Z Axis Belt drive

Posted by cozmicray

|

Z Axis Belt drive April 08, 2016 05:49PM |

Registered: 11 years ago Posts: 1,049 |

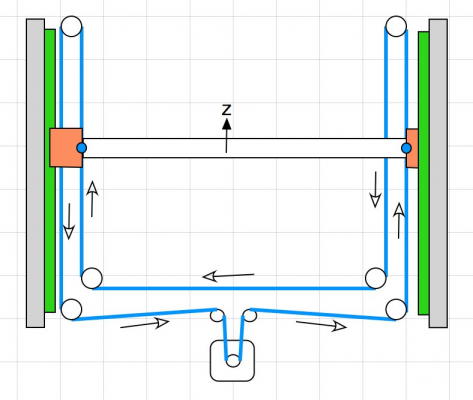

How about a belt drive Z axis?

Anybody out there do a Z-Axis using belts instead of lead screws

The deltas run up/down on belts?

Something like this using one motor

Green are glide rails, Orange glide trollies, Blue belt

Have to look at belt forces and whatnot to balance out

pull and tug?

Cheaper than leadscrews?

May have higher resolution?

Anybody out there do a Z-Axis using belts instead of lead screws

The deltas run up/down on belts?

Something like this using one motor

Green are glide rails, Orange glide trollies, Blue belt

Have to look at belt forces and whatnot to balance out

pull and tug?

Cheaper than leadscrews?

May have higher resolution?

|

Re: Z Axis Belt drive April 08, 2016 06:58PM |

Registered: 10 years ago Posts: 73 |

|

Re: Z Axis Belt drive April 08, 2016 07:24PM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: Z Axis Belt drive April 08, 2016 08:53PM |

Registered: 11 years ago Posts: 1,049 |

Quote

Dust

Much lower resolution (compared with a standard m5)

WHY? --- 20 tooth pulley --- 37mm circumference ---- 0.01mm/step(1/16 stepping un-geared)

Also when power is removed the carriage will fall

I'll use geared stepper or stepper with brake

Any belt stretch (which is inevitable) will break this... something need to be adjustable

With one continuous belt -- stretch so what?

Will stretch in one print run be that much?

|

Re: Z Axis Belt drive April 08, 2016 09:19PM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: Z Axis Belt drive April 08, 2016 10:16PM |

Registered: 11 years ago Posts: 5,780 |

I agree with points on the resolution or screw vs direct belt drive, but adjustability of belt tension is easy. There are 4 pulleys and the motor itself that could be made adjustable to set belt tension if you follow the OP's diagram.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z Axis Belt drive April 09, 2016 02:52AM |

Registered: 10 years ago Posts: 14,672 |

Check out the CoreXY CoreXZ design, it uses belts to drive and support the Z axis.

Z resolution on deltas is typically 0.0125um or 0.01um per microstep, which turns out to be sufficient. You can double it by using 0.9deg/step motors.

Edited 1 time(s). Last edit at 04/09/2016 04:26AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Z resolution on deltas is typically 0.0125um or 0.01um per microstep, which turns out to be sufficient. You can double it by using 0.9deg/step motors.

Edited 1 time(s). Last edit at 04/09/2016 04:26AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z Axis Belt drive April 09, 2016 04:08AM |

Admin Registered: 13 years ago Posts: 6,998 |

Also check out corexz [hackaday.com]

|

Anonymous User

Re: Z Axis Belt drive April 09, 2016 04:13AM |

Quote

Dust

a m5 based z axis with 1/16th drivers and 1.8 degree steppers is 4000 steps per mm ie 1 step is 1/4000 ie 0.00025 mm/step

re belt stretch, im meaning over time.. not just one print... you need something to be adjustable to re tighten it

Just that this kind of resolution is totally unnecessary, that M5 (or any M ) are to assemble things NOT move them accurately, that most of the time they are bent, have a rough surface, need a backlash nut that will wear out fast (I see people using steel nuts), that you you need high RPM which is not exactly the realm of stepper ....

Leadscrew, yes, but the real ones starting from TR8 and up.

GT2 belts (NOT MXL) are designed for minimal backlash and stretch. To adjust the tension is not an issue, just use mfg specs. A simple scale like this Scale attached to the tensioner eg, is a great help. Comes handy to measure torque with a pulley and string too.

BTW, idler pulleys MUST be toothed when inside the belt ! An smooth pulley will crush the rubber tooth and leads to unreliable tension and wear.

Edited 1 time(s). Last edit at 04/09/2016 04:15AM by MKSA.

|

Re: Z Axis Belt drive April 09, 2016 04:22AM |

Registered: 8 years ago Posts: 3,525 |

I'm using a belt driven z axis on a corexy (I remixed a very popular design so that it works on smartrapcore alu) [www.thingiverse.com]

It works much better than I could have ever hoped for.

I'm using steel reinforced belts, they will stretch but not any time soon they are a huge improvement over the soft black rubber type most of us use.

The bed drops on power off but gently with this design compared with cantilevered belt driven z axis.

I'm using 0.9deg stepper and can very accurately get 0.1mm layers with no z type artefacts, the sides of my prints are very smooth. I could swap to 16 tooth pulley also but it works so why bother?

I'd say it works so well I seriously doubt the need for screws on 3d printers at all. As has been said deltas don't need them and no one associates deltas with poor print quality (those steel reinforced belts really help on the delta too).

Edited 1 time(s). Last edit at 04/09/2016 04:23AM by DjDemonD.

It works much better than I could have ever hoped for.

I'm using steel reinforced belts, they will stretch but not any time soon they are a huge improvement over the soft black rubber type most of us use.

The bed drops on power off but gently with this design compared with cantilevered belt driven z axis.

I'm using 0.9deg stepper and can very accurately get 0.1mm layers with no z type artefacts, the sides of my prints are very smooth. I could swap to 16 tooth pulley also but it works so why bother?

I'd say it works so well I seriously doubt the need for screws on 3d printers at all. As has been said deltas don't need them and no one associates deltas with poor print quality (those steel reinforced belts really help on the delta too).

Edited 1 time(s). Last edit at 04/09/2016 04:23AM by DjDemonD.

|

Re: Z Axis Belt drive April 09, 2016 04:53AM |

Registered: 8 years ago Posts: 3,525 |

|

Re: Z Axis Belt drive April 09, 2016 10:25AM |

Registered: 13 years ago Posts: 268 |

Quote

MKSA

BTW, idler pulleys MUST be toothed when inside the belt ! An smooth pulley will crush the rubber tooth and leads to unreliable tension and wear.

That's not what the applications manual at SDP-SI says. They call out a minimum diameter for non toothed internal idlers, I want to say a 40t equivalent diameter.

|

Re: Z Axis Belt drive April 09, 2016 01:27PM |

Registered: 11 years ago Posts: 1,049 |

I don't see the advantage of core XZ

mixing high speed, long distance axis

with

low speed micro move axis

mixing high speed, long distance axis

with

low speed micro move axis

Quote

dc42

Check out theCoreXYCoreXZ design, it uses belts to drive and support the Z axis.

Z resolution on deltas is typically 0.0125um or 0.01um per microstep, which turns out to be sufficient. You can double it by using 0.9deg/step motors.

|

Re: Z Axis Belt drive April 09, 2016 01:38PM |

Registered: 8 years ago Posts: 3,525 |

Looking at some images of them, the belts/lines are very complicated. There must be some advantage to this design as it seems like adding 8 more pulleys and coupling two very different performing axes is a lot counter intuitive.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Z Axis Belt drive April 09, 2016 05:07PM |

Registered: 10 years ago Posts: 14,672 |

I haven't built a CoreXY, I was just pointing it out as an example of using a belt driven Z axis. I see that it uses extra pulleys to achieve a 3:1 reduction in Z movement.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z Axis Belt drive April 09, 2016 05:57PM |

Registered: 8 years ago Posts: 3,525 |

Well I think a corexz is definitely a belt driven z axis but a core xy can be any type of z axis. I think my point was that I was very dismissive of a belt driven z axis before I got one, originally cantilevered which worked perfectly well too, then I upgraded it to this double sided type. I think a lot of us are conditioned to expect a screw mechanism, despite being quite happy with belts for x and y (or all three in a delta).

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Anonymous User

Re: Z Axis Belt drive April 10, 2016 03:27AM |

Quote

Koko76

Quote

MKSA

BTW, idler pulleys MUST be toothed when inside the belt ! An smooth pulley will crush the rubber tooth and leads to unreliable tension and wear.

That's not what the applications manual at SDP-SI says. They call out a minimum diameter for non toothed internal idlers, I want to say a 40t equivalent diameter.

So reread them ! It is obvious that if the idler is BIG, it can be smooth because the pressure per teeth will be small !

Small idler must be toothed !

All this is just a matter of logic !

Edited 1 time(s). Last edit at 04/10/2016 03:57AM by MKSA.

|

Re: Z Axis Belt drive April 10, 2016 05:17AM |

Registered: 10 years ago Posts: 179 |

At the end of this thread you can read my experience of belt driven z-axis: [forums.reprap.org]

I could also add that I have experienced a few milimeters of belt stretch after a few kilograms of plastic printed. I hope it is just an initial stretch and belt will stay at where it is at now.

Another conclusion I have made in my head is that both screw and belt driven z-axis can deliver great results or be a disaster. It is all a matter of approach and design solutions that are done. Properly mounted screw will work great as will a belt driven driven z-axis with proper pulleys and stiff parts.

I could also add that I have experienced a few milimeters of belt stretch after a few kilograms of plastic printed. I hope it is just an initial stretch and belt will stay at where it is at now.

Another conclusion I have made in my head is that both screw and belt driven z-axis can deliver great results or be a disaster. It is all a matter of approach and design solutions that are done. Properly mounted screw will work great as will a belt driven driven z-axis with proper pulleys and stiff parts.

|

Re: Z Axis Belt drive April 10, 2016 06:04AM |

Registered: 8 years ago Posts: 3,525 |

Having said of this I'm concluding that in a direct comparison of delta, corexy and regular cartesian printers the delta comes out on top for various reasons, as long as you can build and calibrate it correctly.

David are think3dprint3d doing those beta large kossel kits? I think that's what I'd move towards next?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

David are think3dprint3d doing those beta large kossel kits? I think that's what I'd move towards next?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Z Axis Belt drive April 10, 2016 07:06AM |

Registered: 10 years ago Posts: 14,672 |

T3P3 have kept the frame size I think but have changed to a smaller bed with a 24V heater. I think the product liability issues associated with a mains powered bed heater were too great. But it shouldn't be difficult to upgrade that design to a larger bed with a mains powered heater.

I too favour the delta design for small and medium sized printers.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I too favour the delta design for small and medium sized printers.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Z Axis Belt drive April 10, 2016 01:38PM |

Registered: 8 years ago Posts: 3,525 |

I like the look of the robot digg metal corners. Do you think it would be possible to fit these to the t3p3 kossel xl? I'd install a mains bed at a later stage. Finally be a chance to try all this 32bit stuff I keep hearing about

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Z Axis Belt drive April 10, 2016 05:37PM |

Registered: 10 years ago Posts: 14,672 |

I suggest you talk to T3P3 about using metal corners on their xl kit. At least one of the beta users opted for metal corners, but I don't know whether he got them from T3P3 or separately.

Edited 1 time(s). Last edit at 04/10/2016 05:38PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 04/10/2016 05:38PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Anonymous User

Re: Z Axis Belt drive April 13, 2016 04:40AM |

Quote

DjDemonD

Having said of this I'm concluding that in a direct comparison of delta, corexy and regular cartesian printers the delta comes out on top for various reasons, as long as you can build and calibrate it correctly.

David are think3dprint3d doing those beta large kossel kits? I think that's what I'd move towards next?

I totally agree but I bought a Geetech Prusa I3 Al because I felt that it would be a good iand cheap introduction to 3D printer, that it would be usable, I could easily improve it with part I could print.

I felt that starting with a Delta kit with poor parts, firmware, it would be a lot of frustration. Reading this forum, looking at vendor sites, I see so much junk, it is appalling.

|

Re: Z Axis Belt drive April 13, 2016 04:44AM |

Registered: 8 years ago Posts: 3,525 |

I've got a mini kossel from t3p3 and its good. So moving up to a larger kossel would be a straightforward prospect. I think most reviews of the cheaper kossel kits available are fairly frightening.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Anonymous User

Re: Z Axis Belt drive April 13, 2016 04:46AM |

Quote

Edvardas

At the end of this thread you can read my experience of belt driven z-axis: [forums.reprap.org]

I could also add that I have experienced a few milimeters of belt stretch after a few kilograms of plastic printed. I hope it is just an initial stretch and belt will stay at where it is at now.

Another conclusion I have made in my head is that both screw and belt driven z-axis can deliver great results or be a disaster. It is all a matter of approach and design solutions that are done. Properly mounted screw will work great as will a belt driven driven z-axis with proper pulleys and stiff parts.

So, if this stretch exceeds the mfg specifications or is in the norm but exceeds your requirements, it is not a good design and/or not properly done.

Besides, GT2 normally used has negligible stretch.

BTW, a fully belt driven Z axis like in the initilal post is not a good idea.

Edited 3 time(s). Last edit at 04/13/2016 10:20AM by MKSA.

Sorry, only registered users may post in this forum.