Problems with Larger Nozzles

Posted by 750magna

|

Problems with Larger Nozzles February 17, 2016 02:30PM |

Registered: 10 years ago Posts: 24 |

I've been testing out printing with my E3D v6 and a .8mm nozzle. What I've noticed is a fairly substantial increase in blobs and slight layer misalignment once I start upping the layer thickness. Prints at .3mm layer height look quite good, going up to .4mm I start to see evidence of some small bubbles on the side of the print, but layer alignment still looks good. Once I jump to .6mm things start to get a little bit messier. Layers aren't aligning nearly as well, corners are severely rounded and infill is rough and has holes in it. I know the filament I'm using is good, and my machine is tuned well, so I'm guessing that something to do with print settings isn't working out when I up the layer thickness. I'm using simplify3D BTW.

Has anyone else run into these issues? If so please share tips and or settings you've used to improve quality. I love the reduction in build time these bigger nozzles allow, but if I can't get neatly stacked layers they're going to be a lot less useful.

Thanks

Has anyone else run into these issues? If so please share tips and or settings you've used to improve quality. I love the reduction in build time these bigger nozzles allow, but if I can't get neatly stacked layers they're going to be a lot less useful.

Thanks

|

Re: Problems with Larger Nozzles February 17, 2016 06:30PM |

Registered: 9 years ago Posts: 1,873 |

What layer widths are you using? It seems counter-intuitive for big layers to be more of a problem than small ones, you'd think everything worked in your favour as layer sizes go up, provided you keep within the extrusion rate limit of your hot-end. Have you checked the max rate your hot-end can handle and compared it with the rates you are printing at?

|

Re: Problems with Larger Nozzles February 17, 2016 09:05PM |

Registered: 10 years ago Posts: 24 |

Layer width is set to auto. Simplify 3D calculates that @ .96mm. I've played around with speeds and flow rates too. I'm typically running between 30- 60mm/second which I consider fairly slow and safe. Reducing the flow tends to leave gaps in the infill and poor layer adhesion, so I'm pretty sure I've got that dialed in good.

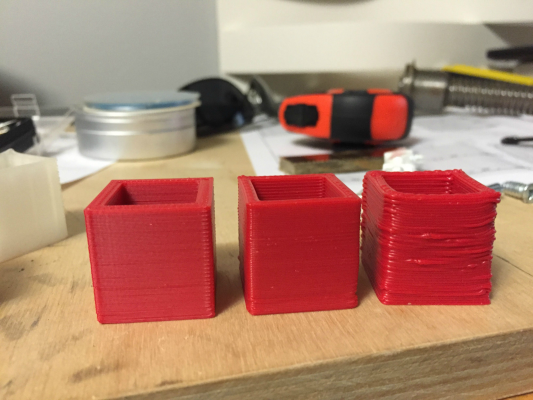

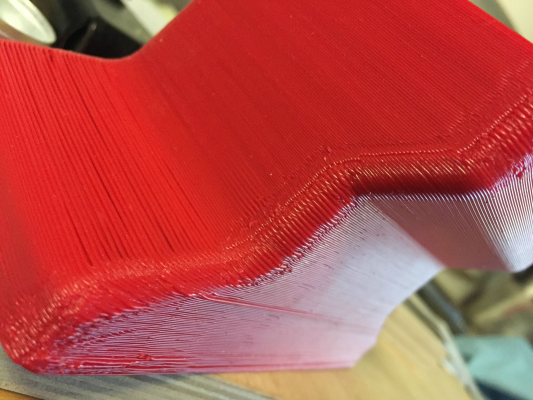

I've attached some images that show a little more about what's going on. For the calibration cubes, the far left is printed with a .4 mm nozzle, the center is with a .8mm nozzle @ .4mm layer height, and the right one is @ .6mm layer height. Below is a larger part I printed. It's single wall and .4mm layer height. One side turned out pretty well while the other side not so much.

I've attached some images that show a little more about what's going on. For the calibration cubes, the far left is printed with a .4 mm nozzle, the center is with a .8mm nozzle @ .4mm layer height, and the right one is @ .6mm layer height. Below is a larger part I printed. It's single wall and .4mm layer height. One side turned out pretty well while the other side not so much.

|

Re: Problems with Larger Nozzles February 17, 2016 09:31PM |

Registered: 9 years ago Posts: 1,873 |

Interesting. If you hadn't told me about the layer height (and showed me the other prints) I would have said it just looks too hot. Maybe try reducing the temperature and see if it cleans up? Not sure why big layers would need a lower temperature though - more retained heat in the larger volume? I should admit I've never tried anything bigger than a 0.4mm nozzle, so I'm just guessing, and hoping to learn from your experience!

|

Re: Problems with Larger Nozzles February 18, 2016 01:46AM |

Registered: 8 years ago Posts: 916 |

Yep, it really looks too hot to me as well. Look at the corners, they're all rounded and curled up -- a sure sign of too much heat (or going too fast so the heat doesn't have time to dissipate between layers).

I'd try adding some cooling as another option to try.

Edited 1 time(s). Last edit at 02/18/2016 01:46AM by nebbian.

I'd try adding some cooling as another option to try.

Edited 1 time(s). Last edit at 02/18/2016 01:46AM by nebbian.

|

Re: Problems with Larger Nozzles February 18, 2016 08:49AM |

Registered: 10 years ago Posts: 37 |

Your problem is heat. It is not that your hotend is too hot for your filament, its that the part is not able to cool since you are putting so much hot plastic down in such a short time. Try a test print with a fan blowing on our part and see if it improves, print 2 at once for a "thermal distraction", or slow your print speed to give the part time to cool off before the next layer goes down

|

Re: Problems with Larger Nozzles February 19, 2016 07:28AM |

Registered: 10 years ago Posts: 550 |

ABS or PLA?

I had to retune the slic3r settings for my 12v 3.00mm E3D volcano completely. Most importantly I had to increase the nozzle temperature for ABS @layer 0.9mm (used to be 0.1 or 0.2mm) to ~260C (used to be 210C) and slow down the print to around 25mm/s (used to be 100-120mm/s). I needed to change these two settings because the ABS didn't stay long enough in the nozzle to get heated up to the correct printing temperature. Bed temperature needed to be increased from my normal 80C to 110C because @80C warping was so strong it even overcame the PEI printplate bonding.

Other thing I had to do was making sure that the diameter of the filament was measured and that that width was set in the slicer making sure that under or over flow of material did not happen, also switched to a single print speed for everything. Using dried ABS was a must.

In the end the prints were nice and I gained 50% in printing time but most impressive thing was the interlayer bonding and using 100% infill the parts were impressively massive and strong.

Edited 3 time(s). Last edit at 02/19/2016 07:32AM by Frans@France.

I had to retune the slic3r settings for my 12v 3.00mm E3D volcano completely. Most importantly I had to increase the nozzle temperature for ABS @layer 0.9mm (used to be 0.1 or 0.2mm) to ~260C (used to be 210C) and slow down the print to around 25mm/s (used to be 100-120mm/s). I needed to change these two settings because the ABS didn't stay long enough in the nozzle to get heated up to the correct printing temperature. Bed temperature needed to be increased from my normal 80C to 110C because @80C warping was so strong it even overcame the PEI printplate bonding.

Other thing I had to do was making sure that the diameter of the filament was measured and that that width was set in the slicer making sure that under or over flow of material did not happen, also switched to a single print speed for everything. Using dried ABS was a must.

In the end the prints were nice and I gained 50% in printing time but most impressive thing was the interlayer bonding and using 100% infill the parts were impressively massive and strong.

Edited 3 time(s). Last edit at 02/19/2016 07:32AM by Frans@France.

|

Re: Problems with Larger Nozzles February 19, 2016 12:16PM |

Registered: 10 years ago Posts: 24 |

I'm printing in ABS. I'm going to try out printing with a fan blowing on the part, and hopefully things will balance out and I won't have issues with warping.

Frans, that's interesting you mention re-tuning for the volcano hotend. I haven't used mine yet, just using the regular E3D with a .8mm nozzle. I'll keep that info in mind when I finally decide to set it up. Going down to 25mm/s sounds like you'd give up most of the speed gains from the thicker layers though.

Even with the .8mm it's nice how much stronger the parts are. Next up for testing will be nylon. As long as I can make sure it's bone dry I hope it will work well.

Frans, that's interesting you mention re-tuning for the volcano hotend. I haven't used mine yet, just using the regular E3D with a .8mm nozzle. I'll keep that info in mind when I finally decide to set it up. Going down to 25mm/s sounds like you'd give up most of the speed gains from the thicker layers though.

Even with the .8mm it's nice how much stronger the parts are. Next up for testing will be nylon. As long as I can make sure it's bone dry I hope it will work well.

|

Re: Problems with Larger Nozzles February 19, 2016 12:36PM |

Registered: 10 years ago Posts: 550 |

Fan and ABS is a very big no-noQuote

750magna

I'm printing in ABS. I'm going to try out printing with a fan blowing on the part, .

it will warp so fast it can be used on starship enterprise

it will warp so fast it can be used on starship enterprise

Please note that when using a large nozzle the total volume coming out of the nozzle is much higher then with the standard 0.4 nozzle. The temperature you are measuring at the nozzle is eaxtly that: nozzle temperature and not plastic temperature! So the filament has less time in the hotend to warm up and you will be extruding colder ABS then when using a smaller nozzle. That is the idea behind the volcano, larger heatblok and longer nozzle so there is more time for the filament to warm up and even then at 25mm/s and 260C the filament is still not that warm...Quote

750magna

I haven't used mine yet, just using the regular E3D with a .8mm nozzle. I'll keep that info in mind when I finally decide to set it up.

A 2 hour print at 100mm/s with the 0.4 nozzle is now a 1 hour print @ 25mm/sQuote

750magna

Going down to 25mm/s sounds like you'd give up most of the speed gains from the thicker layers though.

Note that the print volume speed ~ feedrate * layer height * layer width. So a 100mm/s *.3mm * .4mm = 12mm3/sec where as the volcano will do 25mm/s *.9mm * 1.2mm = 27mm3/sec

So for the same volume the gain will be a factor 27/12 or ~2

I might be able to push the volcano to 30mm/s, I failed at 35mm/s but it might be that replacing the Wade extruder for a full metal extruder would allow for some more pressure and thus have less issues with the lower plastic extrusion temperature.

Edited 6 time(s). Last edit at 02/19/2016 01:03PM by Frans@France.

Sorry, only registered users may post in this forum.