backlash trouble

Posted by icefire

|

backlash trouble March 05, 2016 09:00AM |

Registered: 8 years ago Posts: 168 |

So I've been experimenting lately with backlash compensation in Repetier Firmware.

My initial situation was that I was able to print pretty accurate parts if they are mainly polygonal but round parts didn't seem to be really what I wanted them to be. Circles used to turn out elliptic, egg-shaped, etc.

What I did was use woodmoke's guide to calculate my X and Y backlash. After entering the calculated values in the EEPROM Settings of Repetier FW, the accuracy of circles got dramatically improved.

Image before adjusting backlash: Circles far away from perfect, especially around 5 o'clock:

Image after adjusting backlash: Measuring different diameters results in about 0,07mm deviation which makes it a pretty good circle. Still not perfect but I still much better.

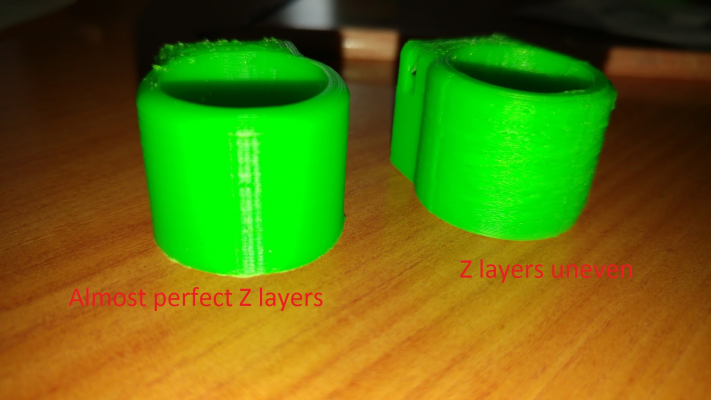

Now circles are almost perfectly round but there a new issue occurred. The printer doesn't print the circles as smoothly as it used to. I hope this makes sense to you. Earlier (before the backlash compensation), the X and Y axis used to move smoothly to print the circle. Now the movement is jerky and not really smooth.Circle accuracy improved but there are some blobs in the layers which later result in uneven Z layers.

These "blobs" are not along the whole circumference of the circle. Only where I suppose that the firmware has compensated for the backlash. These parts of the circle which have the blobs also get the uneven layers in Z.

Here are the blobs (sorry for the bad pic, I was shooting while the heated bed was moving):

And here is the result of the blobs:

In order to better see what I am talking about I shot a short video illustrating the issue. You can clearly see the blobs and how the Z axis "bounces" off them. Tried to print without Z lift but it didn't help even a little bit.

[goo.gl]

So what should I do? Maybe it would be best to just eliminate the hardware backlash so that I don't need any software compensation. But my belt tension is ok, belts are moving freely (no friction or contact to other parts), no slipping of the pulleys on the motor, etc.

So what do you suggest?

Any help is greatly appreciated

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

My initial situation was that I was able to print pretty accurate parts if they are mainly polygonal but round parts didn't seem to be really what I wanted them to be. Circles used to turn out elliptic, egg-shaped, etc.

What I did was use woodmoke's guide to calculate my X and Y backlash. After entering the calculated values in the EEPROM Settings of Repetier FW, the accuracy of circles got dramatically improved.

Image before adjusting backlash: Circles far away from perfect, especially around 5 o'clock:

Image after adjusting backlash: Measuring different diameters results in about 0,07mm deviation which makes it a pretty good circle. Still not perfect but I still much better.

Now circles are almost perfectly round but there a new issue occurred. The printer doesn't print the circles as smoothly as it used to. I hope this makes sense to you. Earlier (before the backlash compensation), the X and Y axis used to move smoothly to print the circle. Now the movement is jerky and not really smooth.Circle accuracy improved but there are some blobs in the layers which later result in uneven Z layers.

These "blobs" are not along the whole circumference of the circle. Only where I suppose that the firmware has compensated for the backlash. These parts of the circle which have the blobs also get the uneven layers in Z.

Here are the blobs (sorry for the bad pic, I was shooting while the heated bed was moving):

And here is the result of the blobs:

In order to better see what I am talking about I shot a short video illustrating the issue. You can clearly see the blobs and how the Z axis "bounces" off them. Tried to print without Z lift but it didn't help even a little bit.

[goo.gl]

So what should I do? Maybe it would be best to just eliminate the hardware backlash so that I don't need any software compensation. But my belt tension is ok, belts are moving freely (no friction or contact to other parts), no slipping of the pulleys on the motor, etc.

So what do you suggest?

Any help is greatly appreciated

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 05, 2016 09:24AM |

Registered: 11 years ago Posts: 5,780 |

If the machine is belt driven and the pulleys are tightly affixed to the motor shafts and the belts are tensioned properly, there shouldn't be any significant/visible backlash. If the extruder carriage or the bed wobble on their guide rails you need to fix them. Make sure the filament is freely coming off the spool and not dragging and pulling against the mechanism. You have a mechanical problem that should be solved with a mechanical solution.

It looks like you're over extruding, too. Have you calibrated the extruder?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It looks like you're over extruding, too. Have you calibrated the extruder?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: backlash trouble March 05, 2016 12:46PM |

Registered: 8 years ago Posts: 168 |

Quote

the_digital_dentist

If the extruder carriage or the bed wobble on their guide rails you need to fix them.

How to test this objectively? There is no visible wobble.

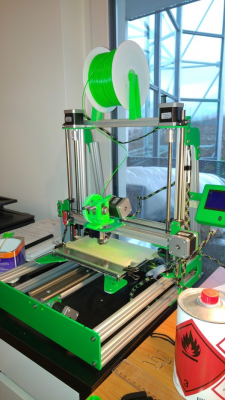

Bed and extruder carriage is belt driven with GT2 pulleys.The printer looks like this:

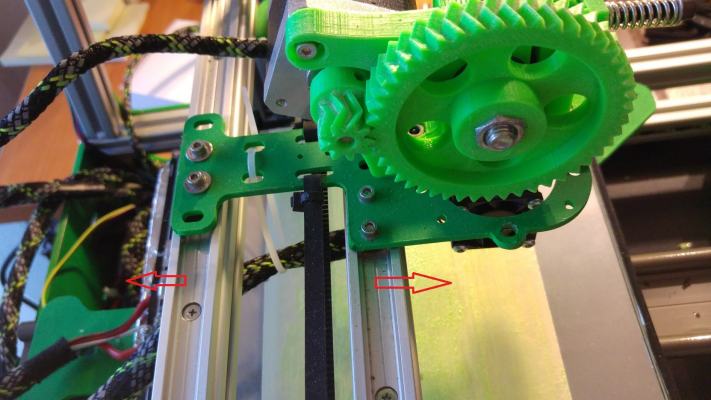

The X axis worries me a little bit. The linear guides is an IGUS system:

[www.igus.de]

However, it did have a little bit of play (even though I ordered preload carriages with no play) so I kinda pulled the two rails apart so that there is real tension on the X axis.

Now there is zero play. But how to test if there is any wobble on the axes? There is none that I can see. And still, I cannot print round circles without backlash compensation.

Still banging my head...

PS.: As far as overextrusion is concerned, the extruder is calibrated. Larger pieces print beautifully with no overextrusion whatsoever. Smaller parts like these liner bushing holders tend to look overextruded indeed, even though I use lower temperatures and print more than one, so that the layers have some time to cool down. Could be a retraction issue - I recently switched from bowden to direct setup and haven't found out the optimal retraction settings. I retract 1mm at the moment - just to have something for starters. As far as the filament is concerned - it spools off the coil with no resistance.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 05, 2016 12:58PM |

Registered: 10 years ago Posts: 550 |

If my circles were not rond the first thing I would do is check my x and y steps / mm calculations, or is a square cube 100% square?

I also see a graphics lcd ? It this a mega/ramp setup? Is the print speed low enough for the mega to handle the calculations & display?

Really surprised by the thin looking carriage! There is no flex in it? Also the belts can not bend that small insert they are connected to?

Edited 3 time(s). Last edit at 03/05/2016 01:01PM by Frans@France.

I also see a graphics lcd ? It this a mega/ramp setup? Is the print speed low enough for the mega to handle the calculations & display?

Really surprised by the thin looking carriage! There is no flex in it? Also the belts can not bend that small insert they are connected to?

Edited 3 time(s). Last edit at 03/05/2016 01:01PM by Frans@France.

|

Re: backlash trouble March 05, 2016 01:06PM |

Registered: 9 years ago Posts: 1,873 |

Quote

I kinda pulled the two rails apart so that there is real tension on the X axis

That doesn't fill me with confidence. If you remove the belts the axis should move smoothly and easily across the full travel, i.e. you should be able to move it easily with your pinky finger. The stepper motors generate large torque for large movements, but a circle is worst case for the motor - the velocity slows to zero and reverses. During the reversal the available torque is small and a sticky axis will freeze once the torque falls below that needed to break the static friction, producing a straight segment in the circle. A belt drive is essentially backlash free, provided the axis is very low friction.

|

Re: backlash trouble March 05, 2016 01:46PM |

Registered: 8 years ago Posts: 168 |

Quote

Frans@France

If my circles were not rond the first thing I would do is check my x and y steps / mm calculations, or is a square cube 100% square?

I also see a graphics lcd ? It this a mega/ramp setup? Is the print speed low enough for the mega to handle the calculations & display?

Really surprised by the thin looking carriage! There is no flex in it? Also the belts can not bend that small insert they are connected to?

X and Y steps are correctly calculated, square parts print well enough.

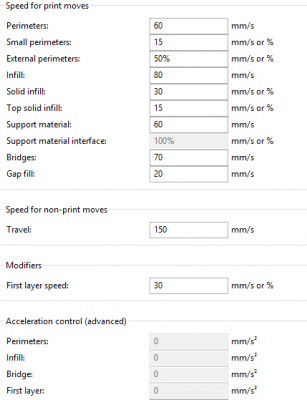

It is a ramps/mega setup (see my signature), lowering the speed hasn't helped. Here is my current speed setup:

I doubt that the belts bend the aluminum parts or that the carriage bends. There is no deformation I can see with a naked eye.

Quote

JamesK

Quote

I kinda pulled the two rails apart so that there is real tension on the X axis

That doesn't fill me with confidence. If you remove the belts the axis should move smoothly and easily across the full travel, i.e. you should be able to move it easily with your pinky finger. The stepper motors generate large torque for large movements, but a circle is worst case for the motor - the velocity slows to zero and reverses. During the reversal the available torque is small and a sticky axis will freeze once the torque falls below that needed to break the static friction, producing a straight segment in the circle. A belt drive is essentially backlash free, provided the axis is very low friction.

I am probably going to opt for another kinematics setup. As a first step I will reduce the preload on the X carriage and see if there is any change/improvement. As you can see in my signature I have increased the current on the X motor (motor drivers are actively cooled).

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 05, 2016 03:00PM |

Registered: 11 years ago Posts: 5,780 |

The two bushings under the extruder are closer together than the distance from them to the third (on the left in your picture) bushing. Your belt pulls on the extruder carriage (which looks pretty flimsy- is it metal or plastic?) between the bushings. That will all lead to instability- your extruder carriage is "walking" along the X axis where it shifts at an angle each time the direction reverses, and maybe even as it moves along in one direction. You need to increase the spacing between the two bushings under the extruder and probably move the belt attachment points apart so they are outside the envelope of the bushings.

Better yet, get one of these: [www.ebay.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Better yet, get one of these: [www.ebay.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: backlash trouble March 05, 2016 03:47PM |

Registered: 8 years ago Posts: 168 |

Quote

the_digital_dentist

The two bushings under the extruder are closer together than the distance from them to the third (on the left in your picture) bushing. Your belt pulls on the extruder carriage (which looks pretty flimsy- is it metal or plastic?) between the bushings. That will all lead to instability- your extruder carriage is "walking" along the X axis where it shifts at an angle each time the direction reverses, and maybe even as it moves along in one direction. You need to increase the spacing between the two bushings under the extruder and probably move the belt attachment points apart so they are outside the envelope of the bushings.

Better yet, get one of these: [www.ebay.com]

I understand your point, but there will be no wobble of the X carriage (3mm aluminum, no plastic) if the linear bushings are play free. This is exactly what I have achieved by pulling apart the two extrusion profiles with the rails mounted on them. If I attempt shaking the X carriage by hand there is no movement of the carriage relative to the X brigde, instead of this the whole printer starts rocking. So the construction is stable. I just reduced the amount of tension on the bushings and currently a test part is printing. I"ll write back in 5 min if anything has changed.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 05, 2016 04:02PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: backlash trouble March 05, 2016 04:16PM |

Registered: 11 years ago Posts: 5,780 |

The bushing surfaces are plastic and will deform under load. I wouldn't trust it to work the way you think it's working.

See [www.igus.com]

Edited 1 time(s). Last edit at 03/05/2016 04:16PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

See [www.igus.com]

Edited 1 time(s). Last edit at 03/05/2016 04:16PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: backlash trouble March 05, 2016 04:50PM |

Registered: 8 years ago Posts: 168 |

Same thing after changing the tension.

Here is a video of me moving it with my pinky finger

I wonder why the blobs from my first post come from.

@ the_digital_dentist: you are probably right. However, if it were true that this design is so bad , this would mean that all mendelmax 2 users in the world have the exactly same problem. An they obviously don't. So I guess that I am doing something wrong.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

Here is a video of me moving it with my pinky finger

I wonder why the blobs from my first post come from.

@ the_digital_dentist: you are probably right. However, if it were true that this design is so bad , this would mean that all mendelmax 2 users in the world have the exactly same problem. An they obviously don't. So I guess that I am doing something wrong.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 05, 2016 05:17PM |

Registered: 10 years ago Posts: 550 |

|

Re: backlash trouble March 05, 2016 05:23PM |

Registered: 10 years ago Posts: 550 |

Quote

icefire

Quote

Frans@France

I also see a graphics lcd ? It this a mega/ramp setup? Is the print speed low enough for the mega to handle the calculations & display?

It is a ramps/mega setup (see my signature), lowering the speed hasn't helped. Here is my current speed setup:

I still think it's a performance issue with the 8bit Arduino. The graphics together with the speed and extra calculations would generate that jerky movement. It's a well know issue specially for the delta's. I have no idea how "heavy" the repetier FW is. Do you also use 1/32 stepping?

|

Re: backlash trouble March 05, 2016 05:26PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: backlash trouble March 05, 2016 05:39PM |

Registered: 11 years ago Posts: 5,780 |

Quote

icefire

@ the_digital_dentist: you are probably right. However, if it were true that this design is so bad , this would mean that all mendelmax 2 users in the world have the exactly same problem. An they obviously don't. So I guess that I am doing something wrong.

OK, if the motion is OK, maybe the problem is the graphic LCD- try disconnecting it and run the print from a host computer.

Edited 1 time(s). Last edit at 03/05/2016 05:43PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: backlash trouble March 05, 2016 05:39PM |

Registered: 8 years ago Posts: 168 |

Quote

Frans@France

I still think it's a performance issue with the 8bit Arduino. The graphics together with the speed and extra calculations would generate that jerky movement. It's a well know issue specially for the delta's. I have no idea how "heavy" the repetier FW is. Do you also use 1/32 stepping?

Yes, I use 1/32 microstepping. What would you suggest in order to test performance? I could print directly from a sd card (which means that graphics remain on) or I could unplug the graphics controller and try again...

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 05, 2016 07:33PM |

Registered: 8 years ago Posts: 168 |

Just printed one test part without graphics controller... maybe it is a bit better, but still no joy. About 0.5 mm deviation in diameter (i.e. still egg-shaped). Still looking for the root cause..

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 05, 2016 08:43PM |

Registered: 11 years ago Posts: 5,780 |

Check the Y axis motion.

Have you ever checked X and Y axes for orthogonality? Print a square and measure the diagonals. If they aren't the same, you'll never be able to print a circle.

Edited 1 time(s). Last edit at 03/05/2016 08:44PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Have you ever checked X and Y axes for orthogonality? Print a square and measure the diagonals. If they aren't the same, you'll never be able to print a circle.

Edited 1 time(s). Last edit at 03/05/2016 08:44PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: backlash trouble March 05, 2016 09:14PM |

Registered: 9 years ago Posts: 517 |

Quote

icefire

Just printed one test part without graphics controller... maybe it is a bit better, but still no joy. About 0.5 mm deviation in diameter (i.e. still egg-shaped). Still looking for the root cause..

If this is Marlin, just unplugging the display won't change anything. The code that drives the display still runs. You need to recompile without a defined display to see a real difference.

|

Re: backlash trouble March 06, 2016 07:35AM |

Registered: 10 years ago Posts: 550 |

I believe he is using repetier FW but I just checked their website and for this firmware you also need to adjust the config file and recompile & upload it..Quote

ElmoC

Quote

icefire

Just printed one test part without graphics controller... maybe it is a bit better, but still no joy. About 0.5 mm deviation in diameter (i.e. still egg-shaped). Still looking for the root cause..

If this is Marlin, just unplugging the display won't change anything. The code that drives the display still runs. You need to recompile without a defined display to see a real difference.

Edited 1 time(s). Last edit at 03/06/2016 07:35AM by Frans@France.

|

Re: backlash trouble March 06, 2016 02:58PM |

Registered: 8 years ago Posts: 168 |

I commented the display settings in configuration.h and uploaded it again. However, this didn't help. I am going to check the orthogonality with some test cubes.

In the meantime I cannot understand why these bubbles started appearing:

As my video above shows, the whole X carriage bounces off them. I don't get it - they were never there and came up when I used backlash compensation in Repetier FW. However, now they won't go away, so maybe it was a coincidence. The bed is perfectly level. Anyway, maybe this is an unrelated issue. Now I am focusing on finding some mechanical fault.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

In the meantime I cannot understand why these bubbles started appearing:

As my video above shows, the whole X carriage bounces off them. I don't get it - they were never there and came up when I used backlash compensation in Repetier FW. However, now they won't go away, so maybe it was a coincidence. The bed is perfectly level. Anyway, maybe this is an unrelated issue. Now I am focusing on finding some mechanical fault.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 06, 2016 03:02PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: backlash trouble March 06, 2016 04:24PM |

Registered: 8 years ago Posts: 168 |

Well, I simply reduced the outside shell thicknes, so that the slicer adds a little bit if infill between the inner and outer perimeters. This solved it for now. I am going to troubleshoot this when I'm done with my mechanical problems...

...which leads me to the next major breakthrough for tonight (at least in my time zone): I think I found where the backlash is coming from. And guess what - it is not the X axis.

My Y axis consists of the following IGUS system: [www.igus.de] (ws-10-40 with wj200um-01-10 to be precise). Well... there is tremendous play in the carriages. The following videos shows what happens when I turn the pulley of the Y motor back and forth by hand. The belt moves, and the bushing shell (housing) moves in turn, but not the "drylin" insert. Have a look for yourself:

[goo.gl]

I hope to find a way to eliminate this play... which would probably solve the issue.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

...which leads me to the next major breakthrough for tonight (at least in my time zone): I think I found where the backlash is coming from. And guess what - it is not the X axis.

My Y axis consists of the following IGUS system: [www.igus.de] (ws-10-40 with wj200um-01-10 to be precise). Well... there is tremendous play in the carriages. The following videos shows what happens when I turn the pulley of the Y motor back and forth by hand. The belt moves, and the bushing shell (housing) moves in turn, but not the "drylin" insert. Have a look for yourself:

[goo.gl]

I hope to find a way to eliminate this play... which would probably solve the issue.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 06, 2016 04:40PM |

Registered: 9 years ago Posts: 1,873 |

Interesting, but as long as the carriage moves with the belt, I don't think that the insert having some back and forward play in the direction of motion makes any difference. Now if it has any side to side play, that might be a different matter. Still, it sure looks unsettling, so I can understand you wanting to remove that play!

|

Re: backlash trouble March 07, 2016 02:47PM |

Registered: 8 years ago Posts: 168 |

Well, the carriage does move with the belt but the play creates a completely different load on the motor when moving the carriage more than 0,2-0,3mm, so I guess the influence of this play should not be underestimated. I am going to eliminate it and then see what happens.

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 07, 2016 07:44PM |

Registered: 11 years ago Posts: 973 |

[/quote]

How to test this objectively? There is no visible wobble.

Bed and extruder carriage is belt driven with GT2 pulleys.The printer looks like this:

[/quote]

I have a single plate i3 and my experience with having my reel on top especially those white ones cos they bound to tight in my opinion if it doesn't come of freely enough it will drag you x

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

How to test this objectively? There is no visible wobble.

Bed and extruder carriage is belt driven with GT2 pulleys.The printer looks like this:

[/quote]

I have a single plate i3 and my experience with having my reel on top especially those white ones cos they bound to tight in my opinion if it doesn't come of freely enough it will drag you x

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: backlash trouble March 08, 2016 06:22AM |

Registered: 8 years ago Posts: 155 |

Are yuo useing Slic3r for the slicing? (repetier has slic3r)? Those blobs I see in the pictures look like a bug in slc3r: the GAP filling. If you are useing slic3r, try setting GAP speed to 0 and test again.

By the way: I have the same problem than you with circles, still trying to solve it.

By the way: I have the same problem than you with circles, still trying to solve it.

|

Re: backlash trouble March 10, 2016 01:55PM |

Registered: 8 years ago Posts: 168 |

The reel is not tight, it spools off with almost no resistance. As far as the blobs are concerned, it was the slic3r gap filling. Using Cura or changing the gap settings solves this. I am still struggling to find some better backlash root cause...

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 14, 2016 08:43AM |

Registered: 8 years ago Posts: 168 |

So I modified the igus carriages so that there is almost no play. This reduced backlash a lot. However, there is still a bit backlash left which I need to compensate in the FW (significantly less than before but still).

My goal is to eliminate all sources of backlash so that I do not need to compensate anything in the firmware. Software compensation has nasty side effects (accuracy of circles is improved, accuracy of everything else gets worse).

So, since I cannot find anything else, I want to ask about the influence of the belt/pulley system. For the X and Y axis I am using a GT2 belt with a 20 tooth pulley, both of them bought from the Chinese site aliexpress.com. Do you think that I should replace the belt and pulleys with such from a more respectable seller? I am thinking of the Dutch site reprapuniverse.com (EU shipping is crucial).

I have no experience in this field so I don't know if the belt and pulleys differ in quality and if the problem could be that I have a Chinese set of belt and pulleys.... What do you think?

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

My goal is to eliminate all sources of backlash so that I do not need to compensate anything in the firmware. Software compensation has nasty side effects (accuracy of circles is improved, accuracy of everything else gets worse).

So, since I cannot find anything else, I want to ask about the influence of the belt/pulley system. For the X and Y axis I am using a GT2 belt with a 20 tooth pulley, both of them bought from the Chinese site aliexpress.com. Do you think that I should replace the belt and pulleys with such from a more respectable seller? I am thinking of the Dutch site reprapuniverse.com (EU shipping is crucial).

I have no experience in this field so I don't know if the belt and pulleys differ in quality and if the problem could be that I have a Chinese set of belt and pulleys.... What do you think?

Self-sourced Mendelmax 2.0-based Reprap Machine -- Ramps 1.4 & Mega 2560 -- DRV8825 (Z@1A, [email protected], [email protected], E@1A) -- genuine E3D v6 direct setup -- 350W custom silicone heated bed -- ABS 1,75mm -- Marlin 1.1.0-RC7 -- Cura 15.04.6

|

Re: backlash trouble March 14, 2016 08:57AM |

Registered: 9 years ago Posts: 1,873 |

It's hard to argue against quality, but I have several sets of Chinese belts and pulleys and I can't see anything wrong with them. I might be wrong, but it would be pretty low on my list of places to look for problems.

I sure wish I could take a look at your machine - everything sounds well done and it's hard to imagine where the problem is coming from!

I sure wish I could take a look at your machine - everything sounds well done and it's hard to imagine where the problem is coming from!

Sorry, only registered users may post in this forum.