Piezoelectric disks for Z contact detect and bed levelling

Posted by leadinglights

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 07, 2017 06:10PM |

Registered: 8 years ago Posts: 487 |

Quote

dart16

OK... so I finally got around to fitting the piezo sensor to my mini kossel, replacing the servo operated optical sensor I had there for bed probing. Can I just say that you guys have the right approach as far as I am concerned... KISS. It works as described..no need to go digital or over complicate the thing.... it is perfect. If I can bludgeon a hole in the middle(ish) of a piezo sensor then anybody can... and it just works. Many thanks to Moriquendi for supplying the board I wouldn't be able to solder surface mount components any more (I can't see them for one thing!!) and ,thanks to everyone else for developing the design and for the ideas...I have re-gained 40mm by remounting the hotend up into the effector with the peizo mount...superb!!...Happy days!!!

I'm glad it's working well for you, keeping things simple is really important I think, the less there is to go wrong the less can go wrong.

As for open source vs closed, if something is successful enough eventually the Chinese will clone it at a fraction of the price. I think that the only way to get paid within RepRap is to try and make sure people want to support the developers, many will simply want the lowest price but some are willing to pay the premium to keep development alive.

Quote

ECJ

Yes! They are two distinct segments, each with its different challenges and results. It is not very pleasant to make comparisons and that is not the intention. I just came here to answer mentions that I would have copied the idea of DjDemonD. It was not my intention to advertise my product.

I don't think anyone's suggesting you copied the design, which is freely available anyway.

Idris

Edited 2 time(s). Last edit at 04/07/2017 06:14PM by Moriquendi.

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 07, 2017 06:20PM |

Registered: 7 years ago Posts: 65 |

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 07, 2017 06:22PM |

Registered: 8 years ago Posts: 3,525 |

Same to you good luck, I do have one question, you have a piezo with a hole in it, how do you drill it?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 07, 2017 06:30PM |

Registered: 7 years ago Posts: 61 |

oops.. he's gone......

I bludgeoned mine with a wood drill...it didn't seem to mind too much...once I had removed the burr. From my (very limited) experience it is not especially critical how the hole is made, providing the ceramic isn't cracked in the process....

Edited 2 time(s). Last edit at 04/07/2017 06:35PM by dart16.

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 07, 2017 07:03PM |

Registered: 7 years ago Posts: 65 |

Yes, it follows an image:

This is a spherical diamond tip for engraving 2mm diameter. Hole with CNC module from my printer. I fixed the disc with double-sided adhesive tape and applied a small amount of silicone oil in the place to be pierced. All this care is necessary because it is ceramic, very hard and brittle material. The hole is perfect without causing micro cracks in the ceramic.

This is a spherical diamond tip for engraving 2mm diameter. Hole with CNC module from my printer. I fixed the disc with double-sided adhesive tape and applied a small amount of silicone oil in the place to be pierced. All this care is necessary because it is ceramic, very hard and brittle material. The hole is perfect without causing micro cracks in the ceramic.

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 08, 2017 03:01AM |

Registered: 12 years ago Posts: 1,450 |

Hi ECJ,

Firstly please let me apologize for any offense that I caused, this was not my intent. In truth I am impressed by how much work you have put into this and possibly a bit envious as my programming skills are seldom used any more.

Your visit to this forum has bought about a great deal of discussion and hopefully done more in one day to bring piezoelectric nozzle contact sensing into the view of the RepRap community than anything else in a long time.

Mike

Firstly please let me apologize for any offense that I caused, this was not my intent. In truth I am impressed by how much work you have put into this and possibly a bit envious as my programming skills are seldom used any more.

Your visit to this forum has bought about a great deal of discussion and hopefully done more in one day to bring piezoelectric nozzle contact sensing into the view of the RepRap community than anything else in a long time.

Mike

Quote

ECJ

Quote

DjDemonD

from the discussion about analogue electronics i.e. Leadinglights's, Moriquendi's and my implementation using an analogue PCB and ECJ's system using his digital microcontroller board. These are two separate but potentially confusing discussions.

Yes! They are two distinct segments, each with its different challenges and results. It is not very pleasant to make comparisons and that is not the intention. I just came here to answer mentions that I would have copied the idea of DjDemonD. It was not my intention to advertise my product.

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 08, 2017 03:30AM |

Registered: 8 years ago Posts: 3,525 |

Dental bur didn't even think of that which is very ironic. That being said my kit at work might not be suitable as it's water cooled although at 350k rpm it'll cut it.

This is making me want to create a dental air turbine handpiece cnc machine.

Edited 1 time(s). Last edit at 04/08/2017 03:46AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

This is making me want to create a dental air turbine handpiece cnc machine.

Edited 1 time(s). Last edit at 04/08/2017 03:46AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 08, 2017 04:54AM |

Registered: 12 years ago Posts: 1,450 |

I have just tried a 2mm diameter flat ended diamond tool and it has cleaned the ceramic off the brass without any overheating, up to now I have used a 2mm diameter tungsten carbide end mill which is getting very blunt as the ceramic seems to be very abrasive.

I have just ordered some genuine Murata discs from Farnell and will try using the diamond tool on these to see how it lasts - I will use a new carbide end mill to go through the brass as brass may block the diamond tool.

BTW, as PZT contains lead, the powder thrown off during machining is potentially hazardous. I think using a lubricant, possibly silicone as ECJ suggested would go a long way to minimizing this risk.

Mike

I have just ordered some genuine Murata discs from Farnell and will try using the diamond tool on these to see how it lasts - I will use a new carbide end mill to go through the brass as brass may block the diamond tool.

BTW, as PZT contains lead, the powder thrown off during machining is potentially hazardous. I think using a lubricant, possibly silicone as ECJ suggested would go a long way to minimizing this risk.

Mike

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 11, 2017 10:07AM |

Registered: 8 years ago Posts: 312 |

You know, even though I have only played a tiny part in all of this, it still gives me great pleasure to see this develop and become useful.

There is a lot of cooperation and sharing of ideas, methods and tests. I simply love it.

So, Leadinglights, Moriquendi and DjDemonD, my compliments to you guys for a job well done and still doing.

There is a lot of cooperation and sharing of ideas, methods and tests. I simply love it.

So, Leadinglights, Moriquendi and DjDemonD, my compliments to you guys for a job well done and still doing.

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 11, 2017 12:39PM |

Registered: 12 years ago Posts: 1,450 |

Thank you Lykle. For my part though, it is just an inability to treat WTF? as a purely rhetorical question. Seeing an 8V pulse from tickling a piezo disk when I expected a few millivolts was a WTF? that re-awakened my training in research. I will keep thwacking piezo disks in different ways until I find out WTF!

I have just been trying out a batch of 10 Murata discs (Murata p/n 7BB-20-6L0, Farnell stock no. 1192520) and they are much more consistent than the no-name brand although they cost £0.64 instead of £0.40. They are also all polarized in the same direction. I will report more in the next few days after I have tried drilling holes in some of them.

Mike

Edit ps. How did your trials of the undrilled mounting work?

Edited 1 time(s). Last edit at 04/11/2017 12:52PM by leadinglights.

I have just been trying out a batch of 10 Murata discs (Murata p/n 7BB-20-6L0, Farnell stock no. 1192520) and they are much more consistent than the no-name brand although they cost £0.64 instead of £0.40. They are also all polarized in the same direction. I will report more in the next few days after I have tried drilling holes in some of them.

Mike

Edit ps. How did your trials of the undrilled mounting work?

Edited 1 time(s). Last edit at 04/11/2017 12:52PM by leadinglights.

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 12, 2017 01:14PM |

Registered: 8 years ago Posts: 312 |

Testing the un-drilled ones is at a standstill at the moment.

All my time is spent on getting the Nimble produced.

But I recently received the new board and a DIY kit for a scope, so perhaps in a few weeks time I can relax a little and work on it.

I am pretty sure the initial idea will work, just need time to test it out. The 20 mm disks fit neatly under the main cylinder of the Nimble. Simple construction, easy to mount and to fiddle with.

All my time is spent on getting the Nimble produced.

But I recently received the new board and a DIY kit for a scope, so perhaps in a few weeks time I can relax a little and work on it.

I am pretty sure the initial idea will work, just need time to test it out. The 20 mm disks fit neatly under the main cylinder of the Nimble. Simple construction, easy to mount and to fiddle with.

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 12, 2017 02:52PM |

Registered: 8 years ago Posts: 3,525 |

So Titan Aero, very popular but how to piezo-it?

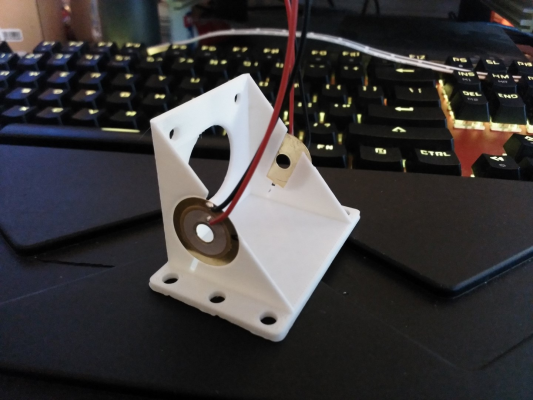

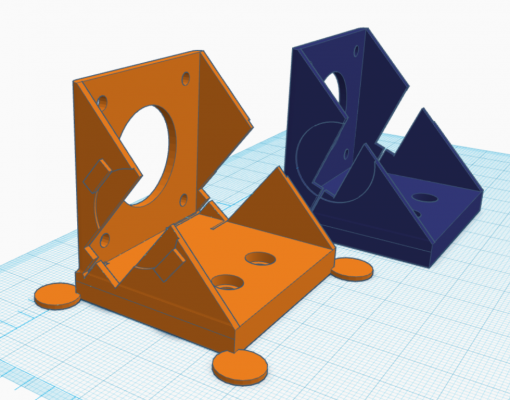

This might be a possibility - it will trigger on a light flex and harks back to Njål Brekke's original piezo carriage design, I have yet to test it (don't have an aero yet but I can test it with a titan).

These do not have to be drilled piezo's, but I have a load of them courtesy of Mike, and figured if it worked with some of his labelled "not great" then it would be very good with some undrilled ones.

Edited 2 time(s). Last edit at 04/12/2017 04:54PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

This might be a possibility - it will trigger on a light flex and harks back to Njål Brekke's original piezo carriage design, I have yet to test it (don't have an aero yet but I can test it with a titan).

These do not have to be drilled piezo's, but I have a load of them courtesy of Mike, and figured if it worked with some of his labelled "not great" then it would be very good with some undrilled ones.

Edited 2 time(s). Last edit at 04/12/2017 04:54PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 15, 2017 03:37PM |

Registered: 8 years ago Posts: 3,525 |

Okay so been trying this out here it is with a titan extruder on my corexy. The discs are bonded in with cyano-adhesive/superglue.

It works but its not perfect, its slightly too mechanically insensitive, so sometimes you get a trigger but the whole assembly bends a little too much before it does, and sometimes not a clear enough trigger. The triggering force is not direct enough like in the hotend mounted module. To get the PCB in the right range requires that VR2 to be set so close to the threshold where the LED changes that it doesn't take much to destabilise it and the tuning drifts off. So not the fault of the electronics, I am just asking for more sensitivity than is reasonable.

So I am trying to tweak the design for the mount to bend the discs more, by leaving a large gap for the disc to span, and extending the cut which creates the "hinge" in the bracket downwards.

I also wonder if it might work better with one piezo rather than two, just thinking if one bend one way and the other bends in the opposite direction I get no signal (they are wired in parallel).

Edited 1 time(s). Last edit at 04/15/2017 03:39PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

It works but its not perfect, its slightly too mechanically insensitive, so sometimes you get a trigger but the whole assembly bends a little too much before it does, and sometimes not a clear enough trigger. The triggering force is not direct enough like in the hotend mounted module. To get the PCB in the right range requires that VR2 to be set so close to the threshold where the LED changes that it doesn't take much to destabilise it and the tuning drifts off. So not the fault of the electronics, I am just asking for more sensitivity than is reasonable.

So I am trying to tweak the design for the mount to bend the discs more, by leaving a large gap for the disc to span, and extending the cut which creates the "hinge" in the bracket downwards.

I also wonder if it might work better with one piezo rather than two, just thinking if one bend one way and the other bends in the opposite direction I get no signal (they are wired in parallel).

Edited 1 time(s). Last edit at 04/15/2017 03:39PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 17, 2017 06:54AM |

Registered: 8 years ago Posts: 312 |

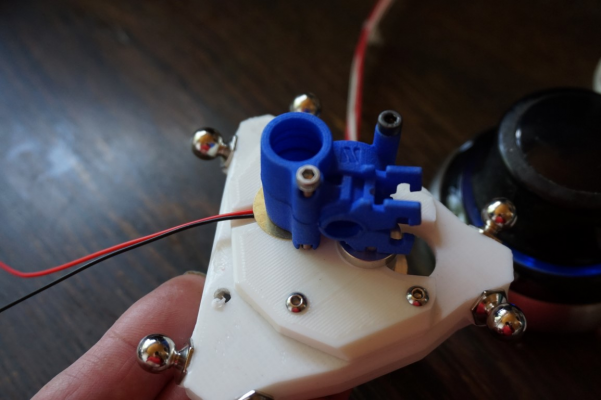

Finally found the time to test this idea properly.

Here I am using the Nimble to transmit the tap force from the hot end to the sensor sitting directly underneath the back of the Nimble.

I am seeing a perfect tap signal in the scope, all I need to do now is mount to to the printer with the sensor board. But happy that so far it works.

Now on to the sensor integration for the Black Widow and such machines. That is going to be just as simple.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

Here I am using the Nimble to transmit the tap force from the hot end to the sensor sitting directly underneath the back of the Nimble.

I am seeing a perfect tap signal in the scope, all I need to do now is mount to to the printer with the sensor board. But happy that so far it works.

Now on to the sensor integration for the Black Widow and such machines. That is going to be just as simple.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 17, 2017 03:39PM |

Registered: 10 years ago Posts: 293 |

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 17, 2017 03:44PM |

Registered: 8 years ago Posts: 3,525 |

Should be about a week or two for a kit (well - drop in unit really, but we could do a kit with a PCB, a couple of pre-drilled piezo's and some cables). It'll be early bird units at first, discounted as there might be teething issues but then we want your feedback. Watch this space (will start a new thread when I have some assembled and tested).

Edited 1 time(s). Last edit at 04/17/2017 03:45PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 04/17/2017 03:45PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 19, 2017 05:16PM |

Registered: 12 years ago Posts: 1,450 |

I have tested my earlier design for a piezo sensor to fit on a watercooled hotend intended for use on my heated Delta printer but the results have been somewhat disappointing. I had hoped to achieve reliable contact pressures in the range of 1 to 2 grams but it looks like that design would be limited to something over 10 grams of contact pressure.

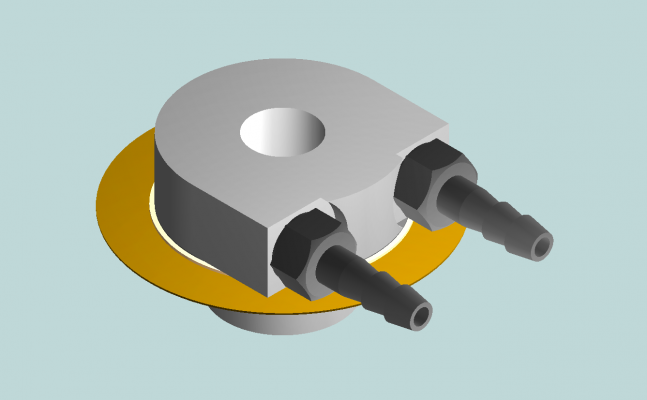

In the hopes of getting back on course I have tried a larger piezo with a very large hole through winch the watercooled heatsink fits this arrangement allows for optimal pressure to be applied to the piezo element. In the CAD view below I have only shown the watercooled heatsink and piezo. Also below is a photo of a 35mm piezo disc with a 16mm hole. This amount of piezo material still gives a very good sensitivity.

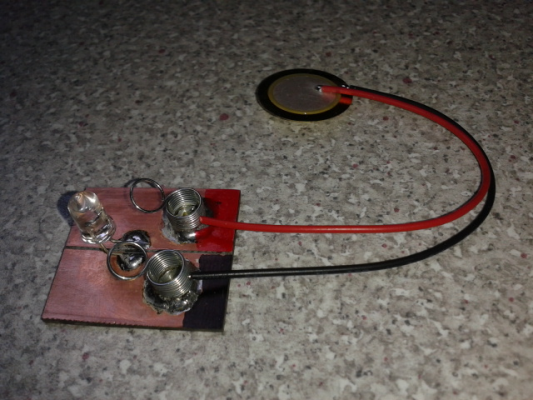

As unbranded piezos come with indeterminate polarization it is useful to be able to check which wire is positive - the colour of the wire is not necessarily correct. To this end I made up a simple jig consisting of a LED with two clips for the wire. Depending on the direction of polarization of the piezo the LED will flash either when pressure is applied or when it is released. Not all LEDs are usable but I did find several in my recovered LED drawer that worked well even with a 10mm diameter piezo disc.

The springs make a good clip for testing, more reliable than ordinary cheap crocodile clips and are an idea that I have only ever seen used on a 1960s electronics instructional kit.

Mike

In the hopes of getting back on course I have tried a larger piezo with a very large hole through winch the watercooled heatsink fits this arrangement allows for optimal pressure to be applied to the piezo element. In the CAD view below I have only shown the watercooled heatsink and piezo. Also below is a photo of a 35mm piezo disc with a 16mm hole. This amount of piezo material still gives a very good sensitivity.

As unbranded piezos come with indeterminate polarization it is useful to be able to check which wire is positive - the colour of the wire is not necessarily correct. To this end I made up a simple jig consisting of a LED with two clips for the wire. Depending on the direction of polarization of the piezo the LED will flash either when pressure is applied or when it is released. Not all LEDs are usable but I did find several in my recovered LED drawer that worked well even with a 10mm diameter piezo disc.

The springs make a good clip for testing, more reliable than ordinary cheap crocodile clips and are an idea that I have only ever seen used on a 1960s electronics instructional kit.

Mike

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 19, 2017 05:40PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 19, 2017 07:09PM |

Registered: 8 years ago Posts: 487 |

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 19, 2017 07:34PM |

Registered: 8 years ago Posts: 3,525 |

It might be relevant to this, there is a thread on duet forum by Russ who is collecting data on sensors, he tried to get his printer to give him 0.000mm range with direct electrical contact from nozzle to bed, managed a range of 0.001mm over 30 probes but couldn't get to 0.000. I contributed some data showing a fairly respectable score for piezo especially given its a fixed probe. But his data for microswitches was impressive most beat Piezos in spread and std deviation but they're either servo or removable so real world repeatability is probably lacking. Tricky to test though as you have to do home, probe, home, probe which means your endstops factor in too. Which lead to musings on how to test endstops.

Perhaps with 1g probing force we would see these very small ranges is what I'm wittering on about.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Perhaps with 1g probing force we would see these very small ranges is what I'm wittering on about.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 19, 2017 08:16PM |

Registered: 9 years ago Posts: 1,873 |

I guess I ought to do the math, but I'm somewhat surprised that sub-micron accuracy is either necessary or achievable. A Z0 datum of half the layer height should be perfectly workable, and for distortion correction perhaps a little better is desirable. My virtual napkin calculation suggests anything with a repeatability of 20 to 30 microns should be fine. I'm currently printing on a bed that could do double duty as a cereal bowl using a simple tactile switch pushed onto the nozzle for probing, and loving the ease of use that it has provided.

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 19, 2017 09:11PM |

Registered: 8 years ago Posts: 916 |

Regarding how accurate it needs to be, I find that a change of 0.04 mm is visible in the first layer. It can be the difference between layer lines not quite right, and layer lines perfect. If your sensor is repeatable to less than half that value, then you should be golden. So that works out to roughly 0.02mm. JamesK says 20 to 30 microns, which is pretty much what I've found through experimentation.

I'm starting to get curious enough about this to try it. Is there a circuit diagram somewhere?

I'm starting to get curious enough about this to try it. Is there a circuit diagram somewhere?

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 20, 2017 02:33AM |

Registered: 8 years ago Posts: 3,525 |

[reprap.org]

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 20, 2017 04:06AM |

Registered: 12 years ago Posts: 1,450 |

In the past many people have given reasons why piezoelectric discs would not work, most of these reasons have been shown to be false but the claim that pushing a hot nozzle against the build surface is a bad thing has never been totally dismissed. On my Cartesian printer I have the amplifier set very insensitive to combat the shaking at the end of X and Y moves. The contact pressure was about 100 grams and the time the nozzle remained in contact with the bed was about 16ms. Examining the bed surface under a 40X microscope with oblique lighting there was a barely visible mark on blue tape but nothing on Kapton. Repeating on my Delta printer at 10 grams pressure there was nothing on any surface but when I set the pressure to 20 grams there was again a very faint mark on blue paper.

Since 10 grams is good, having a bit of wiggle room would be better. The target is 1 or 2 grams with 5 grams as a fallback position.

Mike

Since 10 grams is good, having a bit of wiggle room would be better. The target is 1 or 2 grams with 5 grams as a fallback position.

Mike

Quote

Moriquendi

I started on a kit with spring connectors like that and I've just bought my daughter one too, they still make them.

What are the advantages of very low contact pressure? I'd have thought that 1 gram or 10 grammes wouldn't matter provided it was consistent.

Idris

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 20, 2017 04:36AM |

Registered: 8 years ago Posts: 916 |

Thanks. Is there a higher resolution schematic available? That one is really hard to read.

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 20, 2017 04:52AM |

Registered: 8 years ago Posts: 487 |

Quote

nebbian

Thanks. Is there a higher resolution schematic available? That one is really hard to read.

Here you go

I have PCBs made up and ready to post if you prefer, £10 including UK postage.

Idris

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 20, 2017 04:59AM |

Registered: 8 years ago Posts: 3,525 |

I am going to send a module or kit to someone else in Oz, Nebbian, if you wanted we could do combined postage, I am presuming national post would not be too dramatic for one of you to send the other their half of the package, it'll be a week or two though.

Edited 1 time(s). Last edit at 04/20/2017 05:00AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 04/20/2017 05:00AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 20, 2017 06:33AM |

Registered: 7 years ago Posts: 65 |

Quote

leadinglights

In the past many people have given reasons why piezoelectric discs would not work, most of these reasons have been shown to be false but the claim that pushing a hot nozzle against the build surface is a bad thing has never been totally dismissed. On my Cartesian printer I have the amplifier set very insensitive to combat the shaking at the end of X and Y moves. The contact pressure was about 100 grams and the time the nozzle remained in contact with the bed was about 16ms. Examining the bed surface under a 40X microscope with oblique lighting there was a barely visible mark on blue tape but nothing on Kapton. Repeating on my Delta printer at 10 grams pressure there was nothing on any surface but when I set the pressure to 20 grams there was again a very faint mark on blue paper.

Since 10 grams is good, having a bit of wiggle room would be better. The target is 1 or 2 grams with 5 grams as a fallback position.

Mike

I do not understand why you care about this question of probing with the heated nozzle. Of course there is variation with heating, but I assume it's always the same. Here I do the probing with the cold nozzle and compensated with z offset and never had problems.

Is there really any plausible reason to probe with the heated nozzle? I wonder what it is.

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 20, 2017 06:48AM |

Registered: 9 years ago Posts: 1,873 |

Quote

ECJ

I do not understand why you care about this question of probing with the heated nozzle. Of course there is variation with heating, but I assume it's always the same. Here I do the probing with the cold nozzle and compensated with z offset and never had problems.

Is there really any plausible reason to probe with the heated nozzle? I wonder what it is.

The heated nozzle is primarily a convenience issue - one of the key advantages of any nozzle based probing system is not having to figure out the probe to nozzle offset, so having to figure an offset back in again to allow for thermal expansion is a bit of a nuisance. There's also the question of plastic on the nozzle if you probe cold, where as if you probe hot any residual plastic should get pushed out of the way. Still, both of those factors can be work around, so probing with a cold nozzle is certainly workable if someone is very concerned about their printing surface getting marked. On the other hand, if you have a warpy bed like the typical pcb surface, it's important to have the bed at printing temperature to get meaningful results.

|

Re: Piezoelectric disks for Z contact detect and bed levelling April 20, 2017 07:50AM |

Registered: 8 years ago Posts: 3,525 |

My thoughts are probe at 130 deg C nozzle temp (below ooze temp) with bed fully heated to 1st layer temperature for the material you intend to print. You wont damage your bed at this temperature for the brief contact involved.

The hot nozzle ensures that any residual plastic at the nozzle has minimal/no effect on your probed height. Of course you should clip it with a wire cutter or whatever beforehand but we're all human and forget occasionally. The heated bed because some (probably a lot) of beds, deform when heated and therefore grid levelling or delta autocalibration will be a poor fit for the actual bed surface.

The effect of thermal expansion is minimal we did a calculation based on an e3d hotend where the nozzle, heater block and the lowest part of the heatbreak are expected to expand when heated from 130 deg C to 250 deg C it was only 0.02mm, so account for it it you want but its probably not worth it, however from 20 degrees to 250 degrees its more like 0.035 which may have more of an effect.

As for not having to have any z- offset, currently this is not realistic, as there has to be some vertical compliance in the probing module to get a reliable trigger, less so with later module designs, which pre-load the piezo more, but still in the order of 0.1-0.2mm. So I set -0.1 in firmware, and occasionally babystep up/down 0.05mm.

Perhaps referring to the earlier post by Mike about getting a probe to trigger at 1g of force, we might get a result which genuinely requires no offset except thermal if you're bothered by 20 microns error.

But sure probe with a cold nozzle (but a hot bed) if you want to and then work out the offset.

Edited 1 time(s). Last edit at 04/20/2017 07:52AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

The hot nozzle ensures that any residual plastic at the nozzle has minimal/no effect on your probed height. Of course you should clip it with a wire cutter or whatever beforehand but we're all human and forget occasionally. The heated bed because some (probably a lot) of beds, deform when heated and therefore grid levelling or delta autocalibration will be a poor fit for the actual bed surface.

The effect of thermal expansion is minimal we did a calculation based on an e3d hotend where the nozzle, heater block and the lowest part of the heatbreak are expected to expand when heated from 130 deg C to 250 deg C it was only 0.02mm, so account for it it you want but its probably not worth it, however from 20 degrees to 250 degrees its more like 0.035 which may have more of an effect.

As for not having to have any z- offset, currently this is not realistic, as there has to be some vertical compliance in the probing module to get a reliable trigger, less so with later module designs, which pre-load the piezo more, but still in the order of 0.1-0.2mm. So I set -0.1 in firmware, and occasionally babystep up/down 0.05mm.

Perhaps referring to the earlier post by Mike about getting a probe to trigger at 1g of force, we might get a result which genuinely requires no offset except thermal if you're bothered by 20 microns error.

But sure probe with a cold nozzle (but a hot bed) if you want to and then work out the offset.

Edited 1 time(s). Last edit at 04/20/2017 07:52AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Sorry, only registered users may post in this forum.