One less plastic part

Posted by the_digital_dentist

|

One less plastic part February 26, 2016 10:38PM |

Registered: 11 years ago Posts: 5,780 |

My printed ABS X axis motor mount has been bothering me for a long time. The motor runs hot and I have been concerned that the heat would warp the plastic or worse. This is one of the last two "functional" plastic pieces in the machine. I intend to get all of them converted to metal.

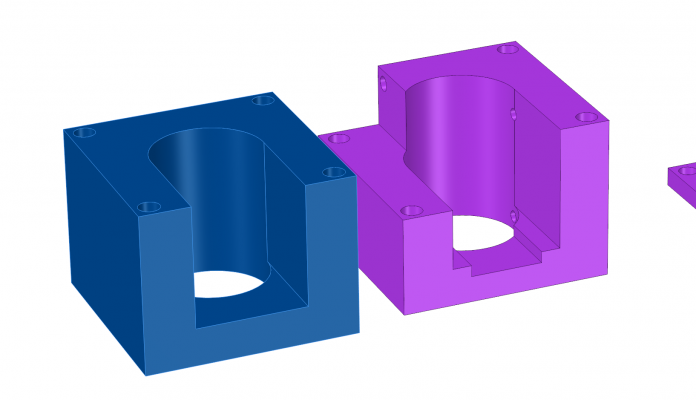

I finally did something about it. I redesigned it to be milled from a block of aluminum, but then saw these on ebay for $22:

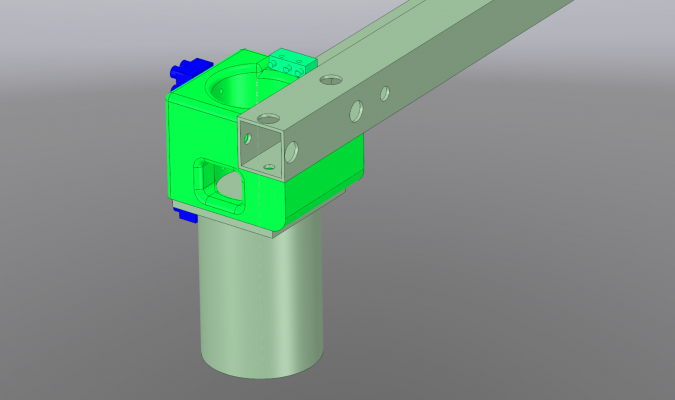

I realized that the hardest part of the milling and drilling was already done, so I ordered one then modified it so that the motor and belt would be in exactly the same positions they are in the plastic motor mount. Modifications involved milling one side and drilling and tapping one hole to attach the block to the aluminum tube that is the "spine" of the X axis, milling a slot to give the belt a little more clearance, and drilling and tapping two holes to mount the terminal block. I printed a limit switch mount to fit.

The end result:

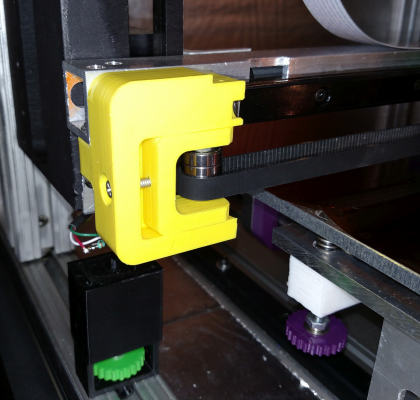

It looks like I was right to be concerned about the heat and the plastic. It looks scorched and the screw holes are distorted:

The final part to replace is the X axis belt tensioner:

Edited 2 time(s). Last edit at 02/26/2016 11:46PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I finally did something about it. I redesigned it to be milled from a block of aluminum, but then saw these on ebay for $22:

I realized that the hardest part of the milling and drilling was already done, so I ordered one then modified it so that the motor and belt would be in exactly the same positions they are in the plastic motor mount. Modifications involved milling one side and drilling and tapping one hole to attach the block to the aluminum tube that is the "spine" of the X axis, milling a slot to give the belt a little more clearance, and drilling and tapping two holes to mount the terminal block. I printed a limit switch mount to fit.

The end result:

It looks like I was right to be concerned about the heat and the plastic. It looks scorched and the screw holes are distorted:

The final part to replace is the X axis belt tensioner:

Edited 2 time(s). Last edit at 02/26/2016 11:46PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: One less plastic part February 27, 2016 05:14AM |

Registered: 8 years ago Posts: 1,671 |

I've seen those mounts around, but couldnt figure a use for them in my setup, if it was a little larger 80mm sqr with 4 extra holes I could use it for Z base, good thinking to adapt it, looks a little trickier on the other end. I managed to cobble together an idler from a standard motor L bracket, and a rod support (tension has to be added my moving or by alternate belt tensioner). I've only a few plastic parts left in mine, but not sure how many I will replace...I'm probably headed in the other direction once printer is making plastic parts, I'll be wanting to add them...maybe just for the second one, i'll try to keep it off the structural parts, and only for holding little parts together.

Edited 1 time(s). Last edit at 02/27/2016 05:53AM by MechaBits.

Edited 1 time(s). Last edit at 02/27/2016 05:53AM by MechaBits.

|

Re: One less plastic part February 27, 2016 10:05AM |

Registered: 11 years ago Posts: 5,780 |

The belt tensioner is probably going to take a lot more milling. I can't think of anything else I can adapt for that job, but I'll be trying. You can see the belt riding low on the pulley- I think it's because the plastic is flexing under the belt tension. IRIC those parts were printed at 50% solid, but they're not stiff enough. I don't think going to 100% fill would fix the problem.

The remaining printed parts are things like thumb wheels, clips to keep the wiring inside the slots in the frame, clips to hold LED light bars, X axis belt clamp, etc., all of which work fine even though they are plastic.

The optical Z axis zero adjuster, which you can see in the last picture, is also printed and may get replaced by a redesigned metal version. I've been seeing some inconsistency in the first layer of prints and I think it is because of slop in that assembly.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The remaining printed parts are things like thumb wheels, clips to keep the wiring inside the slots in the frame, clips to hold LED light bars, X axis belt clamp, etc., all of which work fine even though they are plastic.

The optical Z axis zero adjuster, which you can see in the last picture, is also printed and may get replaced by a redesigned metal version. I've been seeing some inconsistency in the first layer of prints and I think it is because of slop in that assembly.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: One less plastic part February 27, 2016 10:51AM |

Registered: 8 years ago Posts: 67 |

|

Re: One less plastic part February 27, 2016 11:01AM |

Registered: 11 years ago Posts: 5,780 |

Not from the X axis. My Y axis is quite loud and would drown out any noise coming from the X axis.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: One less plastic part February 27, 2016 10:45PM |

Registered: 10 years ago Posts: 553 |

|

Re: One less plastic part February 28, 2016 01:14AM |

Registered: 11 years ago Posts: 5,780 |

What would you like a link to?

You can see the printer by clicking the link in my sig, below.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You can see the printer by clicking the link in my sig, below.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.