adjusted the tensioning screw, checked nozzle size in repetierhost, etc. I just replaced the nozzle and switched to PLA from ABS. The problem continues: prints great then starts "air printing".

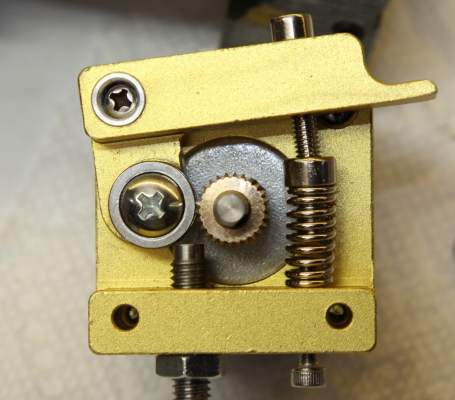

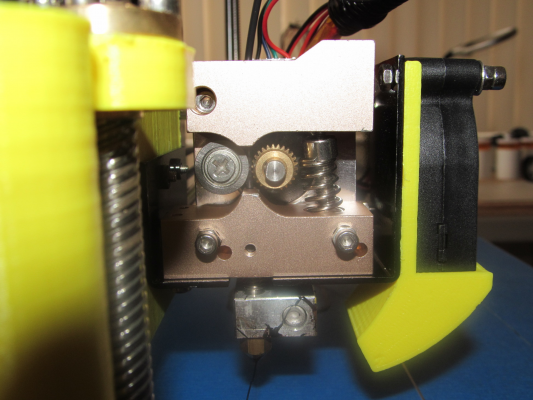

I am to the point where I would like to move away from this extruder to a e3d v6, but in order to do so I need assistance with how I can mount the e3d extruder to my current rig. My X-Axis looks like the attached two pictures. If someone can provide a link to a setup that could be applied to my rig for mount the e3d that would be great. Also a link to a genuine e3d v6 would be appreciated.

TIA

I am to the point where I would like to move away from this extruder to a e3d v6, but in order to do so I need assistance with how I can mount the e3d extruder to my current rig. My X-Axis looks like the attached two pictures. If someone can provide a link to a setup that could be applied to my rig for mount the e3d that would be great. Also a link to a genuine e3d v6 would be appreciated.

TIA

|

Re: mk 8 extruder stop printing February 05, 2016 06:58PM |

Registered: 9 years ago Posts: 1,873 |

Quote

I am new to 3d printing and have a Prusa I3. I am to the point where I can print but the extruder stops extruding filament even though the motor is still turning.

So what happens to the filament? It either has to go somewhere, or the gear grinds a semicircle out of the filament, or the motor stalls and the filament doesn't move.

|

Re: mk 8 extruder stop printing February 05, 2016 08:13PM |

Registered: 8 years ago Posts: 13 |

you ask a good question. there is no indication that the filament is being chewed, i.e., no "chips" and the motor/drive does not make a popping sound. I have checked the filament and there is no semicircular indent. at first I thought the shaft might be freewheeling in the gear but today I disassembled everything and checked the set screw. the gear on the shaft was tight but I replaced the set screw with a stainless one I use in building robotic crawlers. yesterday I purchased a new fan that blows across the heat sync thinking there was an overheating condition. When I say the motor is turning I am basing that on the shaft turning on the other side of the motor. if there is an internal transmission then maybe the motor is turning but the shaft to which the gear is attached is not. I had not considered this possibility. what I will do tomorrow is disassemble the unit and see if the gear actually moves when a manual extrusion is issued. It really does not make sense.

Edited 1 time(s). Last edit at 02/05/2016 08:15PM by blro.

Edited 1 time(s). Last edit at 02/05/2016 08:15PM by blro.

|

Re: mk 8 extruder stop printing February 05, 2016 08:29PM |

Registered: 9 years ago Posts: 1,873 |

It's worth looking into, just so at least you know what the problem is before deciding on the best replacement. I think the shaft is solid and goes straight through the stepper motor, so there shouldn't be any room for confusion there. I got bit by a slipping gear - it's surprisingly easy to overlook, and the behaviour was just like you described. I've no idea why a slipping gear always seems to be ok for the first part of the print and then start slipping. It's made worse by the fact that I can't see the end of the shaft and the drive gear on the mk8, it's hidden by the heatsink. The typical way to check for a slipping gear is to run a witness mark across the end of the shaft and onto the face of the gear. Then, if there's any slippage the marks will become unaligned. It's just a pain having to take the heatsink off to check. Is there a flat on the drive shaft, and the set screw mates onto the flat?

How about the bite of the gear onto the filament? There should be clear tooth marks on the filament after it passes through the extruder, if there aren't the idler is probably not generating enough force to hold the filament against the gear.

If the motor is stalling, sometimes it's easier to feel the problem than to hear it. If you gently hold the filament just before it goes into the extruder, it's very easy to feel the difference between the normal smooth movement and the jitters that happen when the motor starts rocking backwards.

The mk8 design doesn't seem to get much love (and there are quite a few variations), but I've had great luck with mine.

How about the bite of the gear onto the filament? There should be clear tooth marks on the filament after it passes through the extruder, if there aren't the idler is probably not generating enough force to hold the filament against the gear.

If the motor is stalling, sometimes it's easier to feel the problem than to hear it. If you gently hold the filament just before it goes into the extruder, it's very easy to feel the difference between the normal smooth movement and the jitters that happen when the motor starts rocking backwards.

The mk8 design doesn't seem to get much love (and there are quite a few variations), but I've had great luck with mine.

|

Re: mk 8 extruder stop printing February 05, 2016 08:35PM |

Registered: 9 years ago Posts: 1,873 |

I failed to answer your actual questions. Sources for e3d,

[www.filastruder.com]

[e3d-online.com]

I'm afraid I don't know how to adapt the mount, but I'm guessing that either the e3d website will have information, or you might find something on thingiverse, or someone else will chime in here with info.

And welcome to the forum

[www.filastruder.com]

[e3d-online.com]

I'm afraid I don't know how to adapt the mount, but I'm guessing that either the e3d website will have information, or you might find something on thingiverse, or someone else will chime in here with info.

And welcome to the forum

|

Re: mk 8 extruder stop printing February 06, 2016 09:47AM |

Registered: 8 years ago Posts: 13 |

jamesk,

I disconnected the extruder/servo and made a video of what is happening. while the video is not the best it shows a couple of issues along with a picture of the filament after being removed from the hot end.

extruder motor scenario

The video shows the following:

1. the motor, shaft, and gear turn when manually commanded

2. a short length of filament is pulled through

3. when my left thumb and for finger grab the filament above the entry point above the extruder the gear continues to turn, but:

a. this induced jam does not produce a popping of the gear mechanism - yes my right thumb is exerting more upward pressure then the adjustment spring could

b. there is no gouging of the filament

c. there are no fine particles

it is as if the pinch/pressure between the gear and the opposing roller is not strong enough, i.e, the opposing roller is too small in diameter to exert enough pressure against the gear.

the filament looks a bit "swollen". maybe its caused by the heat of the hotend.

and thanks for the links to my original post.

Edited 2 time(s). Last edit at 02/06/2016 09:55AM by blro.

[www.usefulramblings.org]

I disconnected the extruder/servo and made a video of what is happening. while the video is not the best it shows a couple of issues along with a picture of the filament after being removed from the hot end.

extruder motor scenario

The video shows the following:

1. the motor, shaft, and gear turn when manually commanded

2. a short length of filament is pulled through

3. when my left thumb and for finger grab the filament above the entry point above the extruder the gear continues to turn, but:

a. this induced jam does not produce a popping of the gear mechanism - yes my right thumb is exerting more upward pressure then the adjustment spring could

b. there is no gouging of the filament

c. there are no fine particles

it is as if the pinch/pressure between the gear and the opposing roller is not strong enough, i.e, the opposing roller is too small in diameter to exert enough pressure against the gear.

the filament looks a bit "swollen". maybe its caused by the heat of the hotend.

and thanks for the links to my original post.

Edited 2 time(s). Last edit at 02/06/2016 09:55AM by blro.

[www.usefulramblings.org]

|

Re: mk 8 extruder stop printing February 06, 2016 11:18AM |

Registered: 9 years ago Posts: 1,873 |

OK, that's really interesting. The key question is what is preventing the roller from moving closer to the drive gear? In the video it looks very much like there is still clearance between the roller and the gear, there should be nothing preventing those from touching if you apply sufficient force to the lever. (edit, excepting the filament of course)

I don't think I could apply as much pressure to the lever with my thumb as the fully tightened adjustment spring, so I'm wondering if you have been supplied with a weaker than normal spring. Can you post a photo of the extruder with the spring in place? The spring should have a top hat riding in the top (typically just another screw) that the adjustment screw pushes against to increase the tension. I currently have mine cranked all the way in after having some grinding issues with abs, but I use less tension with softer filaments like TPU. With the adjustment screw all the way there is a lot of force on the idler and it certainly can't slip like in your video without shredding the filament. That lack of shredding means you either have something obstructing the travel of the pulley or not enough force on the lever.

Edited 1 time(s). Last edit at 02/06/2016 11:54AM by JamesK.

I don't think I could apply as much pressure to the lever with my thumb as the fully tightened adjustment spring, so I'm wondering if you have been supplied with a weaker than normal spring. Can you post a photo of the extruder with the spring in place? The spring should have a top hat riding in the top (typically just another screw) that the adjustment screw pushes against to increase the tension. I currently have mine cranked all the way in after having some grinding issues with abs, but I use less tension with softer filaments like TPU. With the adjustment screw all the way there is a lot of force on the idler and it certainly can't slip like in your video without shredding the filament. That lack of shredding means you either have something obstructing the travel of the pulley or not enough force on the lever.

Edited 1 time(s). Last edit at 02/06/2016 11:54AM by JamesK.

|

Re: mk 8 extruder stop printing February 06, 2016 12:19PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: mk 8 extruder stop printing February 06, 2016 12:41PM |

Registered: 8 years ago Posts: 13 |

here is a pic of the motor with spring in place. What I should point out is that this mk8 is a two piece assembly. part bolts to the black "U" bracket on the x-axis and the other part with the tension arm bolts to the motor. the spring is then sandwiched in between when mounting the motor to the part bolted to the "U" bracket. in the picture there is a piece of filament in place and with the tension arm under pressure there is about 1mm of clearance between the gear and the edge of the guide wheel so there is nothing that is preventing a greater pinch of say a 1/2 to 3/4 mm before the gear make contact with the edge of the guide wheel. I can still pull the filament out with force and sometimes the gear will turn and other times the filament will slip between to two - very little shaving of filament though. This is a brass gear and I am wondering if the teeth are "sharp" enough to engage the filament.

what about the heat break. Could it be causing a problem in feeding? Right now I am just throwing grenades and hoping to hit something (other than myself :>) ).

[www.usefulramblings.org]

what about the heat break. Could it be causing a problem in feeding? Right now I am just throwing grenades and hoping to hit something (other than myself :>) ).

[www.usefulramblings.org]

|

Re: mk 8 extruder stop printing February 06, 2016 12:50PM |

Registered: 8 years ago Posts: 13 |

Quote

JamesK

I have my spare mk8 on the workbench so I took a quick photo of how it would usually look, minus the heatsink and fan

[attachment 71947 mk8.JPG]

what is interesting in your pic is that your heat break threads into you mk8 and is just below the gear. also your mk 8 is a single assembly which bolts to the motor.

my heat break while threaded slips into the bottom portion of my mk 8 which is "NOT" threaded and held in place by a set screw. I am looking into buying one like yours but in might not mount to my "U" bracket/axis assembly. I have "messaged" my vendor but that is not working too well. Not a problem. I went into this "with both eyes open".

[www.usefulramblings.org]

|

Re: mk 8 extruder stop printing February 06, 2016 01:08PM |

Registered: 9 years ago Posts: 1,873 |

The thing that strikes me about your photo is the lack of pre-load on the spring. It looks like you are missing the second screw in the top of the spring that the adjustment screw bears against to compress the spring. That would explain the lack of force to grip the filament. The heatbreak might be playing a part, but until we get to the point where it's all but impossible to stop the filament with your fingers we have more basic problems

By the way, I don't see anything fundamentally wrong with that design - it looks like a good solid piece of kit and I'm sure we'll get it working. There are steel drive gears available with sharper teeth, but I'm not convinced that tooth sharpness is much of an issue. The brass gear seems to grip fine even on pla.

The big advantage of the steel gears is that they have a smaller diameter so reduce the effective gear ratio of the drive which can help if the stepper is struggling to generate enough force (so if we were dealing with a stalling motor). The down side is that the position of the filament is closer to the shaft of the motor, so the exit hole in the extruder has to match - they aren't a drop in replacement for the brass gears.

Edited 1 time(s). Last edit at 02/06/2016 01:14PM by JamesK.

By the way, I don't see anything fundamentally wrong with that design - it looks like a good solid piece of kit and I'm sure we'll get it working. There are steel drive gears available with sharper teeth, but I'm not convinced that tooth sharpness is much of an issue. The brass gear seems to grip fine even on pla.

The big advantage of the steel gears is that they have a smaller diameter so reduce the effective gear ratio of the drive which can help if the stepper is struggling to generate enough force (so if we were dealing with a stalling motor). The down side is that the position of the filament is closer to the shaft of the motor, so the exit hole in the extruder has to match - they aren't a drop in replacement for the brass gears.

Edited 1 time(s). Last edit at 02/06/2016 01:14PM by JamesK.

|

Re: mk 8 extruder stop printing February 06, 2016 02:04PM |

Registered: 8 years ago Posts: 13 |

Quote

JamesK

The thing that strikes me about your photo is the lack of pre-load on the spring. It looks like you are missing the second screw in the top of the spring that the adjustment screw bears against to compress the spring. That would explain the lack of force to grip the filament. The heatbreak might be playing a part, but until we get to the point where it's all but impossible to stop the filament with your fingers we have more basic problems

By the way, I don't see anything fundamentally wrong with that design - it looks like a good solid piece of kit and I'm sure we'll get it working.

Its the small photo. The second spring you refer to is there it is just difficult to see in the pic. I can replace the adjustment screw with a longer one. This would give me more compression turns. Now where is that box of M3 screws. I am trying to acquire your optimism.

This is almost like rocket science.

This is almost like rocket science.[www.usefulramblings.org]

|

Re: mk 8 extruder stop printing February 06, 2016 02:11PM |

Registered: 9 years ago Posts: 1,873 |

Don't worry, it only seems complicated at first. Once you get printing it will be easier to separate out the issues and see what's what. If you deal with all the components individually printers are quite simple machines.

Yes, get some more load on the spring (lots more load!) and see if that doesn't improve things

Yes, get some more load on the spring (lots more load!) and see if that doesn't improve things

|

Re: mk 8 extruder stop printing February 07, 2016 10:33AM |

Registered: 8 years ago Posts: 13 |

Jamesk,

First let me say thanks for hanging in with me on this. This morning I was able to complete a print. Its like you said "were not getting enough grip on the filament". What I changed was the length of the "tension" screw. It allowed for more turns and therefore greater compression on the spring and that translated into more "pinch" between the gear and the guide roller. I also removed the fan and heat sync so I could get a better look into what was happening should it fail. It did not fail, but completed.

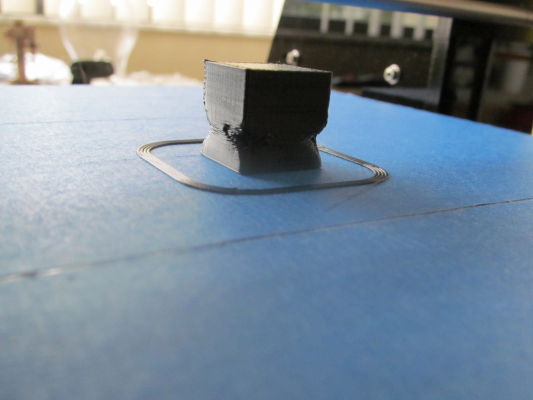

this first picture shows the setup after using the longer tension screw and after doing a successful manual feed. Here is the problem with this extruder kit: the longer screw turned to achieve this compression forces the spring out of the recessed opening in the idler arm and it starts to "bend" towards the gear. You can see it here in the picture. I can see where it could make contact if over tightened and this would be a whole new set of problems, but for now I will just live with it.

here are some pics of the completed printed cube.

The following pic show some obvious deformity in the early stages. When I noiticed it I turned on the fan to cool the object and things began to change for the better throughout the rest of the print. Earlier in my attempts to get a print to finish I "turned off object cooling" in the slic3r program because when the fan kicked on during an abs print the bed temp dropped fast in the cool room and this violated the thermal overload logic which aborted the print altogether. I need to make more adjustments but at least I have a completed print.

In the short video that follows it shows this print in operation. You can see the feed path through the extruder and the force of the pull on the filament. This is what was missing for the whole proceeding two weeks of frustration (blush). Before this longer screw I would tighten the shorter screw until it bottomed out and still no reliable feed. Go figure. Now lets see what will happen when I reassemble with the heat sync and fan in place. Will it still function? or will the dynamics change again?

print video

Again thanks. I am feeling optimistic.

Edited 5 time(s). Last edit at 02/07/2016 10:44AM by blro.

[www.usefulramblings.org]

First let me say thanks for hanging in with me on this. This morning I was able to complete a print. Its like you said "were not getting enough grip on the filament". What I changed was the length of the "tension" screw. It allowed for more turns and therefore greater compression on the spring and that translated into more "pinch" between the gear and the guide roller. I also removed the fan and heat sync so I could get a better look into what was happening should it fail. It did not fail, but completed.

this first picture shows the setup after using the longer tension screw and after doing a successful manual feed. Here is the problem with this extruder kit: the longer screw turned to achieve this compression forces the spring out of the recessed opening in the idler arm and it starts to "bend" towards the gear. You can see it here in the picture. I can see where it could make contact if over tightened and this would be a whole new set of problems, but for now I will just live with it.

here are some pics of the completed printed cube.

The following pic show some obvious deformity in the early stages. When I noiticed it I turned on the fan to cool the object and things began to change for the better throughout the rest of the print. Earlier in my attempts to get a print to finish I "turned off object cooling" in the slic3r program because when the fan kicked on during an abs print the bed temp dropped fast in the cool room and this violated the thermal overload logic which aborted the print altogether. I need to make more adjustments but at least I have a completed print.

In the short video that follows it shows this print in operation. You can see the feed path through the extruder and the force of the pull on the filament. This is what was missing for the whole proceeding two weeks of frustration (blush). Before this longer screw I would tighten the shorter screw until it bottomed out and still no reliable feed. Go figure. Now lets see what will happen when I reassemble with the heat sync and fan in place. Will it still function? or will the dynamics change again?

print video

Again thanks. I am feeling optimistic.

Edited 5 time(s). Last edit at 02/07/2016 10:44AM by blro.

[www.usefulramblings.org]

|

Re: mk 8 extruder stop printing February 07, 2016 11:57AM |

Registered: 9 years ago Posts: 1,873 |

That's great news - congrats! Now I understand why I couldn't see the screw, it was hiding in a recess in the arm. That's a nice piece of design, just a shame the spring wasn't strong enough to match. Maybe you can get a stronger or longer spring so that you could have the best of both worlds. The other option would be to make a spacer to go at the bottom of the spring to add some pre-load from that end.

You'll need the fan and heatsink on the extruder for sure, the mk8's depend quite heavily on sucking the heat out of the bottom block of aluminum that the heatbreak goes through, and without the fan the heat is likely to build up causing the filament to swell and the print to fail. One of my mk8s came with a much weaker fan than the other, so I have a replacement on order. The good fan is noisy but generates a significant amount of draft out of the top of the heatsink. The other fan is very quiet and I can barely feel any air moving. With that one, the heatsink gets noticeably hot.

Is the black cube pla? That sure looks like it benefited from the extra cooling The conventional wisdom is that pla will benefit from a part cooling fan, and abs generally doesn't need it, and may suffer weak layers if you use one.

The conventional wisdom is that pla will benefit from a part cooling fan, and abs generally doesn't need it, and may suffer weak layers if you use one.

You'll need the fan and heatsink on the extruder for sure, the mk8's depend quite heavily on sucking the heat out of the bottom block of aluminum that the heatbreak goes through, and without the fan the heat is likely to build up causing the filament to swell and the print to fail. One of my mk8s came with a much weaker fan than the other, so I have a replacement on order. The good fan is noisy but generates a significant amount of draft out of the top of the heatsink. The other fan is very quiet and I can barely feel any air moving. With that one, the heatsink gets noticeably hot.

Is the black cube pla? That sure looks like it benefited from the extra cooling

The conventional wisdom is that pla will benefit from a part cooling fan, and abs generally doesn't need it, and may suffer weak layers if you use one.

The conventional wisdom is that pla will benefit from a part cooling fan, and abs generally doesn't need it, and may suffer weak layers if you use one.

|

Re: mk 8 extruder stop printing February 07, 2016 01:39PM |

Registered: 8 years ago Posts: 13 |

I noticed on your mk8 that you have a screw which passes through the lower block and into the spring (at least it looks that way to me). My lower block has a hole that passes all the way through but uses a very short M3 x 4 to secure the block to the "U" bracket. A longer screw entering into the base of the spring would keep from shifting to the left and might also add stability especially when coupled with your idea of a spacer. The spacer would have to be metal because of the heat. I have some brass M5 standoffs that might work or I am sure I can find something suitable at a big box store.

The black cube is a PLA/PHA product. The write up says it offers the best of both PLA and ABS. I was extruding at 220 (recommended on the spool) with a bed temp of 45. The deformed portion was due I believe to either too hot an extrusion (lower hotend temp would be better or to the need for object cooling. I turned that fan on for the remainder of the print and it seems like it made all the difference. What I noticed about this PLA/PHA product is that it is somewhat more flexible than the ABS. If I am correct then this product might be perfect for "why I bought a 3d printer", i.e., to build tank body bases and super structures. There is no easy way to do this with Lego plates, bricks, hack saws, and Dremel dirlls/saws.

[www.usefulramblings.org]

The black cube is a PLA/PHA product. The write up says it offers the best of both PLA and ABS. I was extruding at 220 (recommended on the spool) with a bed temp of 45. The deformed portion was due I believe to either too hot an extrusion (lower hotend temp would be better or to the need for object cooling. I turned that fan on for the remainder of the print and it seems like it made all the difference. What I noticed about this PLA/PHA product is that it is somewhat more flexible than the ABS. If I am correct then this product might be perfect for "why I bought a 3d printer", i.e., to build tank body bases and super structures. There is no easy way to do this with Lego plates, bricks, hack saws, and Dremel dirlls/saws.

[www.usefulramblings.org]

|

Re: mk 8 extruder stop printing February 07, 2016 01:49PM |

Registered: 9 years ago Posts: 1,873 |

Yes, the screw in the bottom right of my photo serves double duty as spring guide and the main attachment to hold the extruder into the carriage. Putting a longer screw there if yours doesn't reach all the way through would be a good idea. You want it long enough to stop the bottom of the spring from wandering but not so long that it hits the screw at the other end of the spring.

edit: but then, looking at your photo, it looks like there is another recess there to locate the bottom of the spring? In which case it looks like the best bet is to try and find a stronger spring that will fit.

That filament sounds really interesting. I have a bit of thing about trying lots of different filaments. Verging on an addiction really. Oh well, there are worse things than buying too much printer filament.

Edited 1 time(s). Last edit at 02/07/2016 01:51PM by JamesK.

edit: but then, looking at your photo, it looks like there is another recess there to locate the bottom of the spring? In which case it looks like the best bet is to try and find a stronger spring that will fit.

That filament sounds really interesting. I have a bit of thing about trying lots of different filaments. Verging on an addiction really. Oh well, there are worse things than buying too much printer filament.

Edited 1 time(s). Last edit at 02/07/2016 01:51PM by JamesK.

|

Re: mk 8 extruder stop printing February 07, 2016 11:25PM |

Registered: 8 years ago Posts: 13 |

your are right in your comment about the lower having a recessed "hole" to receive the bottom of the spring. And your right about finding a stronger spring. It would be a better solution. I purchased the filament from: here

[www.usefulramblings.org]

[www.usefulramblings.org]

Sorry, only registered users may post in this forum.